1. Safety warnings___________________________________

Improper use or maintenance of this appliance, as well as non-compliance with the safety regulations specified in

this manual, will immediately void the warranty and also exempt the manufacturer from any liability.

Keep this manual for the life of the device and read it carefully before using the device.

The device is intended for professional use ONLY.

Components that have been protected by the customer and manufacturer must not be tampered with by the

installer or the end user of the device.

Installation not in accordance with the manufacturer's instructions may result in damage, injury or fatal accidents.

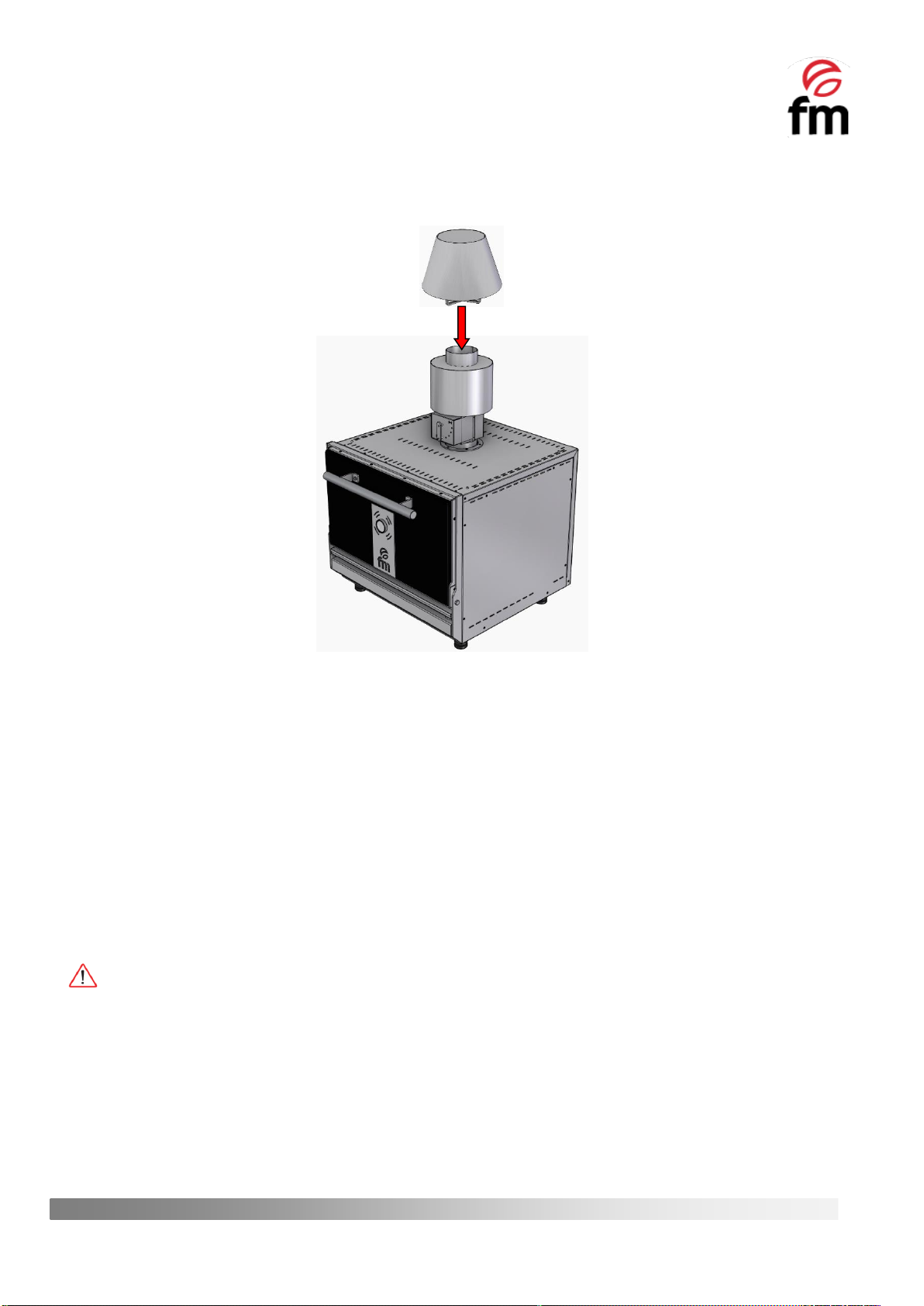

If the unit is to be installed on brackets, use only those supplied by FM and mount the unit according to the

instructions on the packaging.

Non-original spare parts do not guarantee the optimal functioning of the device and will result in the loss of the

warranty.

The device must be operated by appropriately trained personnel.

The nameplate of the appliance provides essential technical information when requesting maintenance or repair

work on the appliance. For this reason, it must not be removed, damaged or modified.

The device must be used only for the purpose for which it was designed.

The interior and exterior surfaces of the oven should be cleaned frequently to ensure hygiene and proper

operation of the oven. These surfaces should not be cleaned with abrasive or flammable products that could

damage the device.

