Fluigent ESS SWITCHBOARD User manual

User Manual

ESS™ platform: SWITCHBOARD, M-SWITCH™, -SWITCH™ and

2-SWITCH™

Version 10A

Page - 2

1.

INTRODUCTION 6

2.

FLUIDIC CIRCUITS EXA PLES 7

3.

USING A 2-SWITCH™ VALVE 8

3.1

Fluidic principle 8

3.2

Description 9

3.2.1

2-SWITCH™ Front 9

3.2.2

2-SWITCH™ Back 10

3.2.3

2-SWITCH™ Top and Bottom faces 11

3.3

Connection 12

3.3.1

Fluidic connection 12

3.3.2

Electric connection 15

3.4

Positioning 16

4.

USING AN -SWITCH™ VALVE 19

4.1

Fluidic principle 19

4.2

Description 20

4.2.1

M-SWITCH™ Front and top 20

4.2.2

M-SWITCH™ Back 21

4.2.3

M-SWITCH™ Bottom face 21

4.2.4

M-SWITCH™ Side face 21

4.3

Connection 22

4.3.1

Fluidic connection 22

4.3.2

Electric connection 25

4.4

Positioning 26

5.

USING AN L-SWITCH™ VALVE 28

5.1

Fluidic principle 28

5.2

Description 29

5.2.1

-SWITCH™ Front and top 29

5.2.2

-SWITCH™ Back 30

5.2.3

-SWITCH™ Bottom face 30

5.2.4

-SWITCH™ Side face 30

5.3

Connection 31

5.3.1

Fluidic connection 31

5.3.2

Electric connection 37

5.4

Positioning 38

6.

USING THE SWITCHBOARD 40

6.1

Description 40

Page - 3

6.2

Connection 41

7.

HOW TO USE THE 2-SWITCH™, -SWITCH™

AND L-SWITCH™ WITH GAS 43

8.

HOW TO START WORKING WITH THE ESS™ 46

9.

FREQUENTLY ASKED QUESTIONS 47

10.

SPECIFICATIONS 48

Page - 4

WARRANTY TER S :

What This Warranty Covers

This warranty is granted by Fluigent and applies in all countries.

Your Fluigent product is guaranteed for one year from the date of delivery at your laboratory against defects in

materials and workmanship.

If found to be defective within the warranty period, your Fluigent product will be repaired or replaced free of

charge.

What This Warranty Does Not Cover

This warranty does not cover routine maintenance, or damage resulting from the failure to maintain the product

in accordance with instructions provided by Fluigent. This warranty also does not cover damage that arises from

accidental or intentional misuse or abuse, alteration or customization, or repaired by unauthorized persons.

How to Get Service

If something goes wrong, contact the Fluigent dealer from whom you purchased your product. Arrange a

mutually convenient time for Fluigent service representative to discuss over the problem and find a solution to

fix the issue. Will be favored any remote repairs, but in case more actions need to be taken, the system will come

back to Fluigent offices (for no additional cost, only if it is under warranty).

The warranty conditions are:

Do never open the SWITCHBOARD, 2-SWITCH

™

, -SWITCH

™

and M-SWITCH

™

devices.

Do not use other cables than cables provided by Fluigent.

Prevent foreign objects or liquids from entering the SWITCHBOARD.

Prevent foreign objects from entering the 2-SWITCH

™

, -SWITCH

™

and M-SWITCH

™

devices.

Connect the power cord to an AC outlet of the correct voltage.

Use the right RJ45 port on the SWITCHBOARD with the right device.

Do not place the product in an unstable location, place the unit in a location with a level surface and a

strong and stable support.

If you are using the ESS™ platform with other flow control systems, please check that the pressure in

your fluidic system does not exceed 100 psi.

Respect the temperature compatibility (from 5°C to 50 °C).

Use the specific connectors provided by Fluigent (Teflon fittings and nuts for the 2-Switch

™

).

Only use 1/16’’ OD tubings with the valves (each type).

For specific use, please contact our Support team at [email protected]

Page - 5

WARNINGS:

Do never open SWITCHBOARD, 2-SWITCH™, -SWITCH™

and M-SWITCH™ devices. Refer all servicing to

after-sales service department (support@fluigent.com).

Prevent any objects or liquids from entering the SWITCHBOARD, this may cause a short-circuit failure

or other malfunction. Failing to respect this advice would:

-Expose you to direct current/voltage in case the device is under voltage which may lead to severe

damages

-Void device’s warranty

-Discharge our company from any liability regarding physical or device damages

Do not place the product in an unstable location, place the device in a location with a level surface and

a strong and stable support.

Do not use other power supply than the one provided with the ESS™. The power supply provided with

the ESS™ has been carefully selected to meet the power requirements of the ESS™ in all configurations

and to comply with all safety standards.

