FSI DAT Series User manual

INSTRUCTION MANUAL

FSI® DAT® SERIES SHELTERS/SHOWERS

& “QE SERIES”® SHELTERS/SHOWERS

ALL FSI® DAT® & “QE SERIES”®

SHOWERS ARE ANSI # 113

COMPLIANT

311 Abbe Road. Sheffield Lake, Ohio 44054

Phone: 440-949-2400

Fax: 440-949-2900

See us on the web at www.fsinorth.com

12/12/19

IN ACCORDANCE WITH NFPA 1851

ALL FSI SHOWERS ARE IDEAL FOR

FIRE FIGHTER WASH DOWN/DECON

IMMEDIATELY AFTER EXITING

FIRE SCENE AND PRIOR TO

REMOVAL OF ANY PPE.

SERVICE TO THE LIFE SAFETY INDUSTRY WORLDWIDE SINCE 1997

2

FSI® DECON SHOWERS AND SHELTERS

OPERATION / MAINTENANCE MANUAL

PLEASE READ THIS INSTRUCTION MANUAL CAREFULLY

BEFORE ASSEMBLING YOUR FSI DECON SHOWER/SHELTER

CONTENTS

INTRODUCTION …...……………………………….…………………………..……3

SAFETY INSTRUCTIONS……………………………………….………………......4

PRINCIPLES OF OPERATION………………………………………………..…….6

FSI SHOWER/SHELTER PACKING LIST & DIAGRAMS……………………......7

UNPACKING FSI SHOWER/SHELTERS…………………………………….…….8

INFLATING FSI SHOWER/SHELTERS – MAKE READY FOR USE……….…..8

OPERATION FSI SHOWER/SHELTERS………………………………………......9

STOWING FSI SHOWER/SHELTERS AFTER USE…………………………..…10

STORAGE & MAINTENANCE………………………………………….…….…11-12

TROUBLESHOOTING………………………………………………….………..12-14

TECHNICAL SPECIFICATIONS……………………………………….………..15-18

DAT®QE® GENERAL SPECIFICATIONS……………………………..…………..19

DAT®QE® SELTER SET-UP INSTRUCTIONS………………...…….……… 31-33

SHELTER/SHOWER ADDITIONAL OPTIONS……………………….………..34-35

DAT®QE® SHOWER SET-UP INSTRUCTIONS……………………………...36-38

WARRANTY…………………………………………………………….……………..39

3

INTRODUCTION

Thank you for purchasing the FSI® DAT® series portable inflatable/framed shelter/shower unit. They have

been designed for rapid deployment and ease of use in emergency situations, offering a top quality multi

use compact inflatable structure. FSI® showers/shelters are offered as complete -SYS Systems, with

multiple optional items available from FSI including HVAC, water heaters and cooling systems, elevation

grids, bladder tanks, waste pumps, air filtration units, lights, conveyors, backboards, etc. FSI® products

provide reliable operation in demanding conditions and situations when used and maintained correctly.

Important Notes

This operation manual should be thoroughly reviewed and understood prior to initial use of the unit.

If you are new to FSI® Shelters/Decon Showers, for your own comfort and safety, we strongly recommend

you obtain handling and operation experience before assuming command of the unit. Your FSI® authorized

distributor will be pleased to advise and assist you.

PLEASE KEEP THIS MANUAL IN A SECURE PLACE AND KEEP IT WITH THE UNIT PERMANENTLY.

If there are any questions or concerns, please contact FSI® prior to operation.

Please note FSI® cannot be held responsible for any damage and/or equipment malfunction, resulting from

the lack of reviewing and following instruction manual instructions, and/or from lack /absence of proper care

and maintenance.

FSI® operates a policy of continual product development, and as such both the product and this manual

may be subject to technical alterations without notice.

This manual should be made available to the operating personnel for reference purposes in the event of an

operating/technical query.

On scene coordinators are responsible at all times for the correct and proper use, movement, carry/lift

weight per person, cleaning & use in various dangerous environments. FSI® merely supplies set-up, care,

use & maintenance guidelines.

