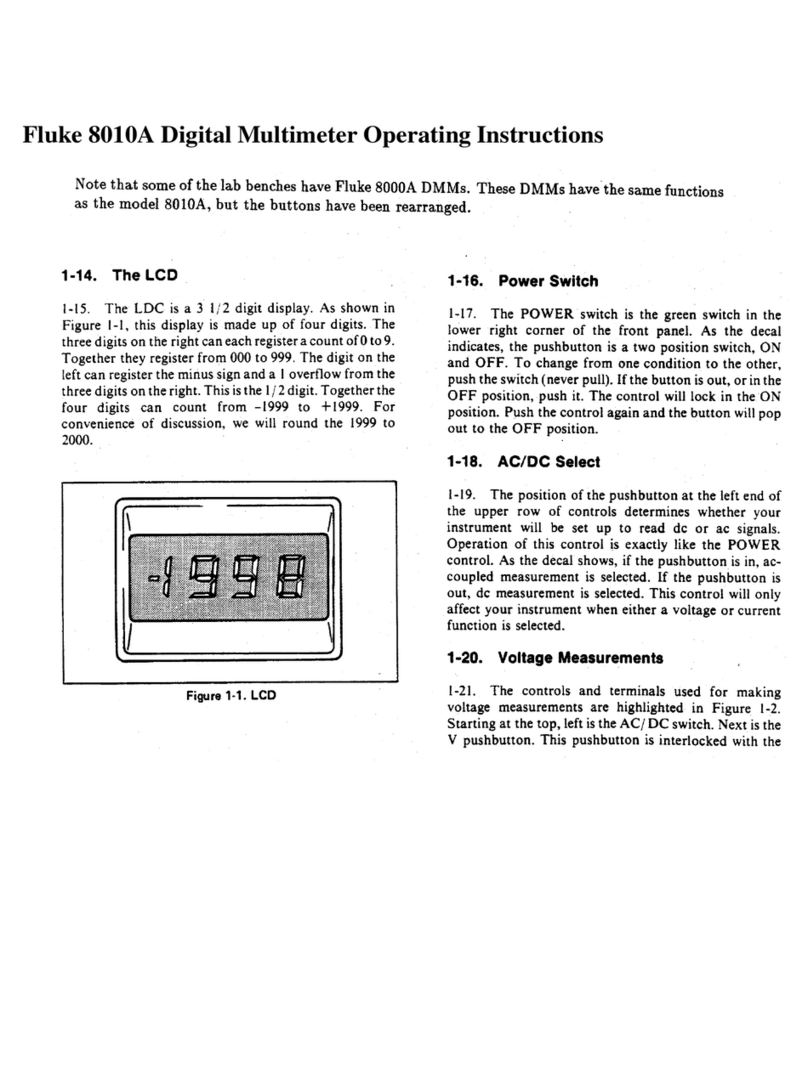

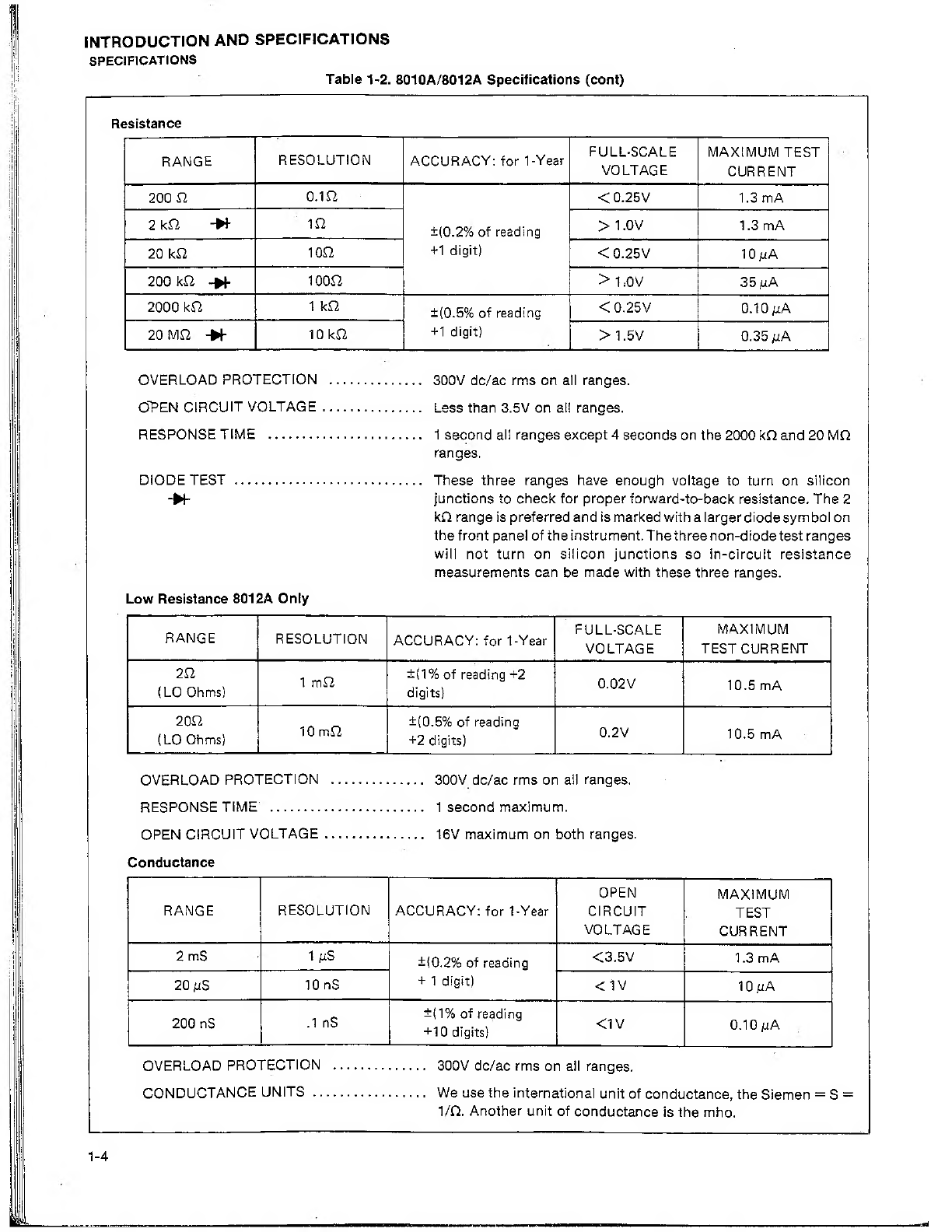

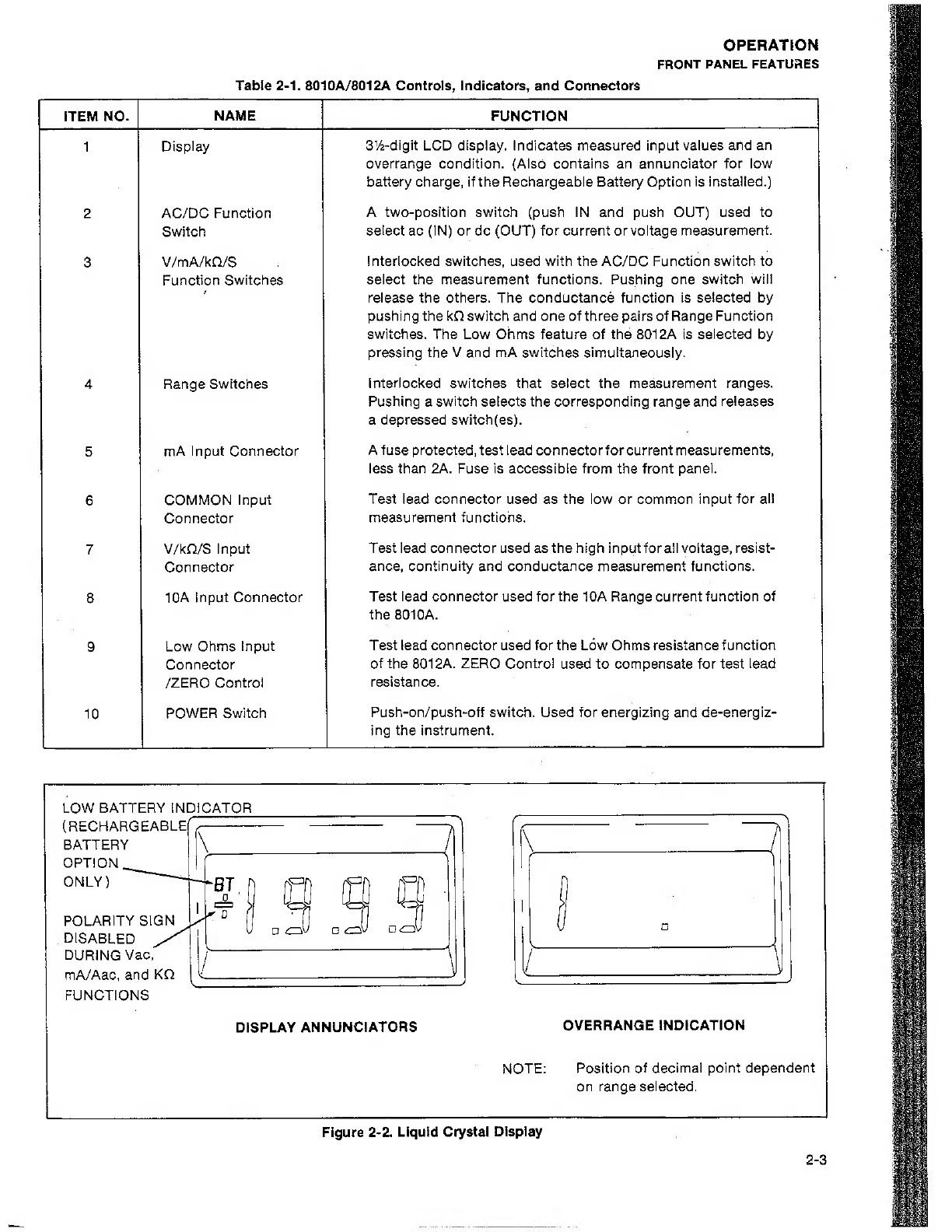

Fluke 8010A User manual

Other Fluke Multimeter manuals

Fluke

Fluke 8808A Configuration guide

Fluke

Fluke 8845A User manual

Fluke

Fluke 106 User manual

Fluke

Fluke 28IIEX User manual

Fluke

Fluke 8050? User manual

Fluke

Fluke 8845A Operating and maintenance manual

Fluke

Fluke Biomedical MPS450 Operators User manual

Fluke

Fluke 110 Use and care manual

Fluke

Fluke 1587 FC User manual

Fluke

Fluke 8020A User manual

Popular Multimeter manuals by other brands

PeakTech

PeakTech 4000 Procedure of calibration

YOKOGAWA

YOKOGAWA 90050B user manual

Gossen MetraWatt

Gossen MetraWatt METRALINE DMM16 operating instructions

Tempo Communications

Tempo Communications MM200 instruction manual

Elenco Electronics

Elenco Electronics CM-1555 operating instructions

Mastech

Mastech MS8238C user manual