FMG PL245 User manual

EQUIPMENT

LLP FARM MACHINERY GROUP OY

LEVYTIE 4 ● 74510 IISALMI

TEL. +358 (0)20 1984 020 ● FAX +358 (0)20 1984 029

OPERATORS MANUAL

PL245-PL360

ORIGINAL

OPERATORS MANUAL D0005D

BULLDOZER BLADE

Page 2

ORIGINAL

EY-VAATIMUSTENMUKAISUUSVAKUUTUS TUOTTEESTA

LLP Farm Machinery Group Oy vakuuttaa, että markkinoille saatettu kone täyttää direktiivin

2006/42/EY ja standardit SFS-EN ISO 12100 ja SFS-ISO730-1.

FÖRSÄKRAN OM ÖVERENSSTÄMMELSE

LLP Farm Machinery Group Oy försäkrar härmed att tillförda maskin uppfyller

maskindirektivet 2006/42/EY och standard SFS-EN ISO 12100 och SFS-ISO730-1.

CERTIFICATE OF CONFORMITY FOR A PRODUCT

LLP Farm Machinery Group Oy certifies that the following machine, which has been brought into

the market, conforms to directives 2006/42/EY and standards SFS-EN ISO 12100 and SFS-ISO730-1.

SAMSVARSERKLÆRING FOR MASKIN

LLP Farm Machinery Group Oy bekrefter herved at følgende maskin, som er sendt ut på markedet, er i

samsvar med direktivene 2006/42/EF, SFS-EN ISO 12100 og SFS-ISO730-1.

Tuote / Produkt / Product / Produkt:

Valmistusnumero / Tillverkningsnummer

/ Serial number / Serienummer:

Teknisen tiedoston kokoaja / Teknisk

dokumentation samlare / Technical file collector: Sakari Ruotanen

Valmistaja / Tillverkare / Manufacturer LLP Farm Machinery Group Oy

/Produsent:

Osoite / Adress / Address / Adresse: Levytie 4, FIN-74510 Iisalmi

Puhelin / Telefon / Telephone: +358 (0) 201 984 020

Paikka / Ort / Place / Sted: Iisalmi

Aika / Datum / Date / Dato:

Allekirjoitus / Underskrift / Signature

/ Signatur:

Nimenselvennys / Namnförtydligande Markku Lappalainen

/ Clarification of signature

/ Tydeliggjøring av signatur:

OPERATORS MANUAL D0005D

BULLDOZER BLADE

Page 3

WARRANTY TERMS

All the products produced by LLP Farm Machinery Group Oy have twenty four (24) months

warranty.

During the warranty period all the defects in material and in workmanship will be covered, in

practical life FMG will replace defected parts with the new parts. Travelling expenses and

freight of partsare not included in warranty.

Warranty will start in the beginning of usage of the product, if nothing else hasbeen agreed.

Warranty is not covering damages due to misuse of product or use in the purposes where it

has notbeen designed, lack of services or product has been modified without the permission of

FMG.

Wearing of the normalusage is not covered by the warranty.

Losses in income, costs and loosen working hours caused by the defected part is not covered

by the warranty.

Warranty repairs should be done by the FMG service dealer or service dealer appointed by the

manufacturer.

In case the defects shown in reclamation is not valid or if case otherwise is not in the warranty

area FMG has right to reject from the compensation.

Warranty reclamation should be done in written form by the FMG seller within one (1) month

after notifying the defect.

In case of defect procedure is as follows:

- clarify the defect and defected area

- be prepared to deliver defected parts to the manufacturer

- contact FMG seller and make reclamation as follows:

•type of the product and serial number

•delivery date of the product (invoicing date)

•date of the damage

•description of the damage and pictures

description of the working conditions and the type of the base machine

OPERATORS MANUAL D0005D

BULLDOZER BLADE

Page 4

TO THE OPERATOR

The purpose of this is manual is to provide support and instructions to bulldozer blade

users. Manual contains detailed instructions for driving, operating and maintaining the

bulldozer blade. Make sure that your new bulldozer blade is always handled and

maintained in the correct way in order to ensure reliability and economical operation for

many years.

We recommend that you read the manual thoroughly. Follow the maintenance and service

program carefully and include the daily maintenance in your normal routine. This is both

you and your tractor interest.

Maintenance, repairs and adjustments which are not described in this Operator Manual

require the use of special tools and exact technical data. In case of that kind need please

contact your FMG seller or factory.