The DAT® Series Inflatable structures get their form, strength and stability by means of inflation with air.

The tent is designed as a temporary shower/shelter for multi purpose uses.

ATTENTION: This warning symbol appears in the operating manual next

to operating and safety instructions dealing with rules, regulations and

instructions for the proper operation of your FSI® unit.

4

SAFETY INSTRUCTIONS

This operation manual should be reviewed and thoroughly

understood prior use of the unit.

FSI Pneumatic showers/shelters require a compressed

air/electric inflator/deflator source to inflate them. Operators

should be familiar with the use of the air source utilized, and

aware of any risks associated with it.

The weight of the FSI units vary dependent on the model

purchased. The units are supplied in a carry sleeve/bag* fitted

with handles to permit two or more people to carry the unit. The

carry sleeve/bag* is not to be dragged-but lifted and carried by

the appropriate number of personnel that on-sight coordinators

may deem appropriate.

When used in a hazmat incident, FSI units may come in contact

with substances ‘hazardous to health’. Should this happen, they

should be thoroughly cleaned to prevent contamination of

personnel and any possible cross contamination of equipment

etc. Operators should be aware of this risk, and wear

appropriate personal protection to avoid coming in contact with

these substances. On scene coordinators must manage and be

completely responsible herein.

ATTENTION: FSI Showers/Shelters (as of 09/01/02) are fitted with an

overpressure valve on the inflatable structure, to prevent the

unit from over-inflating and possibly bursting. This valve is fully

automatic in operation, and must not be blocked or adjusted in

any way. If using compressed air to inflate unit, an operator

must stand by at all times and immediately turn off compressed

air source when the overpressure valve is activated as noted by

the “hissing” sound of escaping air. At all times ensure the high

pressure air fill hose is locked to the supplied O/D ring on the air

berm with the supplied locking wire.

5

TEMPERATURE USE GUIDELINES FOR

PNEUMATIC DAT SERIES SHOWERS AND SHELTERS

Hot air expands and cold air compresses and so the weather

impacts the air berms of your DAT series product in use.

COLD WEATHER USE:

Recommended for use in temperatures to -30 C (-22 F)

Fully inflate to the point of the over pressure valve almost being

activated (if activated cease air fill immediately) if being used in

extreme cold weather since the cold air will actually contract

inside the berms and the air berms may feel slightly ‘soft’ to the

touch.

WARM WEATHER USE:

Recommended for use in temperatures to +40 C (+104 F)

When temperatures during use are to exceed 30 degrees C (86 F)

be aware hot air expands and so manually reduce the air

pressure in the air berms or allow over pressure valves to

activate. As the evening shift arrives in continued use, and air

temperature drops re-inflate the unit as colder air causes

internal air pressure to decrease.

AT THE COMMENCEMENT OF EACH SHIFT FSI STRONGLY

ENCOURAGES AND RECOMMENDS THAT THE AIR PRESSURE

INTERNALLY BE CHECKED AND ADDRESSED AS ABOVE, AND

THAT A COMPLETE SYSTEMS CHECK OCCUR ON ALL ITEMS IN

USE WITH THE DAT SERIES SHOWER OR SHELTER SYSTEM.

When removing FSI showers/shelters from the carry sleeve/bag,

ensure there are no sharp objects or glass on the floor that might

tear or puncture the inflatable structure. Avoid dragging the unit

over rough surfaces. The use of a tarp/groundsheet is strongly

recommended for inexpensive protection and maximum

longevity of the floor and berms.

ATTENTION:

ATTENTION:

6

PRINCIPLES OF OPERATION

FSI® Pneumatic showers/shelters are inflated via the use of a compressed air source/electric inflator/deflator

and inflation time is approximately 45 seconds to 5+ minutes (size of unit dependent).

