Forma Scientific 310 Series Operating instructions

Forma Scientific, Inc.

*Refer to listing of models on Page iii.

Millcreek Road, P.O. Box 649

Marietta, Ohio 45750

U.S.A.

Telephone: (740) 373-4763

Telefax: (740) 373-4189

______________________________________

Model: 310 Series*

Direct Heat

CO2Incubator

Operating and Maintenance

Manual

Manual No: 7000310 Rev. 4

Read this Instruction Manual

Failure to read, understand and follow the instructions in this manual may result in damage to the

unit, injury to operating personnel and poor equipment performance.

CAUTION! All internal adjustments and

maintenance must be performed

by qualified service personnel.

Refer to the serial tag on the

rear cover of this manual

FormaModel 310 Series _________________________________________________

ii

The material in this manual is for information purposes only. The contents and the

product it describes are subject to change without notice. Forma Scientific, Inc. makes no

representations or warranties with respect to this manual. In no event shall Forma Scientific,

Inc. be held liable for any damages, direct or incidental, arising out of or related to the use

of this manual.

Manual No. 7000310

4 18943/IN-2794 3/8/00 Updated 310-203 drawing, mounting hdwe & tubing – cntrl panel ccs

-- 18766/IN-2766 12/13/99 Removed RH SNSR ERR alarm ccs

3 18675/IN-2755

18552/IN-2739

11/10/99 Updated illustated parts lists

Blower motor seal change to 730068 & 730069

ccs

-- 18457/IN-2721 8/13/99 Updated 310-203 for parts list change ccp

-- 18390/IN-2714 7/6/99 Updated elect. parts drawing -added outlet label P/N 220259 ccp

2 18117/IN-2701 5/25/99 Updated vinyl push rivets to nylon screws in door reverse ccp

1 18121/IN-2678 3/8/99 Added cord p/n, decl. of conf. for copper, updated parts list ccp

-- IN-2668 2/10/99 Parts list addition deg

0 11/98 Original manual ccp

REV ECR/ECN DATE DESCRIPTION By

FormaModel 310 Series _________________________________________________

iii

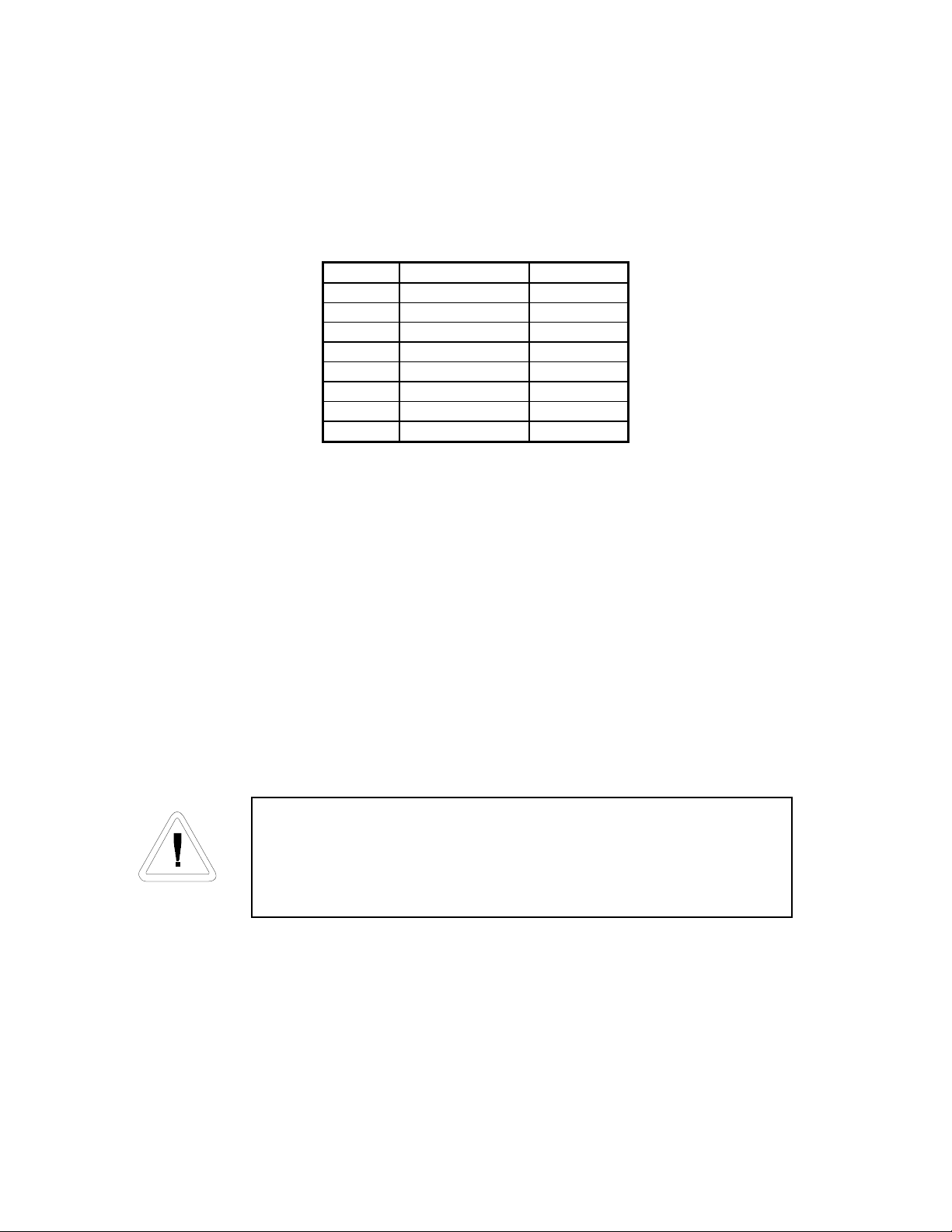

Model CO2 Sensor* Voltage**

310 T/C 115

311 T/C 230

320 IR 115

321 IR 230

350 T/C 115

351 T/C 230

360 IR 115

361 IR 230

*T/C is a thermal conductivity sensor. IR is an infrared sensor.

**All units are 50/60 HZ

If the incubator is not used in the manner specified in this

operating manual, the protection provided by the equipment

design may be impaired.

FormaModel 310 Series _________________________________________________

iv

General Safety Notes used in this Manual

Important operating and/or maintenance instructions. Read the accompanying text

carefully.

Ce symbole attire l’attention de l’utilisateur sur des instructions importantes de

fonctionnement et/ou d’entretien. Il peut être utilisé seul ou avec d’autres symboles de

sécurité. Lire attentivement le texte d’accompagnement.

Wichtige Betriebs- und/oder Wartungshinweise. Lesen Sie den nachfolgenden Text

sorgfältig.

Importante instruccions de operacion y/o mantenimiento. Lea el texto acompanante

cuidadosamente.

Potential electrical hazards. Only qualified persons should perform procedures

associated with this symbol.

Ce symbole attire l’attention de l’utilisateur sur des risques électriques potentiels.

Seules des personnes qualifiées doivent appliquer les instructions et les procédures

associées à ce symbole.