A cleaning procedure other than that recommended by the manufacturer, as well as the use of products not

authorized by the manufacturer, can cause damage to both the appliance and the user.

Risk of burns

Read these warnings carefully and follow its indications when the oven is working or not completely cooled

down.

Touch only the control elements of the appliance and the door opening handle. Avoid touching any other

external parts of the appliance, as these can reach high temperatures.

When moving or handling any component of the device, always use thermal mittens or similar.

To open the appliance door, open it slowly and be careful of the high temperature vapors coming out of the

cooking chamber.

Risk of fire

If you do not clean the appliance properly and as often as necessary, you run the risk of causing the grease and

food residues that accumulate in the cooking chamber to combust.

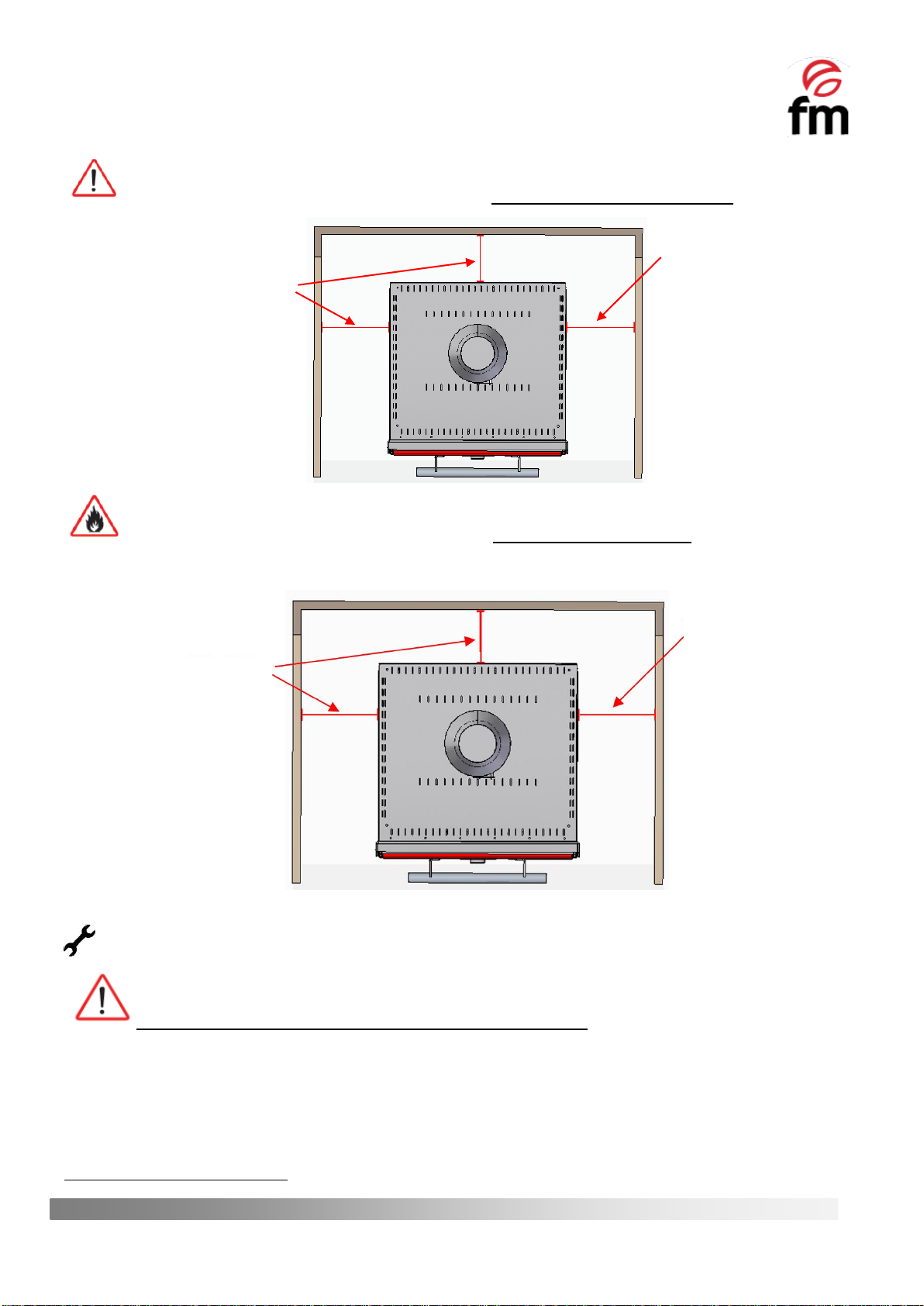

The recommended safety distances from this furnace must be strictly adhered to. Otherwise fires may occur due

to excessive proximity to highly flammable materials.

The recommended safety distances should be kept clear of any material intended to be used as thermal

insulation.

Whenever the furnace contains an active charge of charcoal, the door must remain closed.

Never pour ashes into containers made of flammable or thermo deformable material.

Failure to comply with these safety regulations exempts FM from any liability and also

renders the warranty completely invalid.