Risk of re or explosion. Flammable refrigerant used. Follow handling instruction carefully. To

be repaired only by trained service Personnel.

Do not puncture Refrigerant Tubing. Do not use this product with ammable gases or ammable

solvents.

Do not store ammable gases, ammable liquids or ammable solids in these units. Do not use

FLAME to check for gas leak.

Do not under any circumstances try to modify or repair valves, regulator, connectors, controls or

any other appliance. Doing so creates the risk of a gas leak.

Keep ventilaton openings clear of obstruction.

Do not damage the refrigerant circuit.

Connect to potable water supply only.

WARNING!

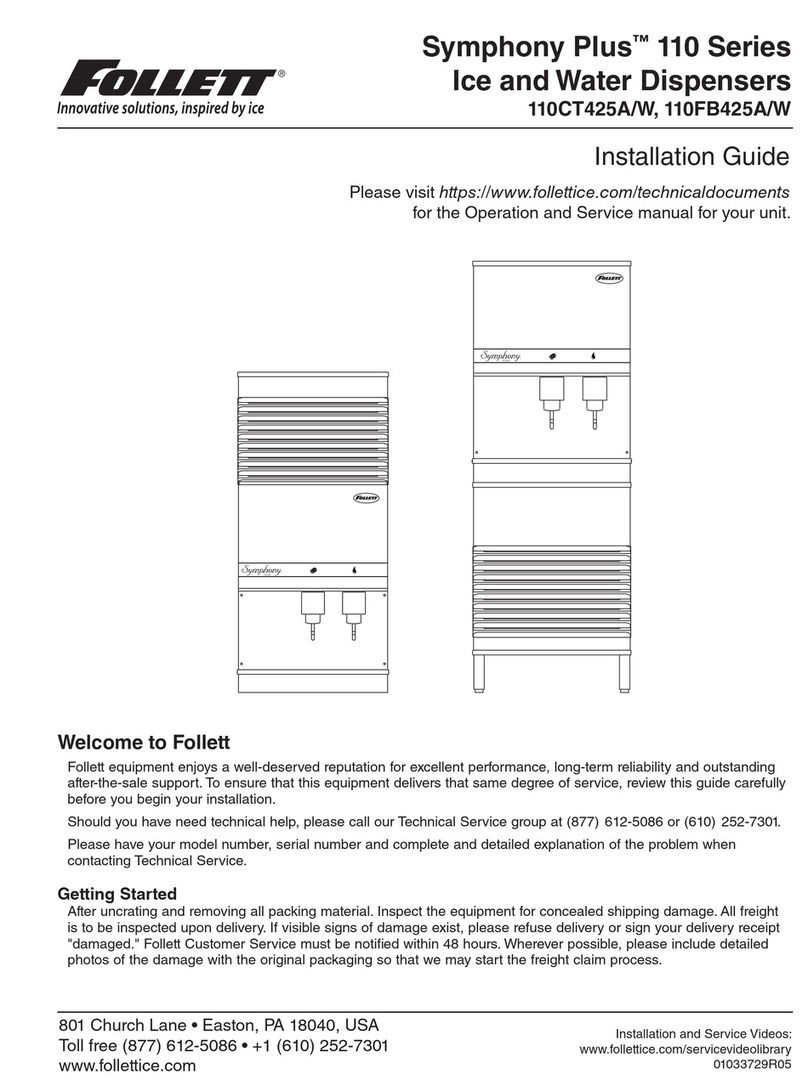

§Read this manual thoroughly before operating, installing or performing maintenance on the equipment. Failure to follow

instructions in this manual can cause property damage, injury or death.

§The ice machine contains R290 (propane) refrigerant. R290 (propane) is ammable in concentrations of air between

approximately 2.1% and 9.5% by volume. R290 (propane) may burn if exposed to a heat source above 470 °C.

§When servicing this equipment, be sure to lock the circuit breaker, and display an in-service notice.

§This equipment contains high-voltage electricity and refrigerant charge. Installation and repairs are to be performed by

properly trained technicians aware of the dangers of dealing with high voltage electricity and refrigerant under pressure.

The technician must also be certied in proper refrigerant handling and servicing procedures. All lockout and tag out

procedures must be followed when working on this equipment.

§Repair on R290 systems must always be done in a well-ventilated area.

§Because R290 is highly ammable, a combustible gas leak detector is required when servicing R290 systems.

§Only use parts recommended or provided by the manufacturer.

§Routine adjustments and maintenance procedures outlined in this manual are not covered by the warranty.

§We reserve the right to make product improvements at any time. Specications and design are subject to change without

notice.

§Do not tilt unit further than 30° off vertical during uncrating or installation.

§Dispenser bin area contains mechanical, moving parts. Keep hands and arms clear of this area at all times. If access to

this area is required, power to unit must be disconnected rst.

§This appliance is not suitable for installation in an area where a water jet could be used.

§This appliance must not be cleaned by a water jet.

§User maintence should not be done by children.

§Follett recommends a Follett water lter system be installed in the ice machine inlet water line (standard capacity

#00130229, high capacity #00978957, carbonless high capacity #01050442).

§Prior to operation clean the dispenser in accordance with instructions found in this manual.

§Do not block air intake or exhaust.

§This appliance should be permanently connected by a qualied person in accordance with application codes.

§A qualied person shall provide a readily accessible disconnect device incorporated into the xed wiring.

§If the supply cord is damaged, it must be replaced by the manufacturer, its service agent or similarly qualied persons in

order to avoid a hazard.

§This appliance can be used by children aged 8 years and above and persons with reduced physical, sensory, or mental

capabilities, or lack of experience and knowledge if they have been given supervision or instruction concerning use of the

appliance in a safe way and understand the hazards involved. Children should be supervised to ensure that they do not

play with the appliance.

§This appliance is designed for commercial use.

§WARNING! To avoid a hazard due to instability of the appliance, it must be xed in accordance with the instructions.

§Warranty does not cover exterior or outside installations.

§To reduce risk of shock, disconnect power before servicing.

§Connect to potable water supply only.

§Ice is slippery. Maintain counters and oors around dispenser in a clean and ice-free condition.

§Ice is food. Follow recommended cleaning instructions to maintain cleanliness of delivered ice.

2 E12CI414A R290, 230 V 50 Hz