Use only genuine FMG spare parts for optimum performance from your tractor and bulldozer

blade. Spares will be sold through the FMG seller.

OPERATORS MANUAL D0005D

BULLDOZER BLADE

Page 5

0BTABLE OF CONTENTS

TABLE OF CONTENTS.................................................................................................................................... 5

1. SAFETY INSTRUCTIONS ......................................................................................................................... 6

2. CONSTRUCTION....................................................................................................................................... 8

3. TECHNICAL SPECIFICATIONS ............................................................................................................... 9

4. BULLDOZED BLADE USE ....................................................................................................................... 9

4.1. Using area........................................................................................................................................... 9

4.2. Instruction............................................................................................................................................ 9

4.3. Bulldozer blade use........................................................................................................................... 10

5. SERVICE.................................................................................................................................................. 12

5.1. Daily service...................................................................................................................................... 12

5.2. Weekly service.................................................................................................................................. 12

5.3. Service after 500 working hours........................................................................................................ 12

5.4. Annual service................................................................................................................................... 12

5.5. Lubricating point................................................................................................................................ 13

5.6. Screws to be tighten.......................................................................................................................... 14

OPERATORS MANUAL D0005D

BULLDOZER BLADE

Page 6

1. SAFETY INSTRUCTIONS

This section summarizes the regulations that must always be followed when working with the

bulldozer blade. However, these regulations do not exempt the driver from statutory and other

national regulations regarding traffic safety and occupational health and safety. Safety

regulations that apply to different types of working sites and existing road traffic laws must

always be observed. Tractor safety regulations accepted by the Finnish occupational safety

and health administration have already been taken into account in the equipment design. The

following section describes general safety precautions that must be observed regarding the

use of the bulldozer blade.

IMPORTANT

Do not use the bulldozer blade for other purposes than it has been

designed. Please read this manual carefully before using the implement.

IMPORTANT

Before driving, make sure that all movements and functions work

correctly.

DANGER

When testing different movements of the bulldozer blade make sure that

there is no one close to tractor. Safety distance 5 meters.

IMPORTANT

Advise other users on the use of the implement and ask them to read the

manual.

DANGER

Do not operate with the damaged implement.

IMPORTANT

Use the rotary beacon while working

OPERATORS MANUAL D0005D

BULLDOZER BLADE

Page 7

WARNING

Observe the Operators Manual instructions while working.

WARNING

Pay attention to other road users.

IMPORTANT

Always lower the implement down and stop the engine before leaving the

cab.

IMPORTANT

Never service or clean an implement that is resting on the hydraulics.

Use mechanical support. Always stop the engine for maintenance.

WARNING

Do not disconnect, connect or tighten pressurized hydraulic plugs.

WARNING

Do not inhale oil mist if a pressurized component becomes damaged. If

oil comes into contact with the eyes, rinse with plenty of water and

contact a doctor immediately.

DANGER

Pay attention to the direction of the bulldozer blade in relation to the

tractor. The plough attempts to steer the tractor.

