Foshan Panda hardware CBY.AC User manual

CBY.AC &BF Hand Pallet Truck

Operation Manual and Spares

Foshan Panda hardware Co.,Ltd

1

Thanks for choosing and using forklift. The product is of excellent workmanship with

reasonable design and simple operation. For the purpose of safety and right use of the product,

please read this instruction manual carefully.

Note: All the information is based on the data obtained when this instruction manual is issued.

The company will have right to improve the product at any time without any prior notice.

Therefore, we would like to advise you to obtain our latest information try all means.

1. Standard of Specification

Load: 2000-3000Kg Length of Fork: 1100-1220mm

Width of Fork: 550-685mm Height of Fork:65-190-200mm

Net Weight: 74-90Kg

2. Mounting handle welding prat to Pump Body

Some tools are necessary after purchasing forklift such as an iron hammer and a pinchers. In

addition to these tools, some other parts are necessary such as a positioning bearing(106) and two

elastic pins (107). Note: One of pins is in the positioning bearin(106) and all the other parts are

contained in a plastic bag and bound to the handle welding prat with adhesive plaster.

Note: handle welding prat must match the pump body

106、Positioning bearing

107、Elastic pin

113、Handle welding prat

201、Body frame

322、Limit level

2.1 Put the handle welding prat(113) onto pump core and use hammer hitting positioning

bearing(106) to make it enter hydraulic pump and handle welding prat(113) (note: Make center

hole of positioning bearing(106) in "V' shape and the elastic pin facing yourself). Use pinchers

and hammer to hit elastic pin (106) into the positioning bearing (106).

2.2 Remove nut with wrench and set the handle welding prat(113), remove limit level(322) (see

figure l).

2.3 Make hexagonal nut (104), drop bolt (103) and chain (102) through the center 'hole of

positioning bearing (106), and adjust pedal control(327) and put drop bolt(103) the trough

at front end and make hexagonal nut (104) stick to bottom of pedal control(327).

After done the process, the handle welding prat has been mounted to pump.

3. Adjusting of Buffer Device

On the handle welding prat of forklift, you can view control handle(119). It can be adjusted to

three positions which are:

Raise

Drive Position

Lower

2

After finish operation, the control handle shall be pull back to middle position.

The three positions have been set prior to shipment. For any reason the positions have been

changed, following steps shall be followed for operation:

3.1 At middle position if control handle(119) pressurized and force forklift up, so hexagonal nut

(103) and the metalloid nut(105) on drop bolt(103) shall be adjusted clockwise until no more

raising even forklift pressurized and everything become normal.

3.2 At middle position if control handle pressurized and force forklift down,so hexagonal nut

(104) and metalloid nut(105) shall be adjusted counterclockwise until forklift no more going

down.

3.3 lf control handle (119) is at Lower Position but forklift doesn't go down, hexagonal nut (104)

shall be adjusted clockwise until forklift does down when finger-shaped control arm at Lower

Position. And check operation of handle welding prat at middle position (operation position)

following step 3.1 and 3.2 to ensure hexagonal nut(104) is at right position.

3.4 At Raise Position if control handle pressurized but forklift no raising,hexagonal nut (104)

shall be adjusted counterclockwise until forklift goes up. And check operation of forklift at Lower

and middle position following step 3.1, 3.2 and 3.3 to ensure hexagonal nut(104) is at right

position.

4.Warning

Frequent maintenance is requested for forklift.

4.1 0iling

Check oil level every 3 months and oil can be hydraulic oil: ISOUG32, and its viscosity shall be

30cSt with total volume 0.41t.

4.2 Exhausting

For transport or upside down of pump, air maybe enters hydraulic oil and it will cause no going

up of forklift when control handle at Raise Position pressurized.

Below action may be followed to exhaust air: Pull the control handle (119) to Lower Position and

pull handle welding prat (113) to move it back and forth several times.

4.3 Daily Inspection & Maintenance

Daily inspection may reduce wear of forklift. Pay special attention to wheels and wheel shaft to

find whether thread or line wrapped. After transport, all cargo must be unloaded and make forklift

to the lowest position.