Gefahr von Stromschlägen. Nur qualifizierte Personen sollten die Tätigkeiten

ausführen, die mit diesem Symbol bezeichnet sind.

Potencial de riesgos electricos. Solo personas das capacitadadas deben ejecutar los

procedimientos asociadas con este simbulo.

√Always use the proper protective equipment (clothing, gloves, goggles etc.).

√Always dissipate extreme cold or heat and wear protective clothing.

√Always follow good hygiene practices.

√Each individual is responsible for his or her own safety.

FormaModel 310 Series _________________________________________________

v

Do You Need Information or Assistance on Forma

Products?

do, please contact us 8:00 a.m. to 7:00 p.m. (Eastern Time) at:

1-740-373-4763 Direct

1-888-213-1790 Toll Free, U.S. and Canada

1-740-373-4189 FAX

http://www.forma.com Internet Worldwide Web Home Page

fservice@forma.com Service E-Mail Address

If you

Our staff can provide information on pricing and give you quotations. We

can take your order and provide delivery information on major equipment items or make

arrangements to have your local sales representative contact you. Our products are listed on the

Internet and we can be contacted through our Internet home page.

Our staff can supply technical information about proper setup,

operation or troubleshooting of your equipment. We can fill your needs for spare or replacement

parts or provide you with on-site service. We can also provide you with a quotation on our

Extended Warranty for your Forma products.

Whatever Forma products you need or use, we will be happy to discuss your

applications. If you are experiencing technical problems, working together, we will help you

locate the problem and, chances are, correct it yourself...over the telephone without a service

call.

When more extensive service is necessary, we will assist you with direct factory trained

technicians or a qualified service organization for on-the-spot repair. If your service need is

covered by the warranty, we will arrange for the unit to be repaired at our expense and to your

satisfaction.

Regardless of your needs, our professional telephone technicians are available to assist

you Monday through Friday from 8:00 a.m. to 7:00 p.m. Eastern Time. Please contact us by

telephone or fax. If you wish to write, our mailing address is:

Forma Scientific, Inc.

Millcreek Road, PO Box 649

Marietta, OH 45750

International customers, please contact your local Forma Scientific, Inc. distributor.

Sales Support

Service Support

FormaModel 310 Series _________________________________________________

vii

Table of Contents

Section 1 - Installation and Start-Up

1.1 Incubator Components ................................................................................ 1-1

1.2 Control Panel Keys, Displays and Indicators.............................................. 1-2

1.3 Operation of the Keypad ............................................................................. 1-3

1.4 Displays....................................................................................................... 1-4

1.5 Installing the Unit........................................................................................ 1-4

a. Choosing the Location ..................................................................... 1-4

b. Stacking the Incubators..................................................................... 1-5

c. Preliminary Cleaning and Disinfecting ............................................. 1-7

d. Installing the Shelves ........................................................................ 1-7

e. Installing Access Port Filter .............................................................. 1-8

f. Installing the (optional) HEPA Filter ................................................ 1-8

g. Leveling the Unit .............................................................................. 1-9

h. Connecting the Unit to Electrical Power........................................... 1-9

i. Filling the Humidity Pan.................................................................... 1-10

j. Connecting the CO2Gas Supply........................................................ 1-10

1.6 Incubator Start-Up....................................................................................... 1-12

a. Setting the Operating Temperature ................................................... 1-12

b. Setting the Overtemp Setpoint..........................................................1-12

c. Setting the CO2Setpoint ................................................................... 1-14

Chart 1-1, Set Mode............................................................................... 1-13

Section 2 - Calibration

2.1 Calibration Mode ........................................................................................ 2-1

a. Calibrating the Temperature.............................................................. 2-1

Temperature Stabilization Periods............................................... 2-1

b. Calibrating the Thermal Conductivity CO2System.......................... 2-2

T/C CO2Sensor Stabilization Periods ......................................... 2-2

c. Calibrating the Infra-Red CO2System.............................................. 2-3

IR CO2Sensor Stabilization Times.............................................. 2-3

d. Calibrating the Relative Humidity....................................................2-3

Relative Humidity Stabilization Times........................................ 2-4

Chart 2-1, Calibrate Mode ..................................................................... 2-5

FormaModel 310 Series ________________________________________Contents

viii

Section 3 - Configuration

3.1 Configuration Mode .................................................................................... 3-1

a. Turning the Audible Alarm ON/OFF................................................ 3-1

b. Setting an Access Code..................................................................... 3-1

c. Setting a Low Temp Alarm Limit (tracking alarm) .......................... 3-2

d. Enabling Temp Alarms to Trip Contacts .......................................... 3-2

e. Setting a Low CO2Alarm Limit (tracking alarm)............................. 3-2

f. Setting a High CO2Alarm Limit (tracking alarm) ............................ 3-3

g. Enabling CO2Alarms to Trip Contacts ............................................ 3-3

h. Setting a New Zero Number for T/C CO2Sensors ........................... 3-3

i. Setting a New Span Number for T/C CO2Sensors ........................... 3-3

j. Setting a Low RH Alarm Limit ......................................................... 3-4

k. Enabling RH Alarms to Trip Contacts.............................................. 3-4

l. Enabling Temp/RH to be Displayed .................................................. 3-4

m. Setting an RS-485 Communications Address (1535 only).............. 3-5

n. Selecting a Primary Tank with the Gas Guard Option...................... 3-5

o. Enabling the Gas Guard System ....................................................... 3-5

Chart 3-1, Configure Mode (3 pages) .................................................... 3-7

Section 4 - Alarms

4.1 Alarms (chart of alarms) ............................................................................. 4-1

4.2 Temperature Controller Failure TMP CNTR ERR (alarm) ....................... 4-2

4.3 Sensor Fault Alarms) ................................................................................... 4-2

4.4 CO2 SENS ERR ......................................................................................... 4-2

4.5 IR AUTO Z ERR ........................................................................................ 4-2

Section 5 - Routine Maintenance

5.1 Disinfecting the Incubator Interior.............................................................. 5-1

5.2 Cleaning the Cabinet Exterior..................................................................... 5-2

5.3 Cleaning the Glass Doors............................................................................ 5-2

5.4 Cleaning the Humidity Pan ......................................................................... 5-3

5.5 Reversing the Door Swing .......................................................................... 5-3

5.6 The Electronics Section .............................................................................. 5-6

5.7 Replacing the Power Fuses ......................................................................... 5-9

5.8 HEPA Filter Maintenance (factory installed option) ................................. 5-10

5.9 Replacing the Sample Air Filter.................................................................. 5-10

FormaModel 310 Series ________________________________________Contents

ix

Section 6 - Factory Installed Options

6.1 Connections to External Equipment ........................................................... 6.1

a. Connecting the Remote Alarm Contacts........................................... 6.1

b. Connecting the RS485 Interface ....................................................... 6-2

c. Connecting the Analog Outboards .................................................... 6-2

6.2 CO2Gas Guard ........................................................................................... 6-4

a. Connecting the GO2Gas Supplies .................................................... 6-5

b. Activating the Gas Guard.................................................................. 6-5

c. Operation of the CO2Gas Guard....................................................... 6-5

