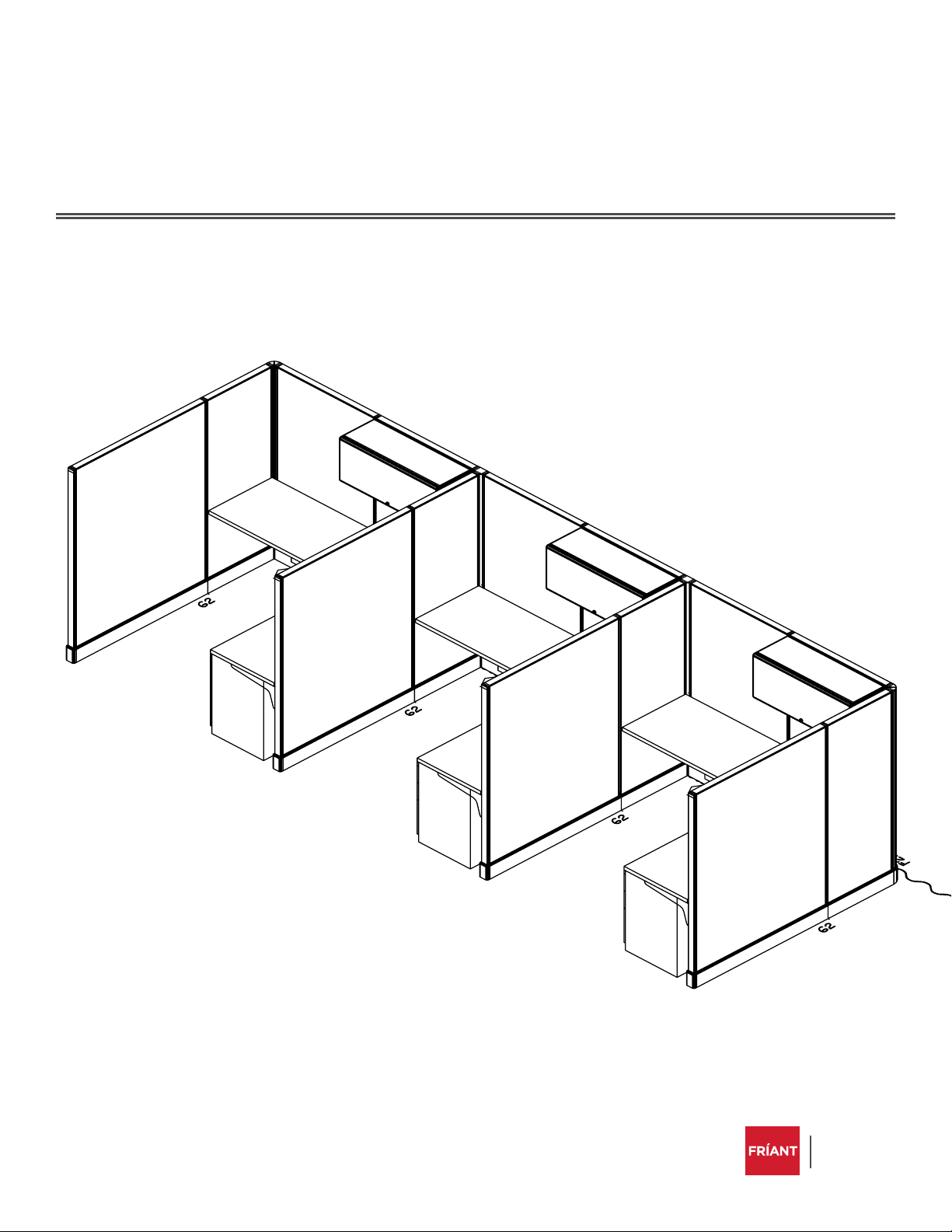

System 2 Installation Manual 3

SYSTEM 2 INSTALLATION MANUAL

Panels & Connectors

Denitions ��������������������������������������������������������������������������� 8

Panel to Connector: Same Height ������������������������������� 9

Panel to Connector: Change of Height �������������������� 10

Panel to Panel: Same Height������������������������������������������ 11

Panel to Panel: Change of Height ������������������������������� 12

Panel to Panel: Installation at Inline Change of

Height ����������������������������������������������������������������������������������� 13

Finished End ���������������������������������������������������������������������� 14

Finished End: Change of Height ��������������������������������� 15

Top Cap ��������������������������������������������������������������������������������� 16

Leveling Panels ������������������������������������������������������������������ 17

Door Handle Instruction ������������������������������������������������� 18

Wall Starts �������������������������������������������������������������������������� 20

Electrical

Denitions & Wiring Diagram ��������������������������������������� 21

Festoons ������������������������������������������������������������������������������ 22

Receptacles ������������������������������������������������������������������������ 23

Ceiling Power Entry ��������������������������������������������������������� 24

Base Power Entry ������������������������������������������������������������� 25

