5

EN

Contents

Safety rules ................................................................................................................................................ 7

General ................................................................................................................................................. 7

Proper use ............................................................................................................................................ 7

Environmental conditions...................................................................................................................... 7

Obligations of the operator.................................................................................................................... 8

Obligations of personnel ....................................................................................................................... 8

Mains connection .................................................................................................................................. 8

Protecting yourself and others .............................................................................................................. 8

Noise emission values .......................................................................................................................... 9

Danger from toxic gases and vapours .................................................................................................. 9

Danger from flying sparks ..................................................................................................................... 10

Risks from mains current and welding current...................................................................................... 10

Meandering welding currents................................................................................................................ 11

EMC Device Classifications .................................................................................................................. 12

EMC measures ..................................................................................................................................... 12

EMF measures...................................................................................................................................... 12

Specific hazards.................................................................................................................................... 13

Factors affecting welding results........................................................................................................... 14

Danger from shielding gas cylinders..................................................................................................... 14

Danger from escaping shielding gas..................................................................................................... 14

Safety measures at the installation location and during transport ........................................................ 15

Safety measures in normal operation ................................................................................................... 15

Commissioning, maintenance and repair.............................................................................................. 16

Safety inspection................................................................................................................................... 16

Disposal ................................................................................................................................................ 16

Safety symbols...................................................................................................................................... 17

Data protection...................................................................................................................................... 17

Copyright............................................................................................................................................... 17

General ...................................................................................................................................................... 18

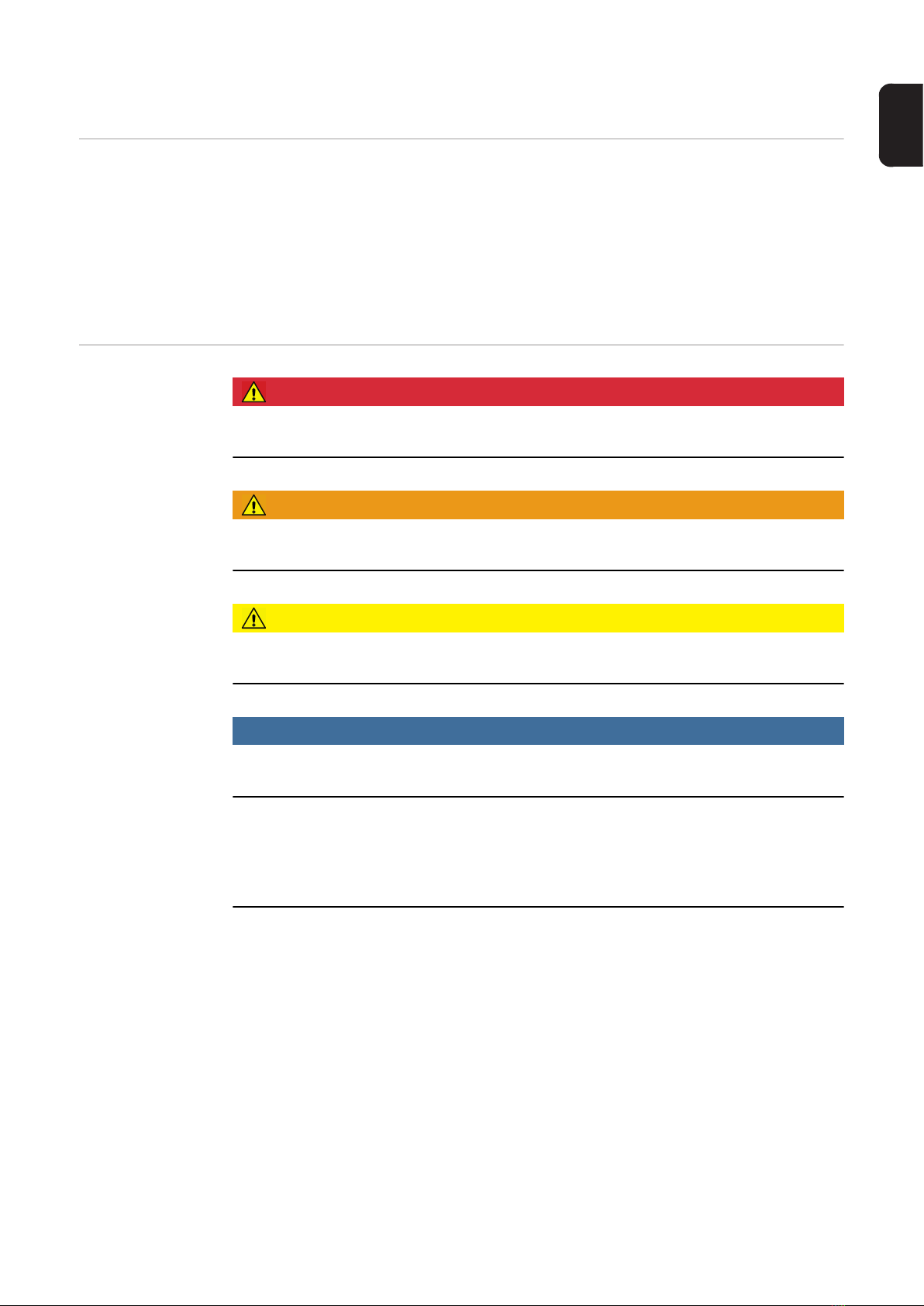

Device concept ..................................................................................................................................... 18

Scope of supply .................................................................................................................................... 18

Validity of "General Delivery and Payment Conditions"........................................................................ 18

Information about the coolant ............................................................................................................... 18

Warning notices on the device.............................................................................................................. 19

Application areas ....................................................................................................................................... 20

FK 4000 ................................................................................................................................................ 20

FK 4000 R, FK 4000 Rob, FK 4000 R FC, FK 4000 R US ................................................................... 20

Options....................................................................................................................................................... 21

FK 4000 auto-transformer..................................................................................................................... 21

FK 4000 R flow sensor with coolant filter.............................................................................................. 21

Thermostat............................................................................................................................................ 21

Coolant filter.......................................................................................................................................... 22

Control elements and connections............................................................................................................. 23

Safety.................................................................................................................................................... 23

Control elements and connections........................................................................................................ 23

Before installation and commissioning....................................................................................................... 24

Safety.................................................................................................................................................... 24

Setup regulations .................................................................................................................................. 24

Information about the coolant ............................................................................................................... 25

Guarantee provisions regarding the coolant pump ............................................................................... 25

Proper use ............................................................................................................................................ 25

Fitting coolant connections to the front of the unit ..................................................................................... 26

Safety.................................................................................................................................................... 26

General ................................................................................................................................................. 26

Fitting coolant connections to the front of the unit ................................................................................ 26

Adapting the cooling unit to the respective mains voltage ......................................................................... 28

Safety.................................................................................................................................................... 28

General ................................................................................................................................................. 28

Possible mains voltages for FK 4000, FK 4000 R, FK 4000 Rob and FK 4000 R FC .......................... 29

Possible mains voltages for FK 4000 R US .......................................................................................... 29