Over-inflation of the structure is designed to be prevented via the inclusion of a pressure relief valve fitted to

the unit. If using compressed air to inflate unit, an operator must stand by at all times and immediately

turn off compressed air source when the overpressure valve is activated as noted by the “hissing”

sound of escaping air. At all times ensure the high pressure air fill hose is locked to the supplied O/D

ring on the air berm with the supplied locking wire.

The structure has reinforced air inflated berms and is usually fitted with two external zipped doors, the first is

the entrance door, and the second is the exit door at the other end as determined by on-scene coordinators.

To deflate the unit an inflation/deflation valve is so equipped to release the air in the structure via a quarter

turn ‘push in’ stem, allowing the FSI® shower/shelter to deflate. Use the supplied inflator/deflator to ’suck’ all

air out of the unit until flat to the naked eye. The unit can then be carefully folded, as it was received, and

packed into the carry sleeve/bag supplied for safe transportation and storage.

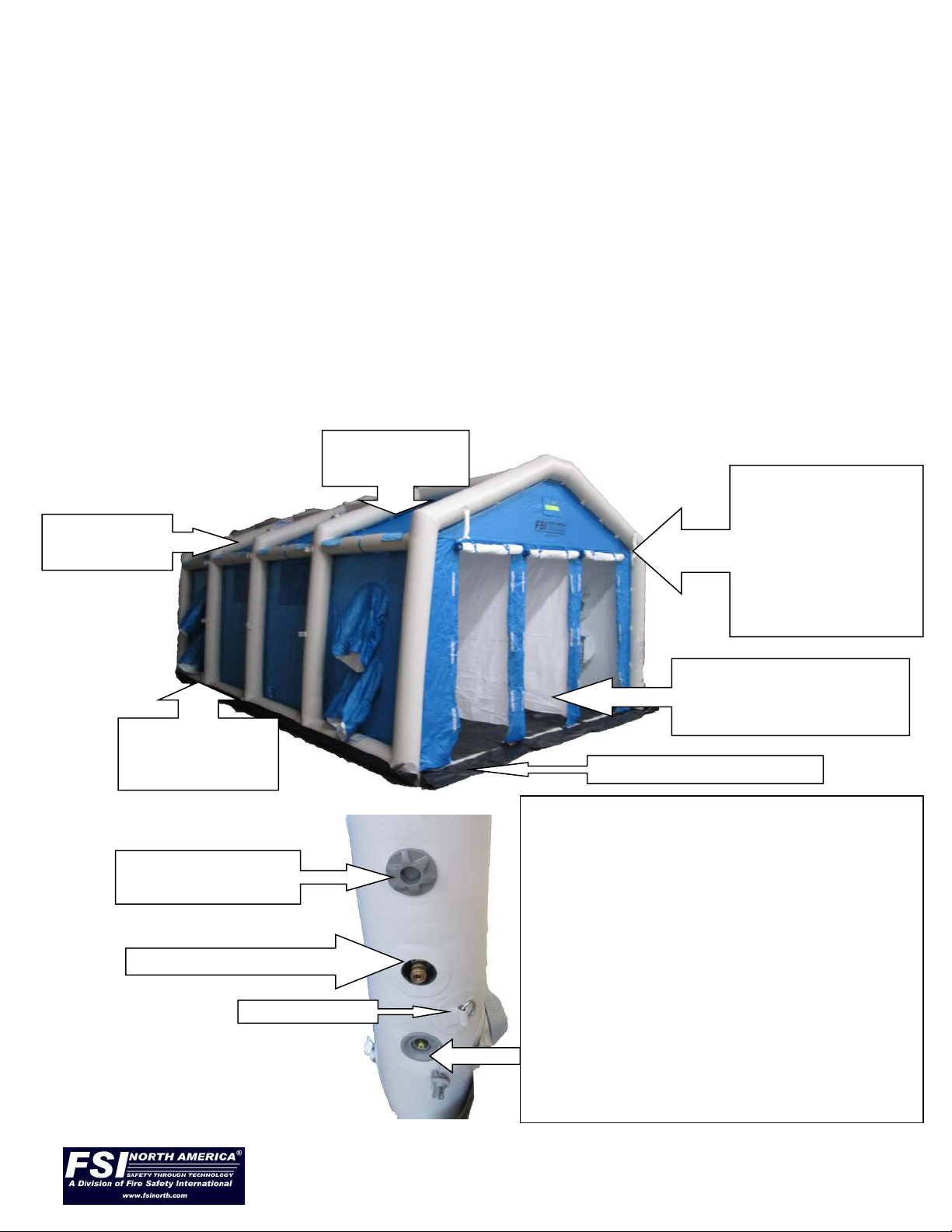

REMOVABLE

CANOPY

TIE DOWN ROPES AT

EACH CORNER TO

TIE FSI® SHELTER

OFF TO FIXED ITEMS

SUCH AS VEHICLES/

FENCES/POSTS/

POLES/OTHER IN

STRONG WINDS

DIRTY ENTRANCE DOOR

(CLEAN EXIT DOOR FROM

SHOWER AT OTHER END)

BUILT IN GROUNDSHEET

ATTACHED YET

REMOVABLE

FLOOR

INFLATABLE

STRUCTURE

FSI SHOWER/SHELTER DIAGRAMS

AIR BOTTLE INLET

ELECTRIC INFLATOR / DEFLATOR

INLET AND DUMP VALVE

INFLATION: Push in and quarter turn clockwise to lock

valve open. When unit fully inflated push in and quarter

