OWNER'S MANUAL

English

EN

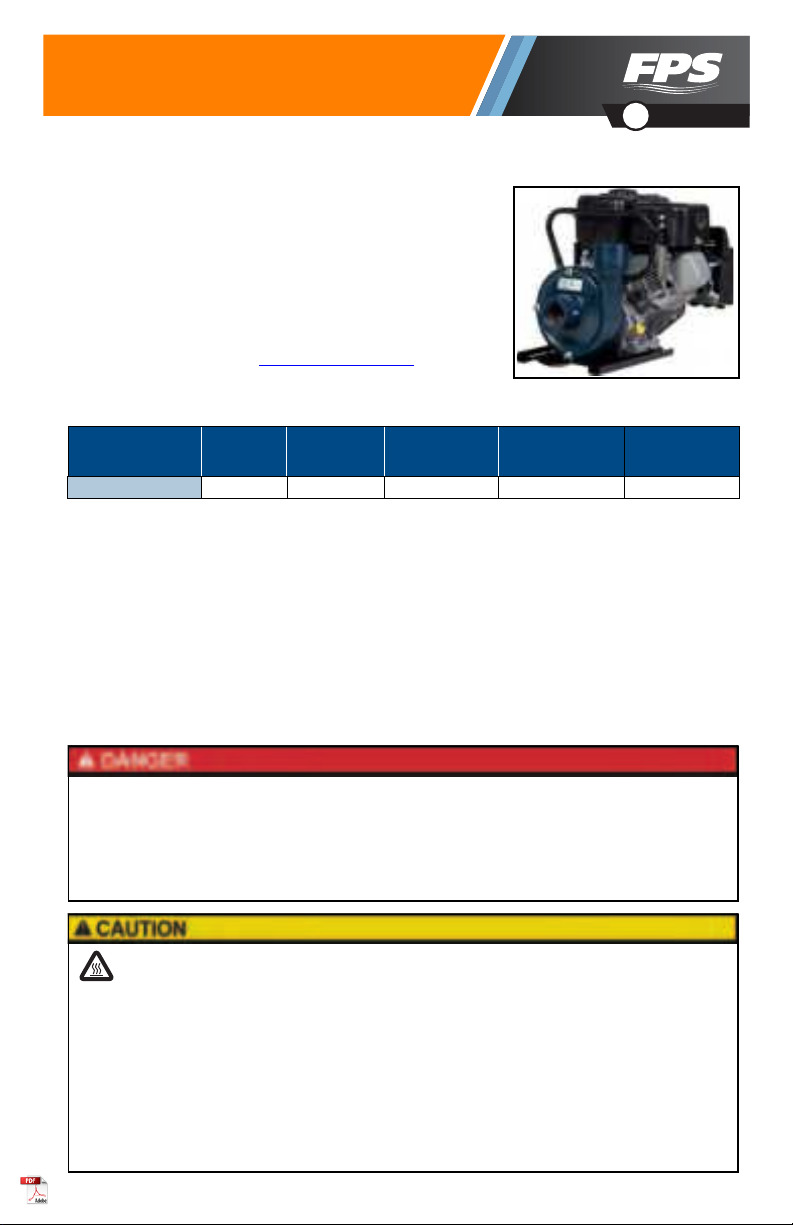

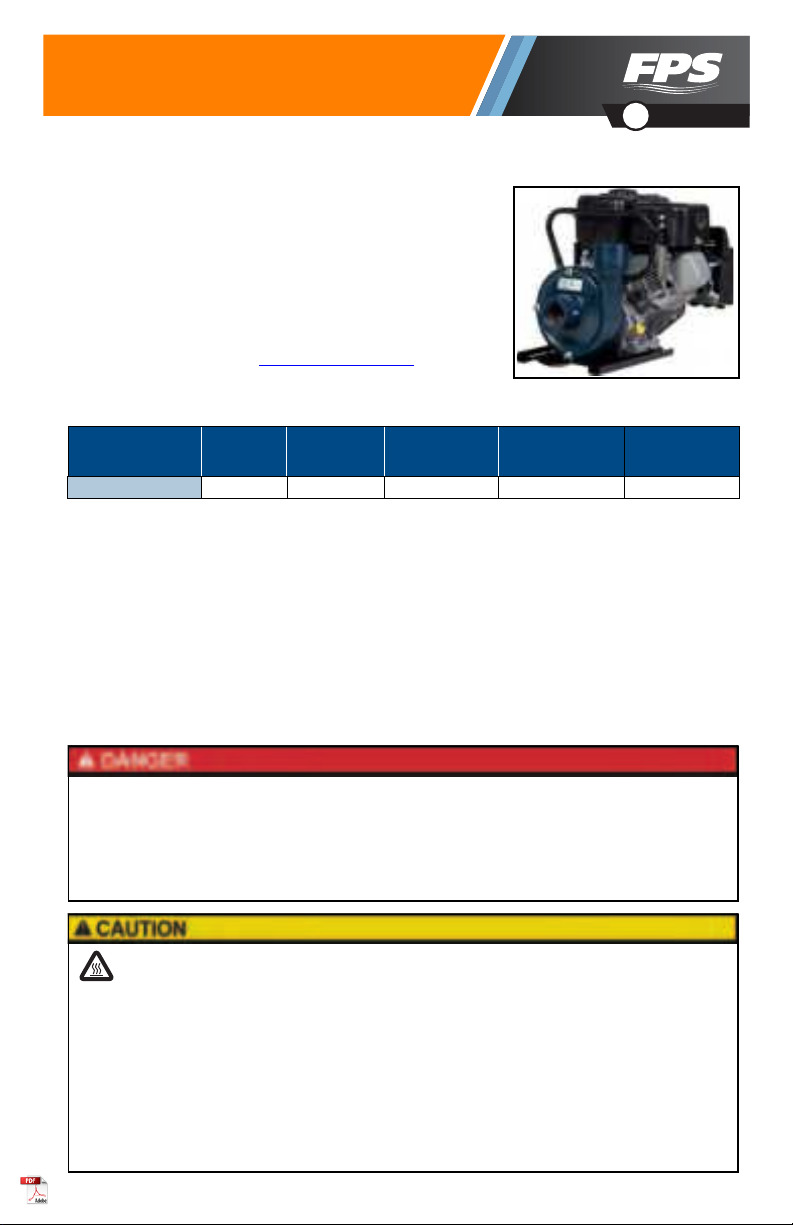

FNG Series Centrifugal Pumps

The FNG Series centrifugal pumps are ideal irrigation or utility pumps, whether as portable units or fixed installations. The centrifugal gas engine pumps can be used in mining, irrigation, construction, and other heavy-duty applications.Refer to the engine manual for instructions and safety details.This product is covered by a Limited Warranty for a period of 1 year from the date of original purchase by the consumer. For complete warranty information, refer to www.FranklinWater.com.SpecificationsSAFETY INSTRUCTIONSThis equipment should be installed and serviced by technically qualified personnel who are familiar with the correct selection and use of appropriate tools, equipment, and procedures. Failure to comply with national and local electrical and plumbing codes and within FPS recommendations may result in electrical shock or fire hazard, unsatisfactory performance, or equipment failure.Know the product’s application, limitations, and potential hazards. Read and follow instructions carefully to avoid injury and property damage. Do not disassemble or repair unit unless described in this manual.Failure to follow installation or operation procedures and all applicable codes may result in the following hazards:Pump TypeItem NumberSuctionDischargeMax TemperatureMax. PressureFNG-23V End Suction902612233 in. (7.62 cm)2-1/2 in. (6.35 cm)212 °F (100 °C)125 psiRisk of death, serious injury, or property damage.

•Do not use to pump flammable, combustible, or explosive fluids such as gasoline, fuel oil, kerosene, etc.•Do not use in explosive atmospheres or hazardous locations as classified by the NEC, ANSI/NFPA70.•Do not handle a pump or pump motor with wet hands or when standing on a wet or damp surface, or in water.•When a pump is in its application, do not touch the motor, pipes, or water until the unit is unplugged or electri-

cally disconnected.Risk of bodily injury or property damage.

•This equipment must not be used by children or persons with reduced physical, sensory or mental abilities, or lacking in experience and expertise, unless supervised or instructed. Children may not use the equipment, nor may they play with the unit or in the immediate vicinity.•An inoperative or malfunctioning pump could lead to flooding, resulting in personal injury or property damage.•Operation of this equipment requires detailed installation and operation instructions provided in this manual. Read entire manual before starting installation and operation. End User should receive and retain manual for future use.•Keep safety labels clean and in good condition. Keep work area clean, well-lit, and uncluttered.•Wear safety glasses while installing or performing maintenance on the pump.