ASD-120 – SEQUENCED POWER DISTRO

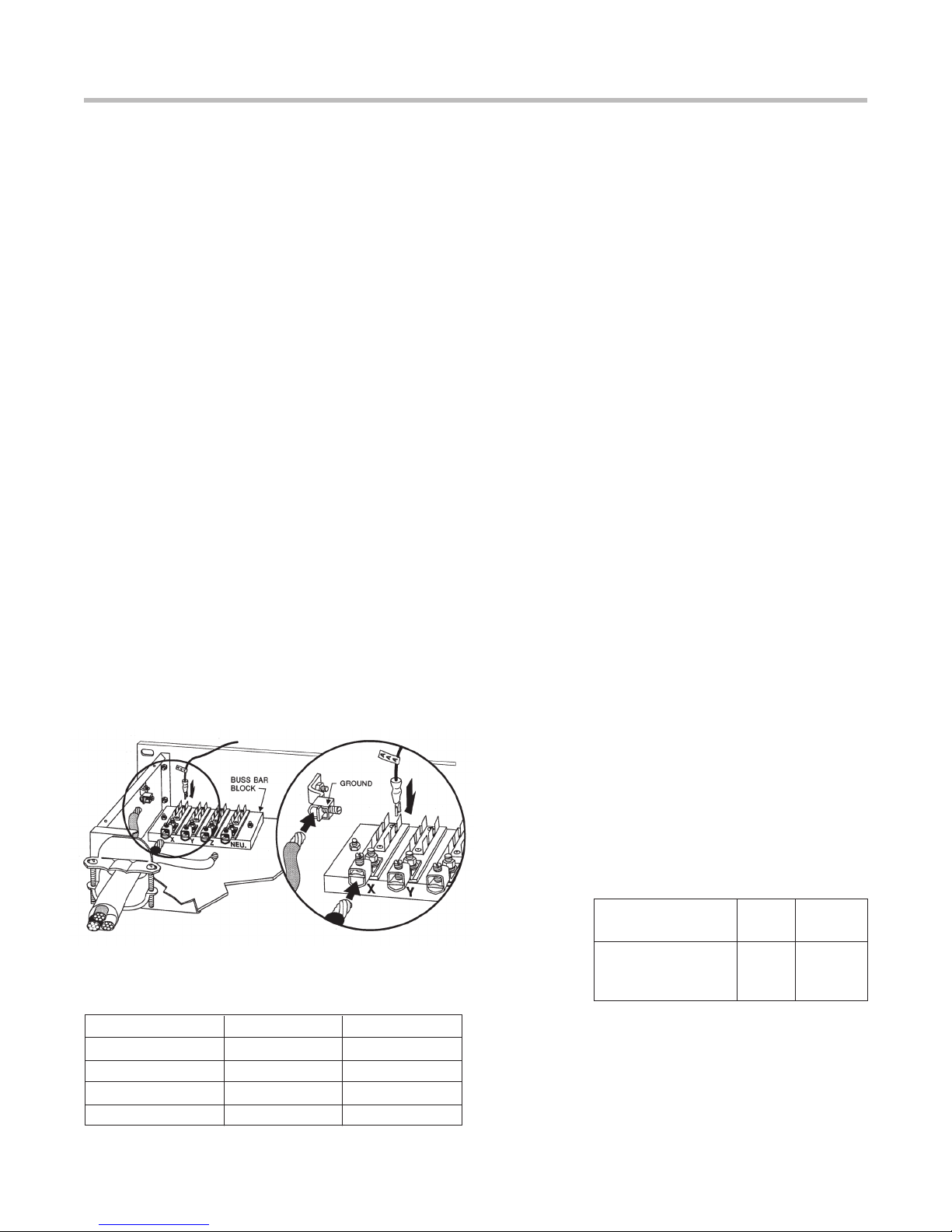

cover. This completes the internal wiring of the

ASD-120.

6. Terminate source end of cable or wire bundle: As

mentioned in item 2 (on page 6), the most common

cable termination is to break the ends out as pig-

tails and leave its hookup to the house electrician in

each venue. In some circumstances, a suitable con-

nector may be provided at the power source and the

cable can be terminated with a mating connector.

Often these will be Cam-Lok®or similar connectors

for each individual conductor.

If you want to provide a way to disconnect the cable

from the ASD-120 for separate storage or shipment,

one good way is to permanently attach a very short

cable to the ASD-120 and terminate it with Cam-Lok,

Meltric, or similar high-current connectors. A long

cable with mating Cam-Loks would then be prepared

which could easily be disconnected and stored. A

good source for custom made high power cables is

800-CAM-LOKS).

Table 4 on page 9.

CONTROLLING

ON/OFF

SEQUENCE:

ADVANCED

The quick start section at the front of the manual is adequate for

typical use. The following is an advanced tutorial and description

for those who are so inclined.