turn counter clockwise to allow valve to pop up and

close. Your shower/shelter is now ready for use.

DEFLATION: To deflate, push in and quarter turn

clockwise to lock valve open. Air will rush out and unit

will begin to deflate. Ensure the tie down ropes are used

to assist the unit in returning to the ground by pulling

them toward each other allowing the unit to collapse into

its’ own footprint. Use the deflation end of the electric

inflator/deflator to ‘such’ the remaining air out of the

unit until flat to the naked eye. Then push in and quarter

turn counter clockwise to allow valve to pop up and

close.

SAFETY OVER

PRESSURE VALVE

O/D RING

7

FSI® SHOWER/SHELTER PACKING LIST

FSI showers/shelters consist of the following items:

Showers/Shelters

in carry sleeve/bag

High Pressure Air inlet

hose and SCBA fitting

to fit all known scba air

cylinders and repair

material swatches

Full instructions for use, repair kit,

stakes, tie down ropes, inflator/deflator

(size depends on size of unit), and ham-

mer.

FSI® SHOWERS/SHELTERS

FSI showers/shelters are offered with multiple optional items with

a few examples as below:

Air Heaters

(F-ZHAF and

F-ZHAFD)

Waste Water

Pump

(F-WSP33AA)

Elevation

Grid

(F-TDMSPC)

Conveyor Systems

(F-RS shown)

Detergent Injection

System

(FSI HEAT 201)

Hand Sprayer

(F-HSP)

Water Heater

(FSI Heat 200A)

F-GH (50’) HOSES

F-GH35 F-GH503510

F-GH25 F-GH5025

F-GH10

F-MX1

(Spine Board/

Transfer Board)

HVAC

(F-DI35HP0100CM)

Manifolds

(F-MMU153,

F-MMU253,

F-MMU156,

F-MMU256) Stringable Lights

F-125-0500-STL

Heavy Duty Bladder Tanks

(F-HD150BT,

F-HD300BT,

F-HD600BT)

Ground Tarps

Asst. sizes

Water Heater

(F-ECC150WH)