If you are using the ESS™ platform with other flow control systems, please check that the pressure in

your fluidic system does not exceed 100 psi

Page - 6

1. Introduction

The Easy Switch Solutions™ platform (or ESS™) provides solutions for path selection in microfluidics. The Easy

Switch Solutions™ platform enables you to implement three (3) different kinds of valves in your microfluidic

circuit.

The 2-SWITCH™ is a 3-port / 2-position solenoid valve: two (2) ports can alternatively be connected to

a third one. The 2-SWITCH™ is fully described in §3.

The -SWITCH™ is an 11-port / 10-position rotary valve: ten (10) peripheral ports can alternatively be

connected to a central one. The M-SWITCH™ is fully described in §4.

The L-SWITCH™

is a 6-port/ 2-position valve for injecting precise volume of fluid or for switching the

fluid to different channels. The -SWITCH™

is fully described in §5.

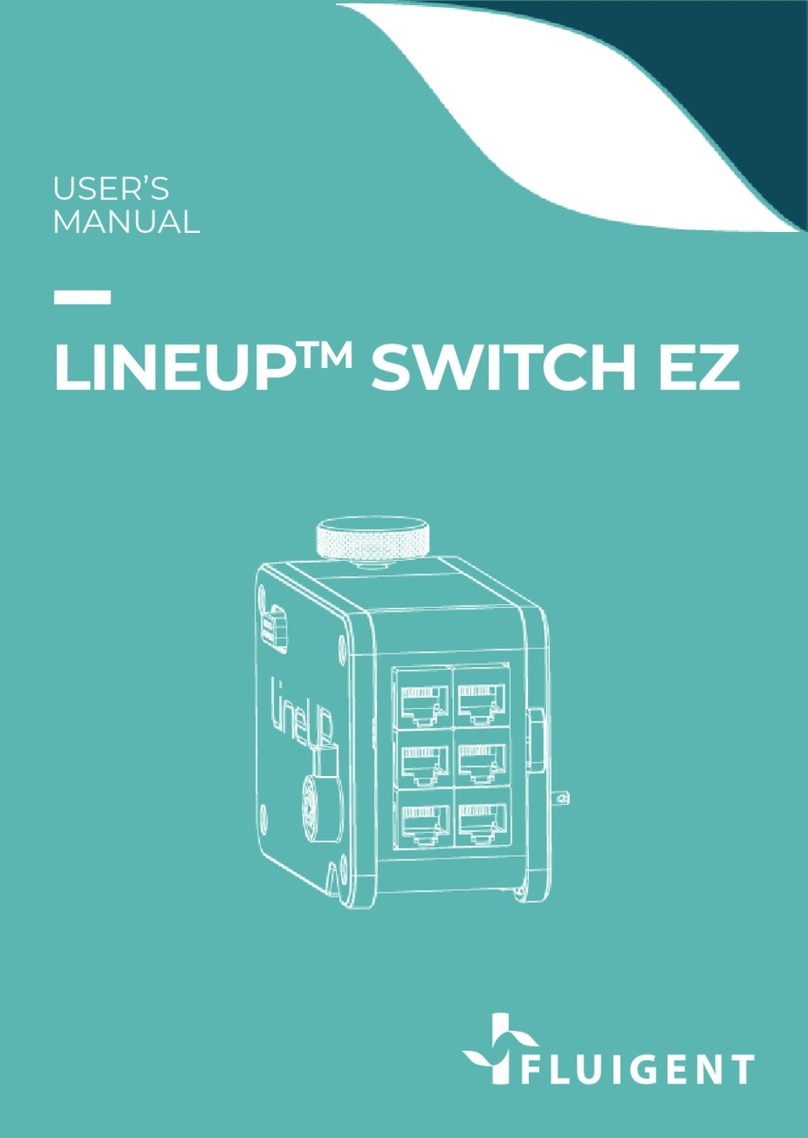

The fourth element of the Easy Switch Solutions™ platform is the SWITCHBOARD: this device hosts up

to four (4) M-SWITCH™ or -SWITCH™ and eight (8) 2-SWITCH™ and provides them power supply. The

SWITCHBOARD is also the link between the connected 2-SWITCH™, M-SWITCH™ and -SWITCH™ and

the controlling software ESS™ Control (cf. ESS™ Control User Manual). The SWITCHBOARD is fully

described in §6.

Combining the 2-SWITCH™, M-SWITCH™ and -SWITCH™ valves thanks to the SWITCHBOARD will give you new

possibilities to easily design and build even the most complex microfluidic circuits. It is also a powerful tool to

simplify your chip design and automate your experiments.

