4

General safety

!!! Important !!!

READ THIS MANUAL BEFORE USING YOUR IRRIGATOR !!

Operating instructions

for Fasterholt FM 4400H

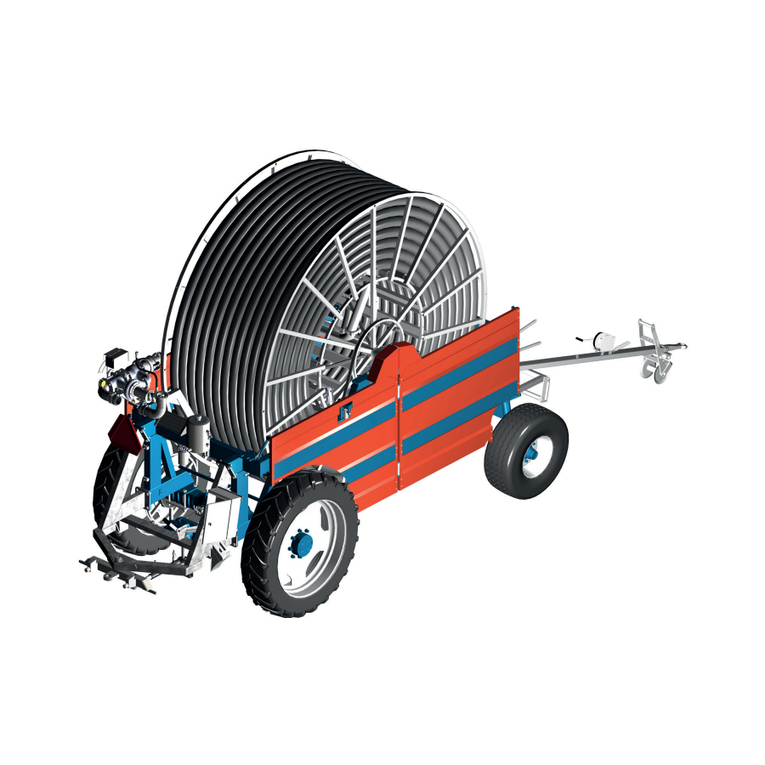

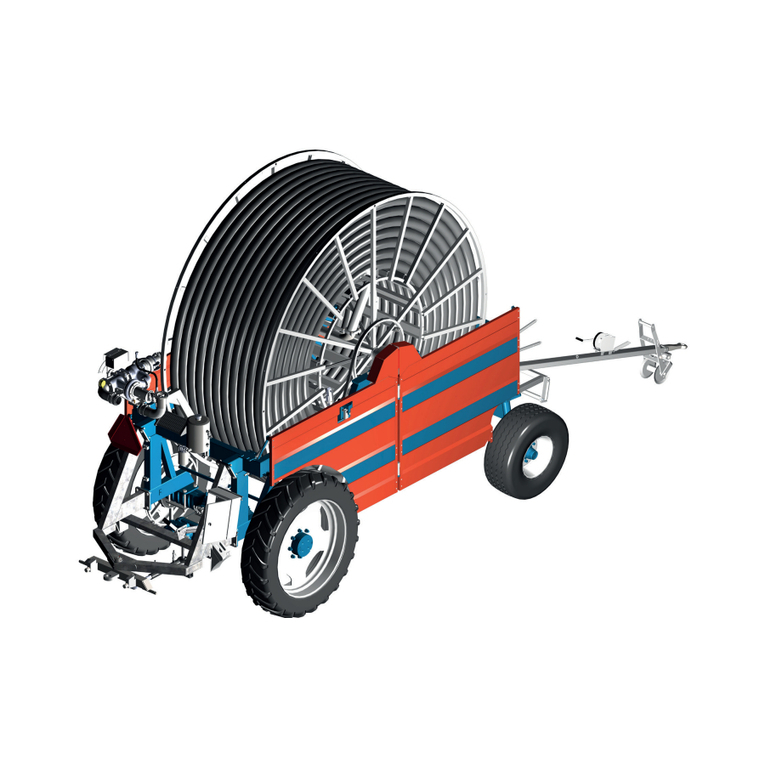

Your new Fasterholt Irrigator is a Danish built machine, but even the

best machines only deliver top results when they are properly used

and maintained.

To ensure that the machine complies with the EU Machinery Direc-

tive, only original spare parts may be used. Otherwise, compliance

will be lost and safety will be entirely at your own risk.

The irrigator is intended for irrigation with clean water from a drilled

well or a watercourse.