8

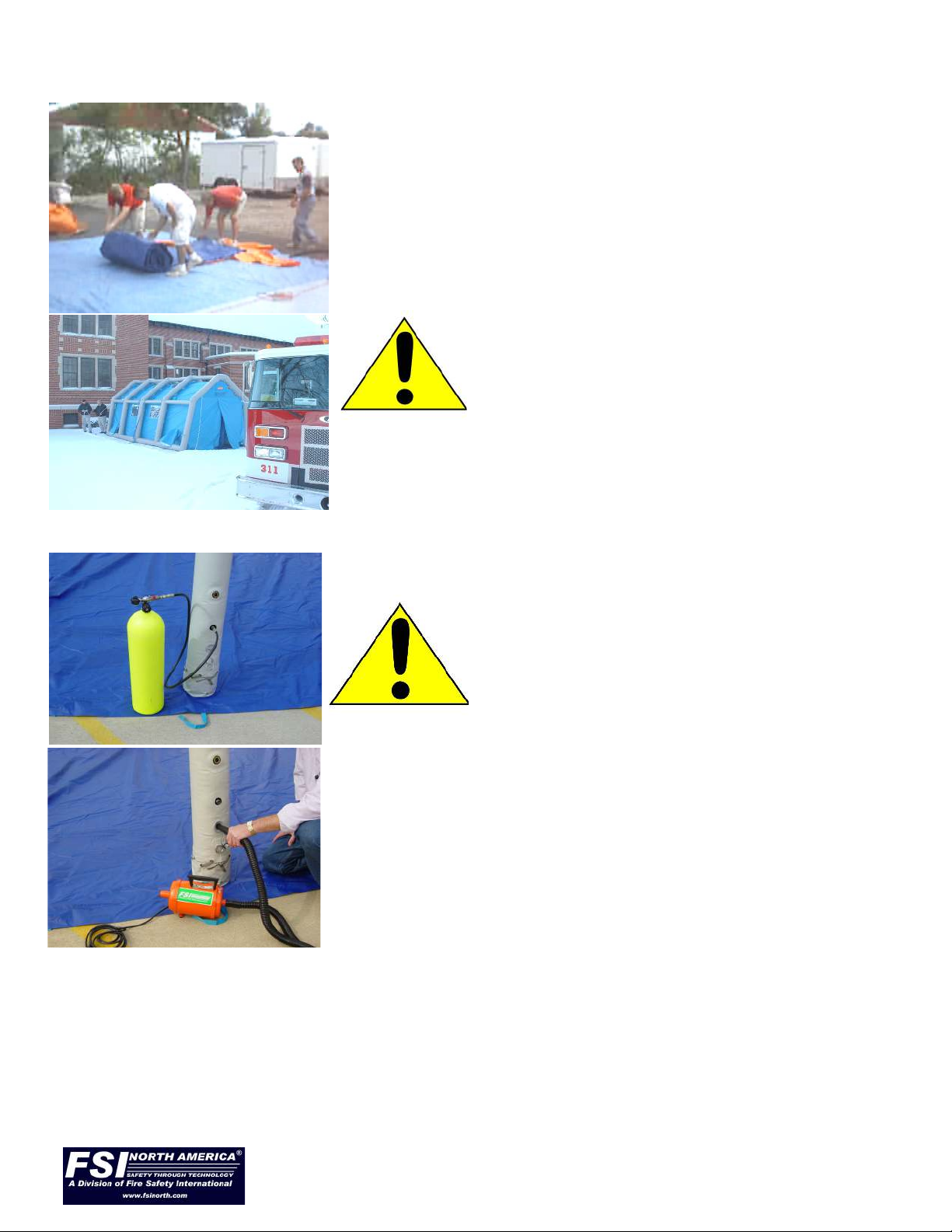

UNPACKING FSI® SHOWERS/SHELTERS

To unpack FSI® shower/shelter and if a pneumatic unit, make ready for inflation

Undo carry bag/sleeve and remove unit. If no groundsheet

or tarp is readily available, the carry sleeve/bag fully

flattened out can be used as a partial emergency

groundsheet to protect the shower/shelter.

Ensure surface is flat and free of sharp objects, place

groundsheet / tarp on ground (FSI® offers as an option),

then unroll FSI® unit either onto groundsheet or onto

ground carefully.

NOTE! LIFT - Do not drag on ground!

Place FSI® unit to suit all site and incident requirements,

ensuring entry/exit doors are aligned in right direction.

On-scene coordinator must make these decisions.