4.4 Lubricating .

Prior to shipment, all bearings and shafts have been applied with sustaining oil. Add oil to these

places on monthly basis or at through cleaning.

5.Guide to Safe Operation

5.1 Prior to operation of the forklift, operator shall thoroughly read the instruction manual and

cautions notes on forklift.

5.2 Normally pull control handle to middle position when dragging forklift. Not only is it easy

for moving handle welding prat but also it can reduce rebounding force the small pump core

applied to handle welding prat. Meanwhile, it can protect hydraulic sealing kits and piston

assembly to prolong life of forklift.

5.3 Personnel not familiar with the equipment or without training don't operate the forklift.

3

5.4 Check forklift prior to operation and pay special attention to wheels (222, 225, 228,315),

handle welding prat assembly, carrier and pedal control arm (327)

5.5 Don't use forklift on slope.

5.6 Don't use forklift to carry personnel.

5.7 0perator shall wear gloves for the purpose of protection.

5.8 During transporting, personnel shall be 600mm away from carrier.

5.9 Pay attention to center of gravity to avoid offset or inclination (Refer Figure 28)

5.l0 Don't overload.

5.11 0perator shall cautiously operate under special circumstances or at special places.

4

6.Troubleshooting

Odr

Trouble

Reason

Troubleshooting

Fork cannot be raised to max.

heigh

--Not enough hydraulic oil.

--Add oil.

2

Fork cannot be raised.

--No hydraulic oil;

--Not pure oil;

--Position of hexagonal nut(104) is

too high and make relief valve open.

--Air in hydraulic oil.

--Add oil;

--Change oil;

--Adjust nut(104)

(Refer to Item 3 and 4);

--Exhaust air.

3

Fork cannot be lowered.

--Cargo offsets or overload and

damaged piston nut (325) or

pump(318)

--Carrier stays at Raise Position for

quite a long time and piston rod gets

exposed and rusted.

--Adjusting nut (104) is not at right

position.

--Replace piston rod(325)

or pump (318).

--Please lower the carrier to

lowest position when it's not

under operation, frequently

lubricate piston.

--Adjust nut (104) (Refer

item 3.3).

4

Oil leakage

--Sealing aged or damaged.

--Some parts broken.

--Replace;

--Replace.

5

No performance of relief

valve when fork is being

lowered.

--Impure oil caused looseness of

relief valve.

--Some parts in hydraulic system

broken or damaged.

--Air in oil.

--Sealing aged or damaged.

--Adjusting nut (104) is not at right

--Replace oil.

--Check and replace

damaged parts.

--Exhaust air (See 4.2).

--Adjust nut (104) (See 3.2)

Personnel without special training please don't attempt to repair forklift by its own.

