The CN-3600SE is readily adaptable to a wide

range of installation requests and requirements.

It was designed from the ground up to be com-

patible with Furman legacy and third party

equipment. Forced Off inputs and selectable DIP

switch settings are provided to allow easy inter-

face to devices, such as alarm systems.

Additional Features

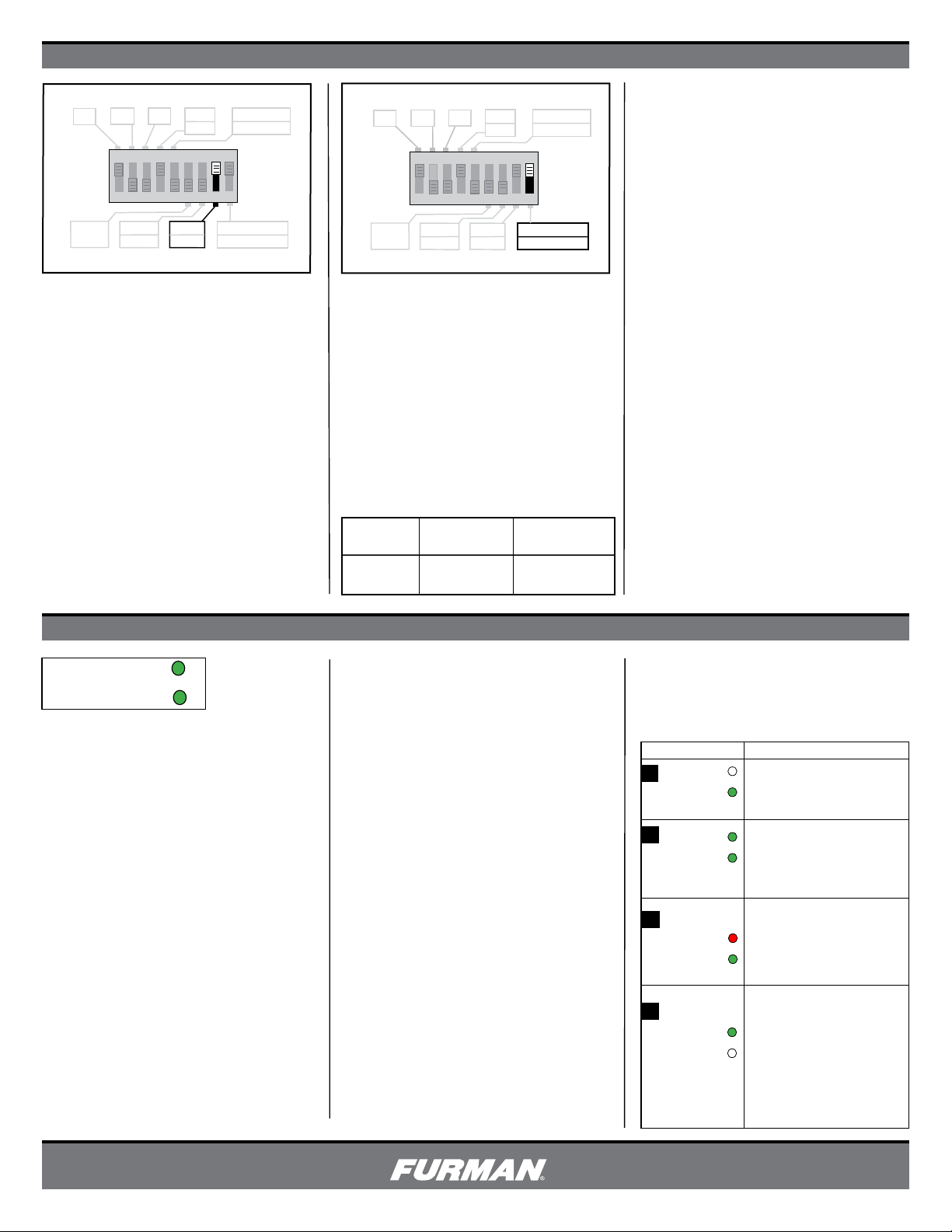

The CN-3600SE is equipped with LED indica-

tors to provide visual aid in tracking conditions

such as power, protection, sequencing and

communication. The CN-3600SE is supplied by

a 1.5mm^2 AWG, 2.5 meter AC cord. All Con-

tractor Series units are backed by our 15 year

Limited Warranty

Important Safety Instructions

1. Please read and follow all instructions.

2. Please keep these instructions.

3. Please heed all warnings.

4. WARNING: This device is intended for indoor

use only. Do not use this device in or near water.

To reduce the risk of fire or electric shock, do not

expose this device to rain or moisture.

5. CAUTION: Always On receptacles are present,

providing constant AC power. To reduce risk of

shock, please disconnect the CN-3600SE from

AC power before servicing any equipment con-

nected to the CN-3600SE Sequencer.