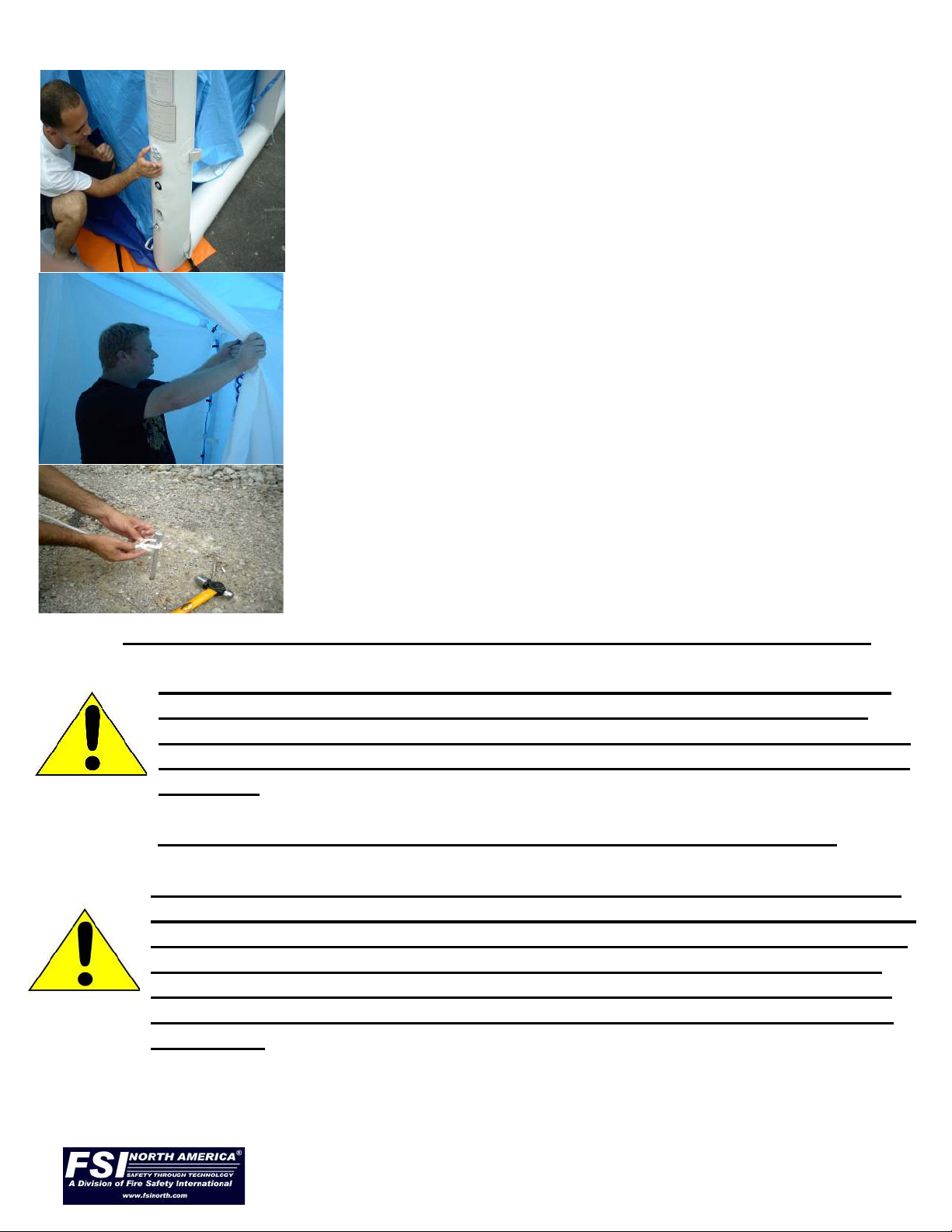

INFLATING FSI® SHOWERS/SHELTERS FOR USE

Follow all instructions located above the fill

valves on every unit EXACTLY.

