Fortador Fortador PRO S User manual

2

NOTE

Before starting, read this operating manual carefully in order to avoid improper use or situa-

tions that may be dangerous for people, animals or objects. The manufacturer shall bear no

responsibility and shall exclude the possibility to apply guarantee terms in the following cases:

Any misuse or use in improper conditions, any damage resulting from normal wear-out or

aging, inappropriate application, neglect, improper operation or storage, exposure to mois-

operator errors, failure to obey this operating manual, or any other events for which the man-

ufacturer cannot be blamed, including any loss or damage in transport.

3

Note ..............................................................................................................................................................................2

Contents.......................................................................................................................................................................3

Introduction.................................................................................................................................................................5

....................................................................................6

Description of the machine......................................................................................................................................7

Safety requirements..................................................................................................................................................8

Unpacking .................................................................................................................................................................10

Before each start-up...............................................................................................................................................11

.....................................................................................12

Cleaning ....................................................................................................................................................................14

Control panel functions .........................................................................................................................................16

..............................................................................................................................................18

Maintenance plan....................................................................................................................................................20

Service screen ..........................................................................................................................................................21

FAQ .............................................................................................................................................................................23

Lamborghini burner error codes and ways they are indicated ......................................................................32

Diagnosis of burner equipment elements, errors and reasons for its operation blockage ....................33

List of spare parts, and the machine’s exploded view drawings...................................................................34

CE Attestation of conformity ...............................................................................................................................39

Transport...................................................................................................................................................................40

Final remarks............................................................................................................................................................41

CONTENTS

5

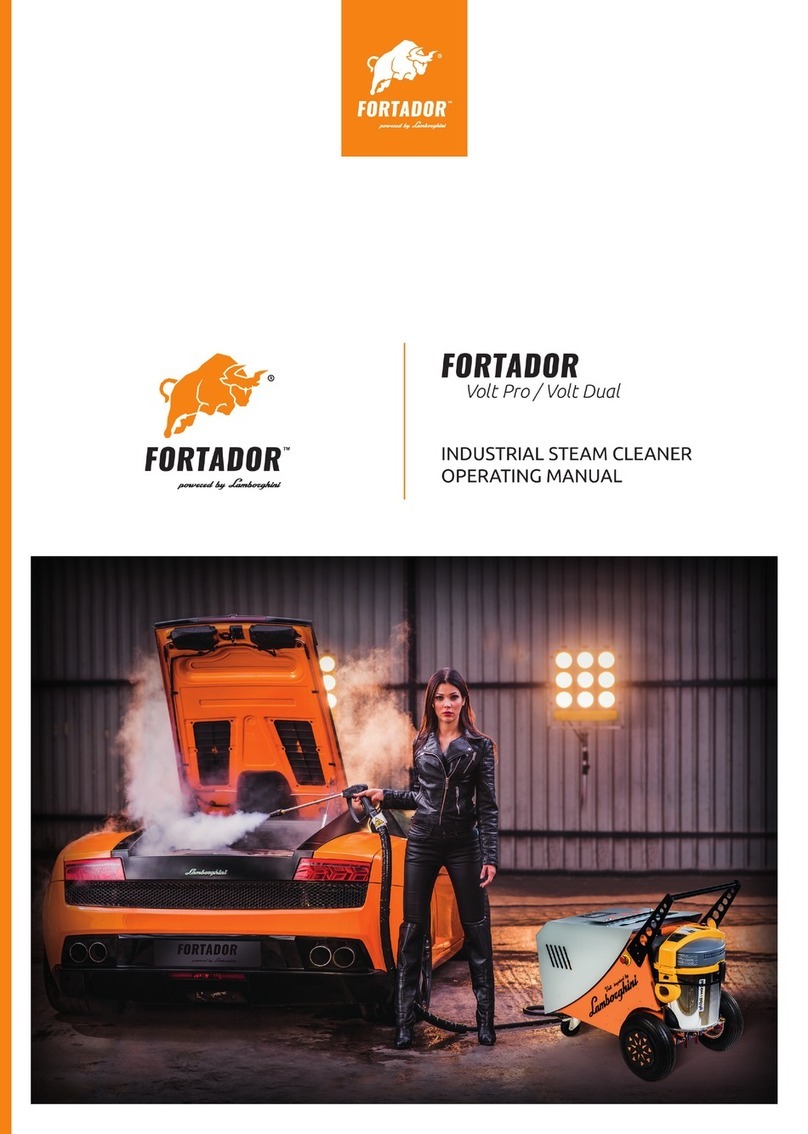

Thank you for purchasing FORTADOR PRO S industrial steam cleaner.