5

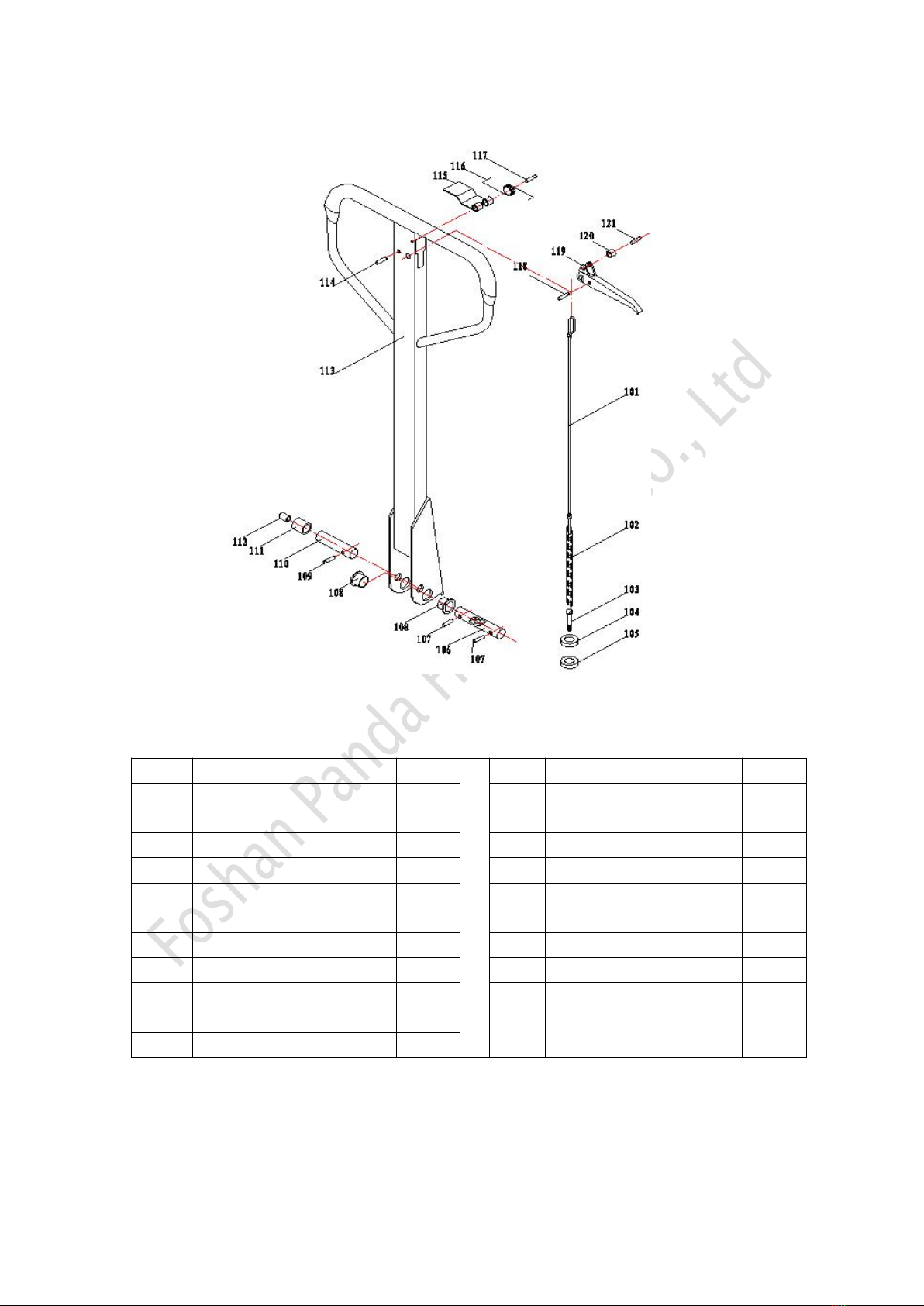

Parts of Handle welding prat

NO.

Description

Qty

NO.