The ESS™ platform has been designed to work at its best performances with FLUIGENT flow control solutions

(MFCS™ and Flow-Rate Platform). It is however possible to use the ESS™ platform with other flow control systems

provided that the pressure applied to the ESS™ devices does not exceed 100 psi.

The ESS™ user manual will show you how to use the ESS™ elements for your daily work. It will describe all the

ESS™ functionalities that will help you to rationalize your microfluidic circuits and automate your experiments.

You will also find examples of applications using the ESS™ and answers to the frequently asked questions about

the ESS™. With these elements you will be able to exploit the full performances of the Easy Switch Solutions™

platform for your application.

Page - 7

2. Fluidic circuits examples

Page - 8

3. Using a 2-SWITCH™ valve

3.1 Fluidic principle

The 2-SWITCH™ is a 3-port / 2-position valve. This means that three (3) ports can be connected with fittings and

tubings to your application, and that it is possible to choose between two (2) positions linking the ports in two

(2) different manners.

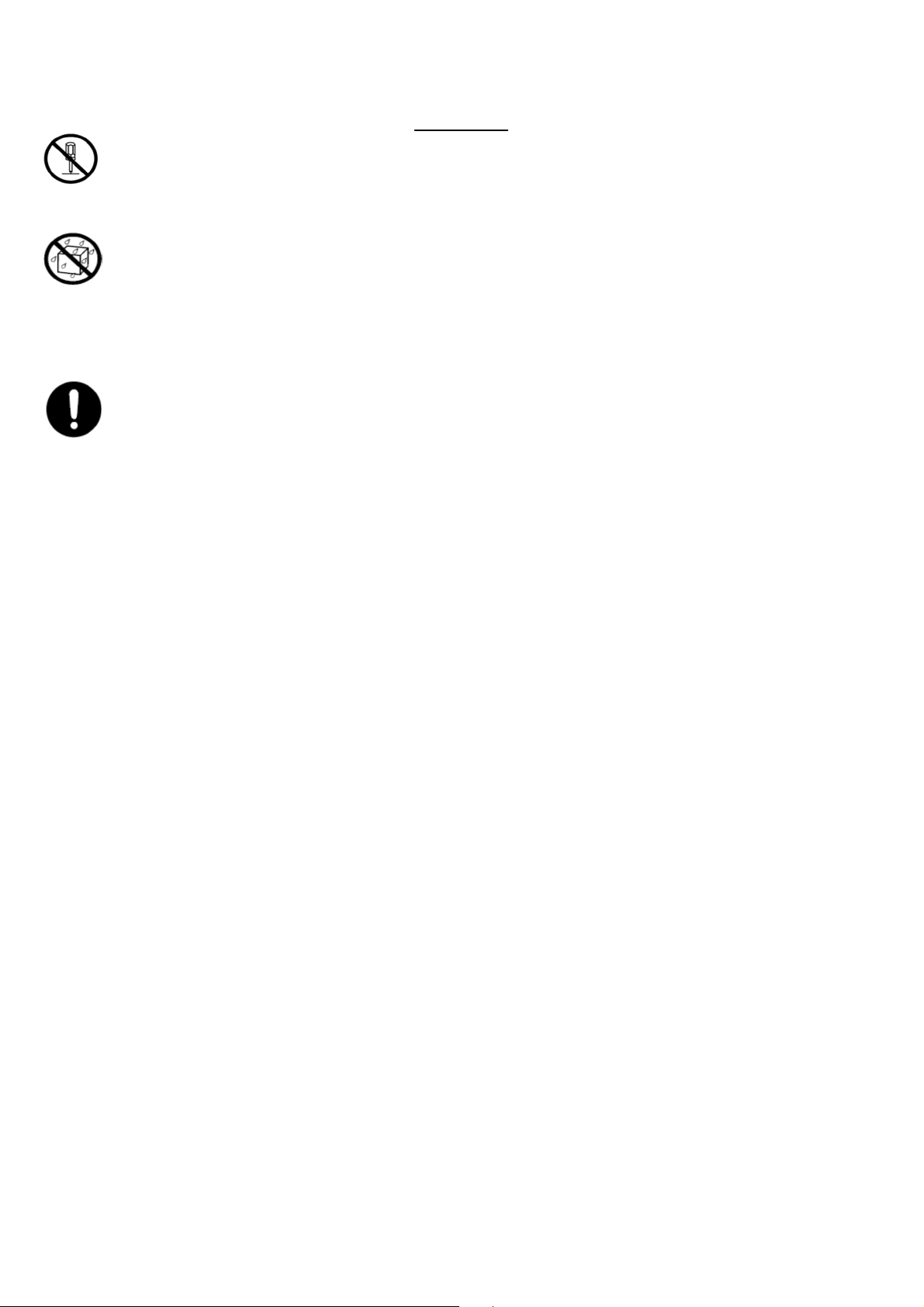

Fluidic 2-way switch

Here is the fluidic diagram of a 2-SWITCH™. The

dark blue “C” port at the bottom of the 2-SWITCH™

is the common port: it can be either connected to

port #1 or to port #2 depending on the chosen

position.