-

capacity and performance as well as lower failure rate than ever before.

The solutions used, which only occur in FORTADOR steam cleaner, make it possible to make the

same time is a solution that has never been used so far. The 7-inch touch display keeps the user

pressure of the boiler.

The heart of the machine is its boiler and burner assembly supplied by the world-renowned

manufacturer, Lamborghini Caloreclima. The highest quality of the combustion system

and low Diesel oil consumption provide for even faster return on investment. Additional

16.6 – 36.6 kW power regulation has made it possible for us to achieve working pressure in the

range of 12 - 16 bar.

INTRODUCTION

Manufacturer and Maintenance Service Provider

www.fortador.com

6

Power supply 230 V, 50 / 60 Hz lub 110 V, 50 / 60 Hz

Power 650 W

Protection class IPX4

Working pressure 12 – 16 bar

Maximum pressure 20 bar

Steam temperature Max. 140º C

Boiler temperature Max. 260º C

Fuel consumption 0.6 l / h

Boiler capacity 10.5 litres

Water tank capacity 20

Fuel tank capacity 10

Detergent tank capacity 5

Noise level 79 dB

50 x 86 x 91 cm

Weight

Technical data are placed at the rating plate at the rear wall of the cover in the

area marked with the red frame. When contacting our Service Dept., please al-

ways refer to your machine’s serial no. from the rating plate.

TECHNICAL

SPECIFICATION

AND DESCRIPTION

OF THE MACHINE

Technical data

7

1. Detergent, water, and fuel tanks

2. Boiler

3. Hydraulic line, washing – solenoid valve, valve

5. Burner

1

6

7

8

9

2

3

4

5

10. Cleaning hose connection – safety quick coupling, valve

11. Cleaning hose connection – safety quick coupling, valve

12. Water drain – valve

13. Detergent drain – valve

14. Fuel drain – valve

15. Permanent water connection – valve

16. Boiler steam drain – quick coupling, valve

7. Wet steam and detergent pumps

9. Water pump

14

15

10

16

11

12

13

DESCRIPTION

OF THE MACHINE

8

SAFETY

REQUIREMENTS

The FORTADOR steam cleaner is an industrial machine that must not be operated by persons who are not aware of hazards

associated therewith.

Guidelines and recommendations contained in this Manual must be properly understood and obeyed if the condition of the

Just as in case of most mechanical machines, all relative safety precautions must be observed while operating and servicing

the machine. Failure to observe this Operating Manual and recommendations contained in it may lead to injury or damage to

the machine or other objects situated nearby. At the same time, it must be borne in mind that it is not possible to present any

exhaustive guidelines or recommendations, which would make it possible to completely eliminate risks during its operation

or maintenance, and while handling or using chemical products that this machine has been designed to process. In case of

special applications and working conditions, some additional safety precautions can turn out to be necessary, which are not

discussed in this document. In such non-discussed cases, the user should obey generally adopted safety rules.

Before starting and operating the machine, please read this Operating Manual thoroughly.

This Operating Manual should be stored for later use or for the successive owner.

This machine heats up to high temper-

atures! Protective gloves and protec-

tive goggles must be worn while oper-

ating the machine.

During operation, hearing protectors

must be worn!

Never use the machine without wear-

ing protective boots.

USE PROTECTIVE

GOGGLES

USE PROTECTIVE

BOOTS

USE PROTECTIVE

GLOVES

USE HEARING

PROTECTION

IMPORTANT:

9

• Prior to each start-up, check residual-current circuit-

breaker for proper operation in line with the procedure

as described in the “before each start-up” chapter. It is

forbidden to operate the machine with faulty residual-

current circuit-breaker, as it may pose a threat of

electric shock!

• Do not submerge the machine or any of its components

• It is strictly forbidden to use the machine in explosive

areas.

• Never use the machine close to toxic / hazardous

substances.

