2 C/E25CI425A/W, C/E50CI425A/W

Contents

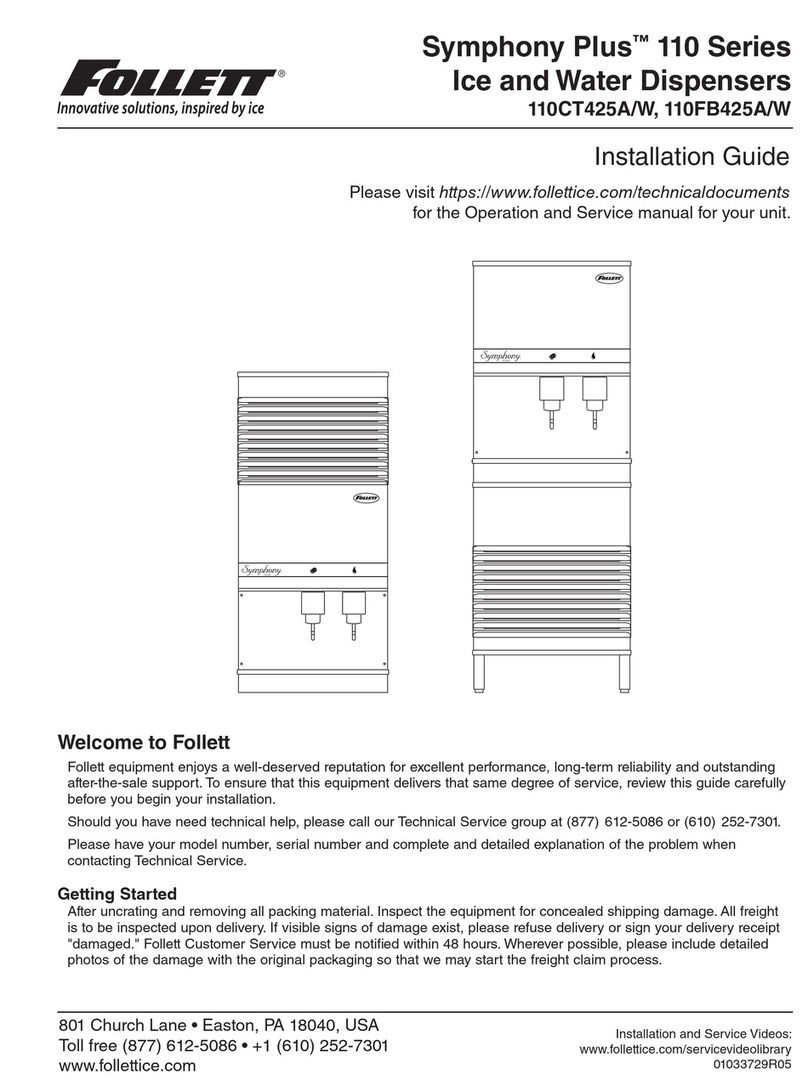

Welcome to Follett. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Before you begin.......................................................................... 3

Specications .............................................................................. 4

Electrical ................................................................................ 5

Ambient................................................................................. 5

Plumbing................................................................................ 5

Ventilation clearances...................................................................... 5

Uncrated weight .......................................................................... 5

Installation ................................................................................. 6

Before you begin.......................................................................... 6