OPERATORS MANUAL D0005D

BULLDOZER BLADE

Page 8

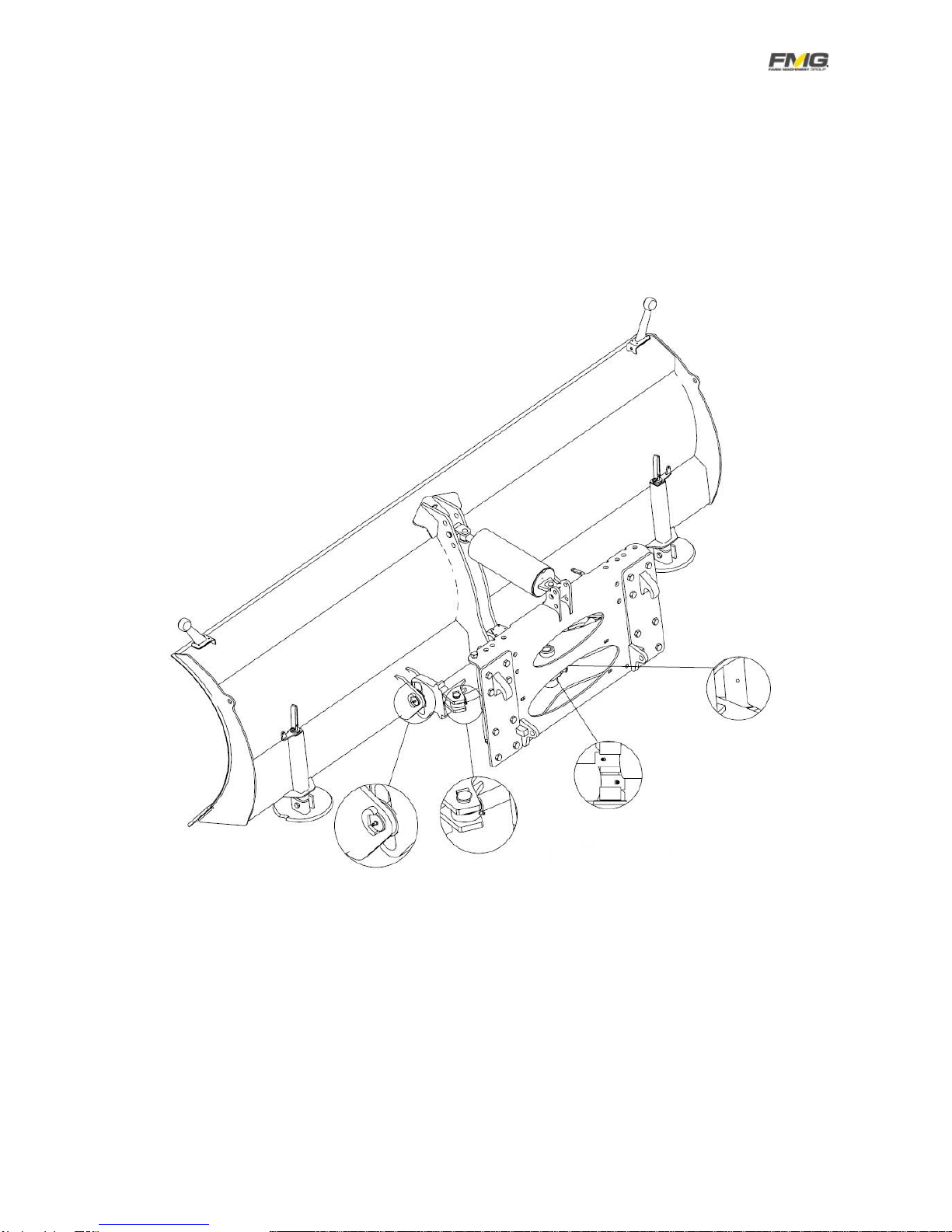

2. 2BCONSTRUCTION

1. Machine bracket

2. Floating bar

3. Turning cylinder

4. Releasing device

5. Main wing

6. Supporting leg

7. Blade

8. Led-daytime running light (Option)

OPERATORS MANUAL D0005D

BULLDOZER BLADE

Page 9

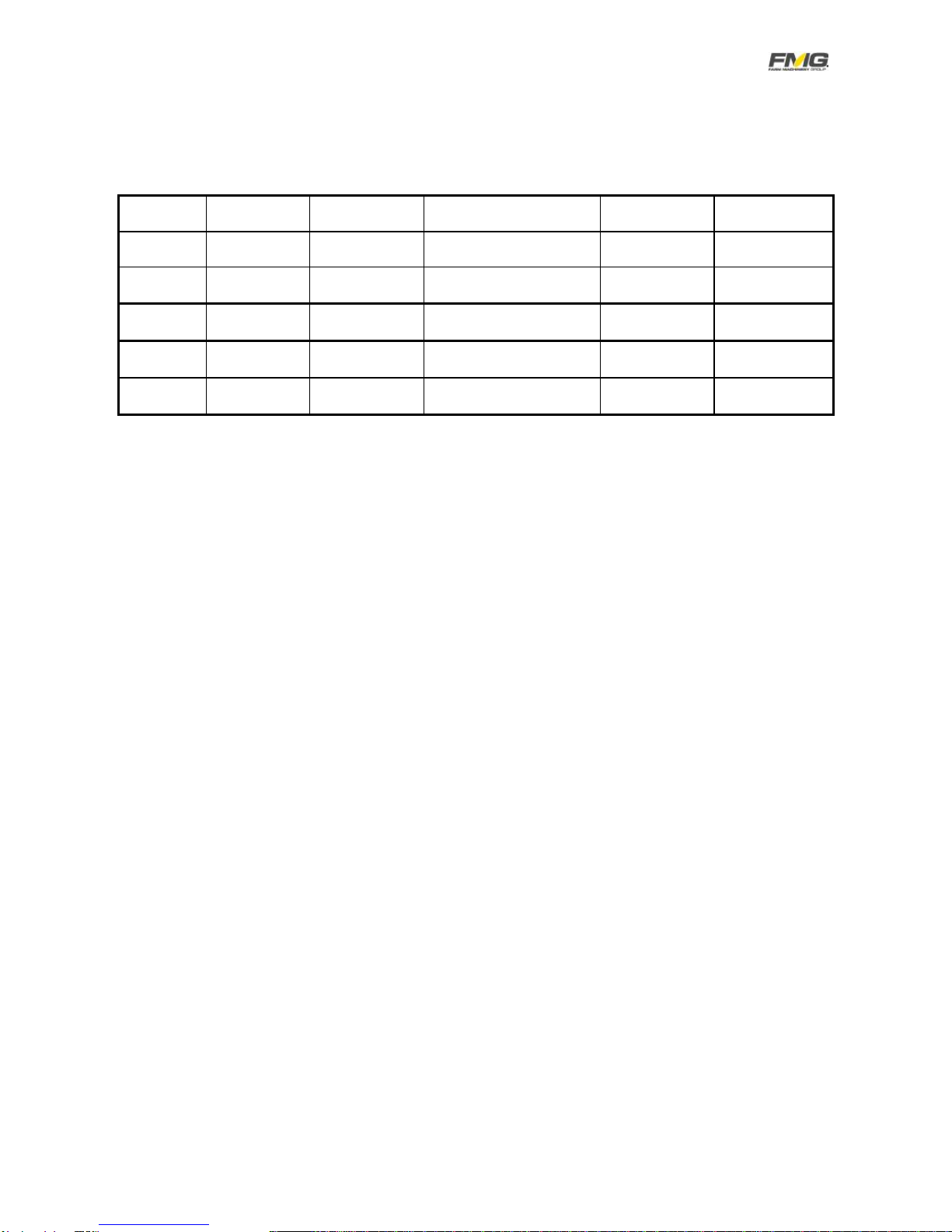

3. TECHNICAL SPECIFICATIONS

4. BULLDOZED BLADE USE

4.1. Using area

Bulldozer blade isespecially designed to the yards cleaning and roads.Bulldozer

blade is also used in peat leveling on peat bog terminals.

4.2. Instruction

Before use check that bulldozer blade is engaged properly to the working machine

and all the locking´s are well done.

Test drive working machine and bulldozer blade combination to ensure that all have

been engaged well. If bulldozer blade is new or it have been modified ensure that air

has been eliminatedfrom the system. Air in hydraulic system could cause

unexpected movements.

When using bulldozer blade ensure that your sight is clear to the ploughing area and

there is not anyone in the dancer zone.

When disengage bulldozer blade, put shields to the hydraulic hoses.

When disengage bulldozer blade outside ensure that ground is balanced to help

next engage.Wood blocks would be beneficial to balance the area.

If bulldozer blade will stay longer period without usage, lubricate piston rods with

CORRSHIELD VPCI-369 corrosion shield or with storage oil to avoid corrosion.

Model

Width (cm)

Height (cm)

Working width (cm)

Weight (kg)

