8

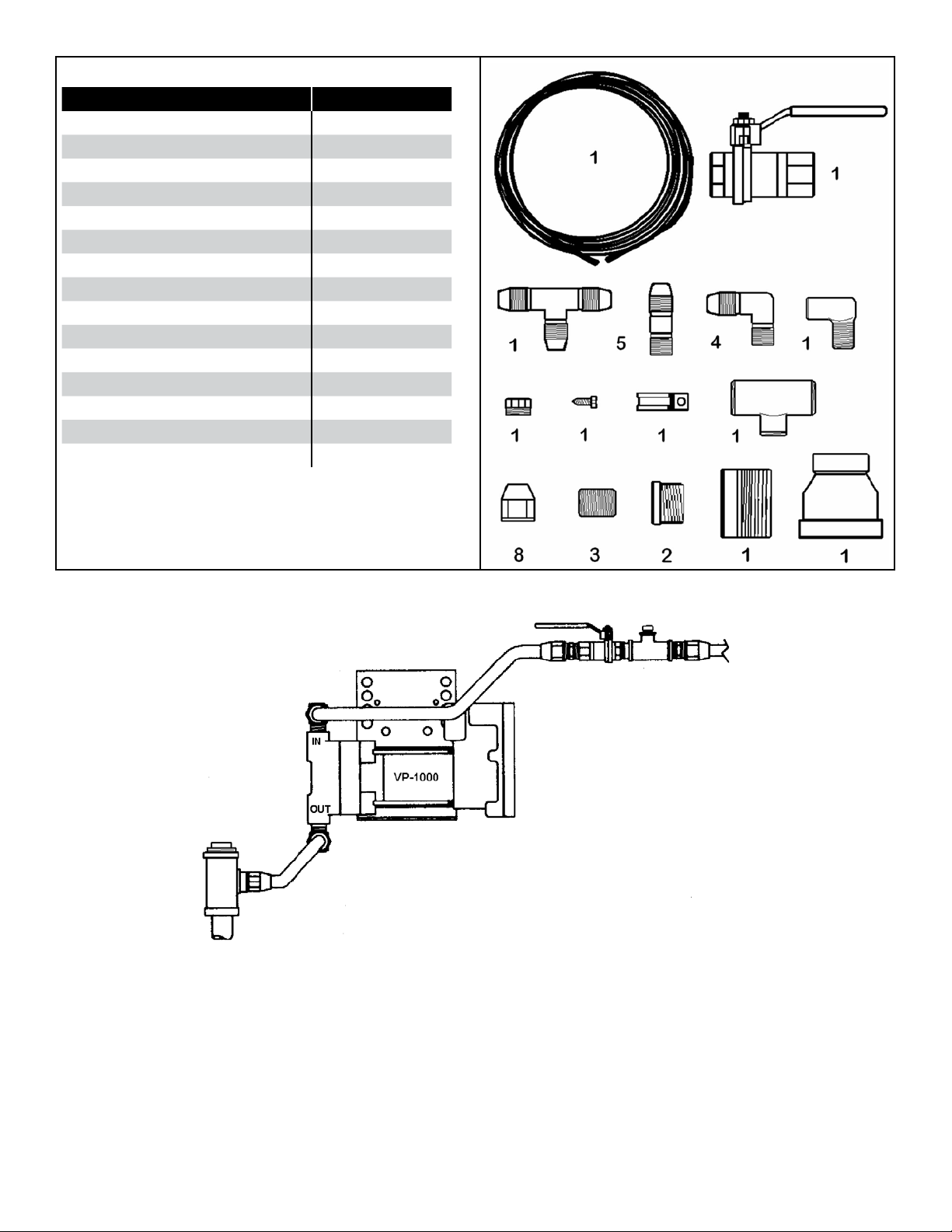

Installing the VP1000-220-IC System

Mounting the Vacuum Pump & Electrical

Conduit Assembly

The VP1000-220-IC System must be installed by a

licensed petroleum technician following all applicable

federal and local codes / regulations.

Warning Disable and tag-out all electrical feeds

into the dispenser. No electrical power

is allowed to the dispenser during the

installation of the vacuum pump and

control module.

The recommended mounting position of the VP1000-

220-IC vacuum pump is with the vacuum inlet and the

electrical connection facing upwards towards the top of the

dispenser.

• The vacuum pump’s performance is not affected by the

mounting location within a dispenser.

• The vacuum pump can be mounted at any location

within the hazardous area of a dispenser if all applicable

NFPA codes are followed.

• The installation must use “UL” approved electrical

conduit, explosion-proof junction box, and electrical

union as required components connecting the VP1000

vacuum pump to the potted conduit.

The vacuum pump can be mounted on any solid surface

or dispenser brace suitable to support the weight of the

pump (32 lbs. / 14.51 Kg). The black steel bracket that is

attached to the VP1000-220-IC Vacuum Pump can be

removed and rotated (3 different mounting positions) so

as to achieve the recommended mounting position of

the pump. If additional support is needed, the use of the

universal steel bracket supplied in the universal hardware

kit is recommended.

1. Begin the installation by mounting the vapor pump

in the hazardous portion of the dispenser. Do not

nal tighten the mounting bolts at this time.

2. Install the Potted Conduit Assembly in an available

barrier knockout (Figure 9). The potted conduit

assembly is used for the electrical conduit

transition from the hazardous area into the

electronic area where the VP1000-220-IC will be

interfaced with existing dispenser electronics.

3. The opening required through the vapor barrier for

the potted assembly must be 1-1/8" in diameter.

Installers can use a sheet metal punch to create

the opening or use an existing knock-out if

available.

4. Remove the top hex nut and washer from the

potted conduit assembly. Guide the assembly

through the knock-out, replace the washer, thread

the hex nut back onto the assembly, and hand-

tighten the assembly into place. If the dispenser

has dual vapor barriers, the rubber washer is

installed on the top side of the lower deck. (See

Figure 9).

Some dispensers have 2 decks.

Dispenser deck(s) between

hydraulics and electronics.

Free space

between decks

List of items included with potted conduit

1. Hex jam nut (2 required)

2. Washer, metal (2 required)

3. Washer, rubber (1 required) if

dispenser has two decks between

hydraulic area and electronics area.

4. ¾" x 6" potted conduit

(36" of wires at module end)

(42" of wires at VP1000-220-IC end)

Wires from

potted conduit

to VP1000-220-IC

Figure 9: List of items Included with Potted Conduit

To power supply

and solenoid signal

To VP1000-220-IC

vacuum pump

Figure 10: Junction Box Wiring

5. After the potted conduit and the VP1000 vacuum

pump are in place (not nal tightened), you can begin

to make up the electrical conduit that will connect the

two components. Keep in mind that an electrical union

and the explosion proof junction box must be installed

between the two points.