Description

Qty

101

Pulling rod

1

112

Roller cover

1

102

Chain

1

113

Handle welding

1

103

Drop bolt

1

114

Elastic pin

1

104

Hexagonal nut

1

115

Return shrapnel

1

105

Metalloid nut

1

116

Return spring

1

106

Positioning bearing

1

117

Elastic pin

1

107

Elastic pin

2

118

Elastic pin

1

108

Cover

2

119

Control handle

1

109

Elastic pin

1

120

Handle wheel

1

110

Roller bearing

1

121

Elastic pin

1

111

Roller

1

6

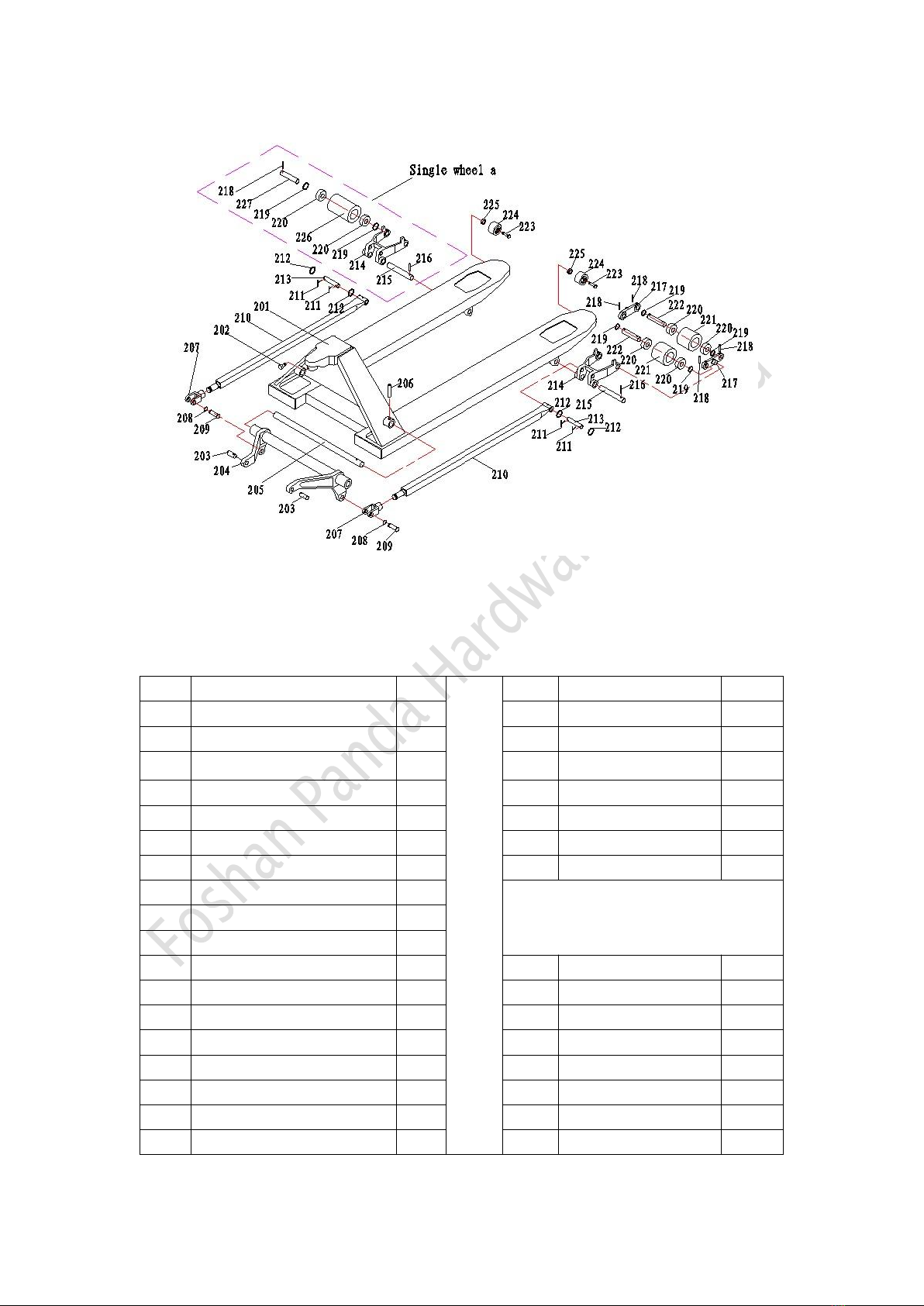

Parts of Body Frame

NO.

Description

Qty.

NO.

Description

Qty.

