forstreich maschinebau TR 24 User manual

Operating Instructions

Felling Wedge TR 24

Content

1 Technical Data ......................................................................................................................1

2 Area of Application –Designated Use..................................................................................1

3 Safety Instructions................................................................................................................2

4 Warranty...............................................................................................................................2

5 Application............................................................................................................................3

6 Maintenance/Testing ...........................................................................................................4

7 Tips........................................................................................................................................4

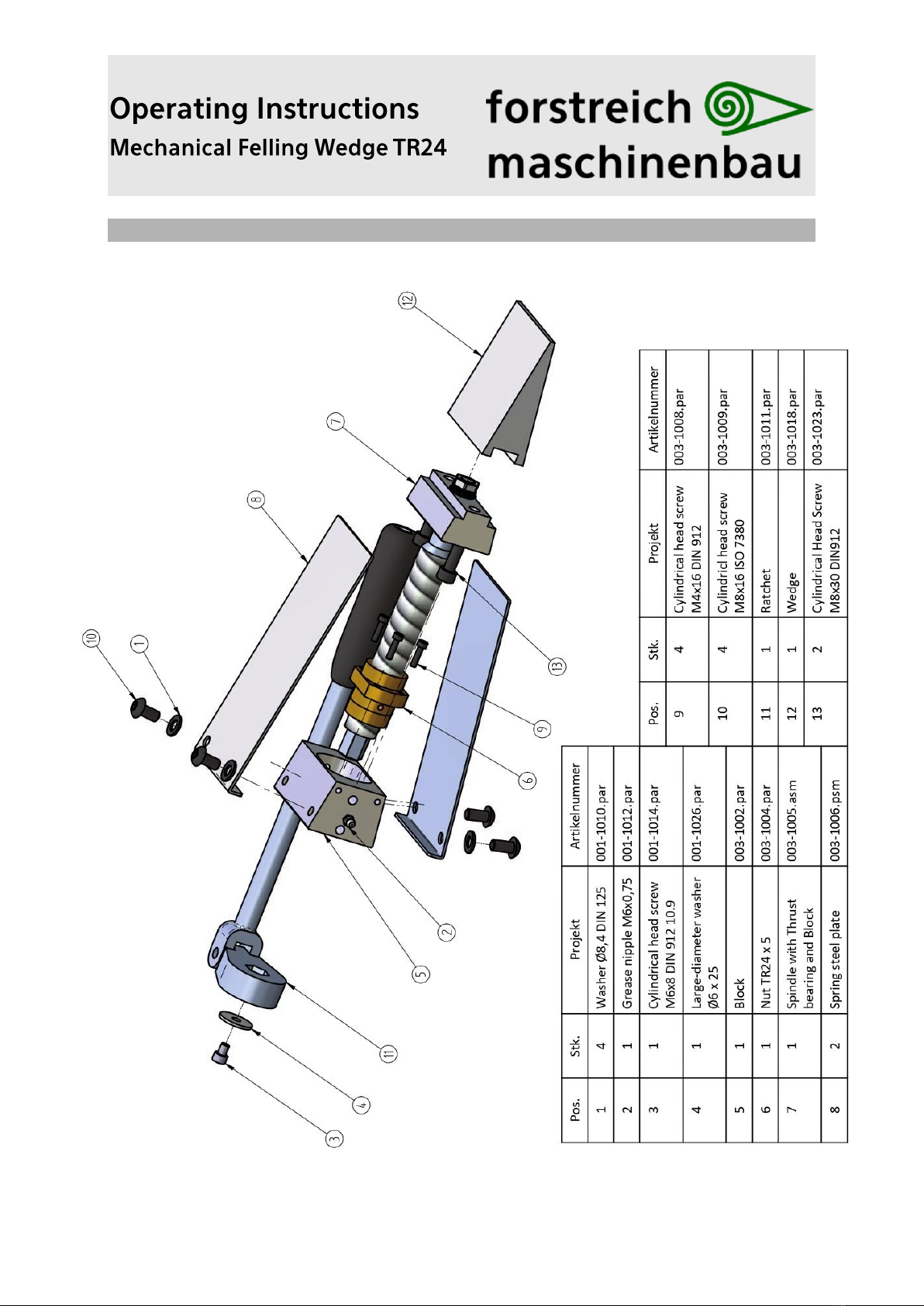

8 Exploded View ......................................................................................................................5

9 EC Declaration of Conformity...............................................................................................6

1

1 Technical Data

Designation

Mechanical Felling Wedge TR24

max compressive force (t)

8

mass (kg)

2.8

length (mm)

350

width (mm)

80

height (mm)

73

stroke/revolution (mm)

5

max torque (Nm)

80 Nm

2 Area of Application –Designated Use

The mechanical felling wedge TR24 is used in logging as a replacement for strenuous wedge

work or as an alternative to the hydraulic felling wedge.