1. Safety instructions/warnings !!

―It is forbidden to stand on the machine during irrigation and

transport

(risk of fatal injury).

―The guards are tted for your own safety - please leave them in

place.

―Remember to tighten the wheel bolts.

―When starting the machine on falling ground, you must be

VERY careful not to disconnect the tractor from the machine

until the machine has been put into gear, otherwise the ma-

chine may run away.

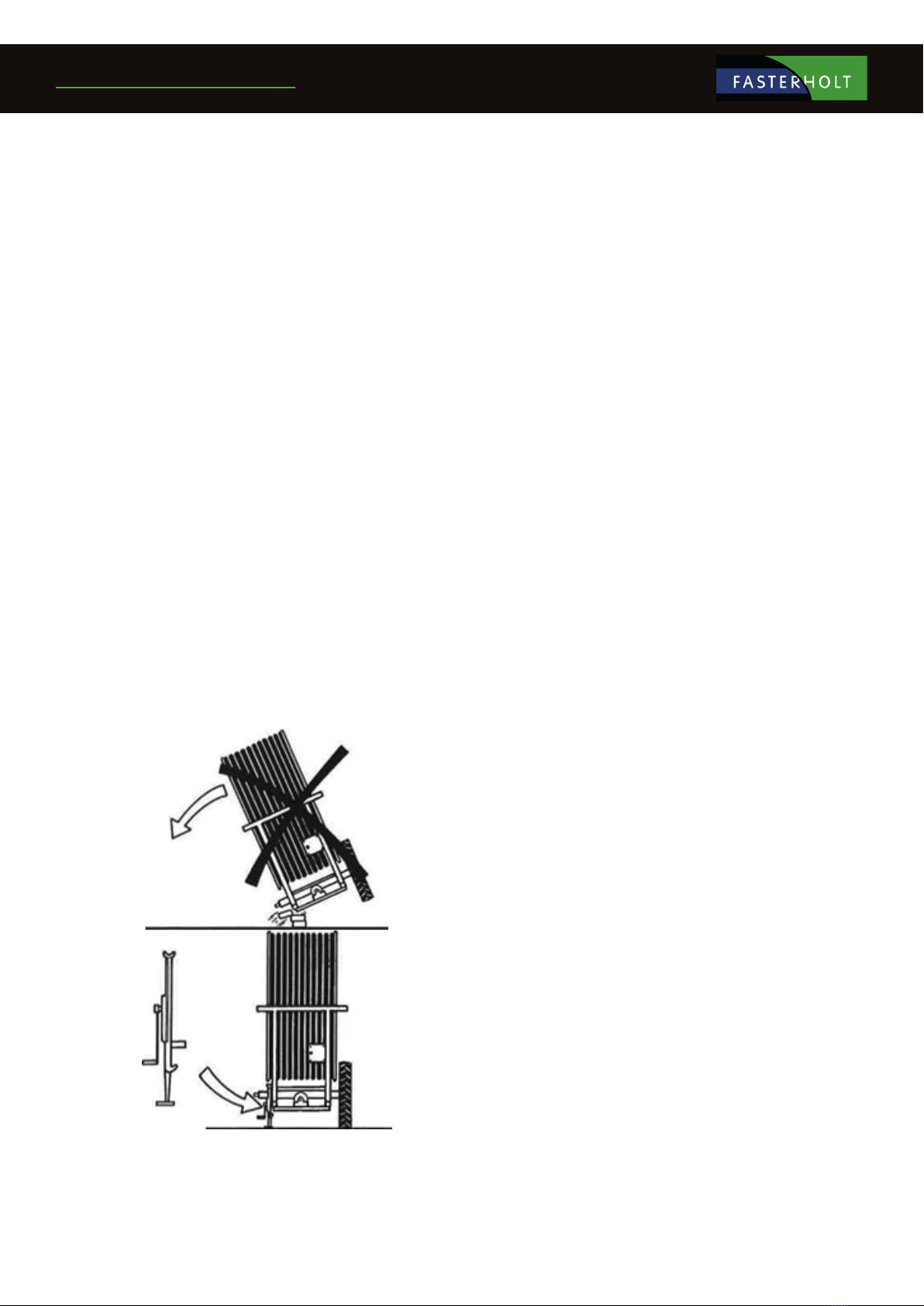

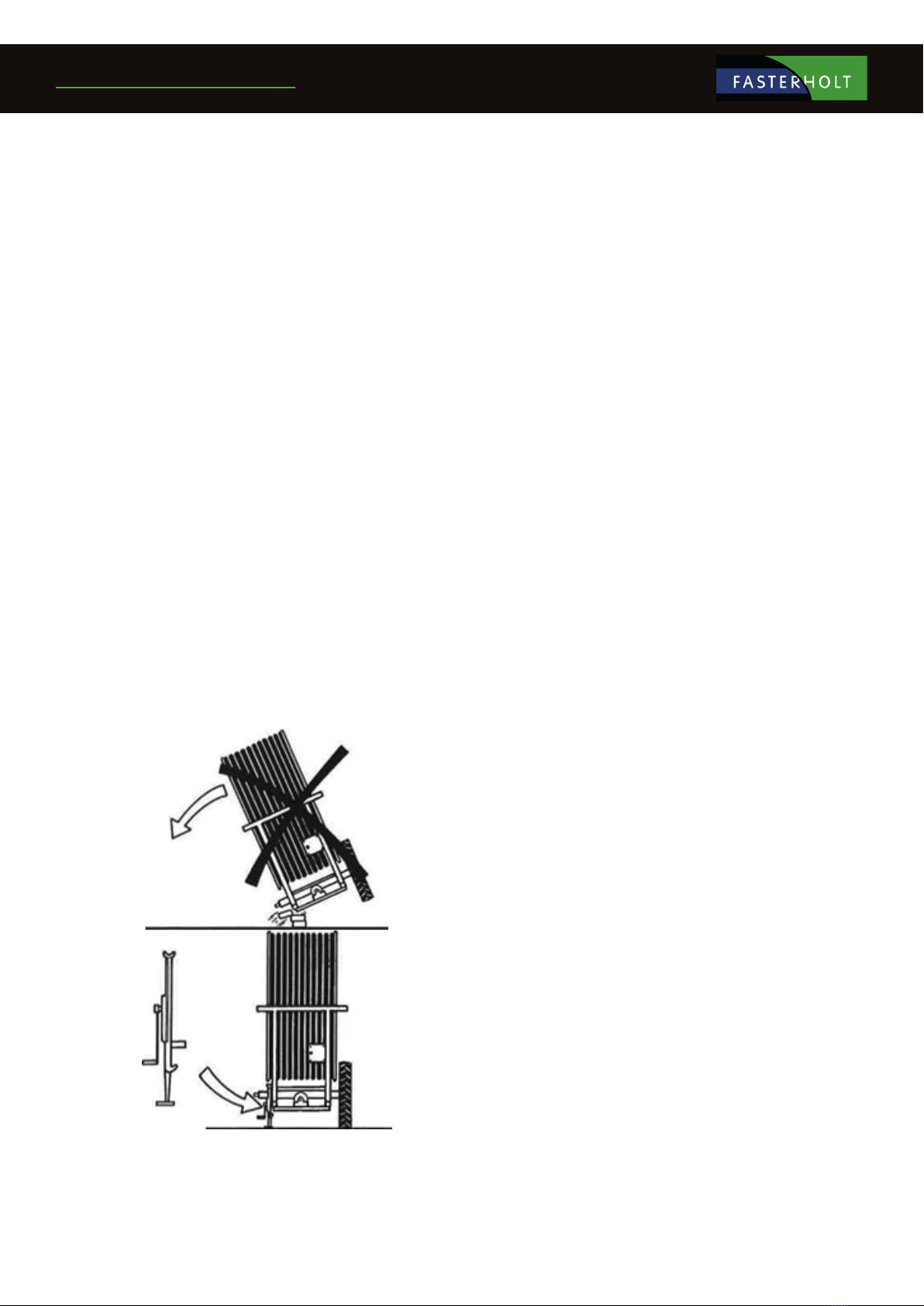

―If a rear wheel is removed, THE MACHINE MUST BE JACKED UP

AND VERY STABLE, because if it overturns, it will fall completely

on its side.

WARNING !!

