Esu LokSound 5 DCC User manual

LokSound 5 DCC

Instruction manual

GHB «DD-1»

P/N 99440

2

1. Introduction.............................................................. 3

1.1. Properties of the decoder..............................................3

2. Initial operation ....................................................... 4

2.1. Function mapping.........................................................4

2.2. Using your LokSound decoder under DCC ....................4

2.5. Analogue operation ......................................................4

3. Decoder settings ...................................................... 5

3.1. Basics of DCC programming .........................................5

3.1.1. Configuration Variables (CV)......................................5

3.1.2. Standardization in the NMRA.....................................5

3.1.3. Bits and Bytes ............................................................5

3.1.4. Programming methods ..............................................5

3.1.4.1. Programming on The Main .....................................6

3.1.4.2. Service Mode Programming ....................................6

3.1.5. Programming procedure using various DCC systems..6

3.1.6. Programming with the ESU LokProgrammer ..............6

3.4. Setting up your LokSound.............................................6

3.4.1. Address Settings ........................................................6

3.4.1.1. Primary Address .....................................................6

3.4.1.2. Extended Address ...................................................7

3.4.2. Configuring the decoders behaviour..........................7

3.4.2.1. Acceleration / Deceleration .....................................7

3.4.2.2. Starting voltage, VMax............................................7

3.4.2.3. Shunting mode.......................................................7

3.4.2.4. Analogue mode......................................................7

3.4.3. Brake sectors .............................................................7

3.4.3.1. DC Brake Mode ......................................................8

3.4.3.3. Lenz® ABC Brake Mode .........................................8

3.3.4. Adjust the sound volume ...........................................8

Contents

4. Decoder Reset .......................................................... 8

5. Appendix .................................................................. 9

5.1. Programming Long Addresses.......................................9

5.1.1. Write address.............................................................9

5.1.2. Read out addess ........................................................9

6. Support and Assistance......................................... 15

Copyright 1998 - 2020 by ESU electronic solutions ulm GmbH & Co KG. Electri-

cal characteristics and dimensions are subject to change without prior notice.

All rights reserved. ESU might not be held responsible for any damage or conse-

quential loss or damage chaused by inappropriate use of the product, abnormal

operating conditions, unauthorized modifications to the products etc...

Not suitable for children under 14 years of age. Inappropriate use may result in

injury due to sharp points and edges.

Märklin® and mfx® is a registered trademark of the company Gebr. Märklin®

and Cie. GmbH, Göppingen, Germany. RailCom is a registered trademark of the

company Lenz Elektronik GmbH, Giessen, Germany.

All the other trade marks are owned by their respective right holders.

ESU electronic solutions ulm GmbH & Co. KG continues to develop the products

according to the company´s politics. Therefore, ESU reserves the right to carry out

changes and improvements on the products listed in this manual at any time and

without any advanced note.

Duplications and reproductions of this documentation are strictly forbidden and

need to be allowed by ESU in writing.

3

Introduction

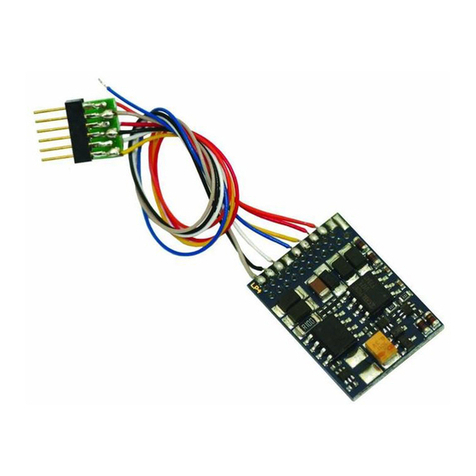

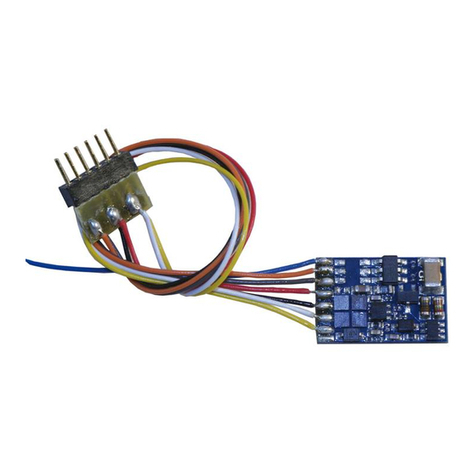

1.1. Properties of the decoder

The “DD-1” can be operated straight out of the box. The appro-

priate operating mode is selected automatically. You do not have

to change any parameters.