Position 1 connects the common port to port

#1 and Position 2 connects the common port

to port #2. The 2-SWITCH™ enables you to

switch between these two positions.

The Default position of the 2-SWITCH™ when

the 2-SWITCH™ is not powered is Position 1.

The 2-SWITCH™ is a bidirectional valve: the

fluid can flow in both directions inside the 2-

SWITCH™ i.e. from the common port to port

#1 / port #2 AND from port #1 / port #2 to the

common port.

Fluidic on/off switch

Another possibility for using the 2-SWITCH™ is to

connect a plug to either port #1 or port #2. This way,

one of the positions of the 2-SWITCH™ (Position 1 for

port #1 or Position 2 for port #2) becomes a closed

position, and the 2-SWITCH™ acts as a fluidic “on/off”

switch.

Example: A plug (gray square) is connected to

port #2. Position 2 is thus closed. In Position 1

fluids can flow through the valve between the

common port and port #1, whereas in Position 2

the fluidic path is closed between the common

port and port #2.

Warning: The fluidic “on/off” switch configuration

only works if port #1 or port #2 is connected with a

plug. If the common port is plugged then no flow

can circulate through the 2-SWITCH™ (bottom

diagram).

FAQ: Should I fill with liquid the plugged path inside

the 2-SWITCH™ before screwing the plug? (cf. §9)

Page - 9

3.2 Description

3.2.1 2-SWITCH™ Front

Here is a picture of the front of a 2-SWITCH™.

The 3 fluidic ports are at the bottom part of the device. The common port is the

central port, included in the device front. When looking at the front of the 2-

SWITCH™, port #1 is the right port and port #2 is the left one.

Two light indicators on the front show the current activated position of the 2-

SWITCH™:

A blue indicator (right) for Position 1 linking the common port to port #1 (right).

A white indicator (left) for Position 2 linking the common port to port #2 (left).

The front of the 2-SWITCH™ also includes a push button at the top to manually

switch between Position 1 and Position 2.

Port #2 Port #1

Common port Common port

Position 2

(white indicator)

Position 1

(blue indicator)

Position

switch

button

Page - 10

3.2.2 2-SWITCH™ Back

Here is a picture of the back of a 2-SWITCH™.

Port #1 is now at the left and port #2 is at the right.

At the centre of the back, a UNC ¼-20’’ thread is inserted to enable the user to

fasten the 2-SWITCH™ to the provided base or to any ¼-20’’ screw-mounted

device (as further explained in §3.4).

At the top of the device we can see the RJ45 port to connect electrically the 2-

SWITCH™ to the SWITCHBOARD. Two light indicators are associated with the

RJ45 port.

The orange indicator lights up when the 2-SWITCH™ is powered.

The green indicator lights up if a “Check connection” identification has

been requested for the 2-SWITCH™ from the SWITCHBOARD (cf. §6.2) or

from the ESS™ Control software (cf. ESS™ Control User Manual).

Warning: Please note that only straight-through wired RJ45 cables are

compatible with the ESS™ (to connect the 2-SWITCH™ with the

SWITCHBOARD). Other types of cable can damage the ESS™, and reciprocally,

the cables provided with the ESS™ should not be used for other applications.

F UIGENT advises to only use the cables provided with the ESS™ for ESS™

operation.

Orange indicator

(Power OK)

Orange indicator + green indicator

(Power OK + Check connection)

RJ45 Port

Port #1

Port #2

¼

-

20’’

insert

Page - 11

3.2.3 2-SWITCH™ Top and Bottom faces

Top face

Here is a picture of the top face of a 2-SWITCH™.

A UNC ¼-20’’ thread is inserted in the centre of

the top face so that the 2-SWITCH™ can be

fastened to the provided base or to any ¼-20’’

screw-mounted device (as further explained in

§3.4).

Bottom face

Here is a picture of the bottom face of a 2-

SWITCH™. A UNC ¼-20’’ thread is inserted in

the centre of the bottom face so that the 2-

SWITCH™ can be fastened to the provided base

or to any ¼-20’’ screw-mounted device (as

further explained in §3.4).

The bottom face and the top face of the 2-SWITCH™ are complementary: two 2-SWITCH™ can be assembled

together by inserting the top face of one 2-SWITCH™ in the bottom of another 2-SWITCH™. Please see §3.4 for

more details.

