- 4 -

I. Descriptions

Kjeldahl method is a classic method for nitrogen determination. Currently, the Kjeldahl method is

frequently applied for determining the nitrogen content of the soil, foods, agricultural products, feeds and

other substances. When this method is applied for the sample determination, three processes including

digestion, distillation, and titration will be gone through, and the distillation is an important process in

Kjeldahl method.

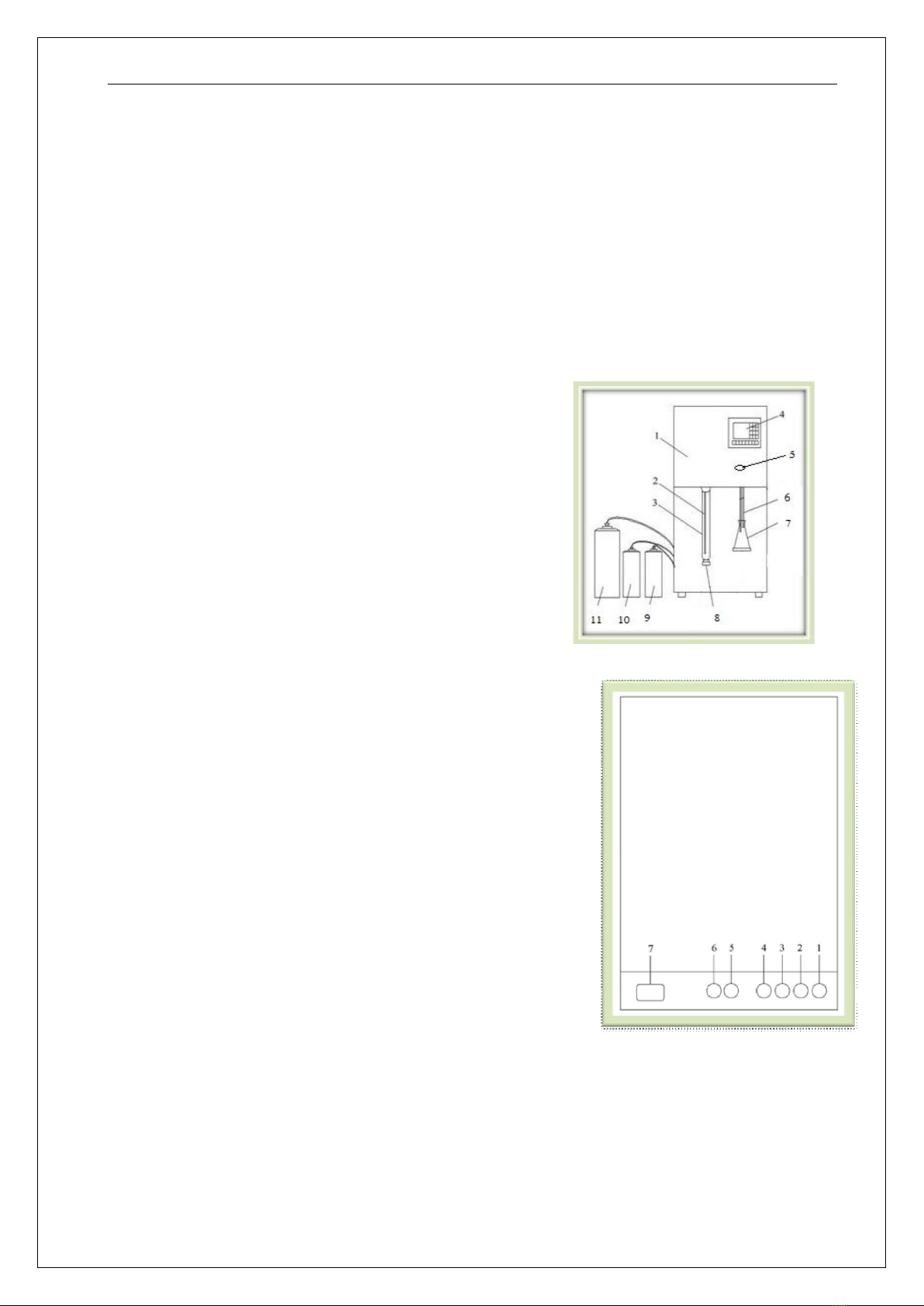

ATN-300 Automatic Kjeldahl Apparatus is a kind of automatic system researched and development

based on the classic Kjeldahl method, which is featured by user-friendly operation and easy learning due to

application of the Chinese menu and man-machine interface.

With two parts of the manual distillation and automatic distillation, ATN-300 is available for manual and

automatic water filling, alkali filling, acid filling, and distillation, which brings large convenience to the

laboratory personnel.

The automatic part of ATN-300 can save ten kinds of different combinations for water filling, alkali

filling, acid filling, and distillation time for setting and application by the user.

ATN-300 has applied the British self-sucking pump method for liquid feeding rather than the inflatable

method applied by many domestic manufacturers, which can place the liquid feeding barrel under the control

console and select the liquid feeding barrel with large capacity.

ATN-300 has been furnished with numerous protection measures, such as the distillation tube absence

protection (no heating or distillation without distillation tube); steam generator overpressure alarm protection

(shutdown and alarm in case of abnormal pressure); steam generator water shortage protection, and earth

leakage protection, so as to ensure safety of operators.

II. Working Principles

When all samples are digested, the distillation can be performed after having been cooled down to the

room temperature. The principles of the distillation process are as follows:

(NH4)2SO4+NaOH=Na2SO4+2H2O+2NH3↑

Under the alkalic conditions, separate the ammonia with the high temperature steam; after that, collect it

with the conical flask containing boric acid absorption liquid (containing mixed indicator); lastly, perform