i

Table of Contents

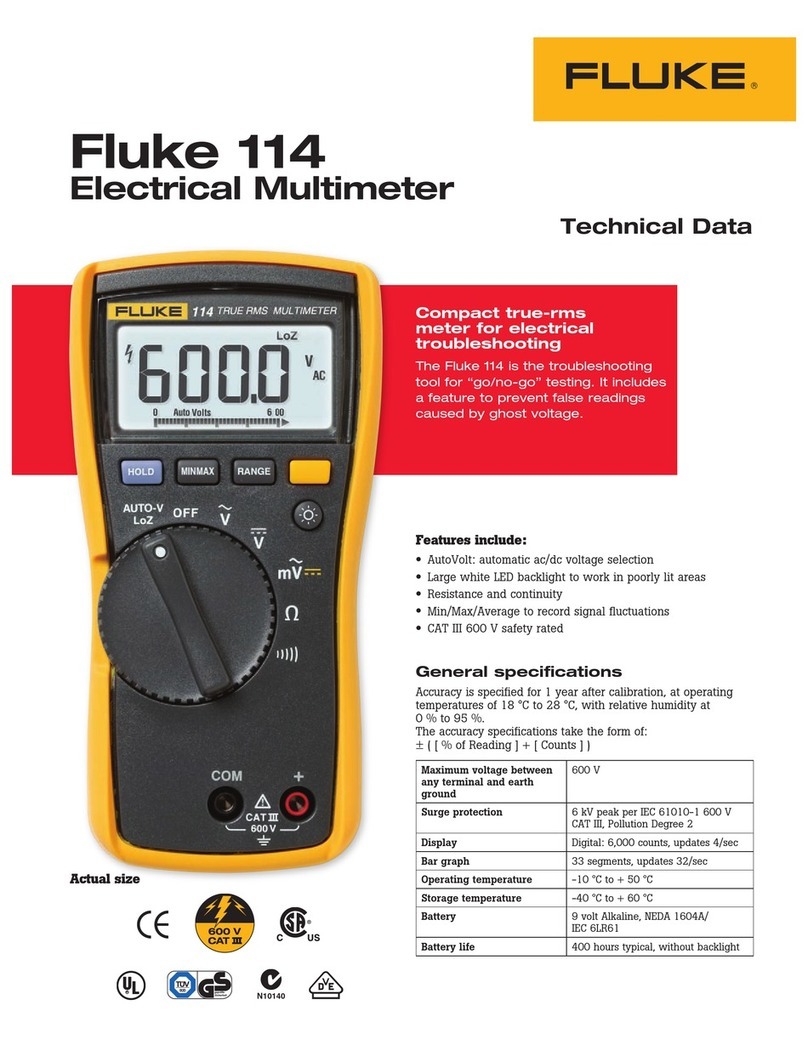

Title Page

Introduction........................................................................................................ 1

Contacting Fluke................................................................................................ 2

Safety Information ............................................................................................. 2

Symbols ............................................................................................................. 3

Specifications..................................................................................................... 4

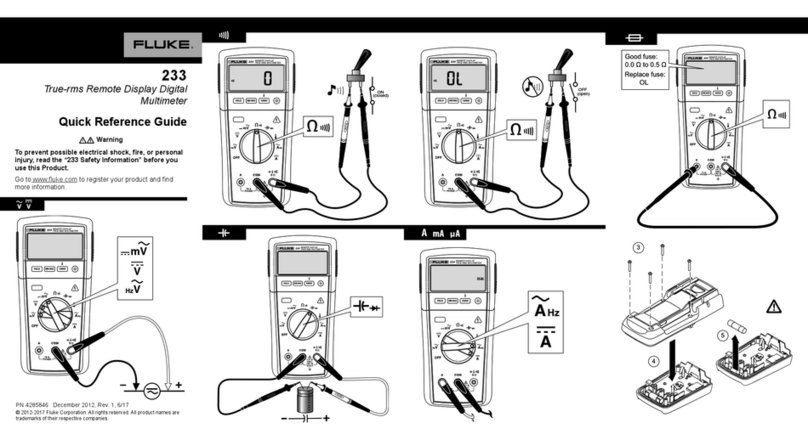

Getting Acquainted with the Meter.................................................................... 5

Maintenance....................................................................................................... 6

Cleaning the Meter ........................................................................................ 6

Battery Replacement ..................................................................................... 6

Performance Tests.............................................................................................. 8

Required Equipment...................................................................................... 8

Testing the Batteries ...................................................................................... 8

Testing the Display........................................................................................ 9

Display Hold Test.......................................................................................... 9

Backlight Test................................................................................................ 9

Spotlight LED Test........................................................................................ 9

Zero Test........................................................................................................ 9

Accuracy Tests .............................................................................................. 9

Calibration Adjustment...................................................................................... 11

Adjustment Subroutines ................................................................................ 11

Front Panel Operation for Adjustment .......................................................... 11

Calibration Error Messages ........................................................................... 12

Calibration Adjustment Procedure ................................................................ 12

Temperature Adjustment Procedure.............................................................. 13

Low Range Adjustment Procedure................................................................ 13

High Range Adjustment Procedure ............................................................... 13

Phase Adjustment Procedure......................................................................... 14

User Replaceable Parts ...................................................................................... 15