Page - 12

3.3 Connection

3.3.1 Fluidic connection

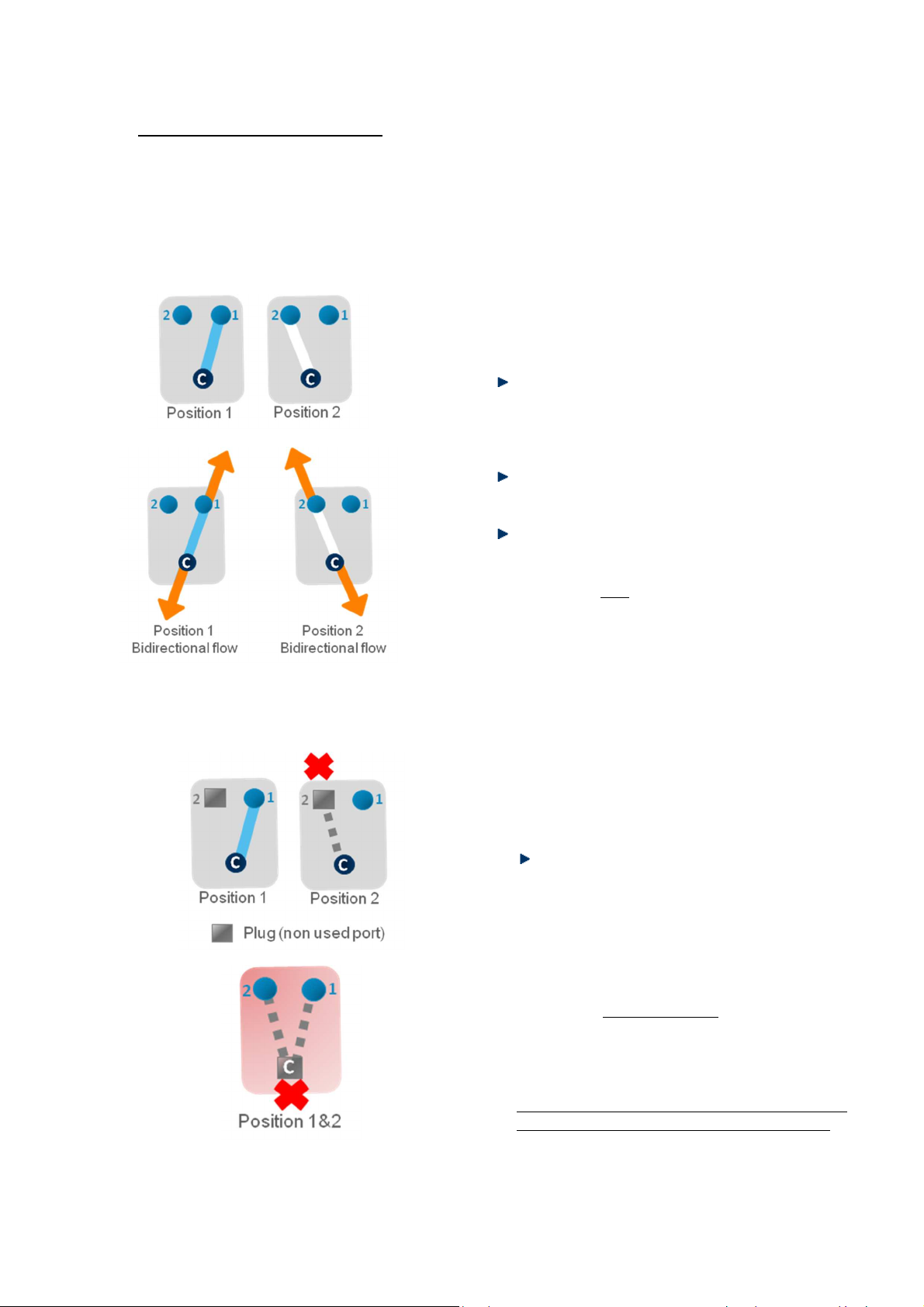

Description of the fittings and tubings

A 2-SWITCH™ has three (3) fluidic ports, described in §3.1 as “Common port”,

“Port #1” and “Port #2”.

The characteristics of those three (3) ports are:

Thread-size: 10-32.

Flat-bottom type (FB).

Compatible with tubings of 1/16’’ external diameter (1/16’’ OD).

To get started, F UIGENT provides you, into the “KIT ESS 2-SWITCH “ :

Six (6) 2-SWITCH™ Teflon connectors.

Twelve (12) 2-SWITCH™ ferrules 1/16’’

One (1) plug Delrin® - 10-32 Flat Bottom.

One (1) meter of FEP tubing: 1/16’’OD (external diameter) and 0.010’’ID

(internal diameter). NB: There is a wide variety of materials and internal

diameters available with 1/16’’ tubing from fittings suppliers to suit your

application.