• Never install the machine on temperature-sensitive

foundations.

• Do not leave the machine in places exposed to the forces

of nature.

• Do not operate machine buttons / valves using excessive

force.

• The machine should be installed on stable level ground.

Make sure that its front wheels are secured during

operation.

• Never block the gun’s trigger.

• Never leave the machine working unattended.

• Do not direct steam jet towards electronic devices.

• While washing your car, make sure that the nozzle is

more than 10 cm away from the surface.

•

drained.

• Use only good quality fuel diesel. Use of any fuel

other than diesel, or any fuel that is contaminated or

diluted, may result in damage to the burner and loss of

guarantee.

• Remember that the hose bending radius can never be

lower than 10 cm. Bending the hose to a tighter radius

damage.

• Operating pressure can be dangerous for people and

animals.

• Operators should be sober, adult, and trained in machine

operation and maintenance.

•

recommended and manufactured by the manufacturer.

• In case power supply cable is damaged, it must be

replaced by an authorised service-provider under pain of

loss of guarantee.

•

add any detergents, chemicals, or descaling agents to the

water tank.

• Do not use distilled water!

• Before starting the machine, check if its operational

openings are free from dirt.

• It is only allowed to use original hoses and guns.

• Do not start the machine if its electrical cable or any

other part is damaged.

• Do not operate the machine in the rain or when it is wet.

• Never tilt or topple the machine when switched on.

•

• Children are absolutely not allowed to contact the

machine.

• Be careful while working near children or animals.

• Do not use the machine when damaged or when its

power supply cable shows any signs of damage. In case

the machine fails to work the way it should, if it fell or

our service dept.: help@fortador.com

• Do not try to pull or lift the machine by its power supply

cable or hose.

•

they are covered by limited guarantee only.

• Never direct steam towards people or animals.

•

ovens or any other heat sources.

•

ventilated areas. Its fumes may pose a threat to your

health.

• Do not operate the machine in an environment with very

high humidity of the air and/ or highly dusted areas.

• When in operation, the machine should not be moved.

• The machine should be connected to electrical

installation that is provided with reliable earthing.

It is forbidden to operate the machine connected to

electrical installation no earthing, as it may pose a

threat of electric shock!

10

Short lance, 1 piece

Cleaning hose, 2 pieces

Repair kit

120 cm

80 cm

116 cm

UNPACKING

Packaging dimensions

1. Carefully remove the machine from its packaging.

2. Check if the machine has not been damaged while being

shipped.

3. Check if its standard equipment is complete. We

recommend to keep the packaging.

STANDARD ACCESSORIES

11

In order to provide for the machine’s proper and safe opera-

tion, this procedure should be conducted before it is started.

1. Check if your hoses have been properly connected.

2. Make sure that your valves work properly.

3.

4. Make sure that your hoses and guns are not damaged.

5. Do not put any heavy objects on hoses, and do not drive

your car on them.

6. Make sure that your steam supply valves are closed if you

7. Check residual-current circuit-breaker operation by

with faulty residual-current circuit-breaker is strictly

prohibited.

8. Before starting the machine the operator should always

check cleanness and tight the cover of water and diesel

12

Wrong Right

-

Important:

Make sure not to start the machine

before you pour the water in.

Connect the hoses to quick couplings.

Make sure that quick couplings are

properly installed.

-

ring clockwise.

1

4

2

3

HOW TO INSTALL AND USE

THE MACHINE FOR THE FIRST TIME

FORTADOR PRO S machine starting procedure.

13

Make sure that hoses are connected correctly. Activate

steam supply valves from the boiler to the hoses. Hold the

gun trigger pressed until steam starts to come out. Pres-

sure will drop for a moment. When the 16 bar pressure is

reached, the machine is ready to work.

Touch the button on the display to start the machine. The

-

ter, and the burner will be activated as soon as the minimum

water level is reached.

After 2-7 minutes, the pressure will reach 16 bar. Such mes-

sage will be displayed on the screen.

Valve open

Valve closed

5

6

7

14

2

3

4

1

CLEANING

Holding the gun in both hands, press the trigger. Note: high

pressure results in gun recoil when its trigger is pressed. Be

careful! Work using both hands. Pull the hose, do not pull

the gun! Do not pull the gun by the hose!

