8.5. Parameters table F06 - Thermostat 1 output minimum time off:

This is the minimum time during which the OUT1 output remains off, i.e., the time interval between the last

stop and next start. It helps to relieve the discharge pressure and increase the lifespan of the compressor.

This delay also occurs when starting up the device. In facilities with several instruments, assigning different

values to the delay time at the start up of each device will allow for demand peaks to be avoided when the

devices are activated at different times.

If the cyclic timer of thermostat 1 is enabled, this time will not be observed.

This function can be switched off by setting it at the minimum value 0 [no,,].

F07 - Delay of thermostat 1 when the instrument is powered on (initial delay):

Time thermostat 1 will wait before activating its control functions. During this time only the temperature is

measured.

This function can be switched off by setting it at the minimum value 0 [,,no].

F08 - Thermostat 1 cyclic mode operation mode:

Allows configuring the cyclic timer associated to output OUT1:

[Off,] - Disabled: Output OUT1 will be constantly on or off depending only on the temperature.

The possible settings for output time on and output time off are, respectively:

[,,,1] - Seconds/Seconds

[,,,2] - Seconds/Minutes

[,,,3] - Minutes/Seconds

[,,,4] - Minutes/Minutes

For configurations 1, 2, 3, and 4, output OUT1 will keep cycling while the temperature of thermostat 1

requires the output to be on. The initial state of OUT1 is always on.

F09 - Thermostat 1 cyclic timer off time:

F10 - Thermostat 1 cyclic timer on time:

Functions [,F09] and [,F10] are used when the user configures OUT1 as cyclic timer, observing the

time base configured in [,F08].

F11 - Sensor 1 indication displacement (Offset):

Enables compensation for any temperature deviations resulting from sensor replacement or change in the

cable length.

F12 - Thermostat 1 alarm indication mode:

Selects how the thermostat 1 checks for the presence of an alarm. Enabling this function only enables the

alarm indication on the display. If you need the alarm output to be activated, you must configure function

[,F30].

[Off,]- Alarm off.

[,,,1]- In-range alarm ([,F13] and [,F14]).

[,,,2]- Out-of-range alarm ([,F13] and [,F14]).

[,,,3]- In-range alarm related to the setpoint ([SP1,] - [,F13] and [SP1,] + [,F14]).

[,,,4]- Out-of-range alarm related to the setpoint ([SP1,] - [,F13] and [SP1,] + [,F14]).

F13 - Thermostat 1 alarm minimum value:

F14 - Thermostat 1 alarm maximum value:

These are the minimum and maximum values for the alarm to actuate if configured in [,F12].

F15 - Thermostat 1 alarm delay when powering on:

The time that the alarm of thermostat 1 will remain off even in alarm conditions.

This time is counted after the time configured in [,F07] has elapsed.

This function can be disabled by adjusting it to the minimum value [no,,].

F16 - Thermostat 2 operation mode:

Selects the 2nd thermostat operation mode (OUT2):

[Off,] - Off: In this mode, temperature sensor 2 can be disconnected. If function F22 is other than

[Off,], output OUT2 will work only as cyclic timer

[,,,1] - Cooling

[,,,2] - Heating

F17 - Thermostat 2 control differential (Hysteresis):

This is the temperature difference (hysteresis) between turning the cooling (or heating) ON and OFF of

the thermostat.

F18 - Minimum setpoint allowed to user (thermostat 2):

Prevents accidental setting of extremely low setpoint temperatures.

F19 - Maximum setpoint allowed to user (thermostat 2):

Prevents accidental setting of extremely high setpoint temperatures.

F20 - Thermostat 2 output minimum time off:

This is the minimum time during which the OUT2 output remains off, i.e., the time interval between the last

stop and next start.

If the cyclic timer of thermostat 2 is enabled, this time will not be observed.

This function can be switched off by setting it at the minimum value 0 [no,,].

F21 - Delay of thermostat 2 when the instrument is powered on (initial delay):

Time thermostat 2 will wait before activating its control functions. During this time only the temperature is

measured.

This function can be switched off by setting it at the minimum value 0 [,,no].

F22 - Thermostat 2 cyclic mode operation mode:

Allows configuring the cyclic timer associated to output OUT2:

[Off,] - Disabled: Output OUT2 will be constantly on or off depending only on the temperature.

The possible settings for output time on and output time off are, respectively:

[,,,1] - Seconds/Seconds

[,,,2] - Seconds/Minutes

[,,,3] - Minutes/Seconds

[,,,4] - Minutes/Minutes

For configurations 1, 2, 3, and 4, output OUT2 will keep cycling while the temperature of thermostat 2

requires the output to be on. The initial state of OUT2 is always on.

