Fraser Anti-Static Techniques, Scotts Business Park, Bampton, Devon EX16 9DN, UK

T

+

44

(0)

1398

331114

F

+

44

(0)

1398

331411

E

[email protected] W

www

.fraser-antistatic.com

2

NEOS 30 OEM-DM-Iss.2

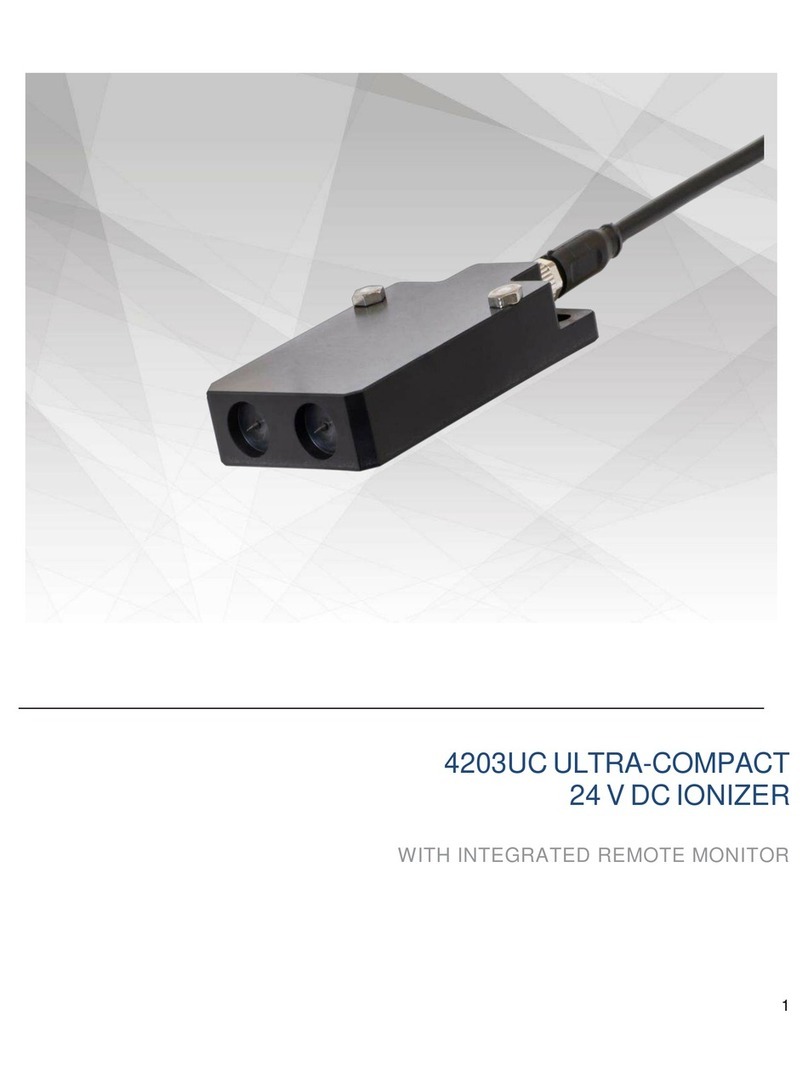

1. BACKGROUND

NEOS

The standard NEOS Bars have become accepted as the most effective static eliminators in their respective classes:

from NEOS 12, which is the most effective short range Bar available

to NEOS 30, which is the most powerful long range Bar available

Please refer to the comparison between the Simco ThunderION 2.0 and the NEOS 30 which was sent to you in February 2019. It

shows that the NEOS 30 is comprehensively better than the market leader at all distances.

Frequency and Long Range Static Neutralisation

It is useful to repeat these notes, as they are essential for understanding the benets of the NEOS 30 OEM and where it ts into the

NEOS range.

The method for neutralising at long distance without air assistance is to reduce the frequency of the ion emission so that it

produces bigger elds of ions which propel each other outwards. This is the basic operation for all pulsed DC static neutralisation.

Generally:

- short distances are neutralised with higher frequency – for example, 50 Hz on the 3014 and 3024F

- longer distances are neutralised with slower frequency – for example, 5 Hz on the 3024L

When NEOS Bars are used in intelligent operating modes (AN or AL) they respond to the polarity of the electric eld from the

object and change the wave pattern to output more ions of the opposite polarity. This effect also compensates to a large degree

for changes in distance within the sensing range. The unipolar elds in AN and AL modes can be larger and so act like slower

frequency elds.