Warning: These fittings have been specifically selected by FLUIGENT to ensure good 2-SWITCH™ operation. F UIGENT advises you to use only these fittings on the 2-

SWITCH™.

Warning: Please note that only tubings of 1/16’’ external diameter should be used with the 2-SWITCH™. F UIGENT does not recommend the use of other tubings sizes with

or without tubing sleeves, as it can damage the 2-SWITCH™ and give non-tight fluidic connection.

NB: When the 2-SWITCH™ is not used or stored, F UIGENT advises you to connect plugs to all ports to protect the fluidic ports from dust.

FAQ: How can I make a junction between a 2-SWITCH™ and tubings with external diameters different from 1/16’’? (cf. §9)

2

-

SWITCH™

Teflon

connector

2-SWITCH™ ferrule 1/16’’

2

-

SWITCH™

plug Delrin®

10-32Flat Bottom

FEP Tubing 1/16’’OD x 0.010’’ ID

Page - 13

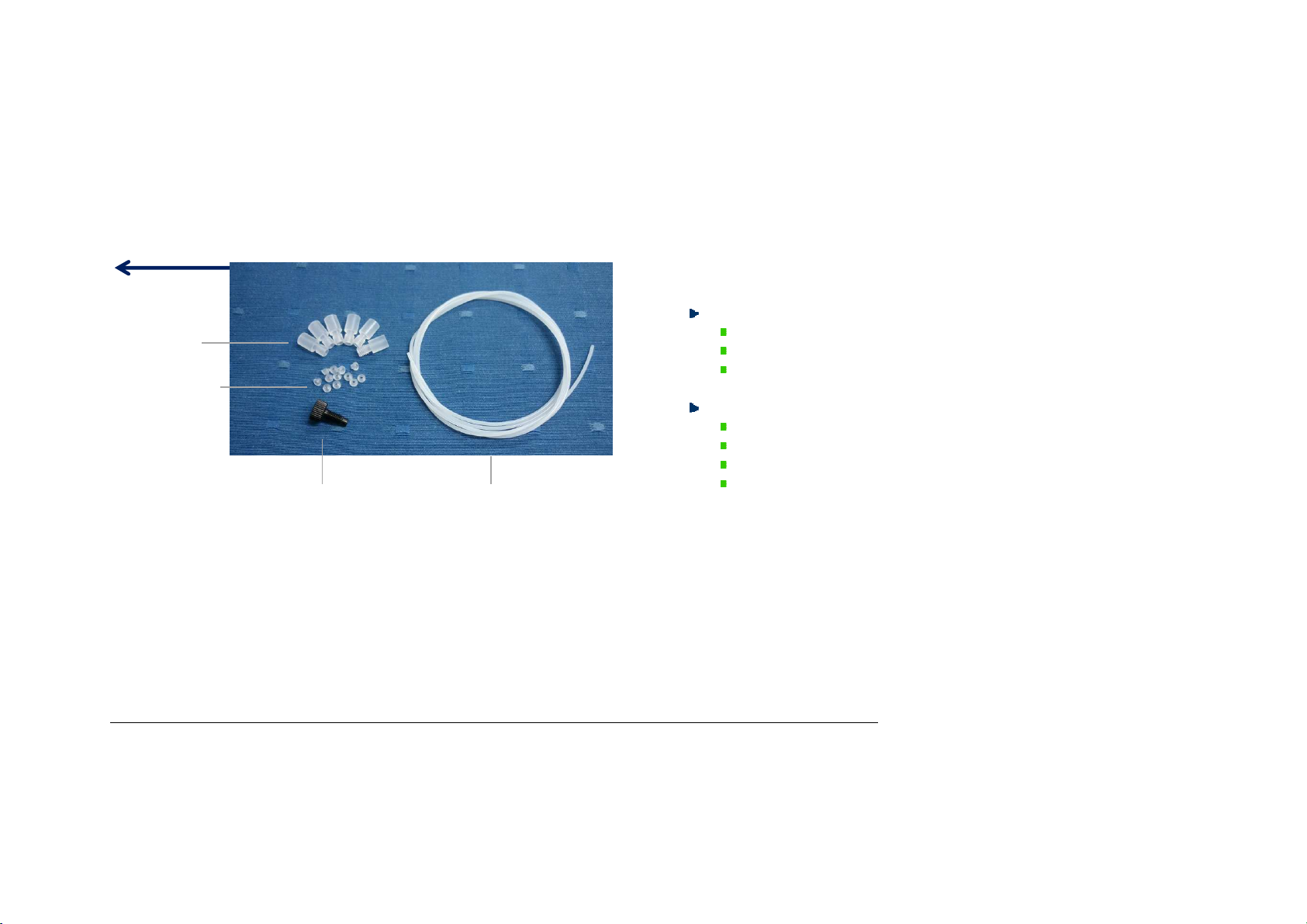

Connecting a 1/16’’ OD tubing to the 2-SWITCH™

1. Cut the 1/16’’ OD tubing to the desired

length, leaving a square-cut face.

