Contents

Safety Instructions ...................................................................................................................................................................... 3

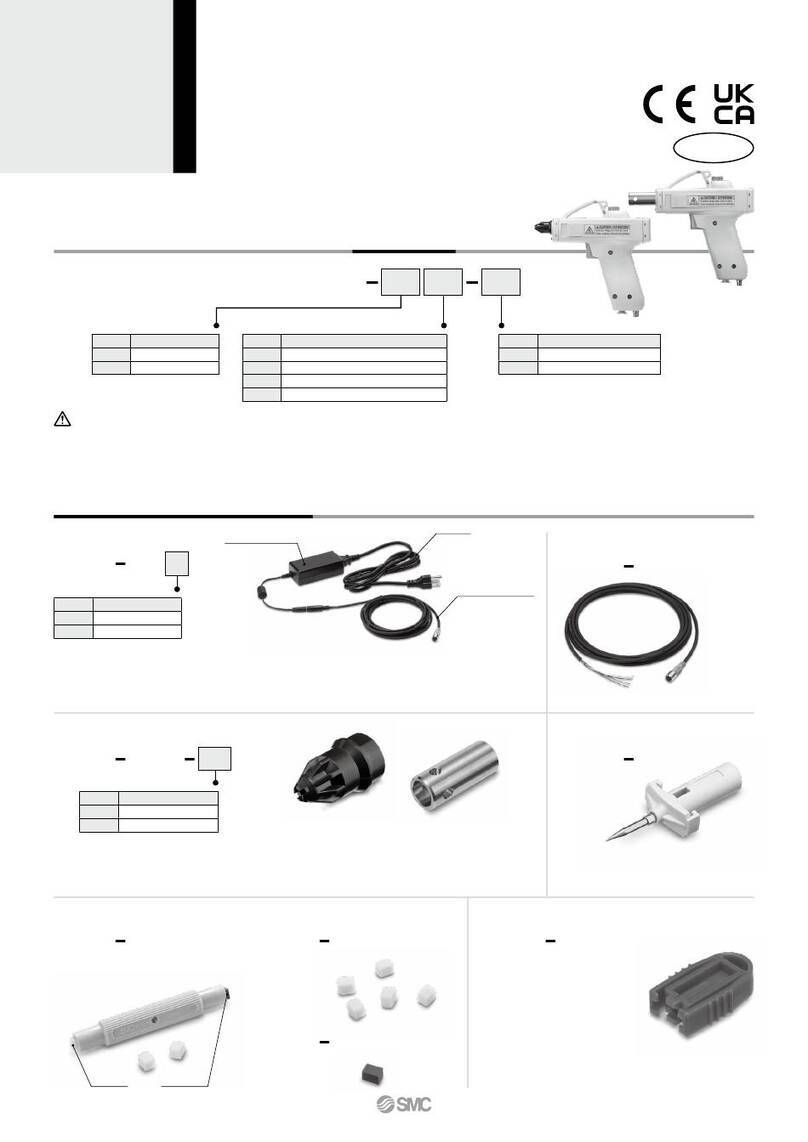

1. How to Order..........................................................................................................................................................................11

1-1. System construction......................................................................................................................................................11

1-2. How to Order...................................................................................................................................................................14

1-2-1. Product number for single unit (to order separately).................................................................................................15

1-2-2. Made to Order...........................................................................................................................................................16

1-2-3. Accessories (ordered separately)..............................................................................................................................17

1-2-4. Sold separately .........................................................................................................................................................18

2. Procedures to Operation.......................................................................................................................................................20

2-1. Flow chart to operation..................................................................................................................................................20

2-2. Initial setting (Initial setting is not necessary for IZT40).............................................................................................20

3. Installation and wiring .........................................................................................................................................................21

3-1. Installation of Ionizer......................................................................................................................................................21

3-1-1. Precautions for Installation........................................................................................................................................21

3-1-2. Adjustment of Pressure (Flow adjustment)................................................................................................................21

3-1-3. Selection of piping port size ......................................................................................................................................21

3-1-4. Distance for installation.............................................................................................................................................22

3-1-5. Installation of bracket for bar.....................................................................................................................................22

3-1-6. Connecting the controller and high voltage power supply module ............................................................................23

3-1-7. Installing the controller and high voltage power supply module ................................................................................25

3-1-8. Routing of cables ......................................................................................................................................................30

3-2. Wiring..............................................................................................................................................................................33

3-2-1. Ground the ground terminal......................................................................................................................................33

3-2-2. Connection Circuit.....................................................................................................................................................33

3-2-3. Wiring of the AC adapter...........................................................................................................................................35

3-3. Timing chart....................................................................................................................................................................36

3-3-1. IZT40.........................................................................................................................................................................36

3-3-2. IZT41、IZT42.............................................................................................................................................................39

4. Function................................................................................................................................................................................43