In AL mode the NEOS 30 can sense a strong electric eld at distances up to about 750 mm. In this range there will effectively be

automatic compensation for distance.

If the electric eld is too weak, usually because the target is too far away, a Manual setting may produce better neutralisation. For

example, the NEOS 30 in setting M1 (0.5 Hz) neutralises at distances over 750 mm more efciently than in AL mode.

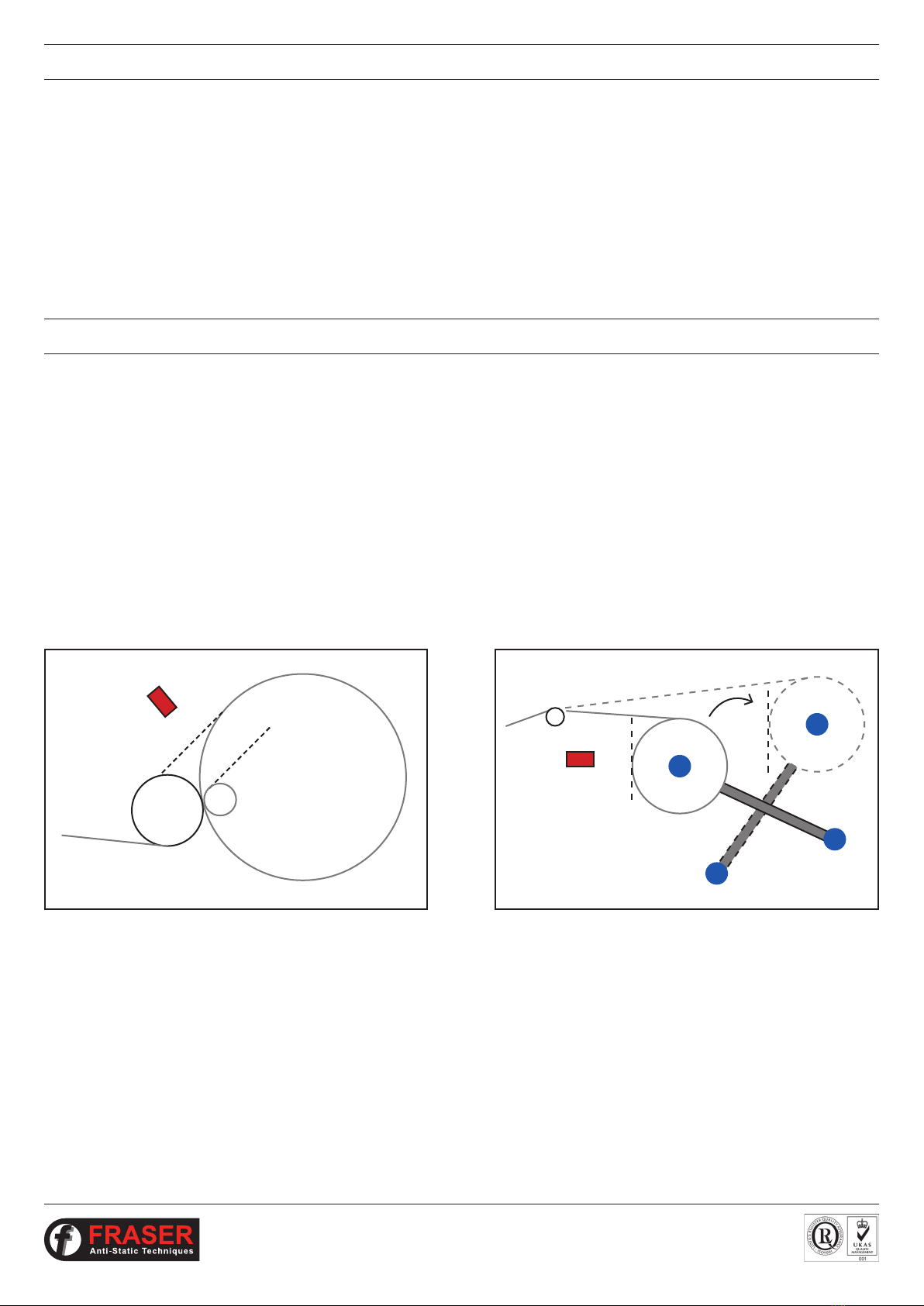

What if the object to be neutralised moves from a short distance to a distance over 750 mm?

For example, from 200 mm to over 1m?

The NEOS 30 OEM has been developed to deal with this problem.

SECTION 1 - PRODUCT INFORMATION