Track voltage 47 Volts maximum

Operating modes DCC, DC

Steady state motor current 1,5A

Function output current 0,25A each

Number of function outputs 10 + 3 Logic outputs

Total current of function outputs 0.5A

Audio amplifier 2W@ 4Ohms load

Speaker impedance 4– 8 Ohms

Memory capacity 128 MBit

Number of sound channels 10

Dimensions 30.0mmx 15.5mm x 4.5mm

1. Introduction

The LokSound 5 DCC decoder by ESU is a versatile digital decoder

integrating a full-featured, 10 channel sound system, various

lighting outputs and a 1.5A motor controller. This key component

of your newly acquired “DD-1” is responsible for all functions,

such as motor control, control of all lighting functions and all

sound and special sound functions.

The decoder supports DCC with RailComPlus. It can also be used

on analogue DC systems.

The “DD-1” is preset at the factory for immediate operation. Nev-

ertheless, we kindly ask you to first read these instructions before

you set this locomotive onto a powered track.

Important warnings:

• This LokSound decoder is designed for use in GHB “DD-1”only.

• Do not expose to wet and humid conditions.

• Do not remove the heat shrink sleeve on the decoder.

• Always disconnect the circuit when installing the decoder.

Please install the body shell before applying voltage.

• To avoid risk of short circuit, ensure that opens ends of wires do

not come into contact with any metal parts of the Locomotive!

• Make sure that no wires are squeezed or cut by the model’s

transmission parts when reassembling the locomotive.

• Handle the speaker with extreme care: Do not touch the mem-

brane or apply pressure!

2. Initial operation

4

The default address assigned to the LokSound decoder is 3. Sim-

ply set your controller to this locomotive number and place it on

the mainline. If everything is set up properly, the “DD-1” should

react as shown on the table 2.1. If you use a DCC system which

supports RailComPlus®, it will most likely ask you to change the

locomotive address. All function button icons will be displayed

correctly after the assignment of the new address.

2.5. Analogue operation

“DD-1” can be used conventionally (=analogue) on DC or AC

layouts. However, the number of the available functions is highly

restriced:

• Driving functions forward – backward – backward

• Light changes

• Motor sounds (automatically)

For analogue operation you can use any DC power supplies. Please

note that a trouble-free operation with electronic driving control

devices (PMW operation) is not guaranteed due to the huge vari-

ety of systems available on the market.

3. Decoder settings

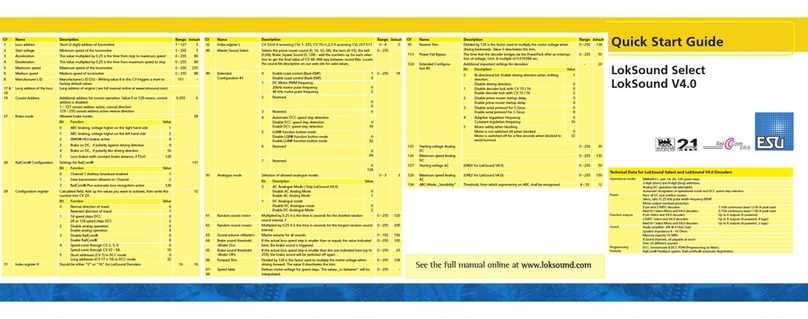

The table starting on page 10 covers setting of the most impor-

Initial operation

2.1. Function mapping

Button Function

F0 Directional Headlights

F1 Bell

F2 Selectable Whistles (CV163 = Value 0-2)

F3 Coupler sounds

F6 Volume Control

F8 Sound on/off

F10 Independent Brake

F14 Wabco Electric «whoop»

F17 Automatic Brake Set/Release Off

F21 Air Horn

2.2. Using your LokSound decoder under DCC

The default address for DCC operation is “03”.

5

tant parameters of the LokSound decoder. A full list of CVs can

be found in the respective manual available for download on our

website www.esu.eu

3.1. Basics of DCC programming

The hardware determines some features such as the number of

function outputs as well as the maximum permitted current of

the motor output. Therefore they are not programmable. Never-

theless, there are plenty of possibilities to influence the behaviour

of the LokSound decoder by adjusting the software-governed

properties. Within the decoder there is at least one memory space

reserved for each adjustable parameter in which numbers or let-

ters can be stored.