F23 - Thermostat 2 cyclic timer off time:

F24 - Thermostat 2 cyclic timer on time:

Functions [,F23] and [,F24] are used when the user configures OUT2 as cyclic timer, observing the

time base configured in [,F22].

F25 - Sensor 2 indication displacement (Offset):

Enables compensation for any temperature deviations resulting from sensor replacement or change in the

cable length.

Sensor 2 may be disabled by adjusting this function to the maximum value [,OFF]. When sensor 2 is

disabled, thermostat 2 is controlled by sensor 1.

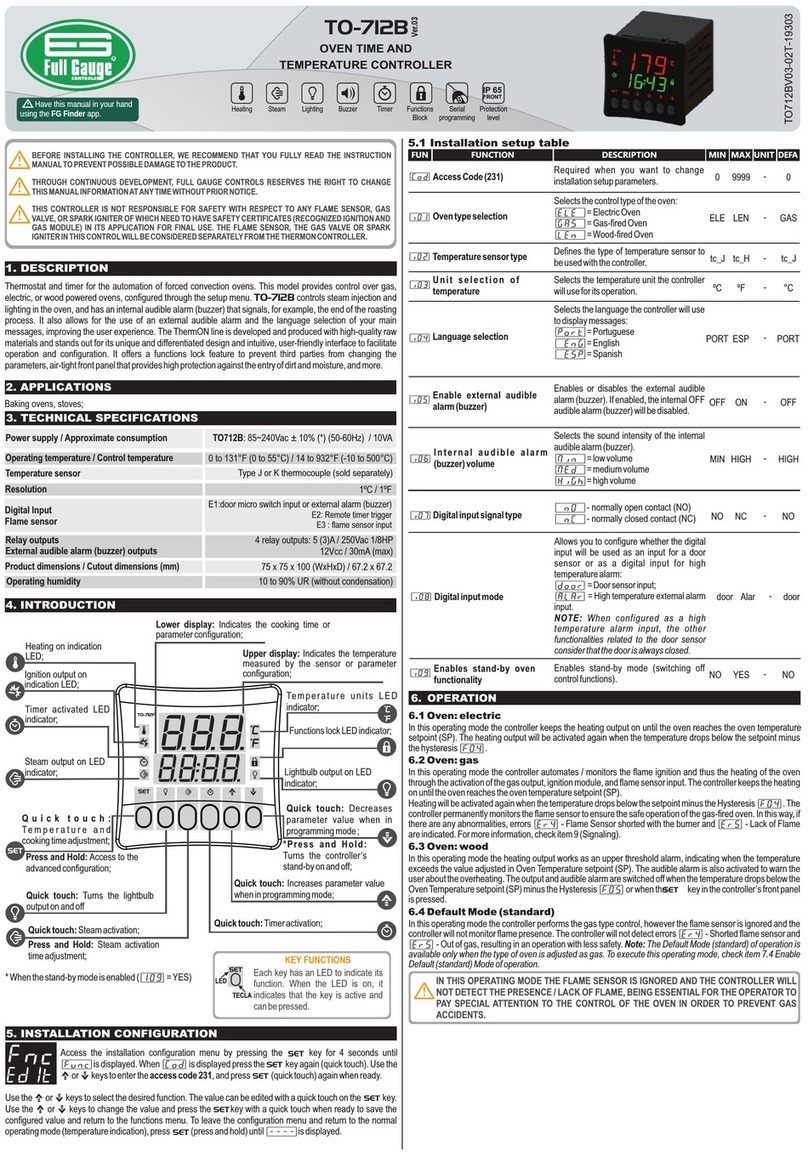

Access code 123 (one hundred and twenty three)

Thermostat 1 operation mode

Thermostat 1 differential control (hysteresis)

Min. setpoint allowed to the end user (thermost. 1)

Max. setpoint allowed to the end user (thermost. 1)

Thermostat 1 output minimum time off

Delay of therm. 1 when the instrument is powered

on (initial delay)

Thermostat 1 cyclic timer operation mode

Thermostat 1 cyclic timer off time

Thermostat 1 cyclic timer on time

Indication offset for sensor 1

Thermostat 1 alarm indication mode

Thermostat 1 alarm minimum value

Thermostat 1 alarm maximum value

Thermostat 1 alarm delay on power on

Thermostat 2 operation mode

Thermostat 2 differential control (hysteresis)