201

Body frame

1

219

Gasket

8

202

Inner hexagonal screw

1

220

Bearing

8

203

Connecting bearing

2

221

Front wheel

4

204

Lever frame

1

222

Front wheel bearing

4

205

Lever bearing

1

223

Hexagonal screw

2

206

Elastic pin

1

224

Climbing wheel

2

207

Fork ear

2

225

Metalloid nut

2

208

Washer for bearing

2

Single wheel part

209

Fork ear connector

2

210

Pushing rod welding

2

211

Open pin

4

214

Front wheel frame

2

212

Gasket

4

215

Positioning bearing

2

213

Pushing road connector

2

218

Elastic pin

2

214

Front wheel frame

2

219

Gasket

4

215

Positioning bearing

2

220

Bearing

4

216

Elastic pin

2

226

Single wheel

2

217

Double-wheel side board

4

227

Single wheel bearing

2

218

Elastic pin

8

218

Elastic Pin

4

7

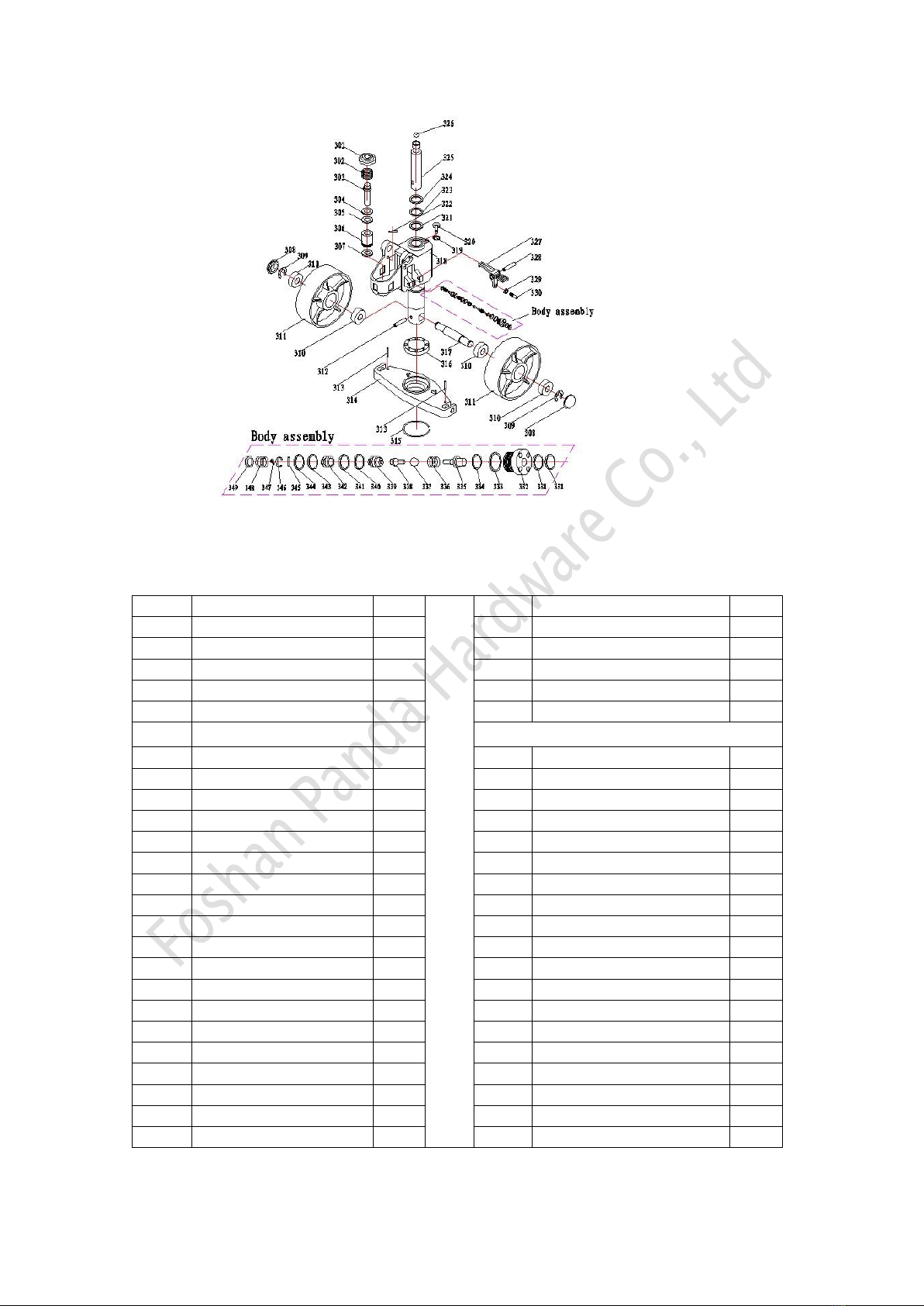

Parts of oil Pump

NO.

Description

Qty.

NO.

Description

Qty.

