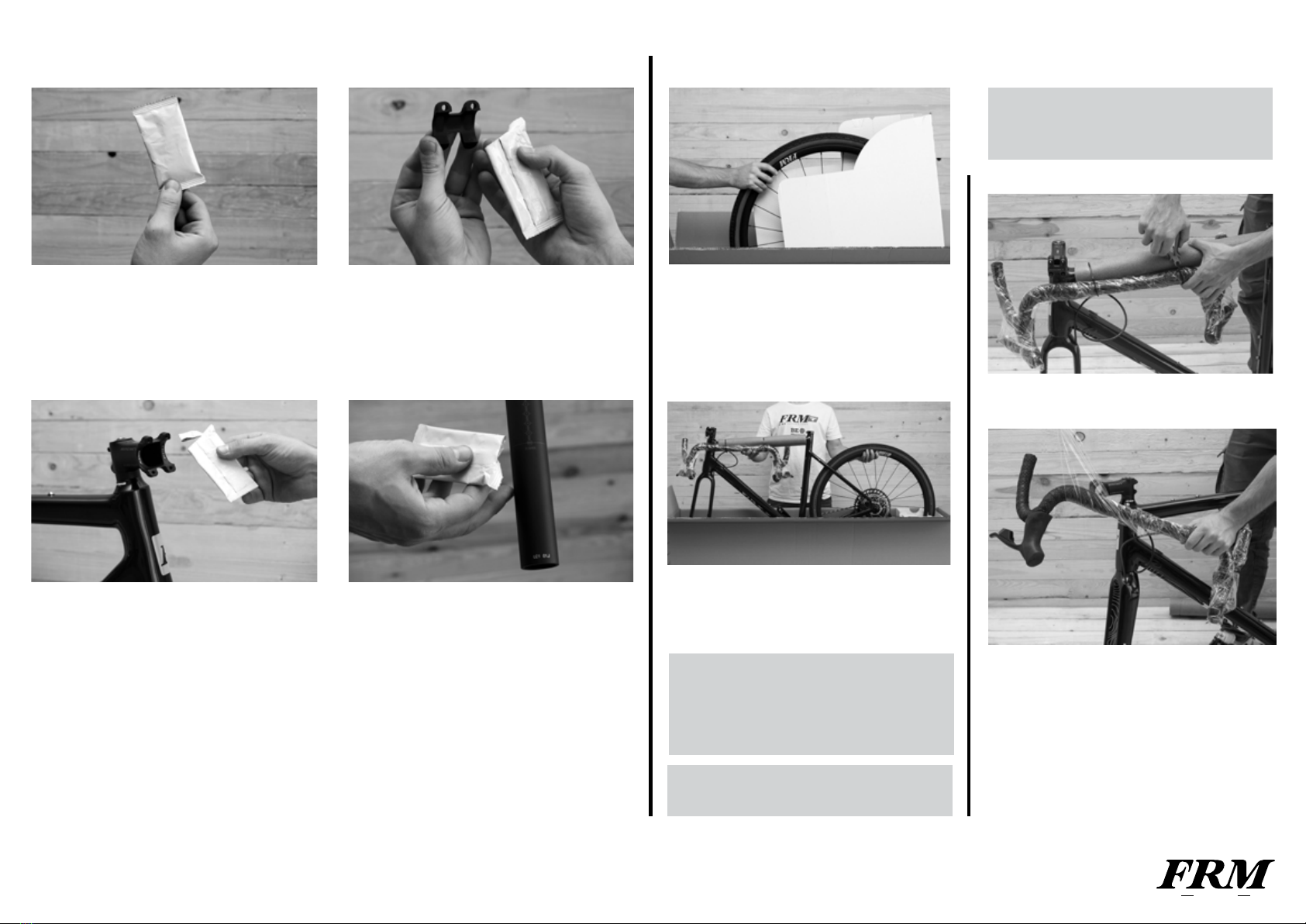

USING THE FRM ASSEMBLY PASTE

Carbon fibre components are particularly

vulnerable to damage caused by exces-

sive clamping force. FRM assembly paste

creates extra friction between two surfac-

es, allowing the necessary torque value to

be reduced by up to 30 %.

This is especially useful in the clamping

areas of handlebars and stem, steerer

tube and stem and seat post and stem,

i.e. three areas where too much clamping

force can damage either component,

causing component failure or voiding the

warranty. By reducing the clamping force,

FRM assembly paste relieves stress on

sensitive carbon surfaces, preventing

damage to fibres or the cracking of the

carbon substructure.

It also retains its effectiveness in wet con-

ditions and provides maximum protection

against corrosion. FRM assembly paste

can be used for all carbon and aluminium

connections. It’s ideal for this purpose, as

it does not harden.

Prior to applying FRM assembly paste,

remove dirt particles and lubricant

residues from the surfaces to be treated.

Apply a thin and even film of FRM assem-

bly paste to the cleaned surfaces using a

brush or a chamois. Mount the compo-

nents, as specified. Use a torque wrench

and never exceed the prescribed maxi-

mum tightening torque! Remove exces-

sive FRM assembly paste and reseal the

small sachet after use.