6.3 Humidity Readout ....................................................................................... 6-6

a. Factors affecting the Humidity level in the Chamber ....................... 6-6

b. Accuracy of the Humidity Readout................................................... 6-7

6.4 Connecting the Uninterruptable Power Supply (270028 and 270082) ....... 6-7

a. Uninterruptable Power Supply 270078, 115volt, 50/60Hz ................ 6-7

b. Uninterruptable Power Supply 270082, 230 volt, 50/60Hz............... 6-8

Section 7 – Specifications

Section 8 - Spare Parts

Section 9 - Electrical Schematics

Section 10 - Warranty Information

FormaModel 310 Series _______________________________________ Installation Start-Up

1-1

Section 1 - Installation and Start-up

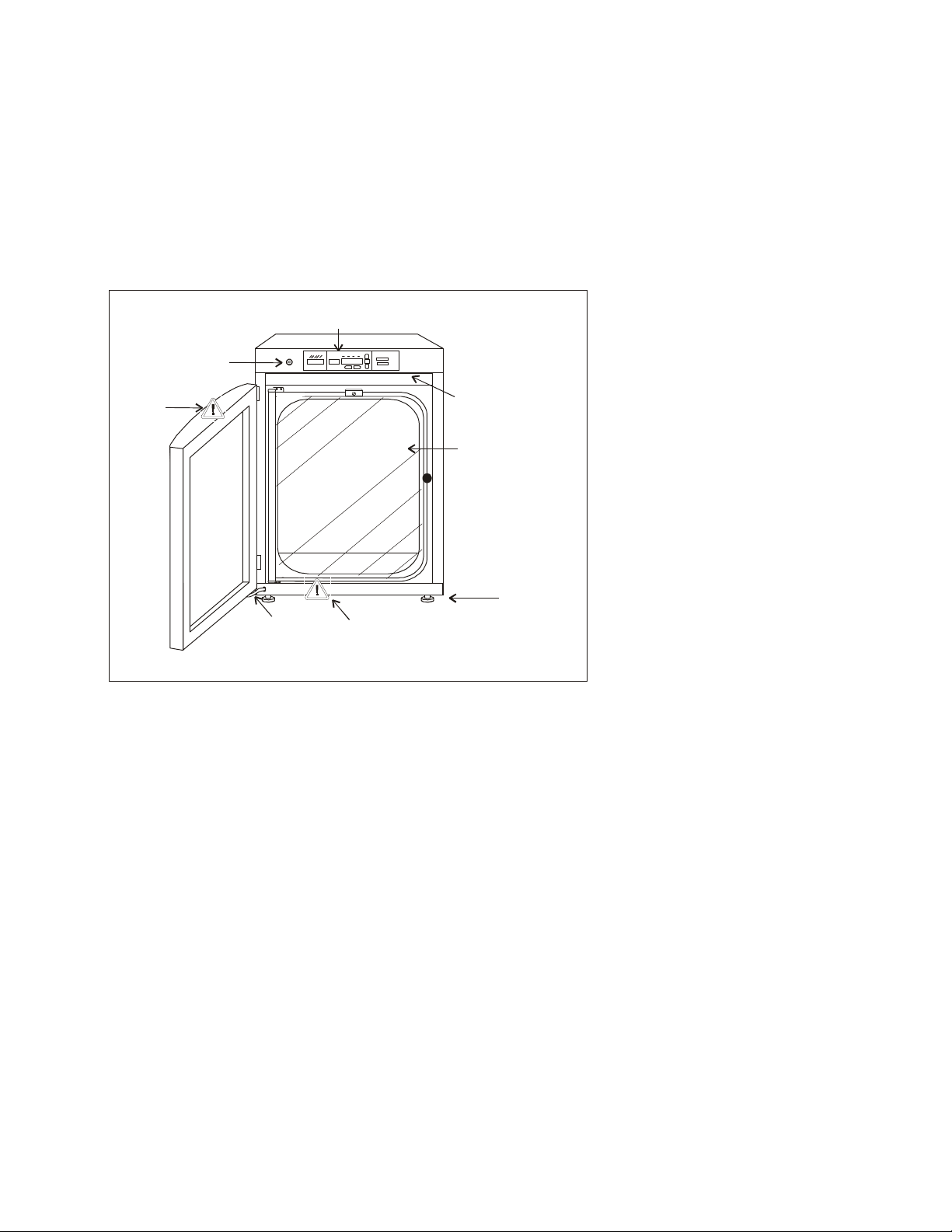

1.1 Incubator Components

•Outer Door - Reversible to

opposite swing, see Section 5.5

•Inner Door - Reversible to opposite

swing, see Section 5.5

•Chamber Gas Sample Port - Used

for sampling chamber CO2content

using a FYRITE or similar

instrument.

•Main Power Switch

•Control Panel - Keypad, Displays

and indicators (See Figure 1-2)

•Leveling Legs - Used to level the

unit

Note: The incubators are stackable. See

Section 1.5.b.

InnerD oor

Leveling

Legs (4 )

DoorHeater

Cable

Contro l Panel

ChamberGas

Sam ple Port Power

Switch

See Section 5

See

Section

1.5

Figure 1-1

FormaModel 310 Series

Direct Heat Incubator

FormaModel 310 Series _______________________________________ Installation Start-Up

1-2

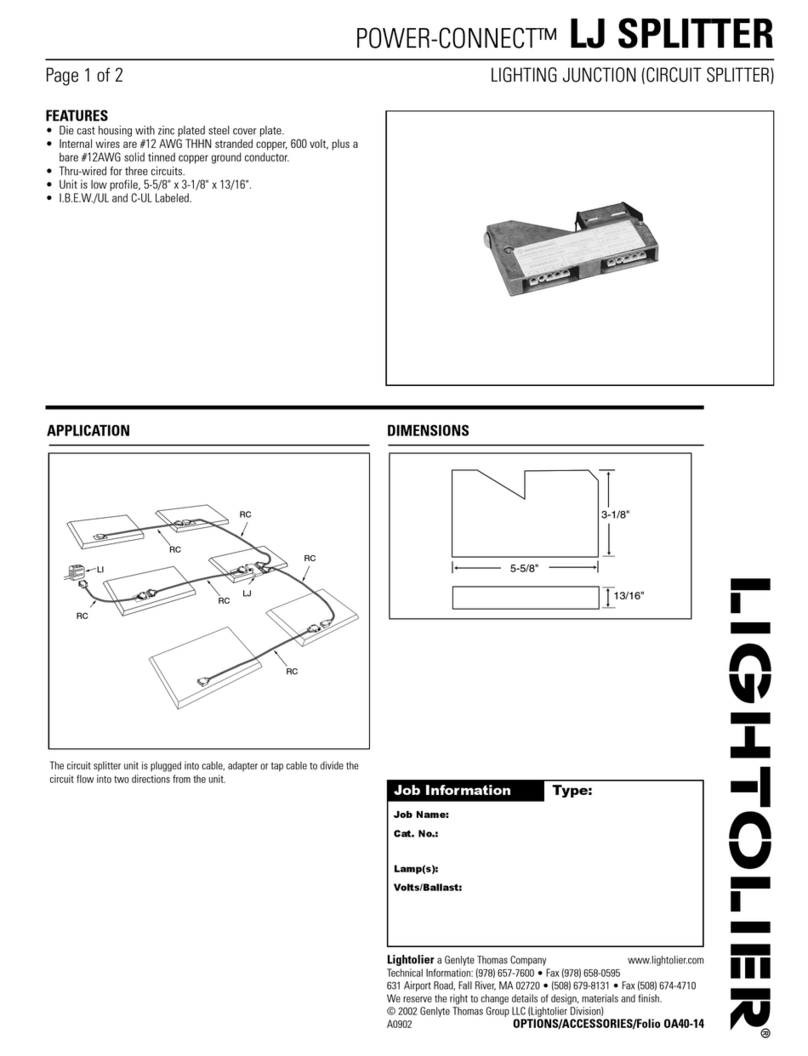

1.2 Control Panel Keys, Displays and Indicators

1. Silence - Silences the audible alarm.

2. Alarm Indicator - Light pulses on/off

during an alarm condition in the cabinet.