Base Cover �������������������������������������������������������������������������� 26

Connector Trim ����������������������������������������������������������������� 27

Finished End Trim ������������������������������������������������������������ 28

Upper Storage

Shelves ��������������������������������������������������������������������������������� 29

Flipper Door ���������������������������������������������������������������������� 30

Worksurfaces

Corner, Extended Corner, 120° & 135° ����������������������� 31

Rectangular ������������������������������������������������������������������������ 32

Transaction ������������������������������������������������������������������������� 33

Lower Storage

Pedestals ���������������������������������������������������������������������������� 34

Lateral Files ������������������������������������������������������������������������ 35

Accessories

Panel-Mounted Tackboard & Markerboards ���������� 37

Tool Bars ������������������������������������������������������������������������������ 38

Cord Managers ������������������������������������������������������������������ 39

LED Tasklight �������������������������������������������������������������������� 40

General Information������������������������������������������������������������������������������������������������������������������������������������������������������������������������������ 4

Safety & Support������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������ 5

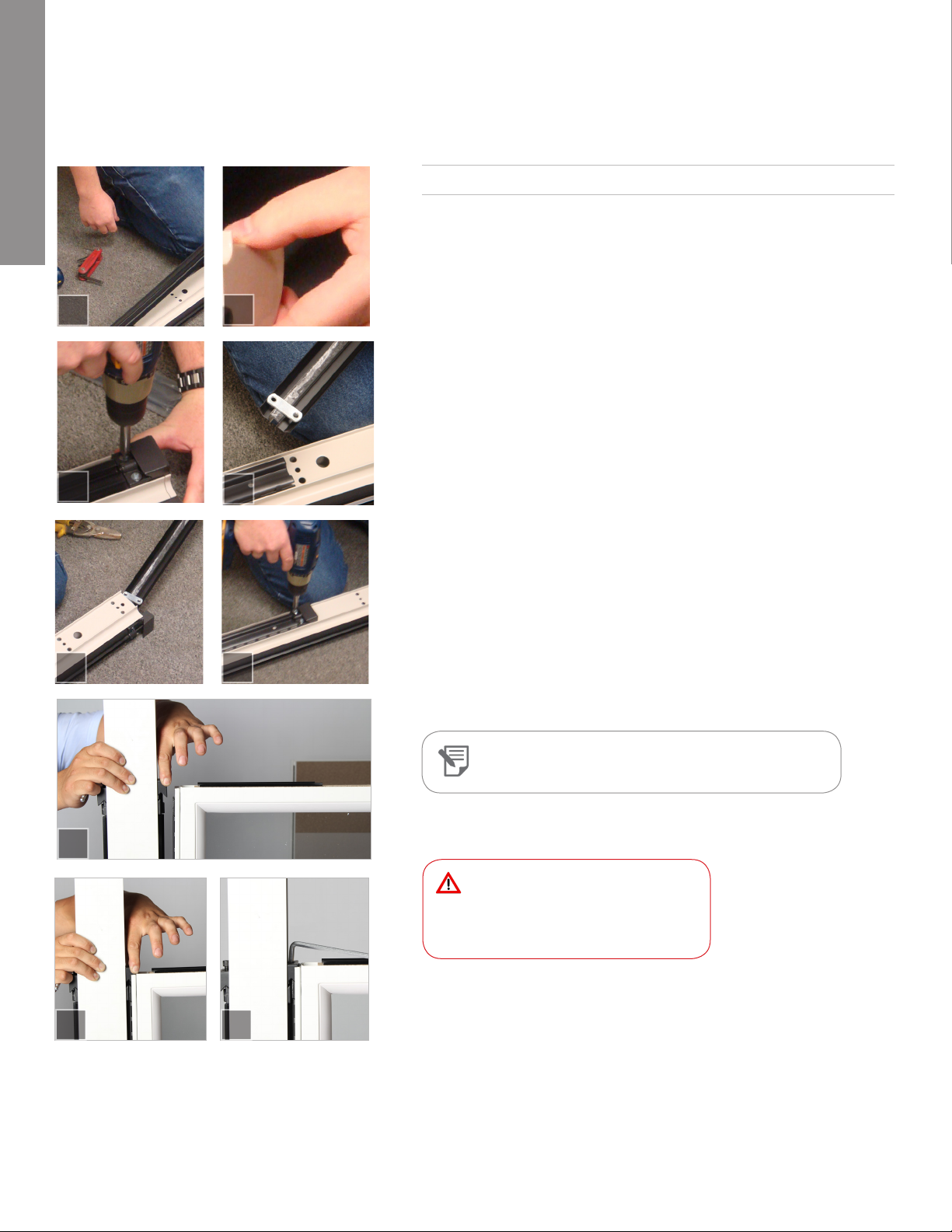

Installation Tools ������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������ 6

Staging & Installation ��������������������������������������������������������������������������������������������������������������������������������������������������������������������������� 7