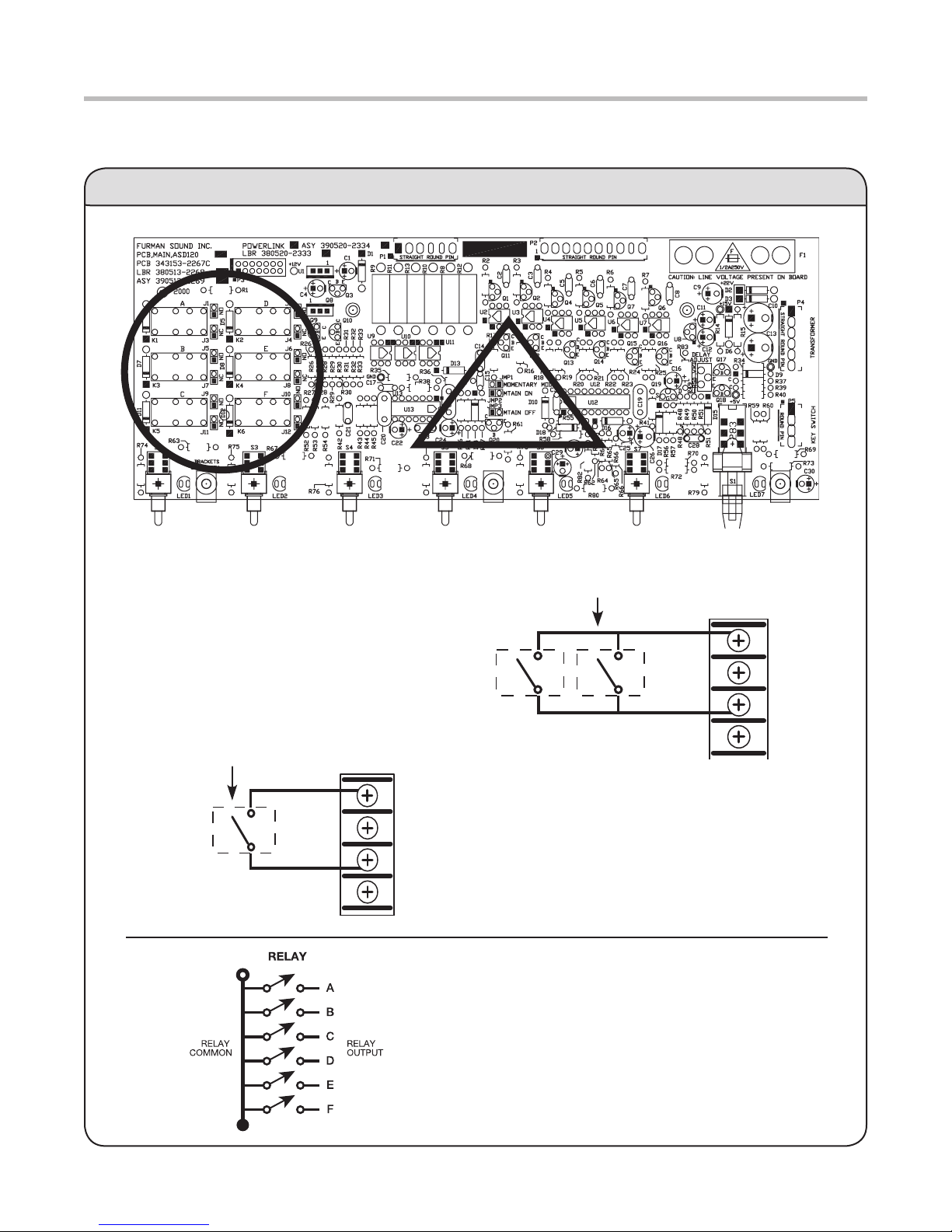

A normal, time-delayed on or off sequence may be

initiated in either of two ways: locally, via the front

panel key switch, or remotely, via a remotely located

maintained or momentary switch connected to the

behavior of any individual circuit may be overridden

switch.

in order from A to F when sequencing on, and turn

the outlets off in the reverse order from F to A when

sequencing off. The time for each step is internally

adjustable with a trim pot, with a range of 0.2 to > 12

seconds per step. (Total time for the entire sequence is

from 1 second to > 1 minute).

Local control: Turning the key to the ON (or possibly

that in the absence of any signal applied to the remote

input, the REM position defaults to on. (If the ASD-120

has been changed from the factory-preset Maintained

Mode to Momentary Mode, you must also press the

purely local control, you should leave the mode set to

Maintained.)

When the unit is turned on with the key switch, the

ASD-120 will stay on if all outlets are already on, or, if

all outlets are off, will begin turning on outlets starting

with outlet A, then B, etc. until all outlets are on. If the

unit was in the middle of sequencing off and had not

yet turned off all outlets, the lowest outlet that was

currently off will go on, so the sequence reverses

without ever deactivating the outlets that had not

yet gone off. The lowest off outlet turns on within 0.2

seconds, regardless of the setting of the delay time

trimpot. The next and all following outlets turn on at

intervals controlled by the trimpot. The factory default

setting is approximately 8 seconds per step.

When the unit is turned off with the key switch, the

ASD-120 will stay off if all outlets are already off, or, if

all outlets are on, will begin turning off outlets starting

with outlet F, then E, etc. until all outlets are off. If

the unit was in the middle of sequencing on and had

not yet turned on all outlets, the highest outlet that

is currently on will go off, so the sequence reverses

without ever activating the outlets that had not yet

turned on. The highest on outlet turns off within 0.2

seconds, regardless of the setting of the internal delay

time trimpot. The next and all following outlets turn off

at intervals controlled by the trimpot.

Remote Control: In the REM position, an on or

off sequence is initiated by one or more switches

connected to the rear panel inputs, or, in Momentary

button. The ASD-120 responds exactly as it does as

described in the preceding section on local control.

See the next section for a discussion of Remote

Operating Modes.

When the key is in either the ON or OFF position, the

rear panel remote control inputs. If the key switch is later

returned to the REM position, the signals supplied to the

rear panel remote inputs will again control the unit.

8