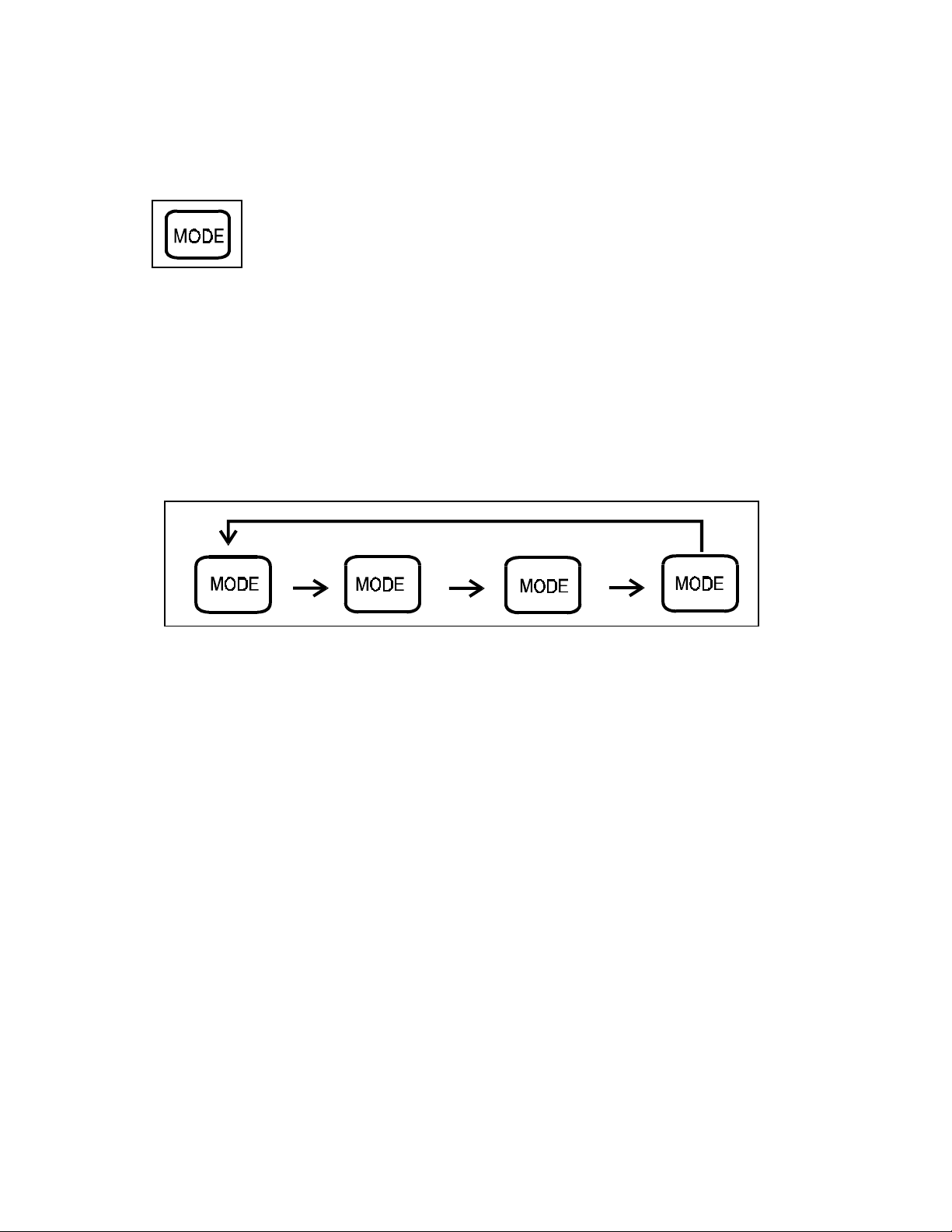

3. Mode Select Switch - Used to select

Run, Setpoints, Calibration and System

Configuration Modes.

4. Message Center - Displays system

status.

5. Mode Select Indicators -

Run: Run Menu

Set: Set Points Menu

Cal: Calibrate Menu

Config: Configuration Menu

6. Up and Down Arrows - Increases or

decreases the number values, toggles

between choices.

7. Enter - Stores the value into computer

memory.

8. Heat Indicator - Lights when power is

applied to the heaters.

9. Temp Display - Program to display

temperature continuously, RH

continuously (with RH option), or toggle

between temperature and humidity (with

RH option). See Section 3.1,

Configuration.

10. Scroll for Parameters Arrows - Moves

the operator through the choices of the

selected mode.

11. CO2 Inject Indicator - Lights when CO2

is being injected into the incubator.

12. % CO2Display - Displays CO2

percentage continuously.

Silence M ode

System OK

36.9

4.9

Enter

R un Set C al C onfig H eat Tem p

In ject % CO

2

Scrollfo r P a ra m e te rs

2

3

4

56

7

89

12

11

10

Figure 1-2

Control Panel

FormaModel 310 Series _______________________________________ Installation Start-Up

1-3

1.3 Operation of the Keypad

The Model 310 Series direct heat incubator has four basic modes which allow

incubator setup: Run, Setpoints, Calibration and System Configuration.

Run is the default mode which the incubator will normally be in during operation.

Set is used to enter system setpoints for incubator operation.

Calibration is used to calibrate various system parameters.

Configuration allows for custom setup of various options.

The chart below shows the selections under each of the modes.