Blade angle

PL245

245

100

173 - 245

615

41/45

PL275

275

100

195 - 275

645

41/45

PL300

300

100

216 - 305

685

41/45

PL330

330

100

237 - 335

715

41/45

PL360

360

100

300 - 360

805

41/45

OPERATORS MANUAL D0005D

BULLDOZER BLADE

Page 10

4.3. Bulldozer blade use

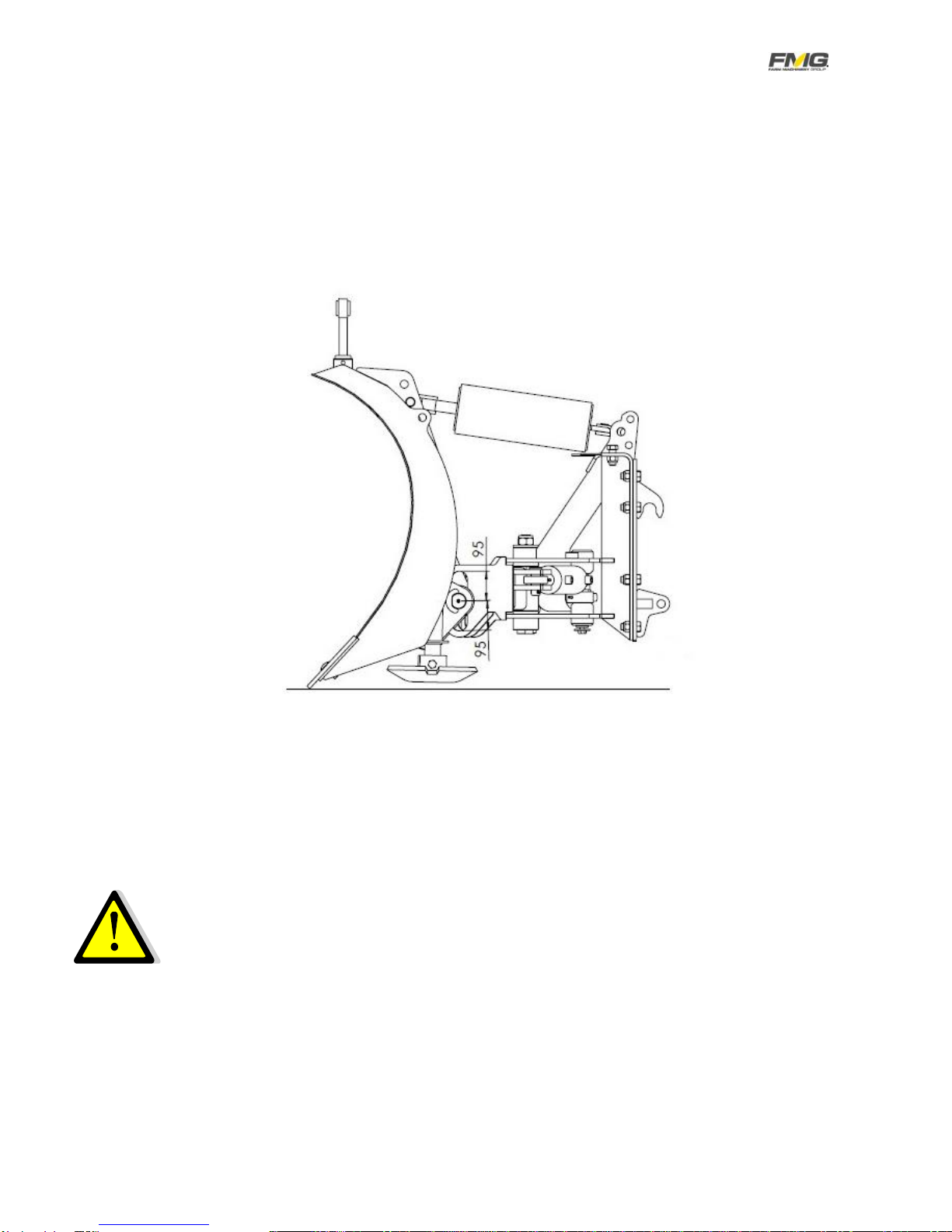

Engage bulldozer blade to the working machine that floating bar is in the mid

position and bulldozer blade is in the balanced position (Picture 1).

Picture 1. Floating bar in the mid position

In case the adapter is wrong change adapter and ensure that screws are tightened

well.

IMPORTANT

When bulldozer blade is new take care that air from hydraulic system will be

eliminated by turning cylinders against to the limit stoppers couple of the time.

Adjust support legs in order to blade will get correct height from the surface.

In case of front loader application beam support are recommended.