2. Slide the nut over the tubing with the nut

thread facing the tubing end being

connected.

3. Slip the ferrule over the tubing, with the

tapered portion of the ferrule facing the

nut. NB: the nuts and ferrules are

specifically designed to work together.

F UIGENT advises you to only associate the

provided ferrules with the provided nuts

and vice-versa.

4. Insert the assembly into the receiving port,

and while holding the tubing firmly against

the bottom of the port, tighten the nut

finger tight.

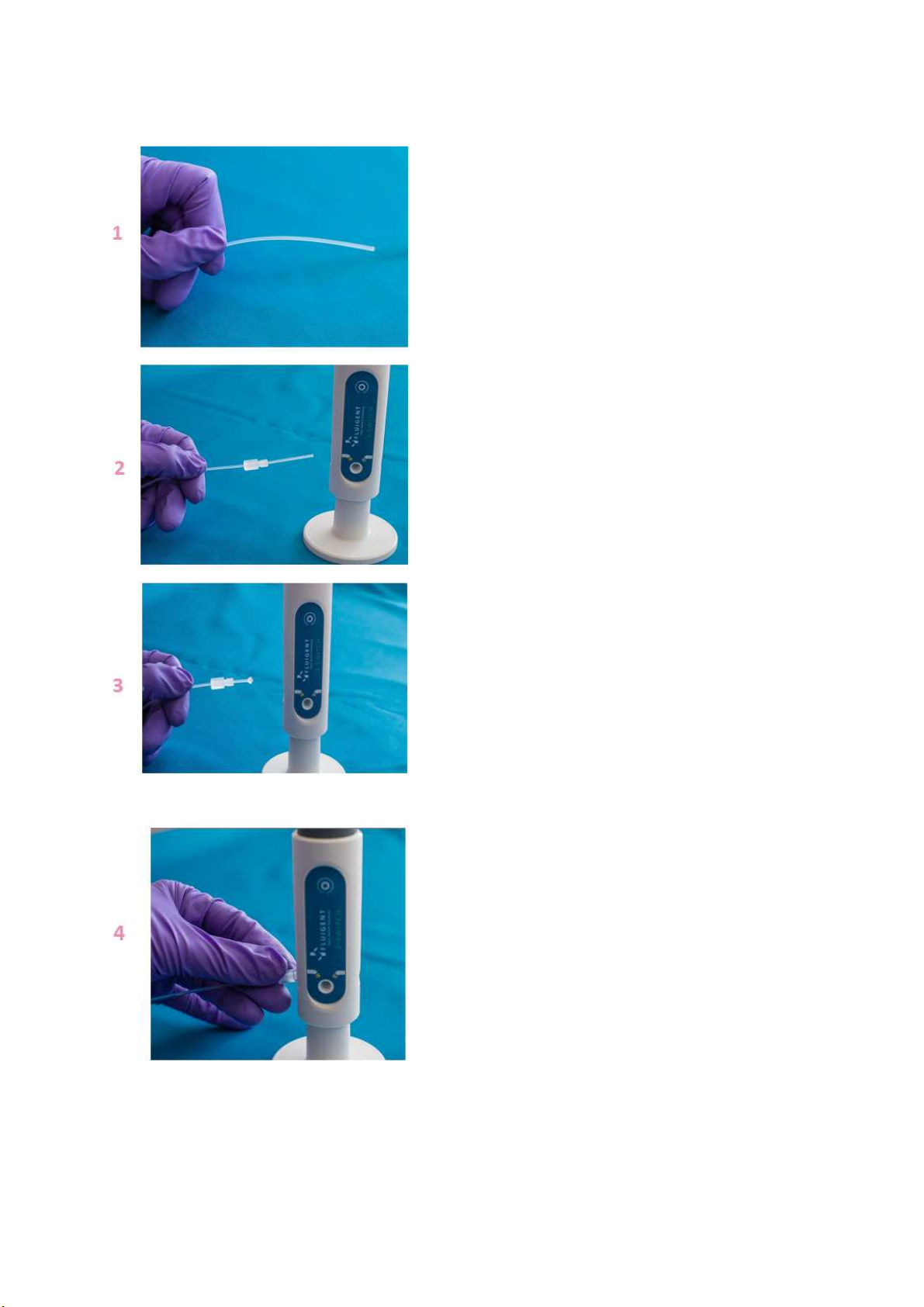

Page - 14

5. To check the tightness of your connection,

you may pull gently on the tubing: it must

stay fitted in the ferrule and nut.