You could visualise the storage spaces as index cards in a large file

box. In order to make sure you find the right card again, they all

have numbers and / or names outlining the properties of this par-

ticular card such as “locomotive address“ or “maximum speed“.

Just imagine you can write information onto these cards. Adjust-

ing the settings means nothing else but erasing one entry and

replacing it with another. Moreover, you are able to do that at any

time. However, you cannot write onto every card: some bits of

information such as the manufacturer’s code are firmly encoded.

Thus, you can determine the content of the storage spaces in the

decoder even during operation and, of course, the decoder will

follow the instructions. Via the procedure known as “Program-

ming“, you can enter the desired data into the storage spaces.

3.1.1. Configuration Variables (CV)

The LokSound decoders follow the CV concept developed in the

US. CV stands for “Configuration Variable“ and indicates that the

storage cells described above are not only variable but they also

determine the behaviour of the decoder.

3.1.2. Standardization in the NMRA

The NMRA (National Model Railroad Association) has defined

which CVs determine certain parameters of a decoder. The DCC

standard allocates fixed numbers for certain CVs (adherence is

obligatory). This greatly simplifies things for the user since decod-

ers of most manufacturers comply with this standard and there-

fore dealing with CVs requires the same process with the same

CV-numbers regardless of the manufacturer.

The DCC concept permits you to enter numbers ranging from 0 to

255 into CVs. Each CV carries only one number.

While the position number is predetermined, the range of values

may vary. Not all CVs must accept values ranging from 0 to 255.

The permitted values for LokSound decoders are listed in the table

starting on page 10, showing the most important available CVs.

3.1.3. Bits and Bytes

Most CVs contain numbers: CV 1 for instance contains the lo-

comotive address. This can be any number between 1 and 127.

While most CVs expect numbers to be entered, some others are

rather like a “collection point“ of various “switches“, that admin-

ister different functions in one CV (mainly “on“ or “off): CVs 29

and 49 are good examples: you must calculate the value for these

CVs yourself. The value depends on which settings you want to

program:

Have a look at the explanations for CV 29 in the table on page 11:

firstly, decide which options should be active. The column “Value“

has two numbers for each option. If the option is switched off,

the value is 0. Otherwise, it is a number between 1 and 128. Add

all the values for the respective options to arrive at the correct

value for this CV.

3.1.4. Programming methods

LokSound decoders support all NMRA programming modes as

there are the programming track modes (Direct Mode, Register

Mode, Paged Mode) and the mode for the main (“POM“, “Pro-

gramming on the Main“).

3.1.4.1. Programming on The Main

Initial operation Decoder settings

6

Decoder settings

The LokProgrammer 53451 / 53452 offers the easiest and most

comfortable way of setting the CVs of the LokSound decoders

simply by a few mouse clicks.

You can access all properties of ESU decoders with the LokPro-

grammer. You even can erase the sound and download a new

soundpackage. Please see our website for more details.

3.4. Setting up your LokSound

3.4.1. Address Settings

Each LokSound decoder requires a definite address to be address-

able for the central unit. Depending on the type of decoder and

the digital system, there are several possibilities how to allocate

addresses. The LokSound may be setup to listen to either the pri-

mary address (also called “short” address), which provides a range

of 1 to 127 or the extended (“long”) address, which has a range

of up to 9999. Based on your preferences and your command sta-

tion’s capabilities, you may select either the primary address or the

extended address for usage. Be aware that some DCC systems do

not support the full range of available addresses.

Bit 5 in CV 29 switches between short and long address. The de-

coder can only respond to one address at a time. If CV 29, Bit 5 is

cleared, the decoder listens to the primary address stored in CV 1.

If CV 29, Bit 5 is set, the decoder listens to the extended address

stored in CV 17 AND CV 18.

3.4.1.1. Primary Address

Normally you would control LokSound decoders with the short

address that is stored in CV 1. In DCC mode, the permitted values

range from 1 to 127. In order to enable the decoder to “listen“ to

the short address you must delete bit 5 in CV 29.

Some digital systems (e.g.: ROCO® Lokmaus2, Lenz® digital plus,

Lenz compact) only support the values 1 – 99 as short addresses.