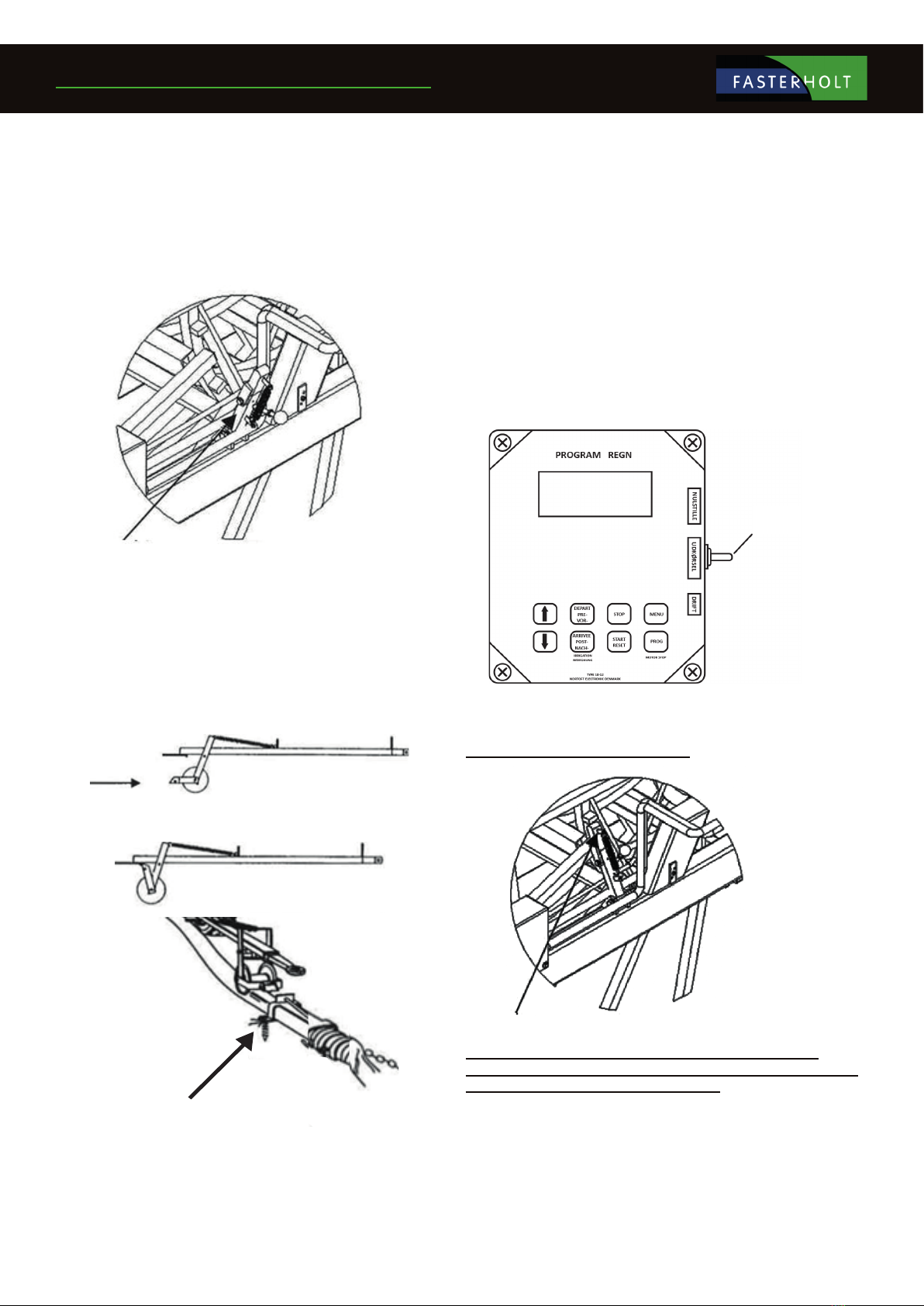

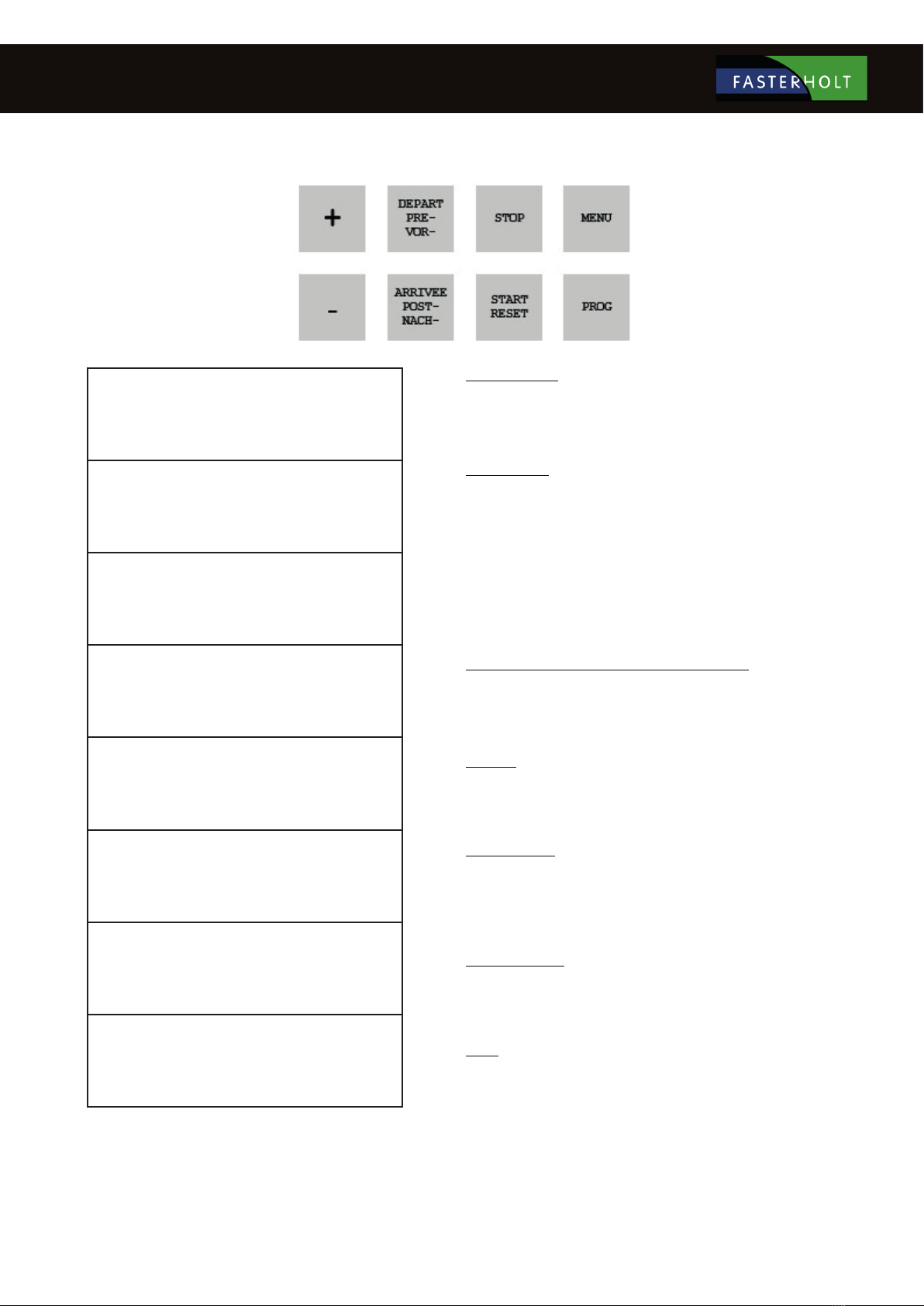

―To perform an EMERGENCY STOP, pull the cable for the mi-

swinding bar or press STOP on the COMPUTER.

―V-belts may only be tted after the machine has been unwound

for the rst time. (only the rst time the machine is used for

irrigation.)