If using an SCBA cylinder and the

supplied black color high pressure fill

hose with locking clip and fitting please

review those instructions carefully and

follow them exactly.

Follow all instructions located above the fill valves on every

unit EXACTLY.

If using the supplied inflator deflator use in the manner as

shown herein following all instructions located on the berms

of the unit.

Allow a steady, clean flow of air to inflate the unit. It will take approx. 45 seconds to 5+

minutes to inflate the unit (size of unit dependent) from an SCBA cylinder, and slightly

longer if using a compressor or the electric inflator/deflator. Remove/disconnect inflat-

or/deflator once unit is fully inflated.

NOTE! Support roof of FSI shelter as it inflates! (help unit stand) . In deflation mode en-

sure the tie down ropes are used to assist the unit in returning to the ground by pulling

them toward each other allowing the unit to collapse into its’ own footprint.

9

With on-scene coordinator oversight, carefully attach hose

to scba/dive air cylinder and lock hose to air berm D ring

using supplied locking clip. Then turn on cylinder air VERY

slowly. Then inflate unit until overpressure valve

operates - indicated by sound of escaping air (escaping air

can also be easily felt by hand. IMMEDIATELY turn off

compressed air supply. The overpressure valve will close

automatically when excess air has escaped from unit.

NOTE! Never cover/block the overpressure valve, as

the unit may become over pressurized and fail.

Make the following final checks:

Check that the unit is upright, that all valves are closed,

and no leaking is occurring. If, in the unlikely event a leak

is discovered, deflate unit and repair before using. (See

instructions for notes on how to repair punctures.)

In the event of/in case of windy conditions, always tie

off unit to the ground using supplied tie down ropes

and stakes, and/or lash to solid objects (e.g., vehicles).

OPERATING FSI UNIT - WATER INLET PRESSURE GUIDELINES

FSI Shower systems have all been designed to handle a maximum

incoming water pressure of approx. 55 psi (3.6 Bar). If the water

pressure coming into the FSI shower unit is unknown or will exceed

55 psi – FSI requires the use of a water pressure reducer – available

from FSI.

** INLET WATER PRESSURES in FSI Decon Shower Systems:

Each and every section of spray nozzle heads and multiple function

trigger guns is equipped with a shut off valve and a quick disconnect

feature. If you find the inlet water pressure is not capable of feeding

all water outlets with sufficient water pressure to provide a proper

shower – then shut off all shower heads not currently being used .

This will best ensure maximum water pressure is available where it

is needed.

INFLATION USING HIGH PRESSURE COMPRESSED AIR:

FSI® DAT® AND DAT® ‘QE SERIES’® DECON SHOWERS ARE ANSI 113 COMPLIANT.

10

FSI units have been designed for use by personnel with some knowledge or training in

decontamination procedures. On-scene coordinators must always determine correct use.

Proceed as follows:

Unzip / separate velcro closure doors at the entrance to the unit. The entrance is normally

the location nearest to the inflation/overpressure valves but this must be as determined by

on-scene coordinator.

At night, the relatively translucent construction and reflective striping above the doors and on

the berms of the FSI unit will allow light from external sources to illuminate the interior and

clearly show the entry and exit points.

STOWING FSI® SHOWER/SHELTERS:

If using Accessories such as air/water heaters/ decon

showers, disconnect and remove all showers, heating , air

cooling units, lights, elevation grids, and so forth from inside

the shower/shelter or in close proximity to.

Wipe up any residual water inside the unit, and make sure

interior is completely dry.

To deflate unit, make sure the entrance and exit doors are

unzipped and rolled up.

Ideally place one person or more at each end of FSI shelter;

then open the deflation/dump valve.

The FSI shower/shelter will rapidly deflate (usually within 1

minute or so). As the unit collapses, each person should pull

inwards on the end pillars, so the roof collapses neatly

on top of the lower part of the unit.

Ideally fold the shower/shelter back up exactly as received.

Failing that, fold the shower/shelter in three or more sections

starting at the end furthest from the deflation/dump valve.