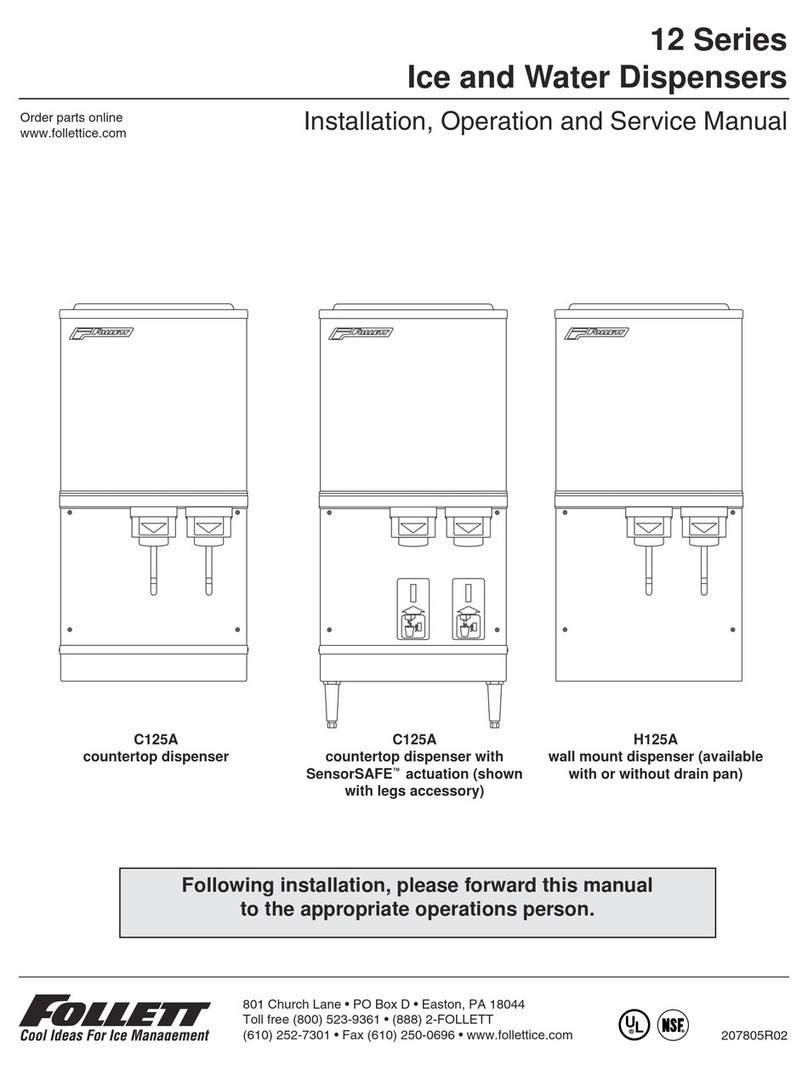

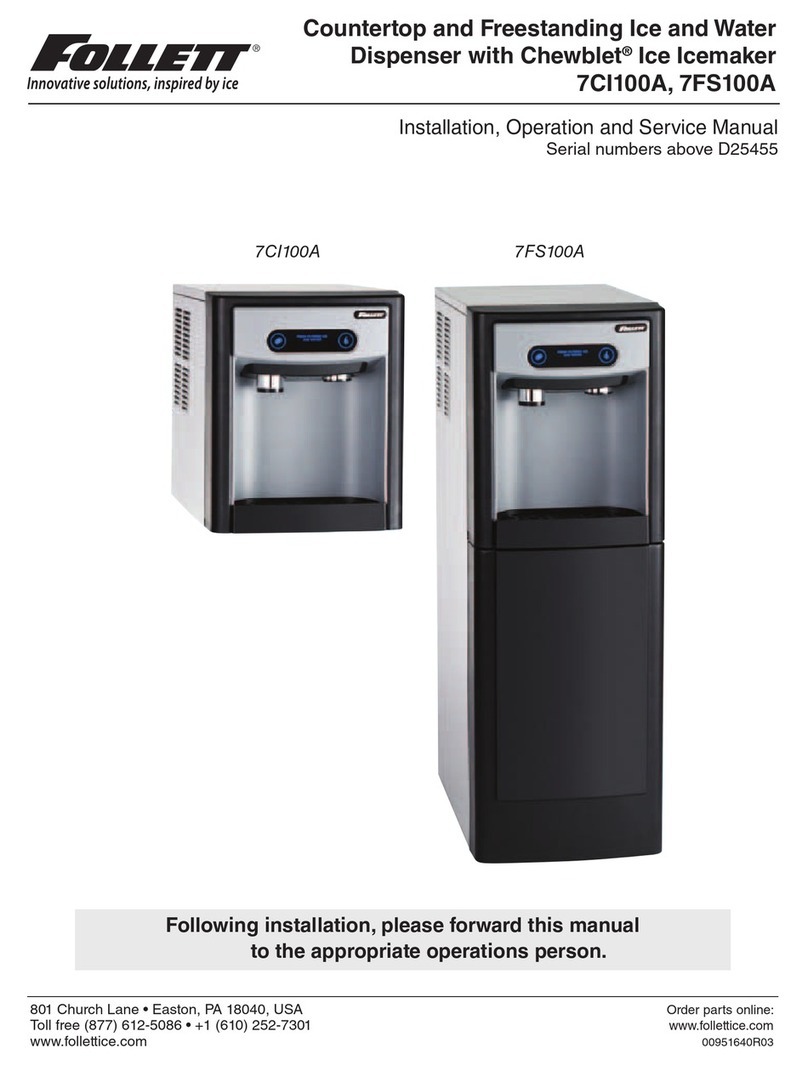

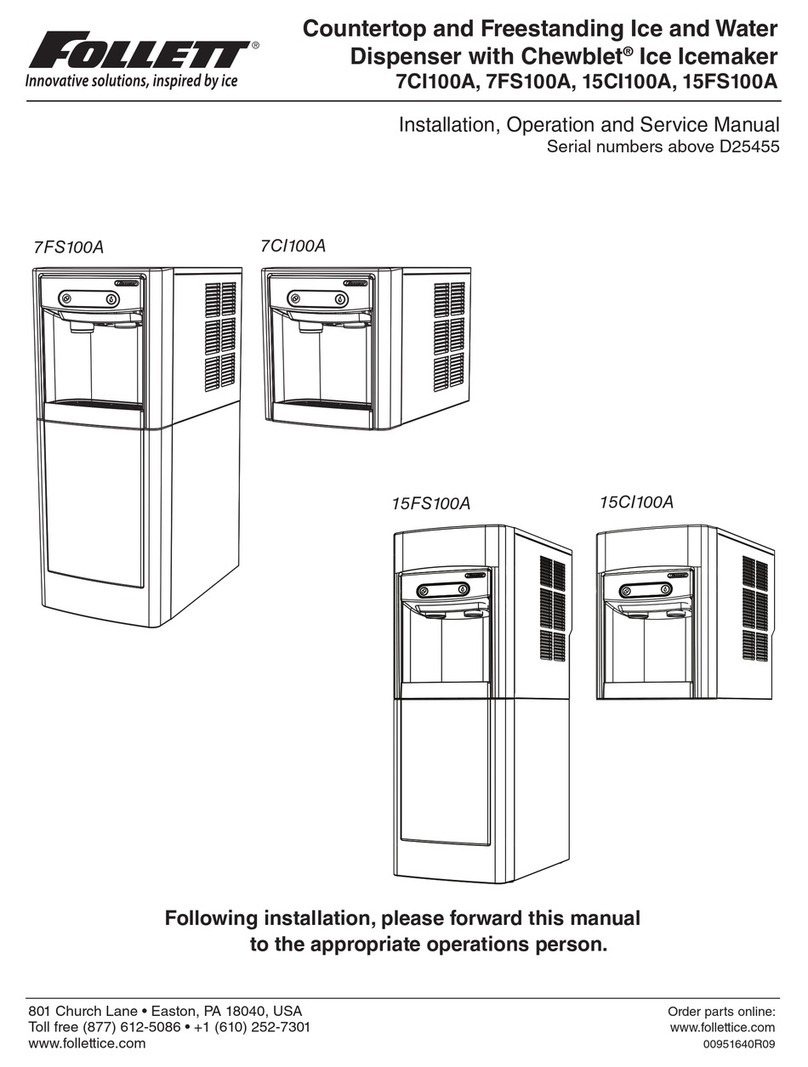

Installing countertop dispensers with rear exiting utilities (no legs) ................................... 6

Installing countertop dispensers with bottom exiting utilities ........................................ 7

Installing wall mount dispensers.............................................................. 8

User information ........................................................................... 11

How the dispenser works ...................................................................11

Cleaning/descaling and sanitizing ............................................................ 11

Weekly ................................................................................ 12

Monthly ................................................................................ 12

Semi-Annually (more often if conditions dictate) ................................................ 12

Service ................................................................................... 15

Ice machine Operation (all models) .......................................................... 15

The icemaking process.................................................................... 15

Water system ........................................................................... 16

Wiring diagram .......................................................................... 18

Ice machine operational and diagnostic sequences ............................................. 20

Diagnostic Stages........................................................................ 25

Refrigeration system...................................................................... 30

Dispenser troubleshooting .................................................................. 32

Lever model troubleshooting guide .......................................................... 32

SensorSAFE model troubleshooting guide .................................................... 32

Ice machine removal instructions ............................................................. 33

Evaporator disassembly ................................................................... 37

Evaporator reassembly .................................................................... 38

Gearmotor replacement ................................................................... 38

Replacement parts ......................................................................... 39

Dispenser exterior........................................................................ 39

Wheel motor and drive system .............................................................. 40

Dispense chute and splash panel (models with SensorSAFE infrared dispensing) ..................... 41

Dispense chute and splash panel (models with lever dispensing) .................................. 42

Dispenser electrical box – SensorSAFE models ................................................ 43

Dispenser electrical box – lever models....................................................... 44

Water and drain ......................................................................... 45

Water treatment accessories for Symphony Plus ice and water dispensers ........................... 46

Air-cooled ice machines ................................................................... 47

Water-cooled ice machines. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Evaporator replacement parts .............................................................. 51

Ice machine electrical components ............................................................