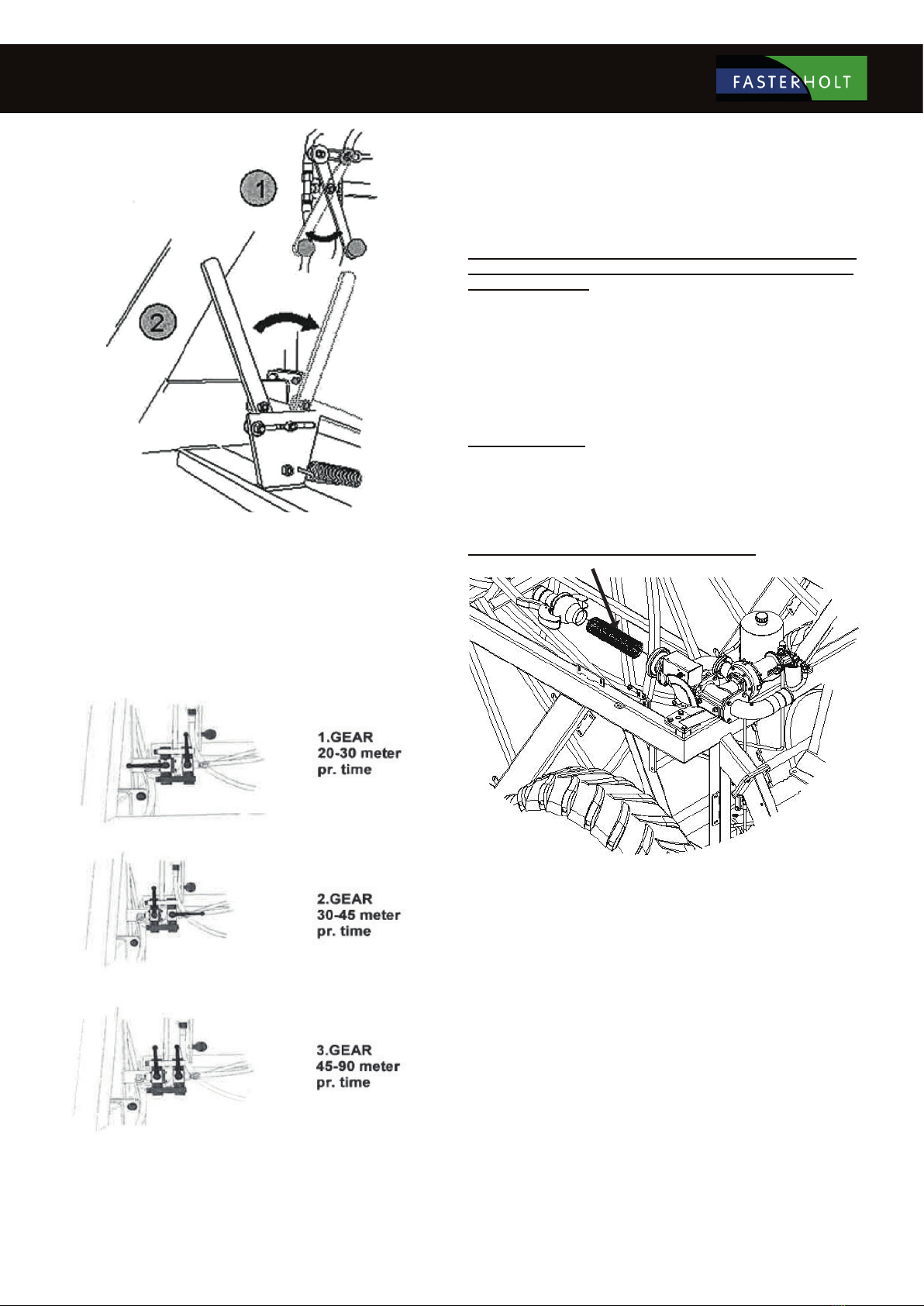

―The gun must face out to the side when unwinding the ma-

chine.

―STAND ASIDE when the gun is operating.

―WARNING against contact with overhead power lines with the

machine or water jet. Avoid irrigation on or near power lines.

―During transport on uneven roads/elds, move VERY carefully

according to the conditions.

―Max. transport speed with water in the hose is 15 km/h.

―When parking the machine, use the wheel chocks mounted by

the rear wheels.

―DANGER !! Avoid welding in the paint layer! Before welding,

remove all paint from the welding area

―Avoid inhalation of grinding dust.

―Hydraulic oil can be harmful to health:

―Skin contact may cause allergies.

―Inhalation of oil mist may cause lung disease.

―Leakage of oil under high pressure is dangerous, an oil jet can

enter the skin, eyes, etc.

―If a hydraulic system leak is found, stop the system immediately

and rectify the fault.

―Note that due to operation, the oil may be 70 degrees Celsius or

even hotter. This can lead to a risk of scalding during separa-

tion.

―IMPORTANT Maximum battery charging power is 2 amps.

Charging more than 2 amps may cause the battery to crack.

The battery must be charged at a temperature between 0 °C

and +40 °C. NEVER place the battery in a sealed container while

charging. During winter, the battery must be removed and

stored in a dry place indoors in a fully charged state.

―Avoid sparks and ames on and around the battery.

―Do not short circuit the battery.

―Never disassemble the battery.

―If you come into contact with the battery's sulphuric acid,

wash immediately with water. If acid comes into contact with

eyes, rinse thoroughly with water and seek medical attention

immediately.

―Pay attention to the battery compartment. If there are cracks,

deformities, electrolyte leakage, etc., replace the battery imme-

diately.

―If the battery is dirty, clean it as soon as possible.

―Disposal of oil spills:

―If oil spills are found, they should be cleaned up immediately

with rags or oil absorbent powder.

―Spilled products, as well as rags and powder used for oil spills,

must be stored in sealed metal containers and delivered to the

municipal collection site.

―Batteries, hoses, tyres and other parts of the irrigation machine

must be disposed of at an approved recycling site.

If the machine is to be moved via public roads, it must rst be

drained of water.