MINIMAX LINE -- INSTRUCTIONS FOR THE USER ROXELL - 001 - 2111

I--4

DIRECTIONS FOR OPERATING THE SYSTEM

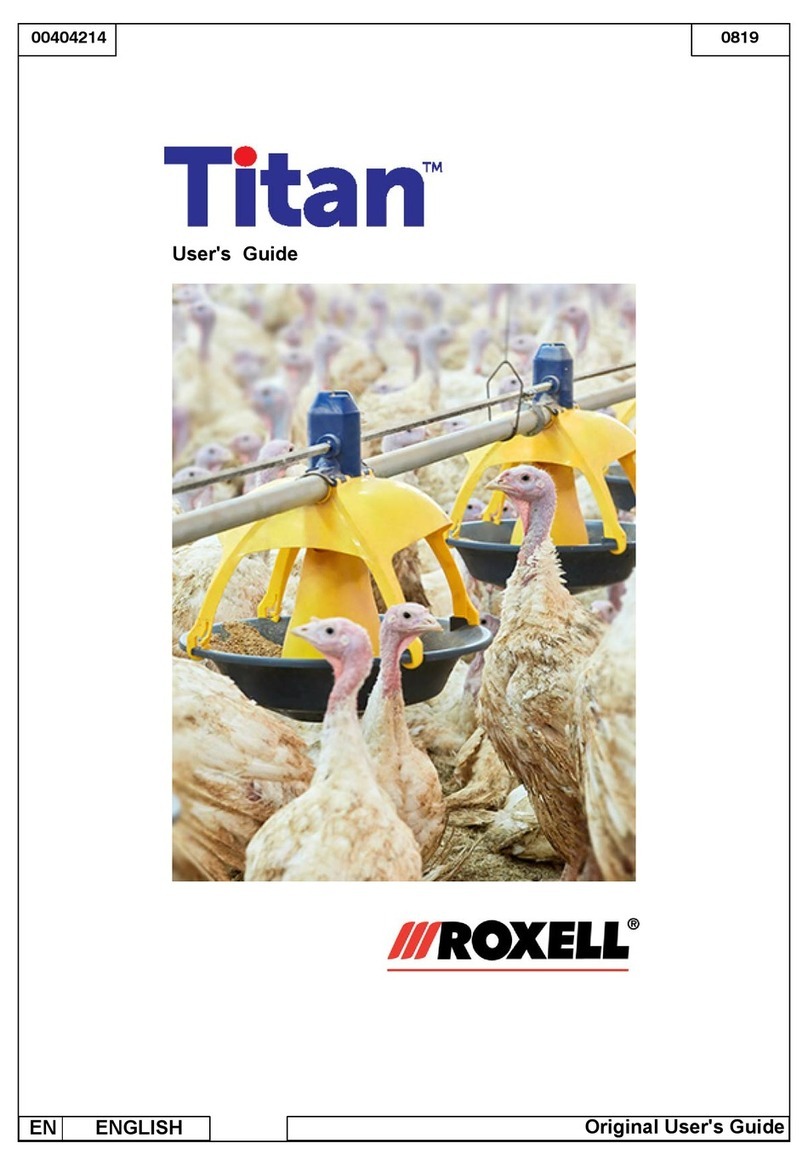

Minimax line = feeding system for broilers, turkeys (0--14

weeks), layers, quails, guinea fowl and ducks

PUTTING THE SYSTEM INTO USE

The oil on the new auger and the tubes will slow up feed

transport at the beginning.

When using a new feeder line for the first time, fill up the

hopper with 25kgs of feed.

NEVER PUT YOUR HANDS INTO THE

FEED INTAKE BOOT WHILE FILLING

THE PANS.

Switchonthefeederuntilthisfeedisdistributed,thenrepeat

the procedure until the whole line is filled. By doing this :

-- you limit the load on the motor of a long feeder line.

-- atthesametime,youtesttheswitchesandmakesurethat

the feeder line has been properly installed.

-- you become used to the system.

Ifinsteadtherearesmallmarksofrusteitherontheinsideof

the tube as on the auger, we advise to mix the first 5kg of

feedwithaportion(¦1/4l)ofmaizeoil.Thisistoavoidthe

noise and trembling during the starting up.

CONTROL UNIT

The last feeder pan on the line (the control pan) is the most

important one. It must be emptied first because it starts the

next feed supply.

Take care that there are enough birds eating from this pan.

Birds are sensitive to light, moisture, draught and

temperature. They will shun places with an environment

deviating from the average. You can have more light above

the control pan by installing for example a small spotlight

which lightens the control pan only.

Keep the pan free of litter and manure. It has to be the most

attractive pan on the line.

Take care that temperature, moisture, ventilation are

constant at this location.

Morebirdswillfeedfromthecontrolpansifyouinstallthem

at a distance of 2--3m from the end wall. The same remark

goes for the outside line (next to the side walls).

FILLING THE HOPPERS

The drop tube of the feeder line furthest from the bin is

equipped with a level switch.

This level switch controls the feed supply from the bin.

If,forcertainreasons,thelastlineisnot enoughusedbythe

birds,itispossiblethattheotherlinesmightrunempty. This

can be prevented by using a time clock.

Thetimeclockshouldbesetsuchthatthefeederisregularly

emptied or decreased to a low feed level.

However,youcanhelptoensurethatenough birdseatfrom

the last line by taking care of :

-- ventilation

-- house structure

-- insulation

-- litter

-- distribution of feeders and drinkers.

Whenplannedcorrectly,youwillhaveaveryevenspreadof

the birds over the whole floor area of the house.

USING THE SYSTEM WITH ONE DAY OLD CHICKS

1. Suspend the 100kg hopper at the correct height.

The weight of the filled hopper will stretch the main cable

to which the chain is fixed when the installation is new.

The connection between the hopper and the first feeder

tube will then no longer be level. This can result in

premature wear and/or failures.

If necessary, shift suspension one or more links to level

the line.

2. Put ALL pans on the floor before placing the one day

olds. Then scatter the litter around the pans.

Take care that all feed windows open simultaneously

and completely.

Now the suspension cords of the tubes are suitably

stretched.

As the pans sink deeper into the litter after a few days,

the windows will remain completely open.

Thesuspensionsofhopperandcontrolunitmustalsobe

suitably stretched.

3. Warmupthehouseandthelitteratleast24hoursbefore

placing the birds.

Fill all pans with feed.

Switch off the feeder lines as soon as all pans are filled.

Thechicksnowhaveenoughfeedfortwodays.Onepan

with open windows holds about 1,6 kg -- about 0,6kg

with closed windows.

Refill all pans after two days and stop the feeder lines.

Repeat this every day until thebirdsare5--7daysold.

So you get a good control of feed intake during the

important starting phase.

You can now easily switch over to automatic filling by

means of the control pan. The feeder line starts

automatically as soon as this pan is empty. All pans are

filled.

You can feed automatically from the first day on, but

then you must regularly check feed intake atthe control

pan.