NZ eSTOP™ Operations & Service Manual

Page | 6

Fulton Hogan Signs & Graphics |signs@fultonhogan.com | P: 0800 274 463

The eSTOP™has beendeveloped as a response to aneed for safer working conditions foroperators

controlling alternating flow situations on job sites. It is designed to remove operators from the hazard

zones, butstill allowing the operators to manage traffic movement within the worksite from a safe

distance. In order to reduce the risk to road workers, traffic controllers and road users, the unit must at

all times be operated effectively and consistently by authorized and trained operators.

The eSTOP™must be operated in accordance with all safety, operation and service instructions contained

in the manufacturer's operation and service manual. It is recommended that all operators read and

understand the manual before operating the eSTOP™. Operators must understand and comply with the

manufacturer's instructions as printed in the manual accompanying each eSTOP™in conjunction with the

respective Company’s (User’s) Safe Work Method Statement.

The eSTOP™should only be operated by a designated, competent operator within the scope of on-site

operation parameters (such as the Company’s Safe Work Method Statement).

The eSTOP™shall be installed in a suitable location clear of obstructions. An appropriate risk assessment

shall be conducted to ensure the safe and suitable use of the eSTOP™. Examples of factors to consider

when assessing suitable location are: a safe distance from the traffic path, so that wide loads or turning

vehicles will not impact the unit, length of worksite, volume of traffic and topography. The eSTOP™should

be installed on a stable surface.

The unit including the lanterns (red, yellow and green), yellow light indicator and battery box shall be kept

clean. The equipment shall be handled with care.

The eSTOP™batteries (both for the hand remote control and the lanterns) shall be fully charged before

operating the unit.

The eSTOP™has been tested and certified compliant in accordance with the New Zealand Transport

Agency (NZTA) Technical Note –Portable Traffic Signal Systems, Version 3 : November 2015. The

eSTOP™ is included in the NZTA Code of Practice for Temporary Traffic Management (CoPTTM) Register

of TTM equipment approved for use on NZ roading network (Section I-19). The application of the

eSTOP™shallbe in accordance to these guidelines/standards as well as the respective company’s

worksite risk assessment and approved Traffic Management Plan (TMP).

It should be noted: the eSTOP is a remote control MANUAL operated system, designed to

remove operators from exposure to LIVE traffic. The maximum distance from the HRC and therefore the

operator to the lantern heads is 400m. However, the site distance which the eSTOP can be deployed

varies from site to site and must be deployed in accordance to the worksite risk assessment and

therefore must be set up in accordance to the respective site Traffic Management Plans.

Any modifications madeto the eSTOP™(unless byor approved by ArrowES) could compromise the function

of the eSTOP™and therefore the safe application of the units and voids the warranty of the eSTOP™.

Fulton Hogan Signs & Graphics |signs@fultonhogan.com | P: 0800 274 463

™

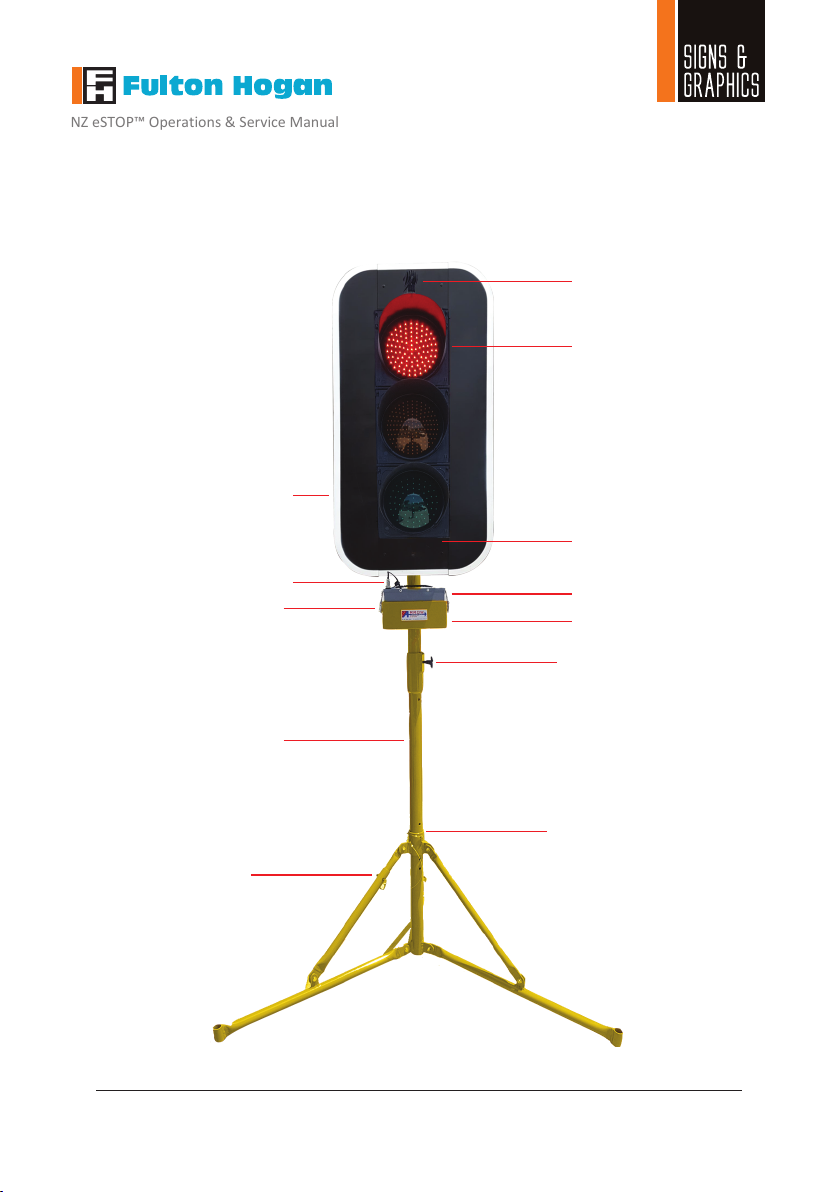

eSTOP™ Unit

Operating life of cluster: 100,000 hours

View angel of cluster: 12⁰

Lantern IP rating: IP45

LED Optics IP rating:IP65

Voltage: 12v

Operating amperage: 1.2 A

Battery (rechargeable) 26 A/H Lithium Iron phosphate

Operating Hours (80% DoD) ~16 Hours

Charging time: 4-5 Hours

Operating Temperature Range: -20 to 90⁰Celsius

Lantern Compliancy AS2144

Hand Remote Controller (HRC)

RF operating frequency: 2.4GHz

Configuration: Single unit or dual unit control

IP rating:IP65

Battery (rechargeable): 3 A/H Lithium Polymer

Operating Hours (50% DoD) ~15 Hours

Charging time: 4-6 Hours

Operating Current: (Transmitting) 120mA

Sleeping Current: 1mA

Operating Temperature Range: -20 to 85⁰Celsius

OverallDevice

Total mass per device (incl. batt,Target Board): 24kg (allocated to 3 components)

Top lantern weight (max lifting weight): 14kg

Tripod leg footprintradius: 0.80m

Wind loading–no sandbag base: ~40km/h

Wind loading–3 sandbag/leg ~50kg: ~100km/h

Dimensions

Maximum working height: 2900 cm

Minimum working height: 2600 cm

Dimensions when stored: 1710 mm x 480mm x 370mm

Base width, fully extended: 1600 mm diameter

Lantern height: 770 mm

Lantern width: 270 mm

Lantern depth: 170 mm

Target Board: 562x1063mm