RUN SETPOINT CALIBRATION CONFIGURATION

Default Mode

Temperature

Temp Offset

Audible

Overtemp

CO2Cal1

Access Code

CO2

IR Cal2

Temp Lo Alarm

RH Cal

Temp Relay

CO2Lo Alarm

CO2Hi Alarm

CO2Relay

CO2Z & S #’s *

RH Lo Alarm

RH Relay

Display Temp

Display Rh

Tank Select

Gas Guard

RS485 Address

1T/C units only Base Unit Displays

2IR units only Option Displays

*T/C units only

FormaModel 310 Series _______________________________________ Installation Start-Up

1-4

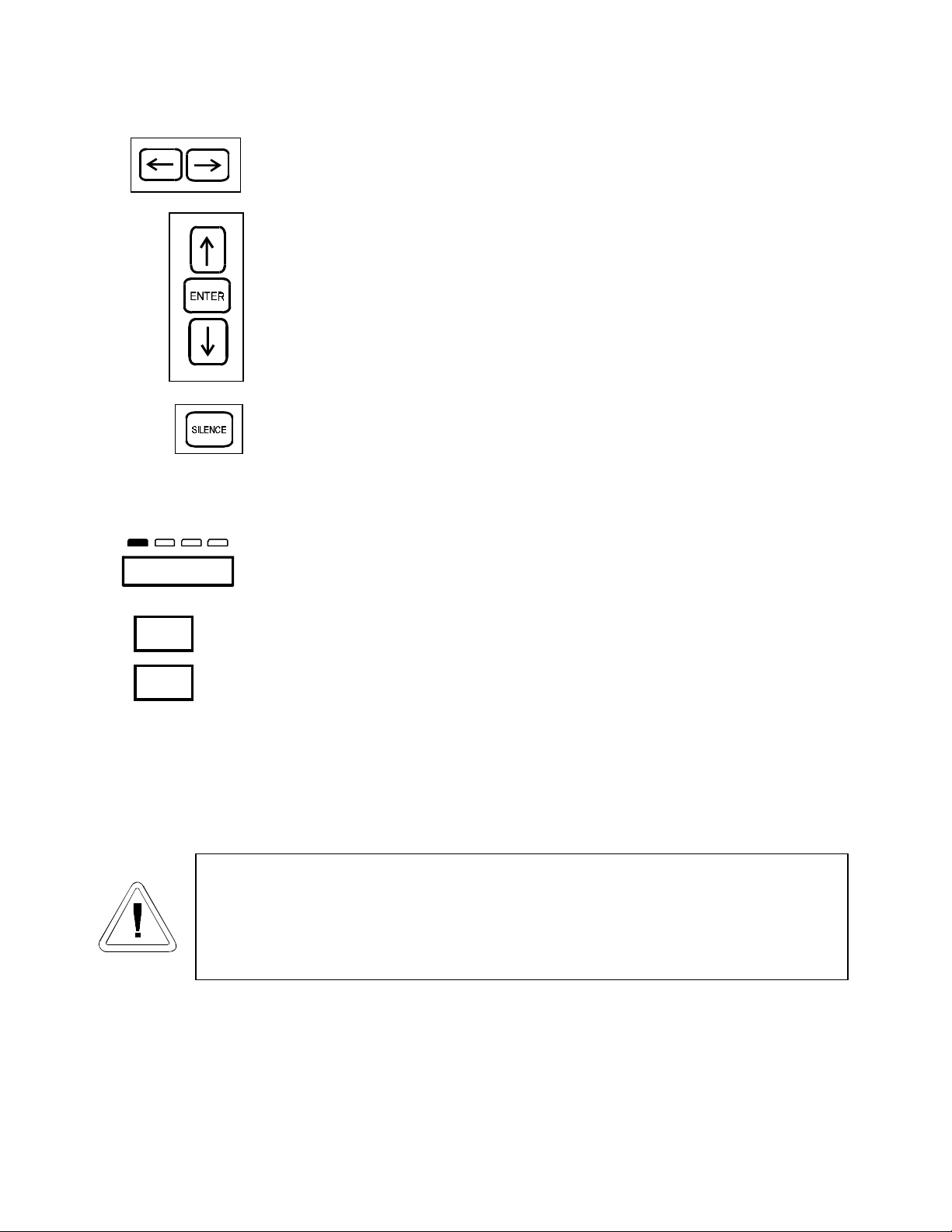

Scroll for Parameters Arrows: Steps the operator through the parameters

of SET, CAL and CONFIG Modes. The right arrow goes to the next

parameter, the left arrow returns to the previous parameter.

Up Arrow: Increases or toggles the parameter value that has been selected

in the SET, CAL, and CONFIG Modes.

Enter: Must press Enter key to save to memory all changed values.

Down Arrow: Decreases or toggles the parameter values that have been

selected in the SET, CAL and CONFIG Modes.

Silence Key: Press to silence the audible alarm. See Section 4 for alarm

ringback times.

1.4 Displays

Message Center - Displays the system status (Mode) at all times. Displays

SYSTEM OK during normal operation, or alarm messages if the system

detects an alarm condition. See Section 4.1, Alarms.

Upper and Lower Displays - These 7 segment displays vary depending

upon the options present and the configuration chosen. The upper display can

display temp or RH, or toggle between them. The bottom display shows CO2

continuously.

1.5 Installing the Incubator

a. Choosing the Location

Single and stacked units must be installed against a wall or similar

structure. Maintain a three-inch clearance behind the incubator for

electrical and gas hook-ups.

1. Locate the unit on a firm level surface capable of supporting the unit’s weight of 205 lbs.

2. Locate the unit away from doors and windows and heating and air conditioning ducts.

3. Lift the unit only by the sides of the cabinet base . Do not attempt to lift it by the front and back .

This places stress on the outer door hinges.

SYSTEM OK

Run Set C al Config

36.9

4.9

Tem p

% CO

2

FormaModel 310 Series _______________________________________ Installation Start-Up