6. Clean only with dry cloth.

7. CAUTION: Do not install near any heat sources

such as radiators, heat registers, stoves, or other

equipment that may produce heat.

8. Protect the power cord from being walked on

or pinched, particularly at plugs, convenience

receptacles, and the point where they exit the

device.

9. WARNING: The DE-9 RS-232 communica-

tions port provides power for Furman accesso-

ries (e.g. BB-RS232). Please verify pin assign-

ment and protocol before connecting any other

manufacturer’s device to this port.

10. Please, only use accessories specified by the

manufacturer.

11. Refer all servicing to qualified personnel.

Servicing is required when the unit has been

damaged in anyway or fails to operate.

12. WARNING: Do not use power cord as the

main power disconnect. The device is intended

for AC power sequencing.

13. Do not defeat the safety purpose of the

Schuko plug. A Schuko plug has two pins and

a grounding contact or receptacle. If the Schuko

plug does not fit into your outlet, please consult

an electrician for assistance.

14. This device is supplied with a detachable

IEC-C19 to CEE-7/7 Schuko power cord. Any

prospective replacement cord must comply with

the minimum ratings of the line cord originally

supplied with this device and be HAR Certified

for use in the country in which the unit is de-

ployed.

15. WARNING: This device must be connected

to an AC outlet with a protective earth ground

connection.

www.furmancontractor.com • 877-486-4738 4

Security and Safety

SmartSequencing™ 101

SmartSequencing™ technology provides a very

simple means of connecting together a group of

Furman Contractor devices to form a network or

“chain” of sequencers. SmartSequencing™ al-

lows all devices within a chain to be controlled

and queried from a single Primary sequencer.

One of the defining characteristics of SmartSe-

quencing™ technology is its ability to allow any-

one to quickly achieve professional results.

SmartSequencing Hierarchy:

In a SmartSequencing™ network, there can only

be one Primary unit. Secondary units respond

to the commands from the Primary. The Pri-

mary unit manages the communications within

the SmartSequencing™ chain. (This includes

principal communication between the chain of

sequencers and the outside world, e.g. Blue-

BOLT®). Secondary units relay messages and/

or execute commands and queries that have

been routed to them by the Primary unit. The

CN-3600SE can serve as a Primary or Second-

ary sequencer depending on the setting of DIP

Switch #8 – more on this later.