Min. setpoint allowed to the end user (thermost. 2)

Max. setpoint allowed to the end user (thermost. 2)

Thermostat 2 output minimum time off

Delay of therm. 2 when the instrument is powered

on (initial delay)

Thermostat 2 cyclic timer operation mode

Thermostat 2 cyclic timer off time

Thermostat 2 cyclic timer on time

Indication offset for sensor 2

Thermostat 2 alarm indication mode

Thermostat 2 alarm minimum value

Thermostat 2 alarm maximum value

Thermostat 2 alarm delay on power on

Alarm output operation mode

Alarm output cyclic timer off time

Alarm output cyclic timer on time

Preferred indication

Sensor error alarm

Enable buzzer

Digital input operation mode

Digital filter intensity applied to the sensor 1

Digital filter intensity applied to the sensor 2

Functions lock mode

Time for functions lock

Control functions shutdown

[,F01]

[,F02]

[,F03]

[,F04]

[,F05]

[,F06]

[,F07]

[,F08]

[,F09]

[,F10]

[,F11]

[,F12]

[,F13]

[,F14]

[,F15]

[,F16]

[,f17]

[,f18]

[,F19]

[,F20]

[,F21]

[,F22]

[,F23]

[,F24]

[,F25]

[,F26]

[,F27]

[,f28]

[,f29]

[,f30]

[,f31]

[,f32]

[,f33]

[,f34]

[,f35]

[,f36]

[,f37]

[,f38]

[,f39]

[,f40]

[,f41]

0

0-Off

0.1

-50

-50

0(no)

0(no)

0-Off

1

1

-5.0

0-Off

-50.0

-50.0

0(no)

0-Off

0.1

-50.0

-50.0

0(no)

0(no)

0-Off

1

1

-5.0

0-Off

-50.0

-50.0

0(no)

0-Off

0

0

t-1

Off

Off

0

0(no)

O(no)

0

15

0(no)

999

2-aquec.

20.0

200

200

9999

9999

4

9999

9999

5.0

4

200

200

9999

2-Aquec.

20.0

200

200

9999

9999

4

9999

9999

5.1(Off)

4

200

200

9999

4

9999

9999

ALL

On

On

6

9

9

2

60

2

-

-

°C

°C

°C

s

s

-

seg./min.

seg./min.

ºC

-

°C

°C

s

-

°C

°C

ºC

s

s

-

seg./min.

seg./min.

ºC

-

ºC

ºC

s

-

s

s

-

-

-

-

-

-

-

s

-

0

1-Refrig.

1.0

-50.0

105

0

0

0-Off

1

1

0

0-(Off)

-50.0

105

0

1-Aquec.

1.0

-50.0

105

0(no)

0(no)

0-Off

1

1

0

0-Off

-50.0

105

0

0-Off

0

0

t-1

On

Off

0

0(no)

0(no)

0

15

0(no)

DescriptionFun Min Max Unit Min Max Unit

DefaultDefault

CELSIUS FAHRENHEIT

0

0-Off

1

-58

-58

0(no)

0(no)

0-Off

1

1

-9

0-Off

-58

-58

0(no)

0-Off

1

-58

-58

0(no)

0(no)

0-Off

1

1

-9

0-Off

-58

-58

0(no)

0-Off

0

0

t-1

Off

Off

0

0(no)

O(no)

0

15

0(no)

999

2-aquec.

36

392

392

9999

9999

4

9999

9999

9

4

392

392

9999

2-Aquec.

36

392

392

9999

9999

4

9999

9999

9(Off)

4

392

392

9999

4

9999

9999

ALL

On

On

6

9

9

2

60

2

-

-

°F

°F

°F

s

s

-

seg./min.

seg./min.

ºF

-

°F

°F

s

-

°F

°F

ºF

s

s

-

seg./min.

seg./min.

ºF

-

ºF

ºF

s

-

s

s

-

-

-

-

-

-

-

s

-

0

1-Refrig.

1

-58

221

0

0

0-Off

1

1

0

0-(Off)

-58

221

0

1-Aquec.