1-5

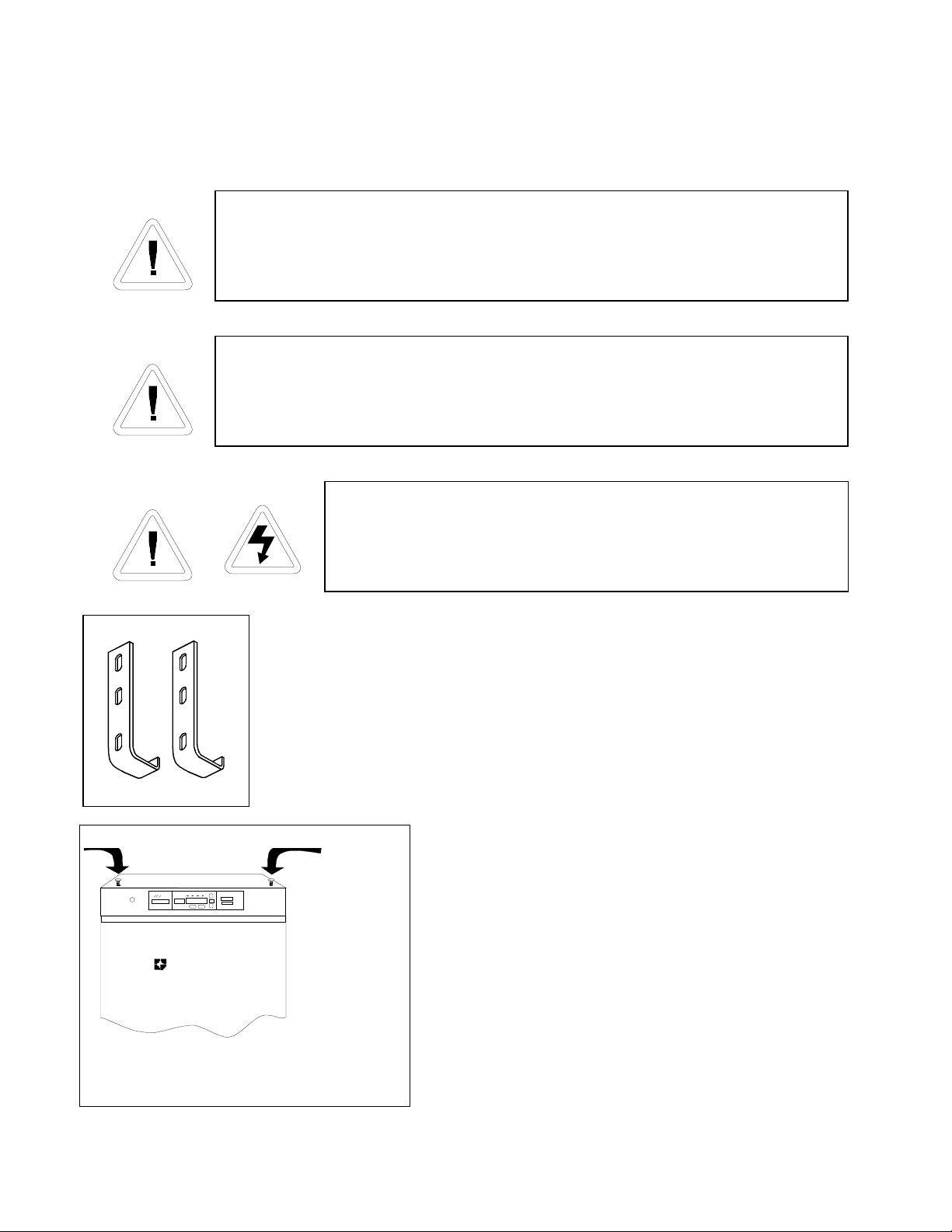

b. Stacking the Incubators

When stacking incubators, the direct heat incubator must be the top unit.

Never stack a water-jacketed incubator on top of a 310 Series unit.

With incubators in a stacked configuration, do not leave both exterior

doors open at the same time.

If the units have been in operation, shut them both off

and pull the plugs before beginning any service work..

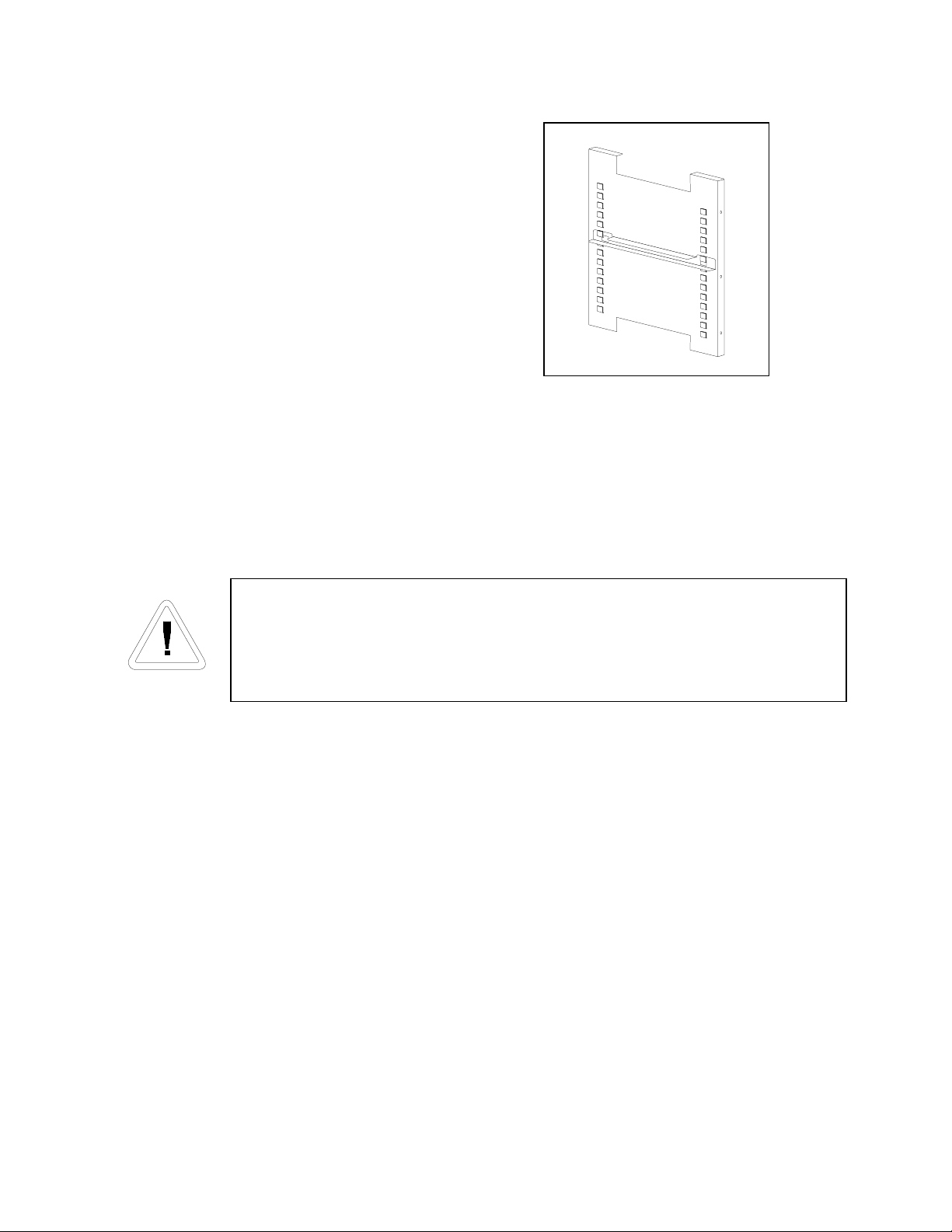

Note: Two stacking brackets (shown at left) are included in the parts bag

included with each incubator.

1. Unscrew the slotted head screws on the top of the

bottom incubator about an inch. Refer to Figure 1-4.

2. Unscrew and remove the leveling feet from the top

unit and lift it onto the bottom unit, offsetting the base

of the top unit approximately 2-3 inches behind the

screws identified by the arrows in Figure 1-4.

3. Remove the kickplate from the top incubator. A

Phillips screw on either end secures the plate. Note that

the bottom of the incubator frame is notched.

Figure 1-3

FormaScientific

Figure 1-4

FormaModel 310 Series _______________________________________ Installation Start-Up

1-6

This incubator weighs 205 lbs. Have sufficient personnel when

lifting.

Lift the unit only by the sides of the cabinet base. Do not attempt

to lift it by the front and back as this places stress on the outer

door hinge.