Connecting a plug to the 2-SWITCH™

1. Simply screw the plug in port #1 or port #2

finger-tight.

Fully connected 2-SWITCH™ in fluidic on/off

configuration. Position 1 is plugged and Position 2 is

opened.

.

Page - 15

3.3.2 Electric connection

Simply plug one connector of the RJ45 blue

cable provided with the 2-SWITCH™ in the

female RJ45 plug at the back of the 2-

SWITCH™. The other connector should be

connected to a port in the blue cables

section of the SWITCHBOARD (See §6.2 for

more details)

If the 2-SWITCH™ is connected to a

powered SWITCHBOARD, the orange

indicator on the female RJ45 connector

lights up.

Warning: Please note that only straight-through wired RJ45 cables are compatible with the ESS™ (to connect

the 2-SWITCH™ with the SWITCHBOARD). Other types of cable can damage the ESS™, and reciprocally, the cables

provided with the ESS™ should not be used for other applications. F UIGENT advises to only use the cables

provided with the ESS™ for the ESS™.

Page - 16

3.4 Positioning

There are several possibilities to set the 2-SWITCH™ up. Please note that the 2-SWITCH™ device does not have

any imposed mounting orientation. The 2-SWITCH™ can be used in any spatial configuration.

Setting-up with the provided base

The base provided with the 2-SWITCH™ can be

screwed to any of its ¼-20’’ inserts.

Mainly, the 2-SWITCH™ can be set-up vertically

on the base by fastening the base into the ¼-20’’

insert of the bottom face or horizontally when

fastening the base into the ¼-20’’ insert of the

back.

NB: It is easier to first connect the RJ45 cable on

the 2-SWITCH™ before screwing the base on the

back face for horizontal positioning.

Vertical positioning

with base

Horizontal positioning

with base

Page - 17

Assembling several 2-SWITCH™ together using the complementary faces

The top and bottom faces of the 2-SWITCH™

devices are complementary: you can assemble

them together by inserting the top face of one

2-SWITCH™ into the bottom face of another 2-

SWITCH™.

As many 2-SWITCH™ as you need can be

assembled together horizontally, and

meanwhile can be set-up on their base fastened

into their back insert.

2-SWITCH™ devices can also be assembled

vertically. F UIGENT advises not to assemble

more than two 2-SWITCH™ together vertically.

Page - 18

Other possible setting-up

The three ¼-20’’ inserts of the 2-SWITCH™

can be used to mount the 2-SWITCH™ on

any frame or support equipped with ¼-20’’

pins such as a flexible rod as shown here

(not provided with the 2-SWITCH™).

¼-20’’ thread is also the standard for all

photographic equipment. You can use for

example a tripod for cameras and screw a

2-SWITCH™ on it (not provided with the 2-

SWITCH™).

Page - 19

4. Using an -SWITCH™ valve

4.1 Fluidic principle

The M-SWITCH™ is an 11-port / 10-position valve. This means that eleven (11) ports can be connected with

tubings, and that it is possible to choose between ten (10) positions linking one of the ten (10) external ports to

the central port of the valve.

Here is the fluidic diagram of an M-SWITCH™. The

dark blue port at the centre of the M-SWITCH™ is

the central port. The light blue ports are the

external ports. The central port can be connected

in turns to each external port, from port #1 to port

#10 depending on the chosen position

(respectively from Position 1 to Position 10).

The Default position of the -SWITCH™ when

the M-SWITCH™ is not powered is the last

actuated position.

The M-SWITCH™ is a bidirectional valve,

meaning that the fluid can flow inside the M-

SWITCH™ in both directions:

Distributor mode: fluid flows from the

central port to one external port

(according to the selected position).

Selector mode: fluid flows from one of

the external ports (according to the

selected position) to the central port.

The non used ports must be closed with

plugs (gray squares on the diagram) to

preserve the M-SWITCH™ good operation.

In the same way as the 2-SWITCH™, it is

possible to use a plugged position to close

a fluidic path.

Page - 20

4.2 Description

4.2.1 -SWITCH™ Front and top

Here is a picture of the front of an M-SWITCH™.

At the top of the picture, the fluidic head of the device can be seen. The head

holds the fluidic ports.

The head of the M-SWITCH™ is made up of the Ram which holds the integrated

fittings and the Spanner, which is tightened around the Ram to clench the

integrated fittings and make tight fluidic connections. The method to connect

tubings to the M-SWITCH™ is detailed in §4.3.1.

This manual suits for next models

3

Table of contents

Other Fluigent Laboratory Equipment manuals