Advantages over classic wedge work:

-vibration-free wedging

-“toppling” the tree is ergonomically cheap and easy on the joints

Advantages over hydraulic felling wedges:

-light weight

-easy maintenance

-good ergonomics with telescopic ratchet

This device does not replace wire ropes and winches. Only use it if you believe that the tree

could be felled with classic wedges. Do not try to fell trees with the mechanical felling wedge

that have a pronounced side or back lean in order to avoid overloading the device. Make

sure you are familiar with this device before you use it.

If the mechanical felling wedge is

not used as intended

overloaded

not or poorly maintained

the manufacturer will assume no liability for damages incurred.

2

3 Safety Instructions

Danger: Failure to follow instructions may result in severe

injuries or even death!

Always work with normal plastic or aluminum wedges for support. Make sure to

keep feeding in the wedges when operating the mechanical felling wedge.

The maximum torque for the mechanical felling wedge is 80 Nm. Apply no more than

31 kg manual force to the extended telescopic ratchet (approx. 580 mm lever length)

to avoid overloading the spindle.

This device does not replace wire ropes and winches. Only use it if you believe that

the tree could be felled with classic wedges. Do not try to fell trees with the

mechanical felling wedge that have a pronounced side or back lean in order to avoid

overloading the device. Make sure you are familiar with this device before you use it.

Do not forcibly drive the mechanical felling wedge TR24 into the felling cut. You

might damage the hexagon head and nut.

Do not push or hit the felling wedge. This could bend the threaded spindle.

4 Warranty

We provide a warranty on the function and flawlessness of the material for 12 months

starting from the date of delivery for the mechanical felling wedge TR24. This does not cover

the consequences of normal wear and tear, overloading, improper treatment, or the

installation of foreign spare parts.

A warranty can only be provided if the device has been submitted to us in one piece without

tampering for testing. Damage caused by material or manufacturing faults will be repaired or

replaced free of charge.

3

5 Application

Felling:

Set the supplied flexible head ratchet to a right rotation. The wedge can be driven in until

the threading on the outside is no longer visible and the telescopic ratchet touches the nut.

Wedge retrieval:

Set the supplied flexible head ratchet to a left rotation. Wind the wedge back until it touches

the nut.

Felling a tree of normal strength:

-Apply a proper felling technique in accordance with the good, professional practice of

forest work.

-Place classic wedges in the saw cut to keep it open.

-Use the saw to widen the cut at the top and bottom before applying the mechanical

felling wedge TR24.Make sure it fits cleanly into the felling cut with all “barbed

hooks”. Both spring steel plates must engage the wood evenly.

-Place the mechanical felling wedge TR24 horizontally into the saw cut (if the wedge is

inserted diagonally up or down, this can lead to increased wear and fatigue).

-Carefully drive the wedge into the saw cut using the ratchet until the tree starts to

fall.

-Keep feeding the classic wedges for support while driving the felling wedge TR24

further into the cut.

4

6 Maintenance/Testing

Please observe the maintenance instructions:

-The mechanical felling wedge TR24 must undergo a visual inspection for damages

before each use.

-Make sure that the threaded spindle/nut is sufficiently lubricated before each use.

Lubricate the threaded spindle/nut at the grease nipple provided for this purpose

and rotate the spindle once both ways.

The nut must be checked regularly for wear.

-Make sure that the surfaces between wedge and spring steel plates are lubricated

before each use. This way, the wear is lessened and the applied force necessity of

the operator significantly reduced.

-Keep the mechanical felling wedge clean at all times to increase its service life.

-Only original spare parts may be used. Contact your local dealer for more

information.

