Table of Contents

Splice Mode.................................................................................................................... 76

1. Splice Mode Selection ................................................................................................................. 77

2. Splice Option ............................................................................................................................... 78

3. Editing Splice Mode.................................................................................................................... 79

4. ECF............................................................................................................................................. 106

5. Sweep Function ......................................................................................................................... 107

6. Manual Splicing Operations .................................................................................................... 108

7. Attenuation Splice Mode ...........................................................................................................114

8. Power Meter Feedback Alignment ...........................................................................................115

9. Special Function settings for tapering......................................................................................118

10. Manual fiber alignment using End-view observation system (FSM-100P+ only)............. 123

Heater Mode ................................................................................................................ 128

1. Heater Type................................................................................................................................ 128

2. Heater Menu (Sleeve Heater)................................................................................................... 129

3. Heater Menu (Fiber Straightener)........................................................................................... 131

4. Heater Mode Setting ................................................................................................................. 132

Splice Result Memory..................................................................................................135

1. Save Splice Results in Memory................................................................................................ 135

2. Comments of Splice Results ..................................................................................................... 140

Setting Menu................................................................................................................ 141

1. Splice Settings............................................................................................................................ 141

2. Maintenance Settings................................................................................................................ 145

3. Machine Settings ....................................................................................................................... 146

4. Menu Lock Settings .................................................................................................................. 151

Fiber Data Learning....................................................................................................153

1. Fiber Type Compare ................................................................................................................. 153

2. Auto Arc Calibration................................................................................................................. 153

3. IPA Data (FSM-100P/P+ Only)................................................................................................ 153

Maintenance Menu ..................................................................................................... 154

1. Arc Calibration.......................................................................................................................... 155

2. Special Arc Calibration............................................................................................................. 156

3. Stabilize Electrodes ................................................................................................................... 157

4. Replace Electrodes .................................................................................................................... 158

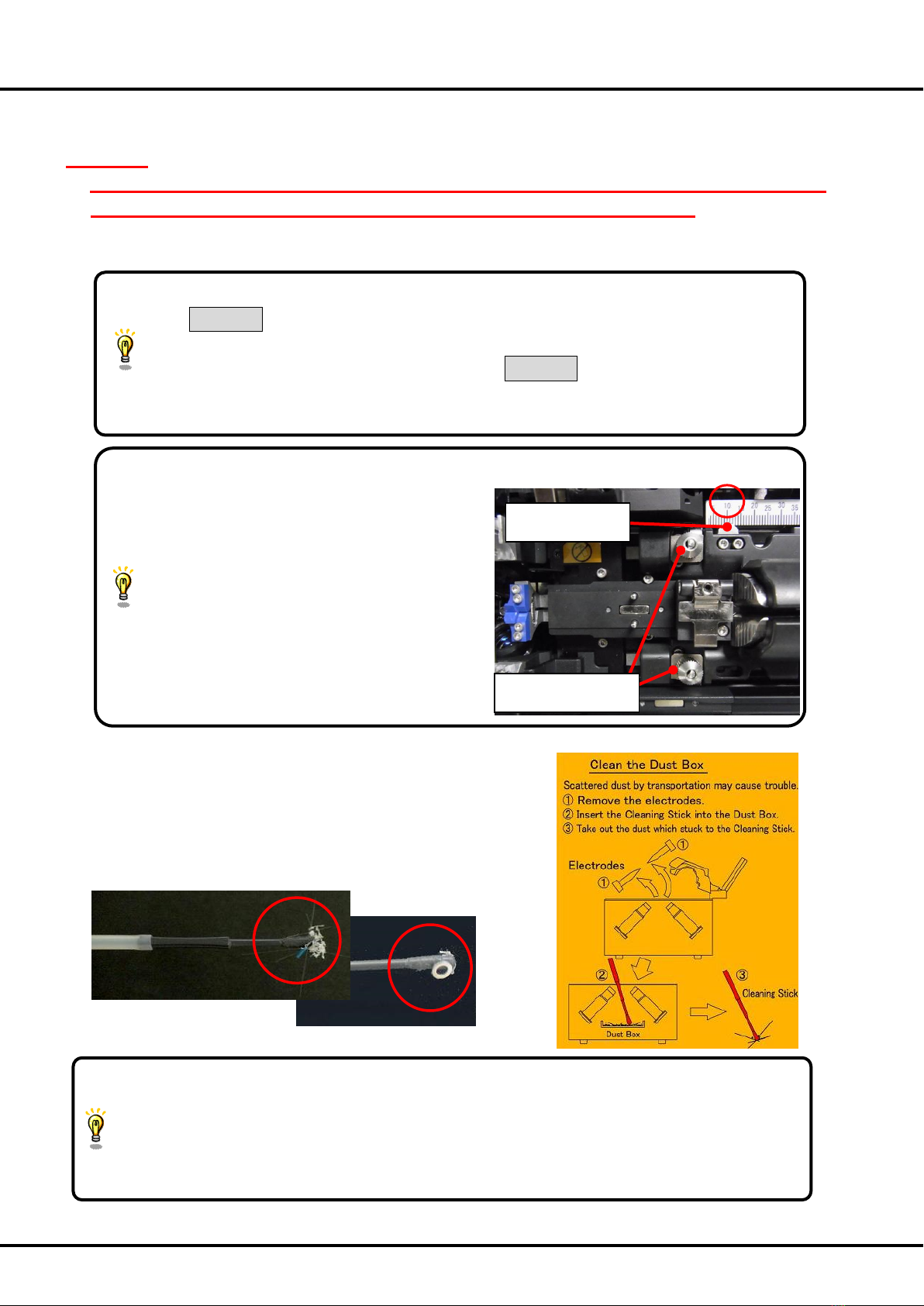

5. V-Groove Cleaning.................................................................................................................... 159

6. Cleaning Electrode (FSM-100M+/P+ Only)........................................................................... 160

7. Diagnostic Test........................................................................................................................... 162

8. Dust Check................................................................................................................................. 163

9. Motor Calibration..................................................................................................................... 164

10. Motor Drive ............................................................................................................................. 165

11. Initialize.................................................................................................................................... 166

12. Maintenance Info. ................................................................................................................... 167

Personal Computer Communication Function..........................................................168

Error Message List ......................................................................................................169