Page 3 of 6 | 20220322

User Manual: Rotomolded Portable Foam Units | English

READ ALL INSTRUCTIONS BEFORE OPERATING EQUIPMENT

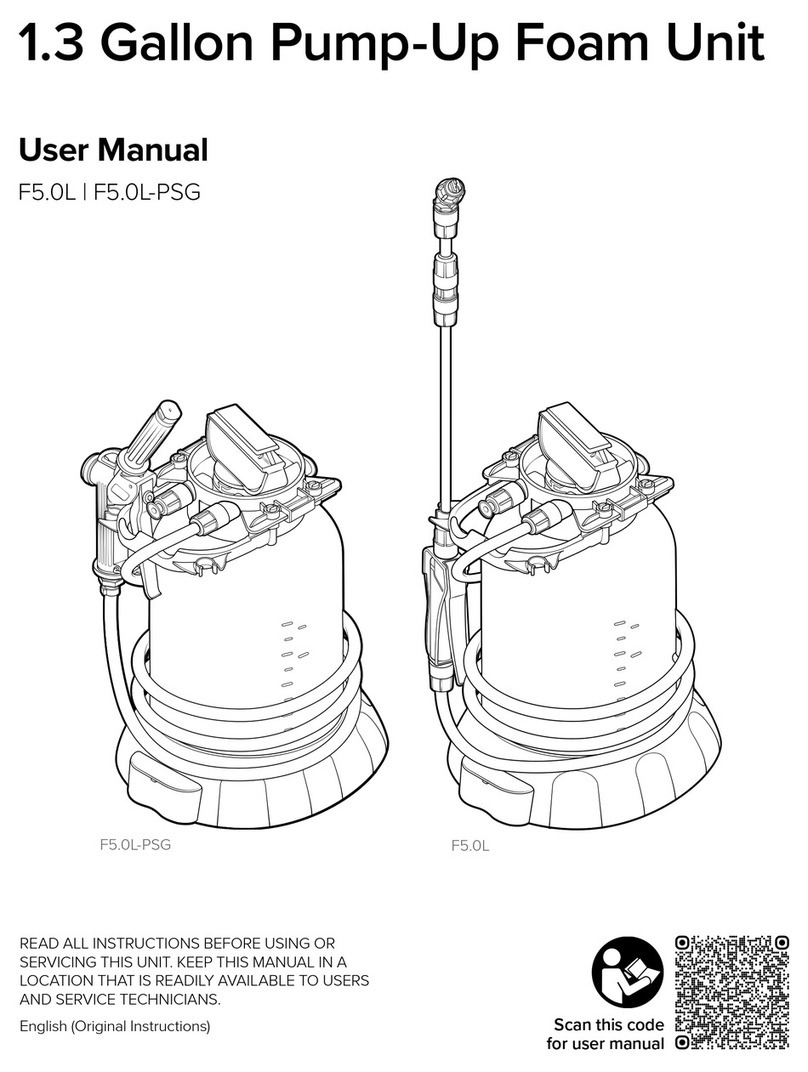

Model No.: FI-5N, FI-5NK, FI-5NV, FI-5N-ST, FI-5NK-ST, FI-5NV-ST

Operaon Instrucons:

1. Follow all instrucons from chemical manufacturer.

Fill the tank with water and the advised percentage of

chemical concentrate.

2. With ball valve (HV60) in the closed posion, plug an air

line into the air ng (AP25).

3. Slowly open the ball valve (HV60) completely.

4. Adjust the needle valve (NV14Y) to desired wetness or

dryness of foam following the steps below:

a. Close needle valve completely in clockwise direcon.

b. Open needle valve in counter-clockwise direcon 3

complete turns.

c. Connue to open valve in ¼ turn increments allowing

30 seconds between adjustments unl proper

consistency of foam is achieved.

Aer Use Instrucons:

1. Flush the unit with fresh water for 5 minutes.

2. Disconnect the air line from the air ng (AP25) and

relieve any remaining pressure in the system by opening

the discharge ball valve (HV60).

3. Close the ball valve (HV60) aer all pressure has been

relieved from the system.

Maintenance Instrucons:

To keep your portable tank foamer operang properly,

periodically perform the following maintenance procedures:

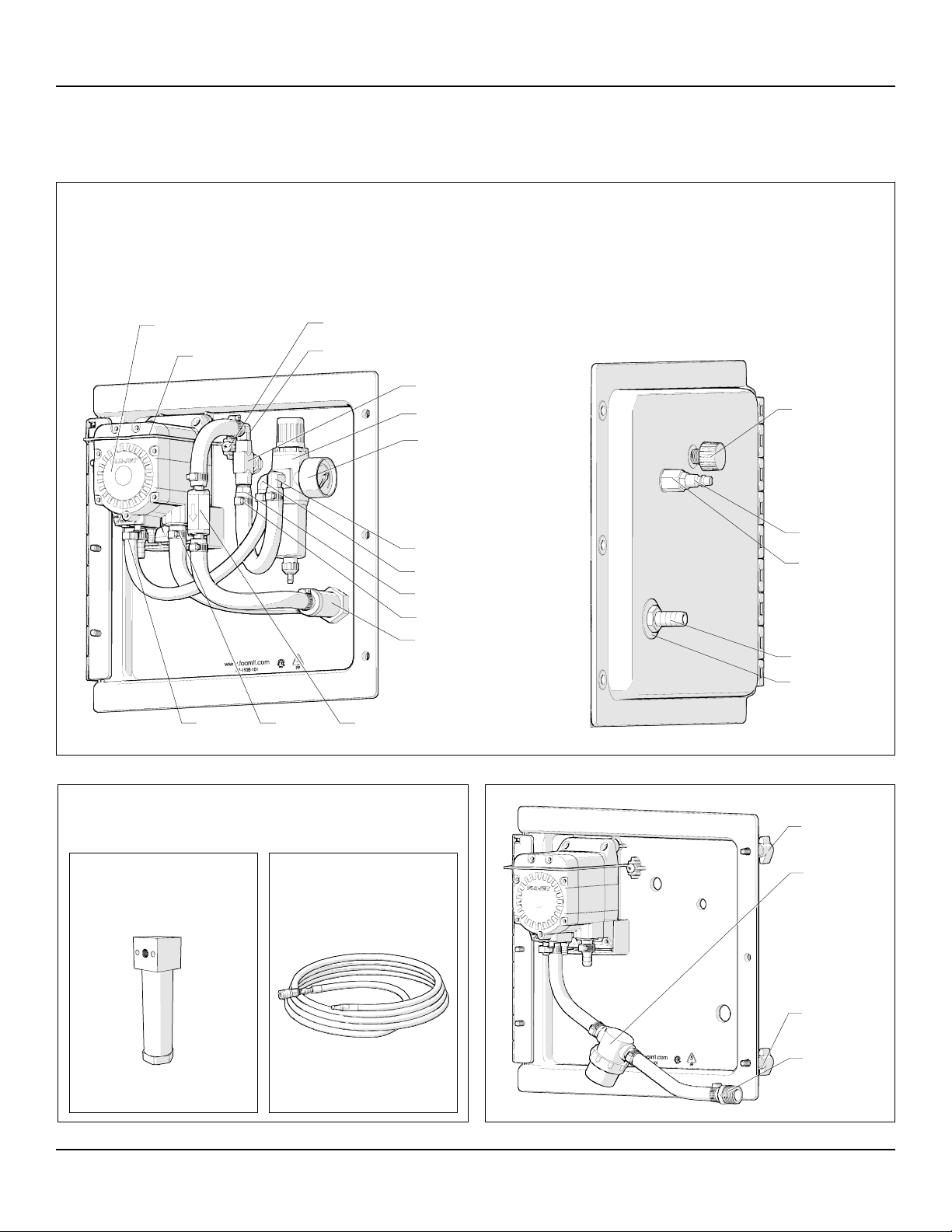

• Check the air pump (P56/P56K/P56V) for wear and leaks.

• Inspect hoses for leaks or excessive wear. Make sure all

hose clamps are in good condion and properly secured.

• Replace lter (AFR25) in regulator (R25) as needed.

• Check the sucon tube and screen for debris and clean as

needed.

• Drain compressor tank on a regular basis to ensure proper

operaon of pump.

Troubleshoong Instrucons:

• Check to ensure the discharge hose is uncoiled properly,

and that there are no kinks that could obstruct uid ow.

• Check air regulator bowl (ABR25) for debris such as

water, oil, or rust parcles. Clean by unthreading the air

regulator bowl from the air regulator (R25).

• If needle valve (NV14Y) valve is open too far, the pump

(P56/P56K/P56V) will cycle improperly due to lack of air

pressure. If this occurs, reset needle valve as described in

Operaon Instrucon #4.

• Make sure proper foaming chemical and concentraon is

being used.

• If air passes through the pump (P56/P56K/P56V) without

cycling, the pump needs to be replaced.

• If foam soluon backs up into air regulator bowl (ABR25),

the check valve (CV38) needs to be replaced.

• If foam comes out wet, no maer where the needle valve

(NV14Y) is posioned, the check valve (CV38) may need to

be replaced.

• Check for proper air pressure on air gauge (AG100). Air

regulator (R25) is factory set at 50 psi (3.4 bar). Operang

range is 40 to 80 psi (3 to 5 bar) with 3.5 to 8 cfm (99.1-

227 l/min)

• If the unit foams at a reduced pressure:

o Check the air compressor supplying the unit. If the

pressure is less than 40 psi, turn the foam unit o

unl the compressor can catch up.

o If the air supply is 50 psi (3.4 bar) or above, check

the AG100, which should read near 50 psi (3.4 bar).

If the AG100 is more or less than 50 psi (3.4 bar),

adjust the pressure by turning the knob on the top

of the air regulator (R25).

o If both of the above are okay, the stainless steel

mixing mesh (SS-MESH) could be plugged. Remove

and clean it by following the instrucons below:

1. Be sure the foam unit is not plugged into an

air supply and be sure to relieve all stored

pressure in the unit by having the ball valve

(HV60) in the open posion.

2. Remove the stainless adaptor (HBSS1212) from

the tee ng (SST12HB38).

3. Remove the screen and the mixing mesh from

inside the tee ng (SST12HB38).

4. Clean any parcles from the mixing mesh and

the screen.

5. Replace the mixing mesh and then the screen

into the back of the tee and screw the stainless

adaptor back into the tee. It is recommended

to use a pipe thread sealant when reinstalling

the stainless adaptor back into the tee ng

(SST12HB38). If the mixing mesh has a lot of

foreign parcles in it, make sure the strainer

(STR38-IL) is sll in place.

• Check for plugged strainer (STR38-IL). Replace strainer if

necessary. Strainer must be used.