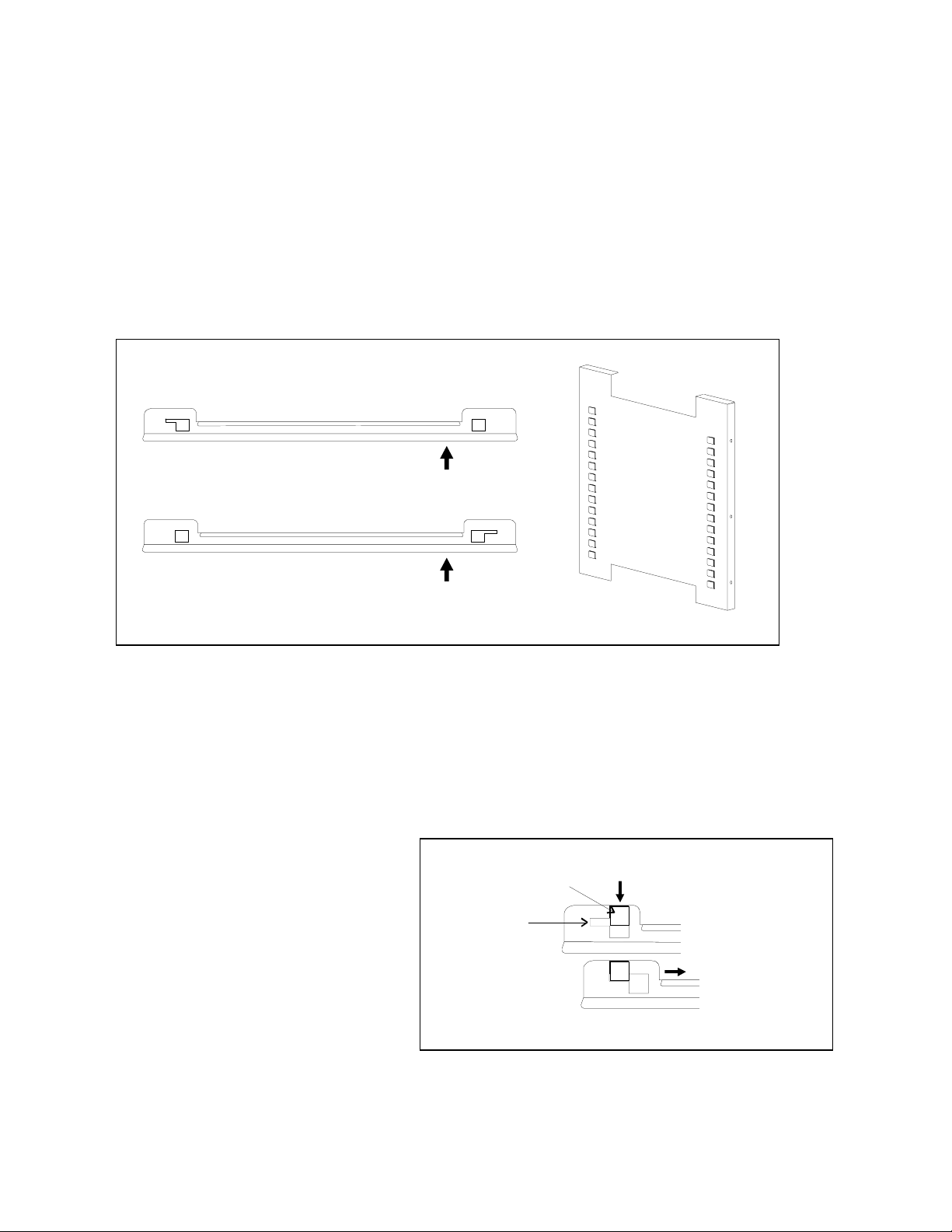

4. Align the sides of the top unit with the

bottom unit and slide the top unit forward

until the notches in the base of the top unit

align with the (2) slotted screws in the top of

the bottom unit. Refer to Figure 1-5.

5. Remove the four nylon plugs on the

lower portion of the back of the upper

incubator.

6. Insert the stacking brackets into the slots

on the back of the control panel of the bottom

unit as shown in Figure 1-6. Align the slots

in the brackets with the mounting holes on

the back of the top incubator. Secure the

brackets with the screws provided in the

stacking kit.

7. Replace the kick plate on the top unit, taking care not to crimp the door heater cable.

8. The stacked incubators are ready for service.

Form a Scien tific

(2 ) slotted screw s

Figure 1-5

Figure 1-6

Back oftop incubator

Back ofbottom incubator

Stacking bracketsStacking brackets

Removevinylplugs

and insertscrews Removevinylplugs

and insertscrews

FormaModel 310 Series _______________________________________ Installation Start-Up

1-7

c. Preliminary Cleaning and Disinfecting

1. Remove the protective plastic coating on the shelf supports and air duct, if present.

2. Using a suitable laboratory disinfectant, disinfect all interior surfaces including shelves

and shelf supports, door gaskets, blower wheel and CO2 sensor. Refer to Section 5.1.

d. Installing the Shelves

1. Install the large sheet metal shelf supports with the tabs facing into the center of the

chamber with their slots up. There are no right side or left side supports, simply turn one

of them to fit the opposite side. Tilt the shelf supports as they are placed in the chamber

so the tops fit into the top air duct, then guide them into the vertical position. Figure 1-7

shows the support as it would be oriented for the right side of the chamber.

2. Referring to Figure 1-7, note that there are left side and right side shelf channels.

3. Install the shelf channels by

placing the channel’s rear slot

over the appropriate rear tab

on the shelf support. Pull the

shelf channel forward and

engage the channel’s front

slot into the shelf support’s

appropriate forward tab.

Refer to Figure 1-8.

Right Shelf Channel

Left Shelf Channel

Shelf Support

Figure 1-7

shelf support

tab

shelf channel

rear slot right side

shelf channel

Figure 1-8

FormaModel 310 Series _______________________________________ Installation Start-Up

1-8

Figure 1-9 shows one of the channels installed on

the right shelf support.

e. Installing the Access Port Filter

Locate the opening in the top left corner of the interior chamber. Install the smaller,

beveled end of the stopper into the opening. See Figure 1-11.

f. Installing the (optional) HEPA Filter

Use caution when handling the filter. The media can be damaged if it is

mishandled.

To avoid damage to the incubator, do not operate the unit without the

HEPA filter in place.

1. Remove the filter from the shipping box.

2. Remove the plastic coating from the filter, using caution not to touch the filter media.

3. Install the filter as shown in Figure 1-10. Refer to Section 5.6 for HEPA filter

maintenance.

Figure 1-9

FormaModel 310 Series _______________________________________ Installation Start-Up

1-9

g. Leveling the Unit

Check for level by placing a bubble style level on one of the shelves. Turn the hex nut on

the leveler counterclockwise to lengthen the leg or clockwise to shorten it. Level the unit

front-to-back and left-to-right.

h. Connecting the Unit to Electrical Power

See the serial tag on the side of the unit for electrical specifications or refer to the

electrical schematics at the end of this manual.

Connect the incubator to a grounded, dedicated circuit.

The power cord connector is the mains disconnect device for the incubator.

Position the incubator so the unit can be easily disconnected.

Plug the provided power cord into the power inlet connector on the back of the cabinet

(See Figure 1-12), then into the grounded, dedicated, electrical circuit.

Access Port Filter Figure 1-11

Blowerfan inlet

HEPA filter

HEPA Filter Figure 1-10

Install in the access

port from the inside

of the incubator

FormaModel 310 Series _______________________________________ Installation Start-Up

1-10

i. Filling the Humidity Pan

Fill the humidity pan with sterile distilled water to within 1/2” of the top. Place the pan

directly in the center of the incubator floor to ensure best humidity and temperature response.