3.4.1.2. Extended Address

Programming on the Main (also called “Operations Mode pro-

gramming”) enables you to program your decoders comfortably

without having to remove the locomotive from the layout. In this

case, the command station talks directly to the decoder by using

its locomotive address, for instance:

“Locomotive number 50, write the value 7 into CV 3!“. Thus

knowing the locomotive address is a precondition. Unfortunately,

you cannot read CV values using this mode.

3.1.4.2. Service Mode Programming

This programming mode usually requires the locomotive to be

placed on a special programming track output of the command

station. CV’s can only be read on the service track unless your DCC

command stations supports RailCom®. You can also reprogram

the locomotive address without knowing the old address since the

command station simply transmits the command “Write value 7

in CV 3!“.

Each decoder receiving this command will execute it.

In order to be able to read back the CV values from your decoder,

the motor terminals must be properly connected to the motor. The

motor is used to produce the “feedback” current pulse detected

by the command station.

3.1.5. Programming procedure using various DCC systems

As each DCC system is different, the procedure for changing a CV

will vary depending upon the system. We are very sorry that we

are unable to provide detailed instructions to cover every system

on the market. We need to assume that you are familiar with your

system. Please consult your DCC system manual for detailed speci-

fication. We tested the LokSound with almost every DCC system

available on the market (as of end of 2010), so there should not

be any general problem.

3.1.6. Programming with the ESU LokProgrammer

7

You can also operate LokSound decoders with extended addresses

(4-digit addresses). The supported values range from 128 – 10239.

The extended address is stored in CVs 17 and 18. You must activate

the usage of the extended address by setting bit 5 in CV 29.

If you want to use your LokSound with the extended address it is

practical to program this address directly with your digital system:

most modern digital systems have a menu for programming long

addresses. The command station not only programs CV 29 cor-

rectly but also assures the correct storage of the values for the long

address in CV 17 and 18.

Both the primary and the extended address may be changed at

any time using service mode (on the programming track).

Some DCC systems (such as ESU ECoS, ESU Navigator) will allow

the decoder address to be modified using Programming On The

Main. LokSound will accept the programming commands, but the

following restrictions apply:

•If the decoders primary address is enabled, the decoder will accept

a new primary address and follow this immediately.

•If the decoders primary address is enabled, the decoder will accept

a new secondary address (write of CV 17, 18).

•If the decoders extended address is enabled, the decoder will only

accept a new primary address. You can not change an extended

address to another number using Programming On The Main.

3.4.2. Configuring the decoders behaviour

3.4.2.1. Acceleration / Deceleration

Acceleration and brake time can be set independently of each

other. Therefore, you could for instance program a short accelera-

tion and a much longer brake time. The time for accelerating from

0 to maximum speed is adjusted in CV 3 while deceleration is set

in CV 4. Permitted values are 0 (no delay ) to 63.

The times set in these CVs work speed dependant. Therefore, the

acceleration distance and the brake distance are longer at high

speeds. In other words, the faster the locomotive moves, the lon-

ger is the distance until it stops.

3.4.2.2. Starting voltage, VMax

LokSound decoders know 256 speed steps internally. They can be

adapted to the characteristic of the locomotive and allocated to

the actual available speed steps (14, 28, or 128):

You can adjust the driving characteristics yourself: enter the start

voltage in CV 2 and the maximum speed in CV 5. The values of

the start and maximum speed are dependent on each other.

Selecting a max speed that is lower than the start speed or higher

than the maximum speed could lead to some erratic driving per-

formance.

3.4.2.3. Shunting mode

The shunting mode reduces the speed to about 50%. Thus, you

have smoother control of your locomotive in the lower speed

ranges, which is important for shunting.

3.4.2.4. Analogue mode

The LokSound can also be used on conventional layouts. By de-

fault, this option is enabled. If you don’t want to use the LokSound

on conventional layouts, please disable the analog mode by clear-

ing bit 2 of CV 29. Disabling this mode is useful if you plan to use

some automatic braking modes.

3.4.3. Brake sectors

Brake sectors have the purpose to slow down the locomotive in-

dependently from the commands issued by the command station.

Frequently, this function serves for stopping a train in front of a

red signal. If a LokSound detects a brake command, it will slow

down with the programmed deceleration and then stop. After this

enforced stop, the locomotive will accelerate again as per the pro-

grammed values in CV 3.