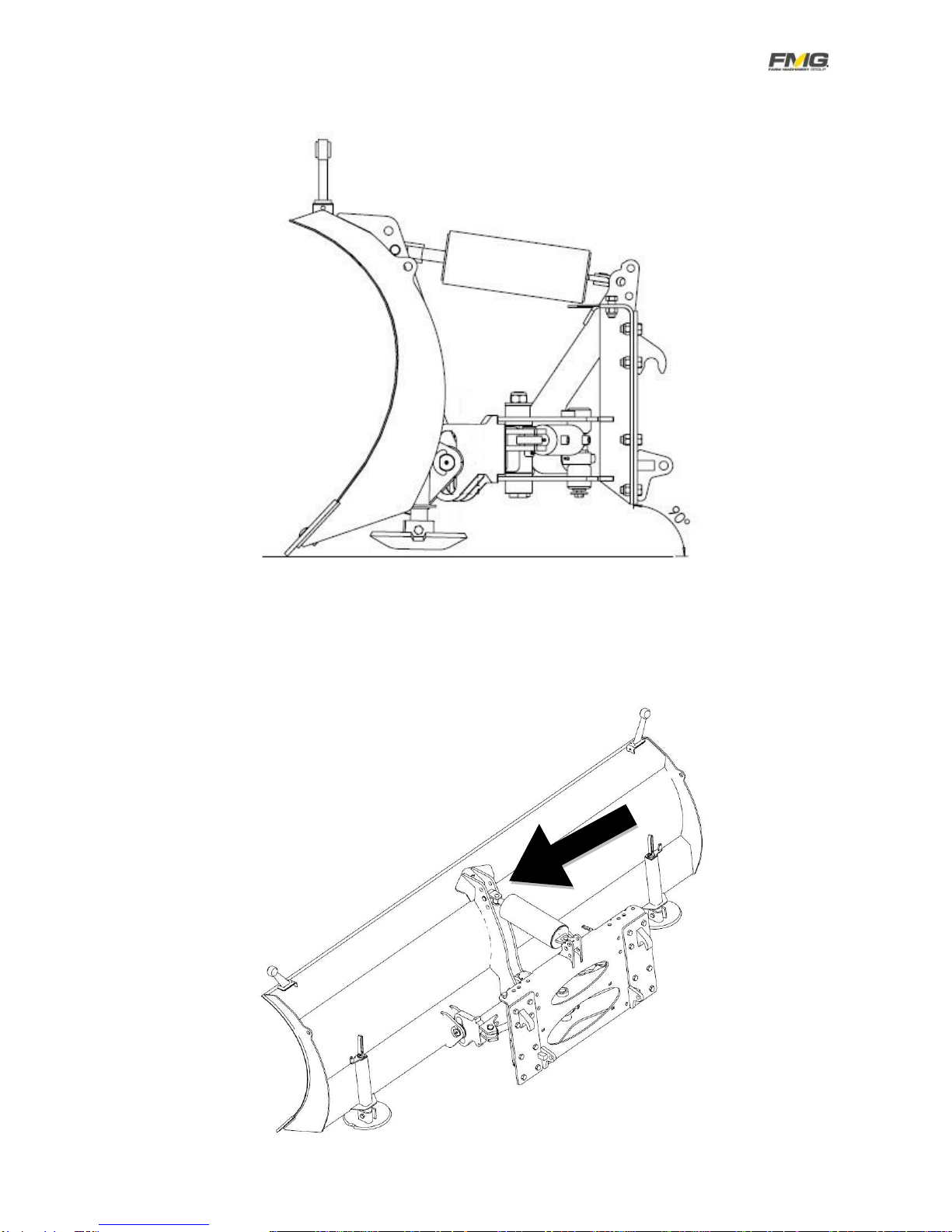

Workingposition of plough is correct when frame is in the upright position (Picture

2).

OPERATORS MANUAL D0005D

BULLDOZER BLADE

Page 11

Picture 2. Plough frame in the upright position

Blade angle is possible to adjust by moving releasing device to anotherhole (3

different alternative) (Picture 3).

OPERATORS MANUAL D0005D

BULLDOZER BLADE

Page 12

Picture 3. Three holes for the releasing device

5. SERVICE

The most important thing to get maximum reliability is good service in time. Service

costs are smaller compared to the repairing´s costs.Below mentioned service

includes all the lubrications and adjustments.

5.1.Daily service

- Check all the blades

- Check tightness of the fastening screws

- Test drive all the movements

- Clean the equipment in the end of the working day

5.2.Weekly service

- Lubricate all the nipples

- Check that there are no leakages

5.3.Service after 500 working hours

- Check all the pins and tightness

- Check tightness of the screws

5.4.Annual service

All above mentioned. Lubricate all the lubrication points always when leaving

equipment to the storage.

NB!

When serving you should follow the service table also taking care

of the previous services.

NB!

Tightness of the screws should be checked also after the first

drive.

NB!

OPERATORS MANUAL D0005D

BULLDOZER BLADE

Page 13

Lubricate also piston rods when leaving equipment to the storage

place.

5.5.Lubricating point

Lubricate nipples shown in the picture (Picture 4). Clean the top of the nipple before

lubrication.