- The following lubricant was used for the initial lubrication:

Fuchs Gleitmo 805 –white high-performance lubricant for long-term lubrication

7 Tips

-Regularly switching the two steel plates is recommended to account for the loads

varying between top and bottom due to askew placement. Thus, creating less bend

in the spring steel plates.

-If the spring steel plates are bent, they can simply be set by hand.

5

8 Exploded View

6

9 EC Declaration of Conformity

Manufacturer: Forstreich-Maschinenbau

Prop. Stefan Reichenbach

Schwarzwaldstr.314

79117 Freiburg

Phone: +49(0)151/11030401

hereby declares that the following product:

Product description: mechanical felling wedge TR24

Year of manufacture: as of 05/2019

complies will all the relevant regulations of the Machinery Directive (2006/42/EC).

The following harmonized standards apply:

EN ISO 12100 Safety of machinery –General principles for design

Risk assessment and risk reduction

Freiburg, May 16th, 2019

Date Signature

As of 05/19

Subject to technical changes

Table of contents

Popular Tools manuals by other brands

SW-Stahl

SW-Stahl 23060L instruction manual

Arrow

Arrow JT27 user manual

Coats

Coats 9500 Installation and operation instructions

Porter-Cable

Porter-Cable PCCGG001 instruction manual

Electric Hoof Knife

Electric Hoof Knife 1F operating instructions

ReelCraft

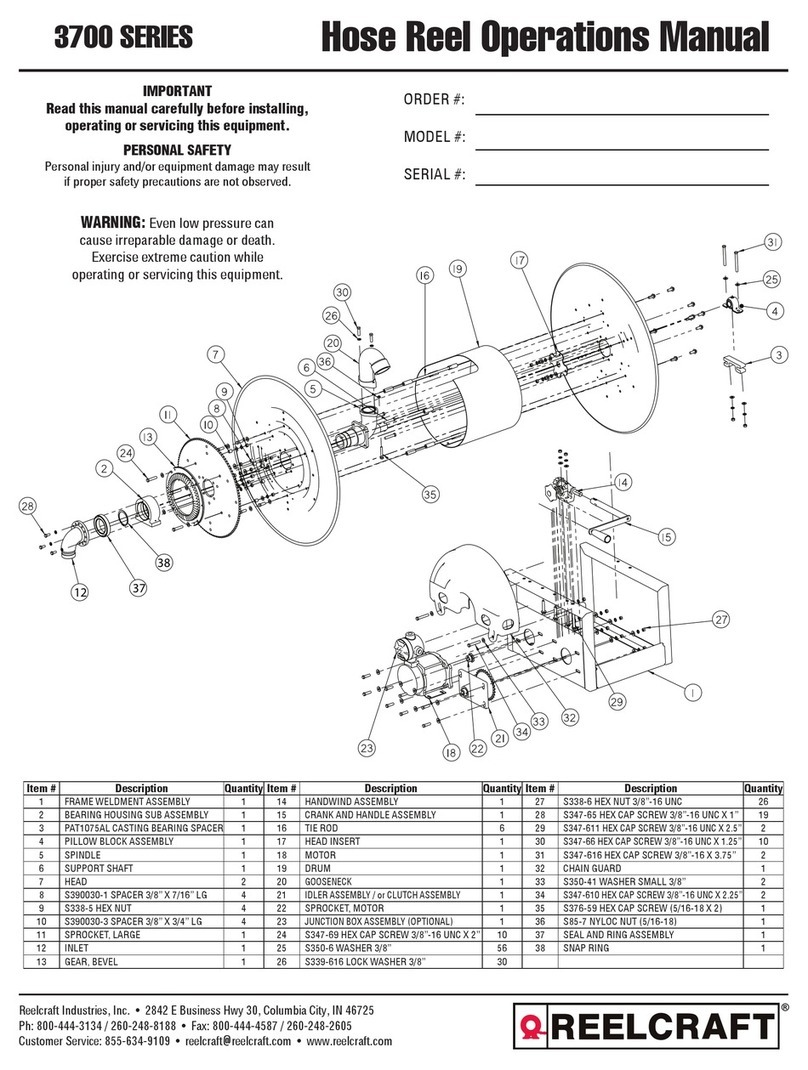

ReelCraft 5400 OLP Operating instructions and parts list