Depending on the type of digital system, there are several options

on how to influence the decoder so that it stops the train.

Decoder settings Decoder settings

8

Decoder settings

Before you change any of the volume control CVs, please make

sure that the CV 31 is set to 16 and CV 32 = 1!

The master volume control CV 63 controls all sound effects. The

resulting sound volume for each individual sound effect therefore

is a mixture of the master volume control settings and the indi-

vidual volume control sliders.

4. Decoder Reset

Enter the value 08 in CV 08.

3.4.3.1. DC Brake Mode

In order to activate the DC brake mode you must set bit 3 in CV

27. The decoder will start brake once it moves from a digital sec-

tor into a DC sector provided the brake mode is active and the

polarity of the track voltage does NOT match the current direc-

tion of travel. The locomotive will stop taking into account the

programmed deceleration.

3.4.3.3. Lenz® ABC Brake Mode

LokSound decoder support the ABC braking technique introduced

by Lenz®. In order to use this function a group of anti-parallel

diodes will be be soldered to one half of the track. The resulting

voltage drop generates an asymmetrical DCC signal. LokSound

decoders will detect the difference between the left and right half

of the signal. If desired, the decoder will be stopped.

Please read the hints within the LokSound manual for further in-

formation.

3.3.4. Adjust the sound volume

The LokSound allows the individual volume control of each sound.

Please refer to the following table to see which CV you need to

change:

Function Slot CV Value

Total volume 63 128

Sound on/off 1

6

9

17

259

299

323

387

155

0

128

20

Selectable Whistles 3275 182

Bell 4283 60

Coupler 5291 20

Wabco Electric «whoop» 7307 128

Independent Brake 11 339 0

Air Horn 21 419 90

9

Decoder settings

5. Appendix

5.1. Programming Long Addresses

As described in chapter 3.3.1.2. the long address is split into two

CVs. The byte with the higher value of the address is in CV 17. This

byte determines the range in which the extended address will be

located. For instance, if you enter the value 192 in CV 17 then the

extended address may be between 0 and 255. If 193 is written into

CV 17 then the extended address will be between 256 and 511.

You can continue this up to addresses with values of 9984 and

10239. The possible values are shown in the table on the right.

5.1.1. Write address

To programme a long address you first of all need to calculate the

values for CV 17 and CV 18 and then programme it. Please note

that it is not possible to programme addresses via the program-

ming mode “POM”.

To programme the long address proceed as follows:

•First you determine the desired address, for instance 4007.

•Then you look for the appropriate address range in the table on

the right. The value to be entered into CV 17 can be found in the

column on the right. In our example, it is 207.

The value for CV 18 is established as follows:

esired address 4007

minus first address in the address range - 3840

=============================== ====

equals value for CV 18 167

•167 is therefore the value to be entered in CV 18. Thus your de-

coder is now programmed to address 4007.

5.1.2. Read out addess

If you wish to read out the address of a locomotive please read

the values of CV 17 and CV 18 one after another and proceed

then in reverse order:

Let’s assume you have read:

CV 17 = 196; CV 18 = 147. Look up the corresponding address

range in the table below. The first possible address within this

range is 1024. Then you have to add the value from CV 18 and

you arrive at the locomotive address:

1024

+ 147

====

= 1171

Address Range Address Range Address Range

from to CV17 from to CV17 from to CV17

0255 192 3584 3839 206 7168 7423 220

256 511 193 3840 4095 207 7424 7679 221

512 767 194 4096 4351 208 7680 7935 222

768 1023 195 4352 4607 209 7936 8191 223

1024 1279 196 4608 4863 210 8192 8447 224

1280 1535 197 4864 5119 211 8448 8703 225

1536 1791 198 5120 5375 212 8704 8959 226

1792 2047 199 5376 5631 213 8960 9215 227

2048 2303 200 5632 5887 214 9216 9471 228

2304 2559 201 5888 6143 215 9472 9727 229

2560 2815 202 6144 6399 216 9728 9983 230

2816 3071 203 6400 6655 217 9984 10239 231

3072 3327 204 6656 6911 218

3328 3583 205 6912 7167 219

Appendix

10

CV Name Description Range Default

1Locomotive address DCC/Motorola® address of locomotive 1 - 127 03

2Start voltage Sets the minimum speed of the locomotive 0 - 255 03

3Acceleration This value multiplied by 0.25 is the time from stop to maximum speed. 0 - 255 11

