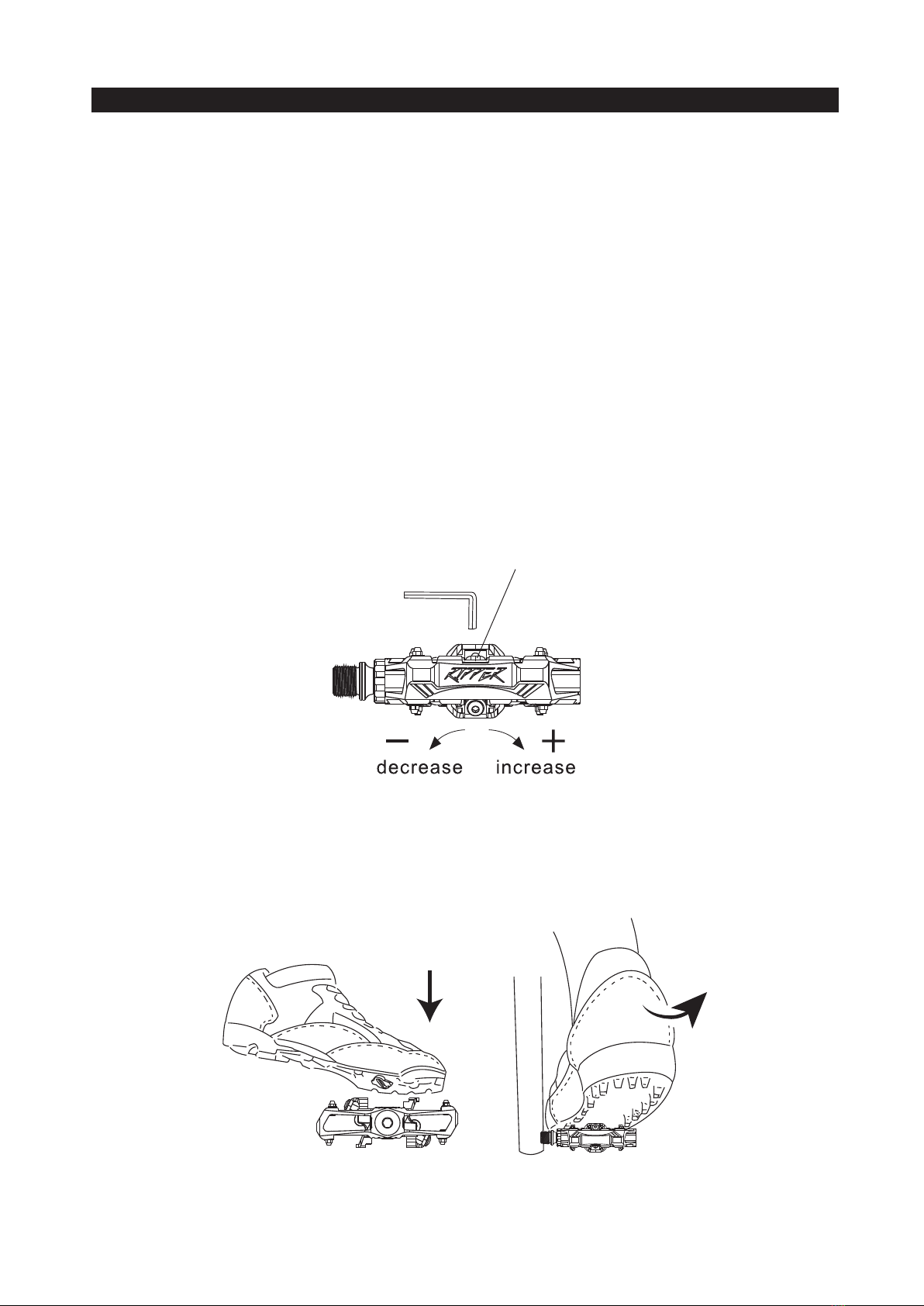

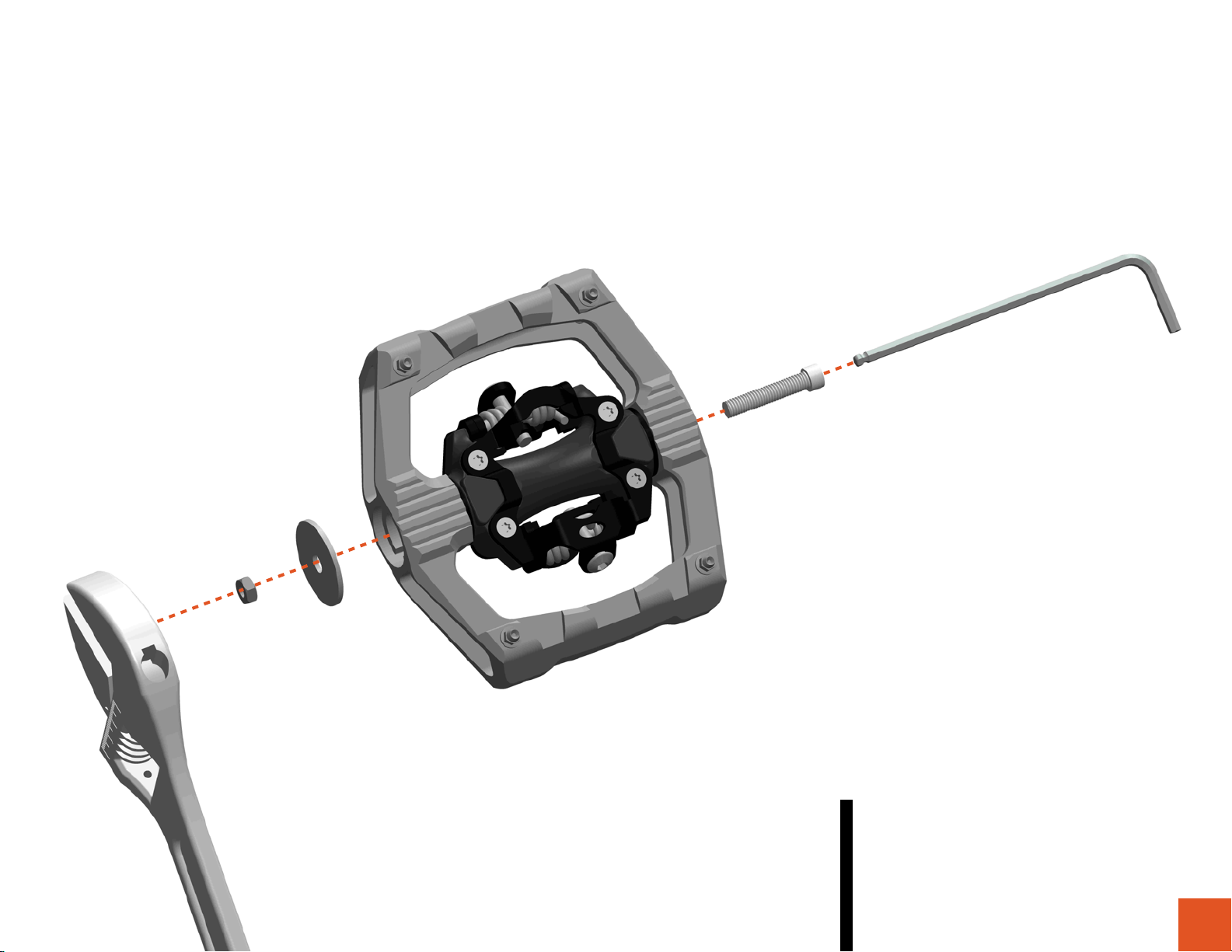

1.Pedals should be serviced if: rotating pedal emits noise, rotation by hand feels

rough, there is play in the bearings.

2.Bearings should be cleaned and regreased at least once every 12 months, or

at least once every 6 months if riding predominantly in wet conditions.Damaged

bearings should be replaced.

3.Replace pedals with fractures in body.

This product is warranted under normal usage against defects in workmanship

and materials to the original purchaser for one year from purchase date.

1.User assumes all risk of personal injury, damage to or failure of the product when

it is used in stunt or ramp jumping, acrobatics or similar activities.

2.Pedals are warranted for use by an individual rider only. Use by multiple riders, or

in a fitness center will void warranty.

3.This warranty does not cover any incidental or consequential damages, such as

personal injury or any other losses due to accident, neglect, misuse, abuse,

modification, normal wear and tear, improper assembly or maintenance.

4.When returning a defective product for warranty purposes, the claimant must

provide proof of purchase and a written description of damages.

5.There are no other warranties implied except this express limited warranty.

MAINTENANCE

IMPORTANT NOTES