For applications requiring abnormally high humidity, the pan should be placed against the

left side wall of the incubator. The ductwork has been modified to allow the pan to be placed

against the wall of the incubator. In some ambient conditions, this may cause condensation to

form in the chamber.

For best operation of the incubator, sterilized distilled, demineralized or de-ionized water

should be used in the humidity pan. Water purity should be in the resistance range of 50K

Ohm/cm to 1M Ohm/cm, or a conductivity range of 20.0 uS/cm to 1.0 uS/cm. Refer to ASTM

Standard D5391-93 or D4195-88 for measuring water purity.

Distillation systems, as well as some types of reverse osmosis water purity systems, can

produce water in the quality range specified. Tap water is not recommended as it may contain

chlorine, which can deteriorate the stainless steel. Tap water may also have a high mineral

content, which would produce a build-up of scale in the reservoir. High purity, ultra pure or

milli-q water is not recommended as it is an extremely aggressive solvent and will deteriorate the

stainless steel. High purity water has a resistance of above 1M Ohm to 18M Ohm. Even high

purity water can contain bacteria and organic contaminants. Water should always be sterilized or

treated with a decontaminant, safe for use with stainless steel as well as safe for the product,

prior to being introduced into the humidity pan.

Check the level and change the water frequently to avoid contamination. Do not allow the

water level to fluctuate significantly. “Dry-outs” will have an adverse effect on the humidity

level and CO2calibration of the T/C units.

See

Section

1.5, 1.6

and 5

Accessory

Outlet

(75 watts max.)

ACCESSORY

75 WATTS MAX

.

RS 485

ALARM CONTACTS

30V MAX / 1A MAX

#2

CO in

j

ect

15

p

.s.i. Re

g

ulated

(103.4 kPa)

#1

CO in

j

ect

15

p

.s.i. Re

g

ulated

(103.4 kPa)

22

a

b

RJ-ll tele

p

hone st

y

le connectors

Used with the o

p

tional Gas Guard S

y

stem

IR CO Units onl

y

c

2

O

p

tional

RS 485

CO Inlet

#1 Tank

CO Inlet

#2 Tank

Remote

A

larms

A

ir

Intake

Power Cord

Connector

b

b

a

a

2

2

c

Figure 1-12

FormaModel 310 Series _______________________________________ Installation Start-Up

1-11

j. Connecting the CO2Gas Supply

High concentrations of CO2gas can cause asphyxiation!

OSHA Standards specify that employee exposure to carbon dioxide in any eight-hour

shift of a 40-hour work week shall not exceed the eight-hour time weighted average of 5000

PPM (0.5% CO2). The short term exposure limit for 15 minutes or less is 30,000 ppm (3%

CO2). Carbon dioxide monitors are recommended for confined areas where concentrations

of carbon dioxide gas can accumulate.

This incubator is designed to be operated with CO2gas only. Connecting a

flammable or toxic gas can result in a hazardous condition.

Gases other than CO2should not be connected to this equipment. CO2gas cylinders

have a UN1016 label on the cylinder and are equipped with a CGA 320 outlet valve. Check

the gas cylinder for the proper identification labels. The CO2gas supply being connected to

the incubator should be industrial grade, 99.5% pure. Do not use CO2gas cylinders

equipped with siphon tubes. A siphon tube is used to extract liquid CO2from the cylinder

which can damage the pressure regulator. Consult with your gas supplier to ensure that the

CO2cylinder does not contain a siphon tube. Gas cylinders should also be secured to a wall

or other stationary object to prevent them from tipping.

A two-stage CO2pressure regulator is required to be installed on the outlet valve of the

gas cylinder. Input pressure to the incubator must be maintained at 15 psig (103.4 kPa) for

proper performance of the CO2control system. A single stage CO2pressure regulator will

not maintain 15 psig (103.4 kPa) to the incubator as the pressure in the CO2cylinder

decreases; therefore, a two stage regulator is recommended.

If higher purity CO

2is desired inside the incubator (greater than 99.5% pure), the

pressure regulator should be constructed with a stainless steel diaphragm, along with

specifying the purity of the CO2from the gas supplier. Follow the manufacturer’s

instructions to ensure proper and safe installation of the pressure regulator on the gas

cylinder.

Consult your facility safety officer to ensure that the equipment is installed in

accordance with the codes and regulations that are applicable in your area.

Distilled or de-ionized water used in the humidity pan must be within a water

quality resistance range of 50K Ohm/cm to 1M Ohm/cm to protect and

prolong the life of the stainless steel. Use of water outside the specified range

will decrease the operating life of the unit and may void the warranty.

FormaModel 310 Series _______________________________________ Installation Start-Up

1-12

The CO2gas supply being connected should be industrial grade 99.5% pure and should

not contain siphon tubes. Install a two-stage pressure regulator at the cylinder outlet. The

high pressure gauge at the tank should have 0-2000 psig range. The low pressure gauge, at

the incubator inlet, should have a 0-30 psig range. Input pressure to the incubator must be

maintained at 15 psig (103.4 kPa).

The incubator has serrated fittings on the back of the cabinet to connect the gas supply.

Refer to Figure 1-12. The fitting is labeled CO2Inlet #1 Tank. Make sure that the

connections are secured with clamps. Check all fittings for leaks.

For units having the CO2Gas Guard option, refer to Section 6.2.

1.6 Incubator Start-Up

With the incubator properly installed and connected to power, the humidity pan filled,

and the unit connected to gas supplies, system setpoints can be entered. The following

setpoints can be entered in Set mode: Temperature, Overtemperature and CO2. To enter Set

mode, press the Mode key until the Set indicator lights. Press the right and/or left arrow

keys until the proper parameter appears in the message center. See Chart 1-1 for more

detail.

a. Setting the Operating Temperature

All 310 Series incubators have an operating temperature range of 10°C to 50°C,

depending on ambient temperature. The incubator is shipped from the factory with a

temperature setpoint of 10°C. At this setting, all heaters and alarms are turned off. To

change the operating temperature setpoint:

1. Press the Mode key until the Set indicator lights.

2. Press the right arrow until “Temp XX.X” is displayed in the message center.

3. Press the up/down arrow key until the desired temperature setpoint is displayed.

4. Press Enter to save the setpoint.

5. Press the Mode key until the Run indicator lights for Run mode or press the right/left

arrow keys to go to next/previous parameter.

Table of contents

Other Forma Scientific Accessories manuals

Forma Scientific

Forma Scientific 3158 User manual

Forma Scientific

Forma Scientific 3980 User manual

Forma Scientific

Forma Scientific 3980 User manual

Forma Scientific

Forma Scientific 3158 User manual

Forma Scientific

Forma Scientific 3920 Operating instructions

Forma Scientific

Forma Scientific 3980 User manual

Forma Scientific

Forma Scientific 3940 User manual

Forma Scientific

Forma Scientific 3950 User manual

Forma Scientific

Forma Scientific 3940 Operating instructions

Forma Scientific

Forma Scientific 3546 User manual