4Deceleration This value multiplied by 0.25 is the time from maximum speed to stop. 0 - 255 06

5Maximum speed Maximum speed of locomotive 0 - 255 255

6Medium Speed Medium speed of the locomotive 0 - 255 88

9Motor PWM frequency Motor PWM frequency as a multiple of 1000 Hz 10 - 50 40

13 Analogue mode F1-F8 Status of functions F1 to F8 in analogue mode 0 - 255 128

Bit Description Value

0 Function F1 1

1 Function F2 2

2 Function F3 4

3Function F4 8

4Function F5 16

5 Function F6 32

6 Function F7 64

7Function F8 128

14 Analogue mode F0,F9-F15 Status of functions F0, F9 bis F15 in analogue mode 0 - 255 01

Bit Description Value

0 Function F0 1

1 Function F9 2

2 Function F10 4

3Function F11 8

4Function F12 16

5 Function F13 32

6 Function F14 64

7Function F15 128

17 &

18

Long address of the loco Long address of engine ( see full manual online at www.loksound.com)

Programming table - List of most important CVs Programming table - List of most important CVs

11

Programming table - List of most important CVs

CV Name Description Range Default

28 RailCom® Configuration Settings for RailCom® 131

Bit Description Value

0Channel 1 Address broadcast disabled

Channel 1 Address broadcast enabled

0

1

1No data transmission allowed on Channel 2

Data transmission allowed on Channel 2

0

2

29 Configuration register The most complex CV within the DCC standards.

This register contains important information, some of which are only relevant for DCC

operation.

14

Bit Description Value

0Normal direction of travel

Reversed direction of travel

0

1

114 speed steps DCC

28 or 128 speed steps DCC

0

2

2Disable analog operation

Enable analog operation

0

4

3Disable RailCom®

Enable RailCom®

0

8

4Motor characteristic through CV 2, 6, 5 (For LokSound 5 DCC only!)

Motor characteristic through CV 67 - 94 (always active on LokSound 5)

0

16

5Short addresses (CV 1) in DCC mode

Long addresses (CV 17 + 18) in DCC mode

0

32

31 Index register H Selection page for CV257-512 16 16

32 Index register L election page for CV257-512 0,1,2,3 0

12

CV Name Description Range Default

49 Extended Configuration #1 Additional important settings for LokSound Decoders 0 - 255 01

Bit Description Value

0Enable Load control

Disable Load control

1

0

1reserved 2

2Reserved 4

3Reserved 8

4Automatic DCC speed step detection

Disable DCC speed step detection

Enable DCC speed step detection

0

16

5LGB® function button mode

Disable LGB® function button mode

Enable LGB® function button mode

0

32

6Zimo® Manual Function

Disable Zimo® Manual Function

Enable Zimo® Manual Function

0

64

7Reserved

50 Analogue Mode Selection of allowed analogue modes 0 - 3 06

Bit Description Value

0Reserved

1C Analogue mode

Disable DC Analogue mode

Enable DC Analogue Mode

0

2

51 «K Slow» Cutoff Inernal Speedstep, until «K Slow» is active 0 - 255 10

52 Load Control param. «K» for slow driving „K“-component of the internal PI-controller for the low speed steps. 0 - 255 15

53 Control Reference voltage Defines the Back EMF voltage, which the motor should generate at maximum speed. The

higher the efficiency of the motor, the higher this value may be set. If the engine does

not reach maximum speed, reduce this parameter.

0 - 255 120

54 Load control parameter „K“ „K“-component of the internal PI-controller. Defines the effect of load control. The

higher the value, the stronger the effect of Back EMF control.

0 - 255 30

55 Load control parameter „I“ „I“-component of the internal PI-controller. Defines the momentum (inertia) of the mo-

tor. The higher the momentum of the motor (large flywheel or bigger motor diameter,

the lower this value has to be set.

0 - 255 50

56 BEMF Influence at VMin 0-100%.

Defines the “Strengh” of the BEMF at minimum speed step

1 - 255 255

Programming table - List of most important CVs Programming table - List of most important CVs

13

CV Name Description Range Default

63 Sound volume Master volume control for all sounds. 0 - 192 129

64 Brake sound threshold «Brake On» If the actual loco speed step is smaller than or equals the value indicated here, the brake

sound is triggered.

