3

SAFETY PRECAUTIONS, OPERATING INSTRUCTIONS FOR VHZ-2300.

1. Work safely! Observe all safety precautions.

2. Entrust the operation and maintenance of the forestry tong only to suitable and reliable persons familiar

with this work and over 18 years of age.

3. Prior to use and at least once a day, check that the forestry tong is working smoothly and correctly. Defects

must be repaired to a workmanlike standard. In addition a qualified person prior to first use and after major

alterations, and never less than once a year must inspect the winch.

4. Prior to maintenance of the winch, uncouple the PTO and stop the tractor. Remove the key in order to

prevent inadvertent restarting.

5. Do not disable safety equipment on the winch.

6. As the traction mechanism, use only static cable of sufficient strength corresponding to the indications on

the maker’s plate in these operating instructions. The breaking force of the choker and towing chains must

be at least double that of the pulling force of the lower cable position marked on the winch.

7. Replace faulty cable promptly.

8. Use only a cable of such length that when fully wound onto the drum the upper cable position does not

exceed the edge disks by more than 1.5 times the diameter of the cable.

9. Before starting the forestry tong, the operator must ensure that no persons are at risk.

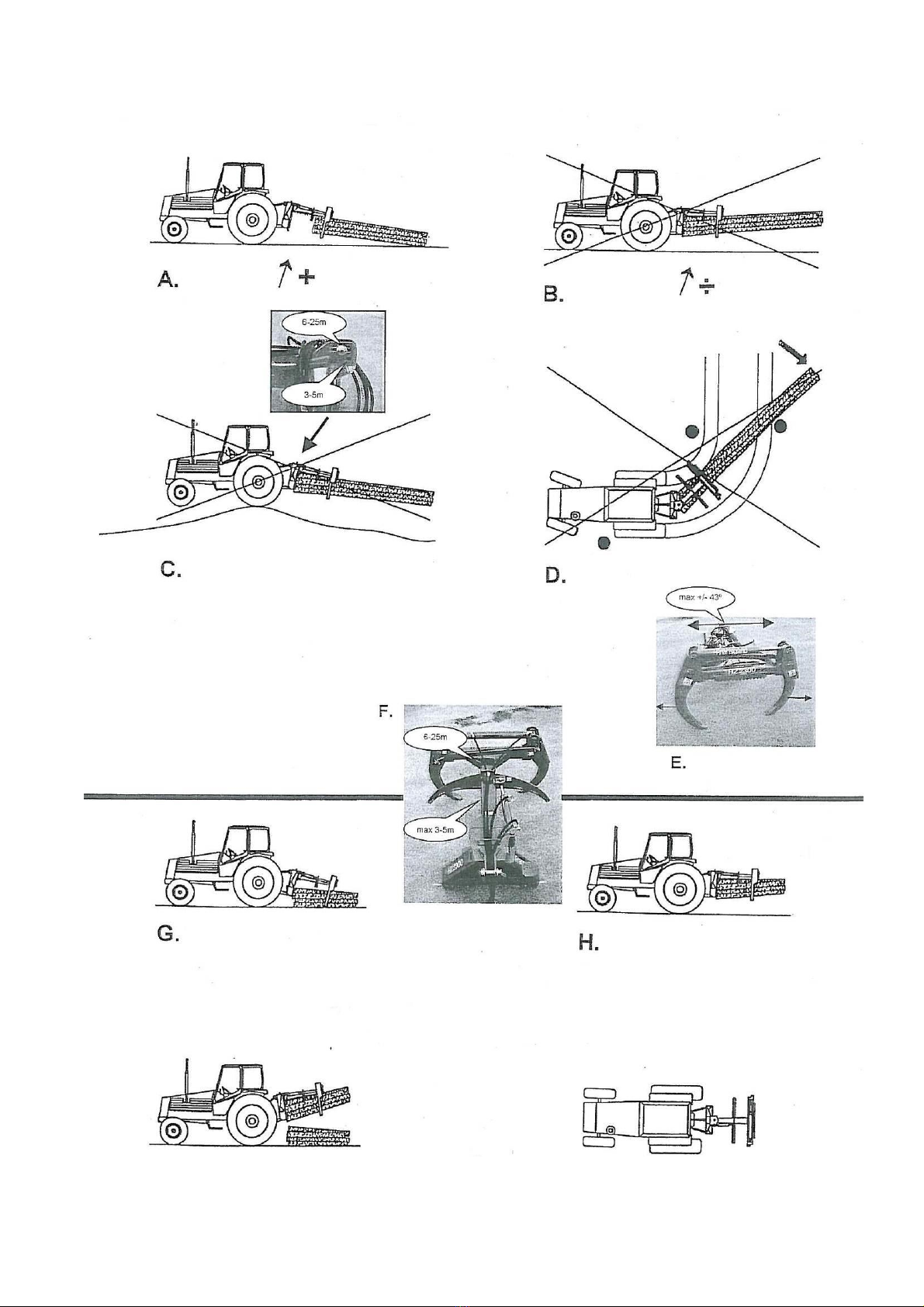

10. The forestry tong must only be operated from a safe position, such that the winch itself, the load, the cable

or the fastening devices do not endanger the winch operator. The driver’s seat on the tractor is considered

a safe position if a sufficiently sized protective grille is arranged between the winch and the driver’s seat.

When operating the winch from outside the driver’s seat, a similar protective arrangement must be

provided for the winch operator, e.g. the tractor itself, a protective grille projecting a sufficient distance to

the side of the winch, or a safe position at a sufficient distance from the tractor, e.g. behind a tree.

11. The winch operator must ensure that, except in the case of danger, at least two winds of the cable

are left on the winch drum.

12. From his position the winch operator must always be able to see the towing load, or otherwise must

ensure that other persons watch the track of the load and that there is constant contact between

watchers’and winch operator by means of pre-arranged signals.

13. While the cable is being worked it is not permitted for any persons to stand in the area between the load

and the winch or in the danger angle between winch, diverter pulley and load.

14. When hoisting over slopes, no one may stand beneath the logs fastened to the cable.

15. When pulling on trees, which are still standing, the traction cable must be attached to the trees before

felling begins. In so doing the position of the tractor must be such that the distance to the tree to be pulled

down is at least double the height of the tree.

16. The tyre profile on the tractor on which the forestry tong is mounted must have good grip, i.e. the tyre

cleats must have at least 40% of the profile height of a new tyre, or the vehicle must be fitted with anti-skid

chains. In snow and icy conditions anti-skid chains must always be fitted.

17. The tractor must be secured with hill support plates or similar prior to starting work. If necessary, secure

the tractor with a cable opposing the direction of pull where the support plate blocks do not afford sufficient

holding power due to the gradient of the land or ground conditions.

18. Select towing load and speed such that the vehicle will not tip over as a result of its construction and type

or the gradient of the land and ground conditions. Select the lowest possible upper cable intake and the

optimal winch pulling direction, i.e. one without sideways deviation.

19. Set the machine on a firm and level basis. It is the responsibility of the owner and users to make sure that

any defects arising from use of the machine are repaired and that the safety conditions are met.

20. At regular intervals and at least twice a year inspect the connecting pins, Item 10, Page 24 for wear. If

necessary replace, as in the case of worn pins the clutch arm may seize up.