301

Spring gland

1

326

Steel ball

1

302

Pump core spring

1

327

Pedal control

1

303

Pump core

1

328

Elastic pin

1

304

Anti-dust ring

1

329

Nut

1

305

Sealing ring

1

330

Fasten screw

1

306

Small pump

1

Value body assembly

307

Copper sheet

1

331

"O"sealing ring

2

308

Anti-dust cover

2

332

Copper nut

1

309

Rand

2

333

"O"sealing ring

1

310

Bearing

4

334

"O"sealing ring

1

311

Rear wheel

2

335

Top rod

1

312

Elastic pin

1

336

Top rod spring

1

313

Elastic pin

2

337

Steel ball

1

314

Bearing board

1

338

High pressure

1

315

Check ring for bearing

1

339

Valve body connector

1

316

Pulling ball bearing

1

340

Cutting edge beaming

1

317

Rear wheel bearing

1

341

"O"sealing ring

1

318

Pump

1

342

High pressure valve body

1

319

Grouped gasket

1

343

Cutting edge beaming

1

320

Inner hexagonal screw

1

344

"O"sealing ring

1

321

Sealing ring

1

345

Elastic pin

2

322

Limit lever

1

346

Spring sheet

1

323

"O"sealing ring

1

347

Screw

1

324

Anti-dust

1

348

Valve core spring

1

325

Piston rod

1

349

Gland

1

8

BF Pump Explosive View

No.

Item Name

Spec

Qt

y

No

.

Item Name

Spec

Qty

No.

Item Name

Spec

Qty

1

Pump Out body 外

体

Iron Caste

1

13

Anti-dust ring

Φ18

泵芯防尘圈

Φ18*26*4.5

/6

1

25

Pressure Adjusting

Screw

调压螺钉

M10*1*8,5

1

2

Bonded washer

组合垫片

Φ10*1*9.5

1

14

Sealing ring

泵芯密封圈

Φ18*26*5

1

26

Bonded washer

组合垫

Φ10*2

1

3

Inner hexagonal

screw 内六角螺塞

M10*1

1

15

Limit Lever

限位杆

Φ7*95

1

27

Inner hexagonal

screw 内六角螺塞

M10*1*9.5

1

4

Piston rod

活塞杆

Φ31.5*263

1

16

Valve end Plug

Screw

组尼阀端螺塞

M20*1.5

1

28

Spring for Ejector pin

撞针弹簧

1.3*9.5*22

1

5

Sealing ring

活塞杆密封件

Φ31.5*41.5*6

1

17

Bonded washer

组合垫

Φ20

1

29

“O” Ring

O形密封圈

Φ6.9*1.8

2

6

“O” Ring

O形密封圈

Φ65*2.65

1

18

Pagoda Spring

宝塔弹簧

Φ0.7*20

1

30

Ejector pin

撞针

Φ10*52

1

7

Top Cover

顶盖

Φ31.5

1

19

Spool of orifice

Valve 阻尼阀芯

Φ4.80*19

1

31

Bonded washer

组合垫

Φ20*2

1

8

“O” Ring

O形密封圈

Φ31.5*3.55

1

20

Valve Body

组尼阀阀体

Φ4.9*11

1

32

Pedestal for Ejector

Pin 撞针座

M20*1.5*

18

1

9

Anti-dust Ring

活塞杆防尘圈

Φ31.5*39.5*5

*6.5

1

21

Steel Ball

钢球

SΦ5

1

33

Hexagon Nut

六角螺母

M6

1

10

Pump Plunger

泵芯(BF)

Φ18*97

1

22

Steel ball

钢球

SΦ6.35

1

34

Socket head cap

screw

开槽平端螺钉

M6*25

1

11

Spring Cover

弹簧压盖

Φ49*2*15

1

23

Cushion for Steel

ball 钢球垫

Φ8*8

1

35

Pedal Control

脚踏控制板

1

12

Plunger spring

泵芯弹簧

Φ5.5*外

48*115

1

24

Spring of Safety

Valve

安全阀弹簧

Φ2*8*16.5

1

36

Elastic Pin

弹性销

Φ8*52

1

This manual suits for next models

1

Table of contents