0 - 255 44

65 Brake sound threshold «Brake Off» If the actual loco speed step is smaller than the one indicated here (up to 255), the brake

sound will be switched off again. .

0 - 255 03

66 Forward Trim Divided by 128 is the factor used to multiply the motor voltage when driving forward.

The value 0 deactivates the trim.

0 - 255 128

67-94 Speed table Defines motor voltage for speed steps. The values „in between“ will be interpolated. 0 - 255 -

113 Power Fail Bypass The time that the decoder bridges via the PowerPack after an interruption of voltage.

Unit: A multiple of 0.032768 sec. See section 6.12.2.

0 - 255 101

116 Slow speed BEMF Sampling period Frequency of BEMF measurement in 0.1 milliseconds at speed step 1 50 - 200 35

117 Full speed BEMF Sampling period Frequency of BEMF measurement in 0.1 milliseconds at speed step 255 50 - 200 150

118 Slow speed BEMF Measurement gap Min Length of the BEMF measuring gap in 0.1 milliseconds at speed step 1 10 - 20 15

119 Full speed BEMF Measurement gap Max Length of the BEMF measuring gap in 0.1 milliseconds at speed step 255 10 - 20 20

124 Extended Configuration #2 Additional important settings for LokSound Decoders -16

Bit Description Value

0Bi-directional bit: Keep driving direction when changing direction.

Do not keep driving direction.

1

0

1Disable decoder lock with CV 15 / 16

Enable decoder lock with CV 15 / 16

0

2

2Disable prime mover startup delay

Enable prime mover startup delay

0

4

3Disable serial protocol

Enable serial protocol

0

8

4Enable Output AUX9 (LokSound 5 H0 only)

Enable Wheel Sensor input (LokSound 5 H0 only)

0

16

5Motor Overload Protection

Motor is not switched off when blocked.

Motor is switched off for a few seconds when blocked to avoid

burnout

0

32

6Disable Automatic parking Brake

Enable Automatic parking Brake (EMK Braking)

0

64

7Reserved 128

125 Starting voltage Analog DC 0-255 70

126 Maximum speed Analog DC 0-255 120

Programming table - List of most important CVs

14

Programming table - List of most important CVs

CV Name Description Range Default

134 ABC-Mode „Sensibility” Threshold, from which asymmentry on ABC shall be recognised. 4 - 32 12

155

-162

Notch Points Notch Point 1 - Notch Point 8: The internal speed step where the diesel engine sound

notches to the next Notch (Not for all sound projects)

0 - 255

163 Sound CV9 Horn Select CV 0 - 255 01

164 Sound CV10 Bell Select CV 0 - 255 0

165 Sound CV11 Brake Squeal Select CV 0 - 255 0

166 Sound CV12 Air Dryer Select CV 0 - 255 0

15

6. Support and Assistance

Your model train dealer or hobby shop is your competent partner

for all questions regarding your LokSound decoder. In fact he is

your competent partner for all questions around model trains.

There are many ways to get in touch with us. For enquiries please

use either email or fax (don’t forget to provide your own fax-no. or

email address) and we will reply within a few days.

The hotline is often very busy and you may encounter delays.

Rather send an email or fax and also check our website for more

information. You will find many hints under “Support / FAQ”

and even feedback from other users that may help you with

your particular question.

Of course we will always assist you; please contact us at:

USA & Canada (English support), please contact:

Phone: +1 (570) 980-1982

Tuesday & Thursday 8:00am - 4:00pm (CT)

Fax: +1 (866) 591-6440

Email: [email protected]

Mail: ESU LLC

1304 Jordan Drive

US-PA-17754 Montoursville

Germany and all other countries, please contact:

Phone: ++49 (0) 731 - 1 84 78 - 106

Tuesday & Wednesday 10:00am - 12:00am

Fax: ++49 (0) 731 - 1 84 78 - 299

Email: www.esu.eu/en/forum

Mail: ESU GmbH & Co. KG

- Technischer Support -

Edisonallee 29

D-89231 Neu-Ulm

www.esu.eu

Support & Assistance

16

Instruction manual - LokSound 5 - GHB „DD-1“

This manual suits for next models

1

Table of contents

Other Esu Media Converter manuals

Esu

Esu SwitchPilot 3 User manual

Esu

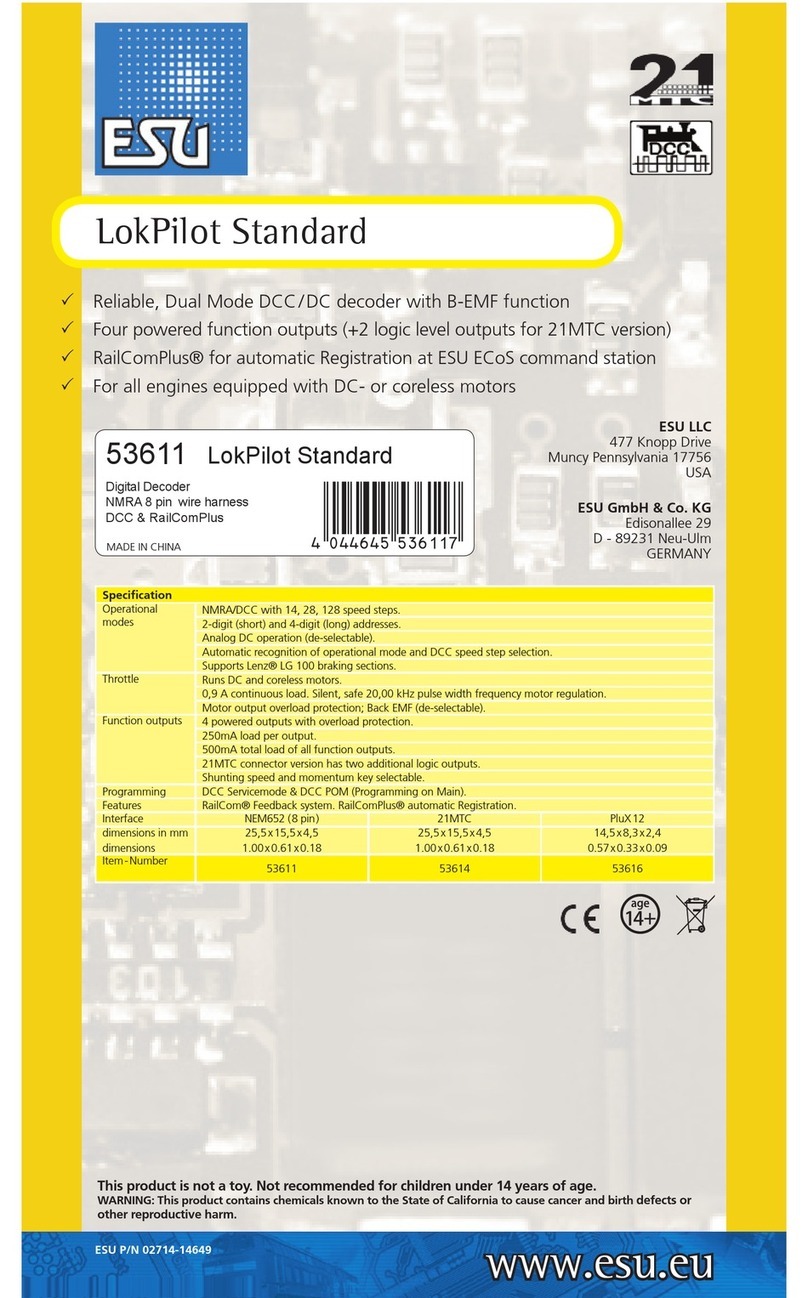

Esu LokPilot Standard User manual

Esu

Esu LokSound micro V4.0 User manual

Esu

Esu SwitchPilot 3 51830 User manual

Esu

Esu LokPilot 52600 User manual

Esu

Esu LokPilot V4.0 User manual

Esu

Esu LokPilot V2.0 User manual

Esu

Esu L.Net converter User manual

Esu

Esu LokSound V3.0 User manual

Esu

Esu SignalPilot 51840 User manual

Popular Media Converter manuals by other brands

Optical Systems Design

Optical Systems Design OSD2167M Series Operator's manual

Craig

Craig CVD508 owner's manual

FSR

FSR MAS 4100A Installation and operator's manual

Sollae Systems

Sollae Systems CSE-M73A user manual

Ross

Ross Opengear UDC-8625A Series user manual

IMC Networks

IMC Networks MediaChassis/I-AC supplementary guide