Picture 4. Lubrication

OPERATORS MANUAL D0005D

BULLDOZER BLADE

Page 14

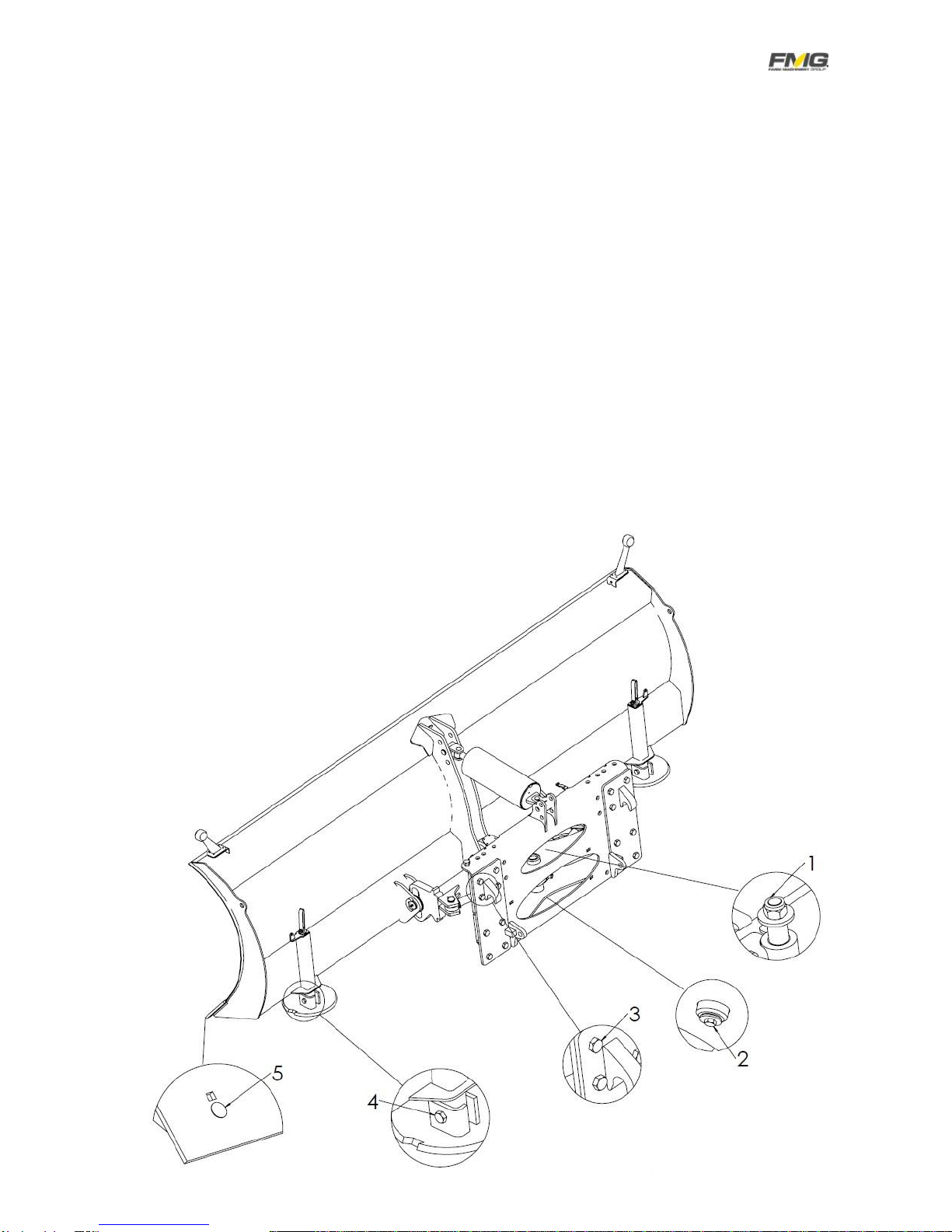

5.6.Screws to be tighten

Tighten all the screws after 10 hours´ drive and after that between 500 working

hours. Check the knife fixing screw daily.

1. Tightening screws of the cylinders

2. Tightening nut of the main pin in the center

3. Tightening screws of the adapters

4. Tightening screws of the support leg

5. All the blade screws

OPERATORS MANUAL D0005D

BULLDOZER BLADE

Page 15

LLP FARM MACHINERY GROUP OY

LEVYTIE 4

74510 IISALMI, FINLAND

PUH. +358 (0)20 1984 020

FAX +358 (0)20 1984 029

www.fmg.fi

This manual suits for next models

4

Table of contents

Other FMG Construction Equipment manuals