4-1. Name of Parts .................................................................................................................................................................43

4-1-1. Controller ..................................................................................................................................................................43

4-1-2. High voltage power supply module ...........................................................................................................................45

4-2. Operation modes............................................................................................................................................................46

4-2-1. Operation modes of IZT40 and IZT41.......................................................................................................................46

4-2-2. Operation modes of IZT42 ........................................................................................................................................46

4-3. High voltage power supply module CH number setting .............................................................................................47

4-4. Controller setting............................................................................................................................................................48

4-4-1. Operation overview...................................................................................................................................................48

4-4-2. Channel selection mode............................................................................................................................................50

4-4-3. Frequency set mode .................................................................................................................................................51

4-4-4. Offset voltage adjustment mode................................................................................................................................52

4-4-5. Balance control selection mode ................................................................................................................................53

4-4-6. Maintenance detection level selection mode.............................................................................................................54

4-4-7. Key-lock setting mode...............................................................................................................................................55

4-4-8. Ion generation stop mode .........................................................................................................................................56

4-5. Alarm function................................................................................................................................................................57

4-5-1. Alarms for IZT40........................................................................................................................................................57

4-5-2. Alarms for IZT41 and IZT42 ......................................................................................................................................58

4-5-3. Details of the alarms .................................................................................................................................................59

5. Performance...........................................................................................................................................................................61

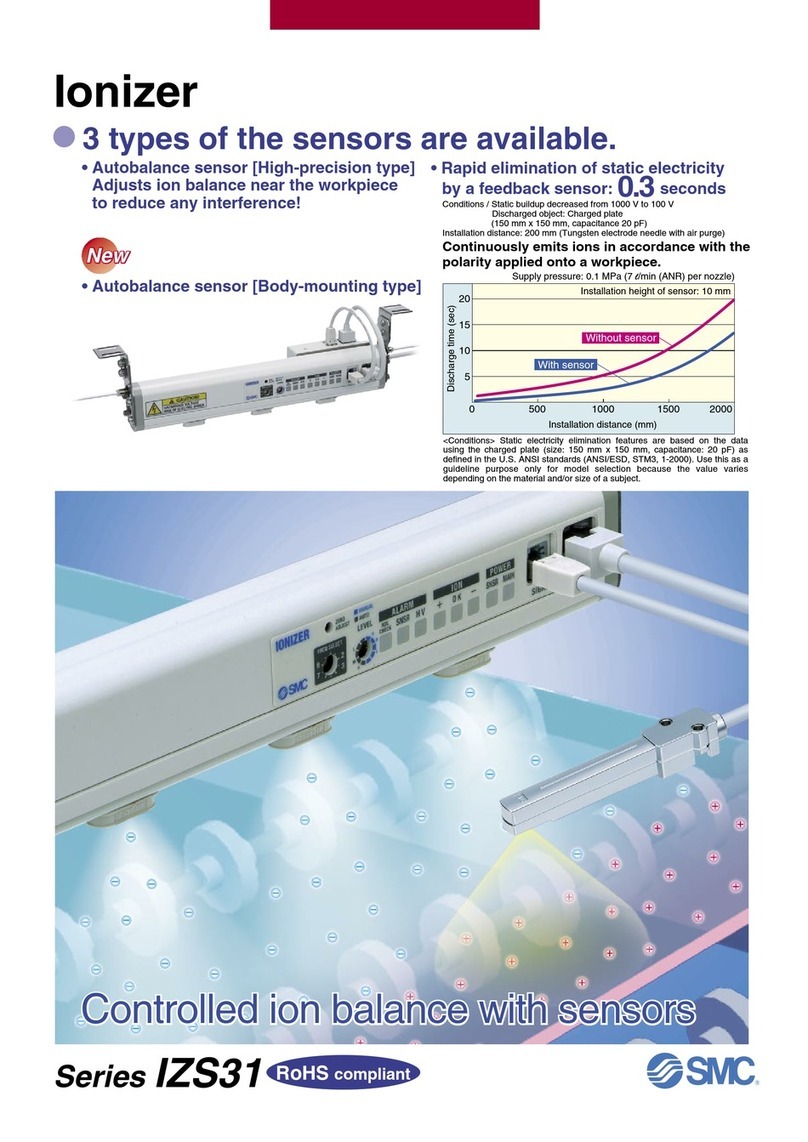

5-1. Installation distance and discharge time (discharge time of 1000V→100V).............................................................61

5-2. Potential amplitude ........................................................................................................................................................63

5-3. Static neutralization range.............................................................................................................................................64

5-4. Flow - Pressure characteristics ....................................................................................................................................67

6. Dimensions ............................................................................................................................................................................68

7. Specifications ........................................................................................................................................................................77

8. Troubleshooting.....................................................................................................................................................................78

9. Maintenance...........................................................................................................................................................................79