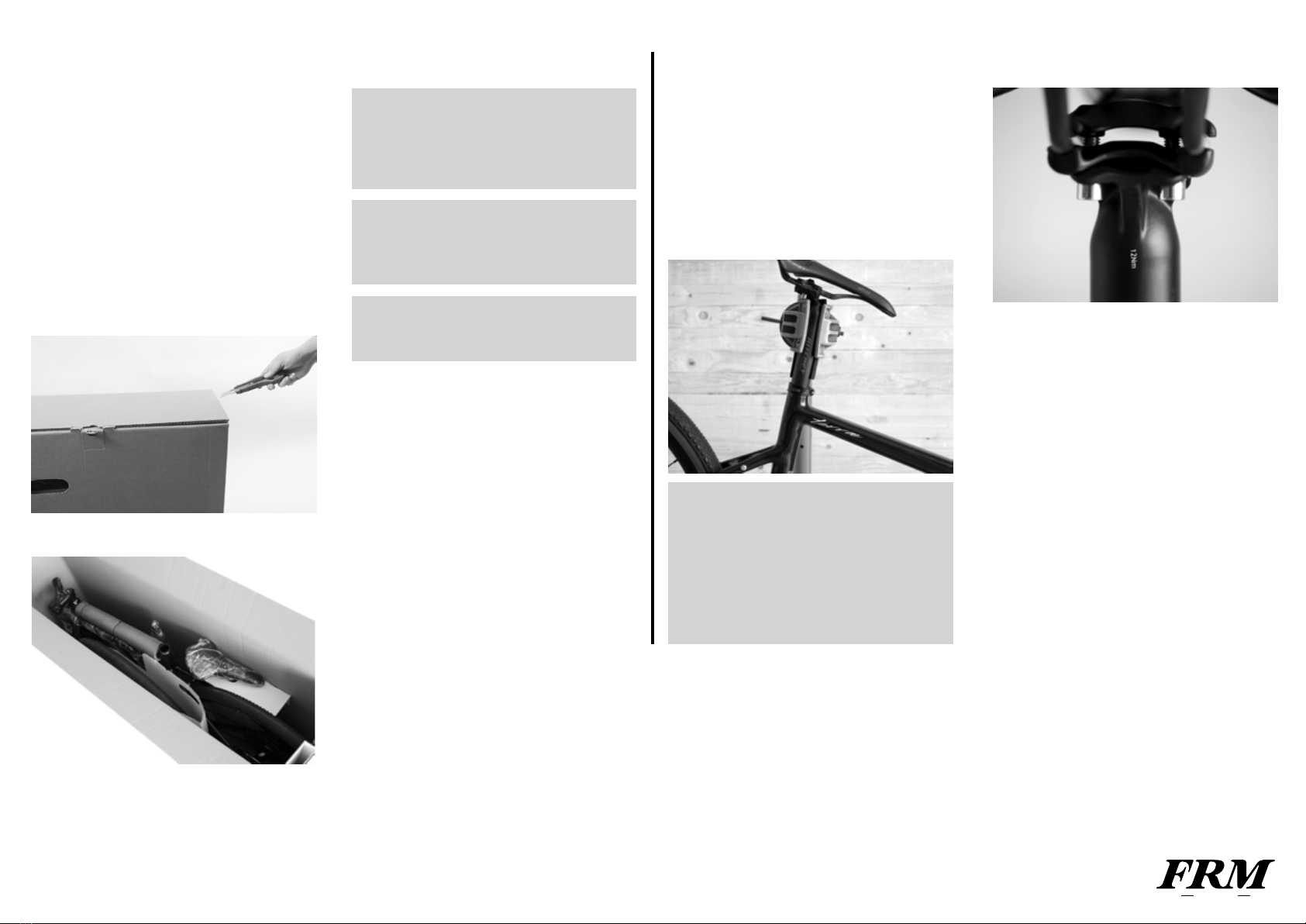

Remove the protective cardboard at one

end.

Take out the cardboard box with the front

wheel stowed in parallel to the bike frame

in the box.

Lift the frame including add-on parts and

rear wheel carefully off the bike box and

make sure it stands safe. Ask your helper,

if necessary, to hold the bike.

MOUNTING THE HANDLEBARS

Keep hold of the handlebars to prevent

any twisting, dropping and damage.

RIDEIN STYLE

Keep the entire packaging material

as well as the cardboard box in a dry

place. If you intend to ship your FRM

or to take it with you on a trip, you will

have everything at hand.

You will not find the wheels packed in

wheel bags in every bike box

Hold the handlebars tightly while lifting

the frame out so that they are not twist-

ed, cannot drop and get damaged.

Remove the protective film and sleeves

from the handlebars. It is recommended

that you remove the protective material in

general by hand. If that is not possible, it is

best to use scissors, and if it is really

necessary, use a box cutter.

Let the handlebars carefully hang down.

UNPACKING