1

-58

221

0(no)

0(no)

0-Off

1

1

0

0-Off

-58

221

0

0-Off

0

0

t-1

On

Off

0

0(no)

0(no)

0

15

0(no)

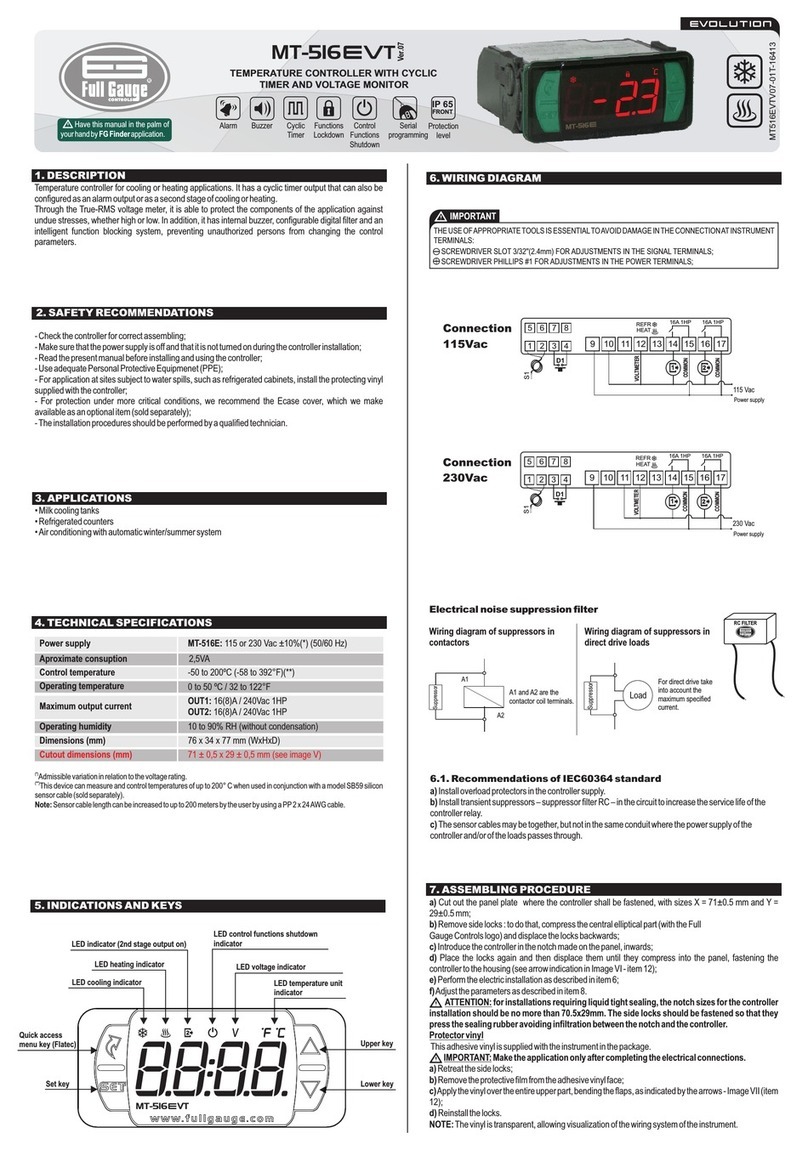

8.5.1. Description of the parameters

F01 - Access code: 123 (one hundred and twenty-three):

It is required when you want to change setup parameters. This code is not required for viewing the

parameters.

It allows entering the access codes provided:

[,123]- Allows you access for changing the table parameters

[,231]- Allows configuring the units of measurement [,=F,] or [,=C,]

F02 - Thermostat 1 operation mode:

Selects the 1st thermostat operation mode (OUT1):

[Off,] - Off: In this mode, temperature sensor 1 can be disconnected. If function F08 is other than

[Off,], output OUT1 will work only as cyclic timer

[,,,1] - Cooling

[,,,2] - Heating

F03 - Thermostat 1 control differential (Hysteresis):

This is the temperature difference (hysteresis) between turning the cooling (or heating) ON and OFF of

the thermostat.

Example: You want to control the temperature at 4.0 °C with a differential of 1.0 °C. Therefore, the

cooling is switched off at 4.0 °C and switched back on at 5.0 °C (4.0 + 1.0), in the heating mode the

output is switched off at 4° C and is switched on again at 3° (4.0 - 1.0), as per the charts below:

Temperature [°C]

Cooling

Setpoint

Setpoint + Hysteresis

Time [S]

Relay Off

Relay On

4°C

5°C

Temperature [°C]

Heating

Setpoint

Setpoint - Hysteresis

Time [S]

3°C

4°C

Relay Off

Relay On

F04 - Minimum setpoint allowed to user (thermostat 1):

Prevents accidental setting of extremely low setpoint temperatures.

F05 - Maximum setpoint allowed to user (thermostat 1):

Prevents accidental setting of extremely high setpoint temperatures.