This will further squeeze air from the unit.

HINT: It is best to use the supplied electric/inflator/deflator to

fully remove air from the unit, but not essential.

Place the carry bag/sleeve over the top of the folded unit,

then roll the unit over so the bag/sleeve is now the right side

up. Alternately fold the unit so the final melon roll fold places

the unit largely in the fully laid out carry bag/sleeve. Center

unit in carry bag/sleeve and pull/cinch straps tightly.

The FSI unit is now ready for transport and storage.

This manual suits for next models

22

Table of contents

Other FSI Shelter manuals

Popular Shelter manuals by other brands

Storage Canopy

Storage Canopy C3340R Assembly instructions

Frabill

Frabill ICE HUNTER 195 instruction manual

Shelters4Less

Shelters4Less SR1588 Assembly instructions

Sealey

Sealey Power Products GSS150819SD instructions

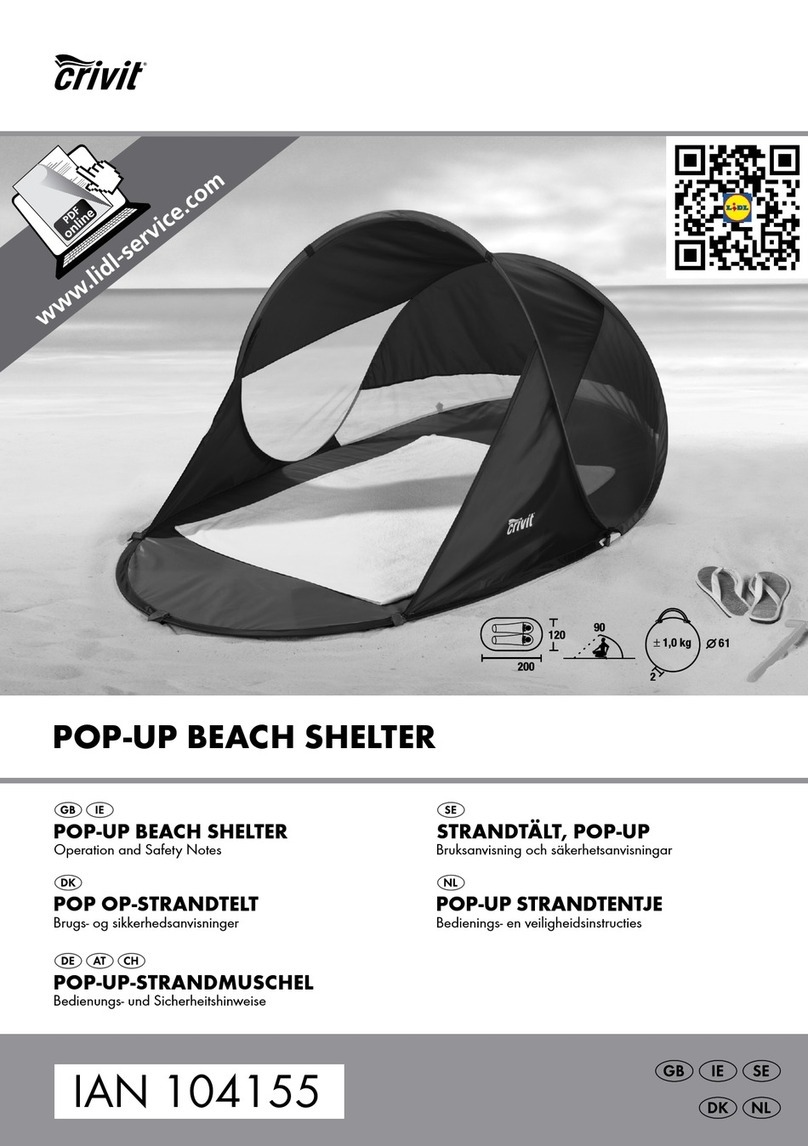

Crivit

Crivit 104155 Operation and safety notes

No Butts Bin

No Butts Bin SR1558-F Assembly instructions