-3-

DANGER!

Read before operation this machine!

It is the owner’s responsibility to instruct all equipment operators and support personal in the operation of

winch.

WARNING!

1) Do not attempt to operate this winch

without proper training.

2) Do not operate this machine until the

owner’s manual has been completely read

and understood.

New owner’s manual are available from

your Dealer or the factory phone + 45 98

63 21 22

(North America: 514 654 6126). If the

warning decals become illegible, new

decals can also be ordered.

3) Keep hands, feet and clothing away from

power driven parts!

4) Ensure that the cable is in good

conditions before operating the winch. If

the cable breaks, parts of it can fly both

toward and away from the winch.

Ensure that all bystanders are out of

reach of the cable when the winch is

used.

5) Never handle cable without shutting of

power-take off!

6) Do not transport logs direct in the cable -

use the log towing bar.

7) This machine has been constructed to skid

and push together timber that has been

felled and is lying on the ground and may

not be used for other purposes. The

machine must not be used to pull vertical

trees or trees that are wedged or jammed,

as this is extremely dangerous.

8) Check moving parts. They should be

fastened in place, in good working

condition and all shields and guards must

be in place.

9) Familiarize yourself with the controls and

how to stop the winch and tractor in an

emergency.

10) Do not let children or incapable persons

operate the winch.

11) Do not wear loose clothing, loose sleeves,

neckties or long uncovered hair around

moving parts of machinery.

12) Park the winch and tractor on level ground

for winching.

13) Operate the winch from a control rope at

least 6 m. to the side of the machine.

Do not operate the winch from the tractor

seat.

14) Ensure that other people do not become

endangered when you are using the

winch.

15) Do not leave the tractor running

unattended.

16) Disengage the PTO an turn the tractor off

before you service the winch. Remove the

keys so the tractor cannot be started up

accidentally.

17) Use only original Fransgård replacements

parts, do not make any modifications.

18) Inform everyone who works with the winch

about risks and how they can avoid

accidents.

19) Stay alert! Do not operate when fatigued.

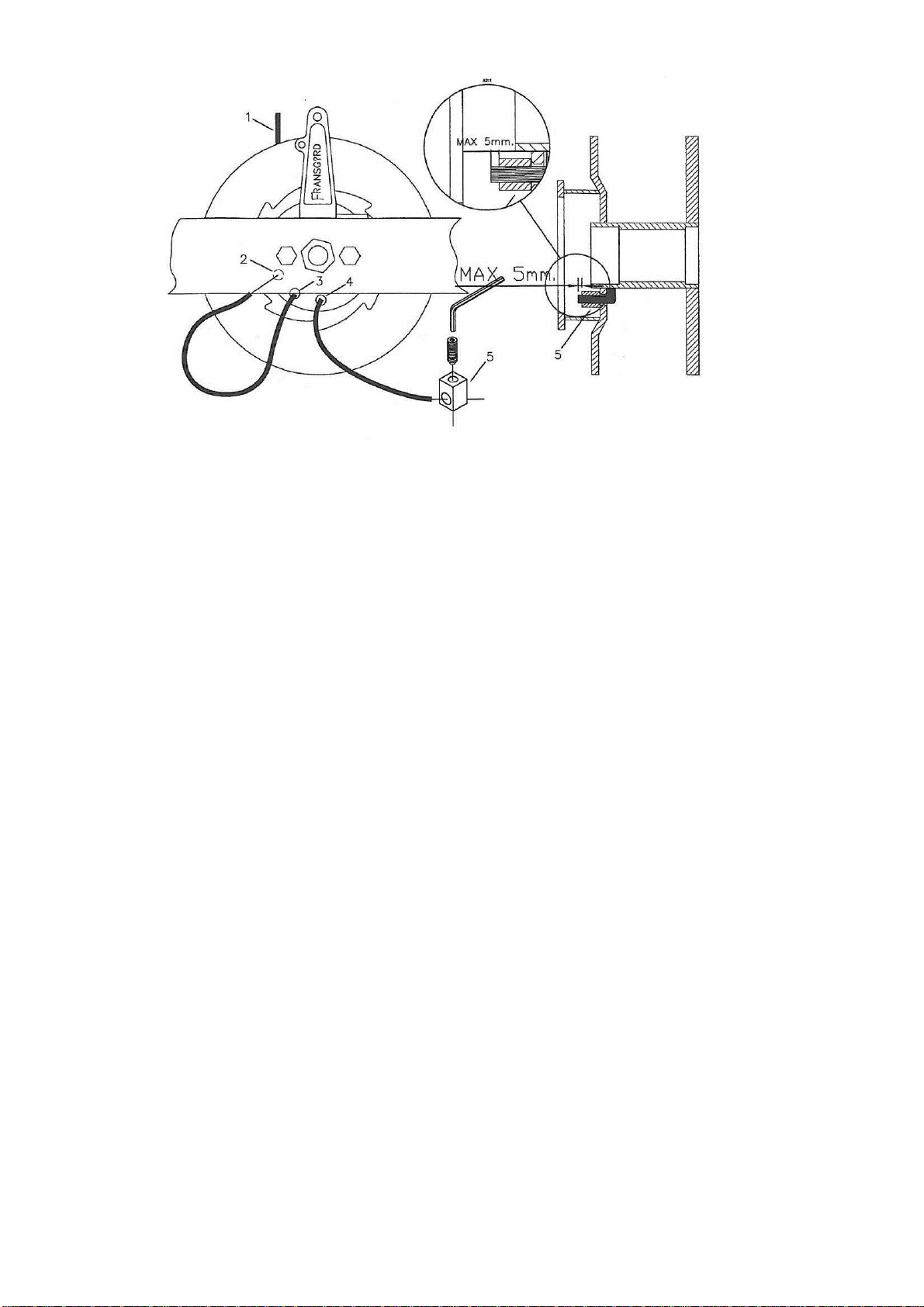

20) Do not winch at sideways angles

exceeding 30° (see drawing).

21) Failure to heed the warnings printed on

the winch or in the owner’s manual might

result serious injury or death.

22) The tractor should not be set in motion

without the “buttends” of the logs (that

have been winched) being raised off the

ground. If this is not done and an obstacle

hits the butt end of the log (s), then the

tractor may turn over and severe injuries

may result.