While moving from one area to another, never pull the gun,

as this may lead to the connection of the hose with the gun

or the gun itself getting damaged.

Direct the steam jet towards the surface being cleaned,

making sure to keep a safe distance of 10 cm between the

gun nozzle and the surface being cleaned.

In case of heavy soiling, use the “wet steam” function

that is activated using the orange arrow marked button.

Steam being fed using the cleaning gun will additionally

contain water mist.

15

In order to remove heavy soiling, it may be required to use

some detergent together with steam jet. Before activating

-

luted in water in proportions as described in the detergent

label.

NOTE: Failure to obey this sequence may lead to detergent

pump getting damaged!

It is not recommended to

use high-foam and acid pH

reaction formulations.

On the screen, activate Detergent feeding, using the button

that is marked with the orange arrow.

Upon completion of work, close the steam supply valves to

the hoses, remove the steam that remains inside hoses by

pressing the gun’s trigger, and then disconnect the hoses

Procedure” Section.

5

6

7

16

Orange background of indicators

When indicators are shown with a red

missing and that they should be

CONTROL PANEL

FUNCTIONS

Main screen

Detergent

feed starting

button(cleaning)

Service screen

Fuel level

indicator

Machine

STOP button

Information screen

Fuel level

indicator

Detergent level

indicator (cleaning)

Wet steam feed

starting button

During water pomp operation or

burner operation suitable indicator

will be highlighted.

17

Boiler water level indicator shows

the relative indication in yellow.

Serial no. display screen

Worked hours count

display screen

Water pomp

ON indicator

Information

screen

Burner ON

indicator

Return to

Main Screen

Boiler water level

indicator (L-low,

M-medium, H-high)

Water pomp

maintenance mode

Detergent

maintenance mode

Machine

STOP button

Wet steam

maintenance mode

Main screen

Serial number

Main screen

Moto hour counter

Burner serial number

18

14

15

10

16

11

12

13

If the machine was connected to an external water supply

source, disconnect the supply hose from valve no. 15.

3

4

1

Place the machine so that the boiler draining outlet is direct-

ed into the open space. Carefully open valve no. 16, paying

special attention to the steam that is coming from the out-

let. High-pressure steam jet may lead to serious burns!

5

2

press the gun’s trigger to release any steam that still re-

mains inside hoses.

as presented herein.

and then disconnect it from its power supply. NOTE: Failure

to observe this sequence may result in damage to the ma-

chine’s controller.

Disconnect the hoses, clean them and roll them up, be-

ing careful not to exceed the allowable bending radius

NOTE: Bending the hose to any radius that is

19

Clean the machine if dirty. By cleaning the machine each

Leave the machine in dry, warm area that is free from dust.

Drain the boiler completely, leaving valve no. 16 in its open

position. This valve can only be closed just before you start

your work.

If the machine is to be stored in temperatures below 0ºC

must be pumped out from the water system, by entering

the maintenance mode by pressing the Maintenance mode

button that occurs for several seconds in the upper part of

the display when the machine is started.

Afterwards, by pressing the button marked with orang ar-

row, the water pump will be run for 5 seconds pumping out

any remaining water from the water system into the boiler.

Repeat this procedure several times, watching if any water

is still present in the tube that supplies water into the wa-

coming out, do not start water pump any more to avoid dry

running.

unscrewing its plastic dome and draining the rest of water.

6

7

8

9

10

11

Button used to start detergent

pump in maintenance mode

Service screen

Water supply tube

from water pump

Button used to start water

pump in maintenance mode

Button used to start wet

steam pomp in maintenance

mode

20

MAINTENANCE PLAN

The FORTADOR steam cleaner is made of best materials. In order to keep it in its

perfect condition, it requires scheduled maintenance in line with the below main-

tenance plan.

Within the guarantee period, scheduled maintenance must be performed by the

guarantee-issuing party or the authorised dealer. Failure to observe this condition

will result in loss of guarantee.

MAINTENANCE OPERATIONS TIME INTERVAL

(WORK HOURS COUNT)

100

sensors 150

Check burner electrodes, and clean

the combustion chamber 200

Descaling

Replace balls and springs in the

cleaning gun 200

Table of contents

Other Fortador Steam Cleaner manuals