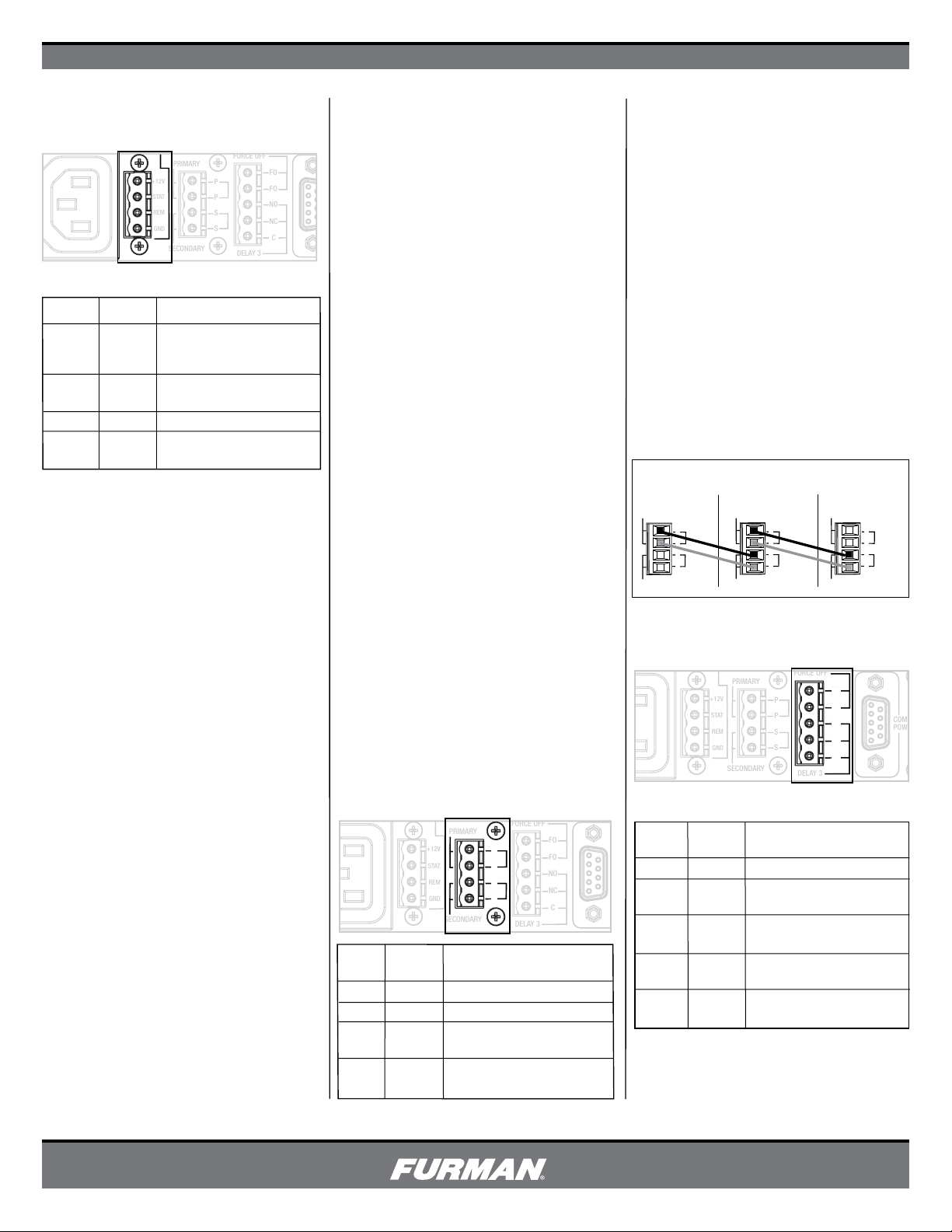

SmartSequencing Communications:

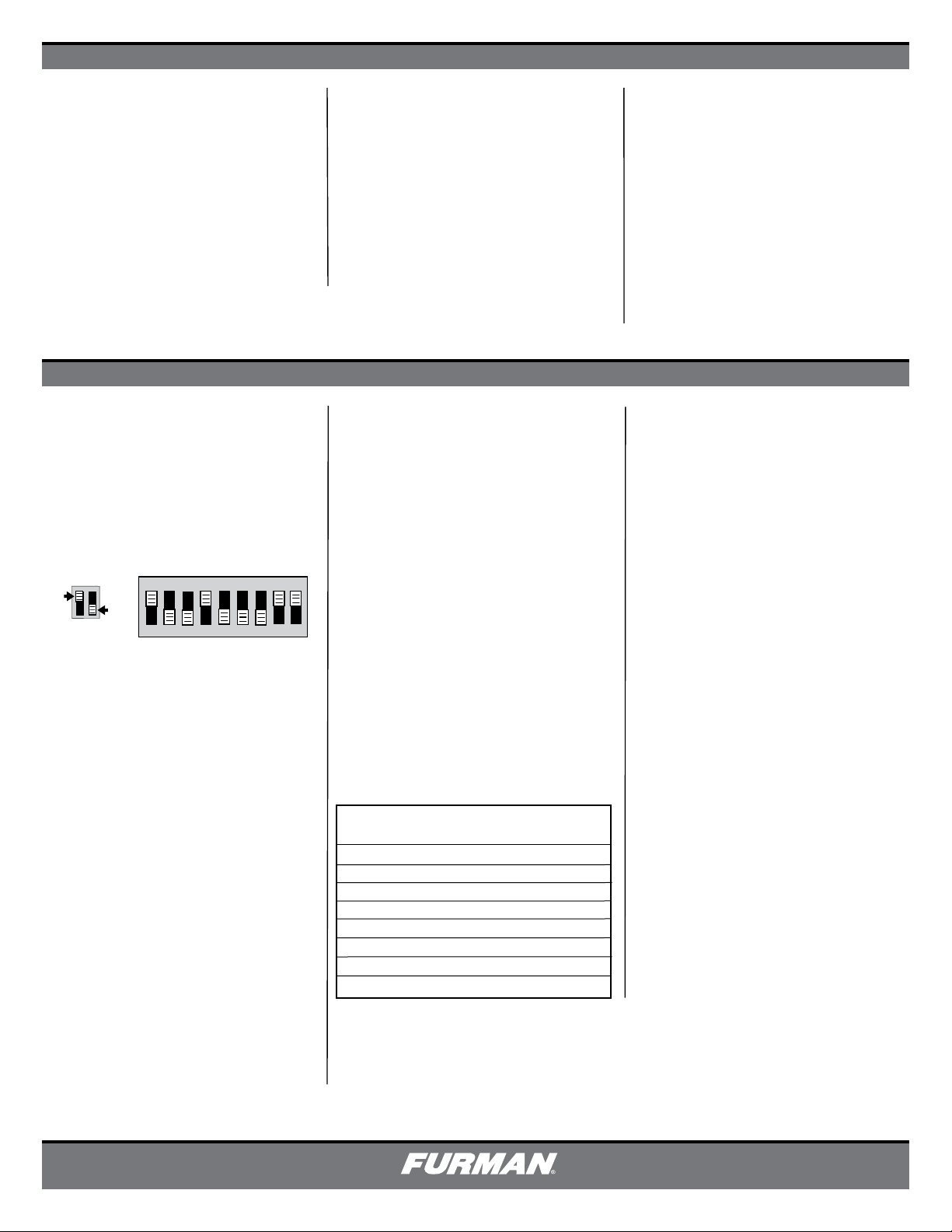

A Furman SmartSequencing™ chain commu-

nicates using a bucket brigade technique. A

Primary sequencer communicates to the first

downstream Secondary sequencer by sending

commands out of its Primary (P) OUT terminals

to the Secondary (S) IN terminals of the next

downstream Secondary sequencer. If there are

additional Secondary sequencers within the

chain, the first Secondary sequencer will com-

municate to the next downstream Secondary

sequencer using its Primary (P) OUT terminals

to the second Secondary (S) Unit’s Secondary IN

terminals. This continues down the chain until

the last Secondary sequencer has received the

message. The last Secondary sequencer will

receive commands into its Secondary (S) IN

terminal port but will not forward the message

because there are no more units downstream.

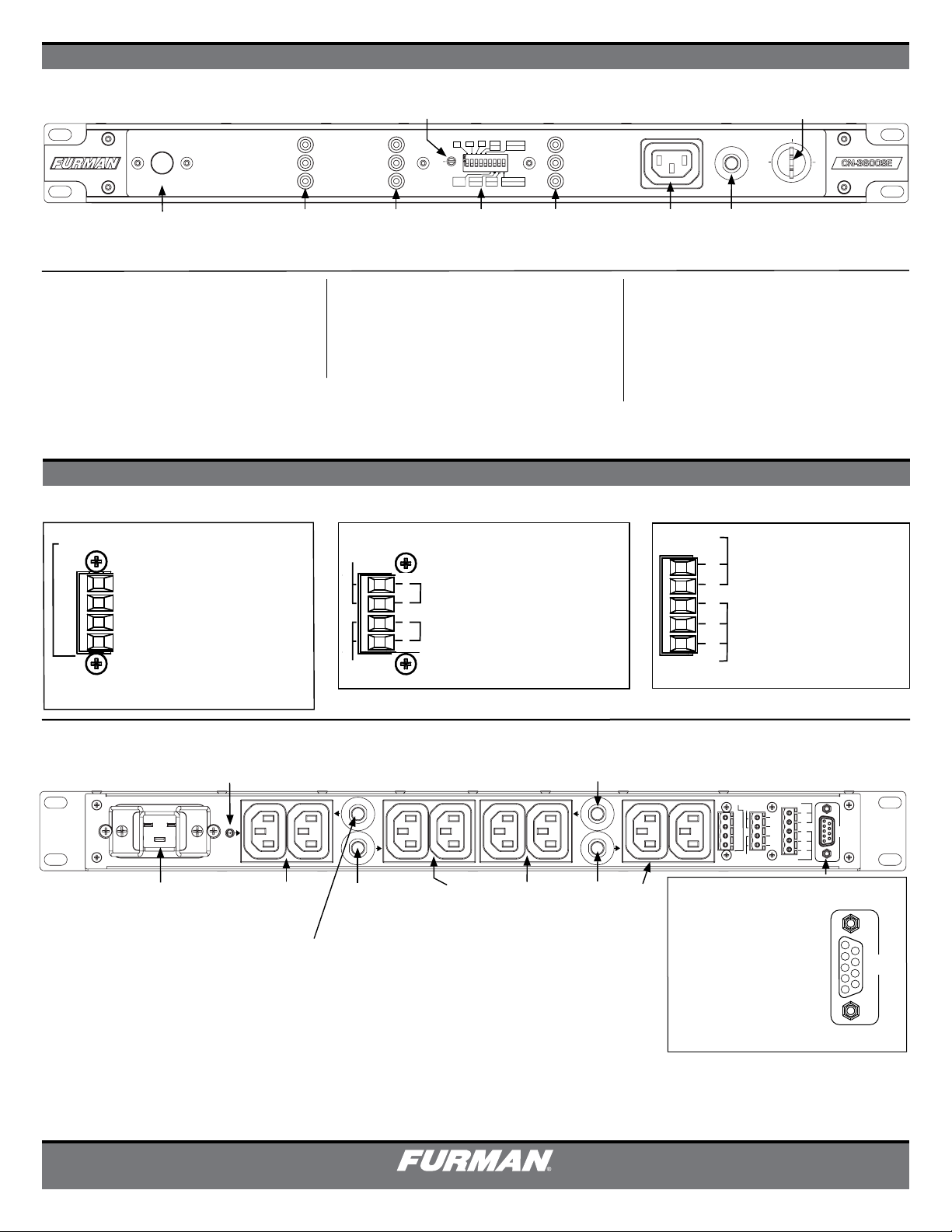

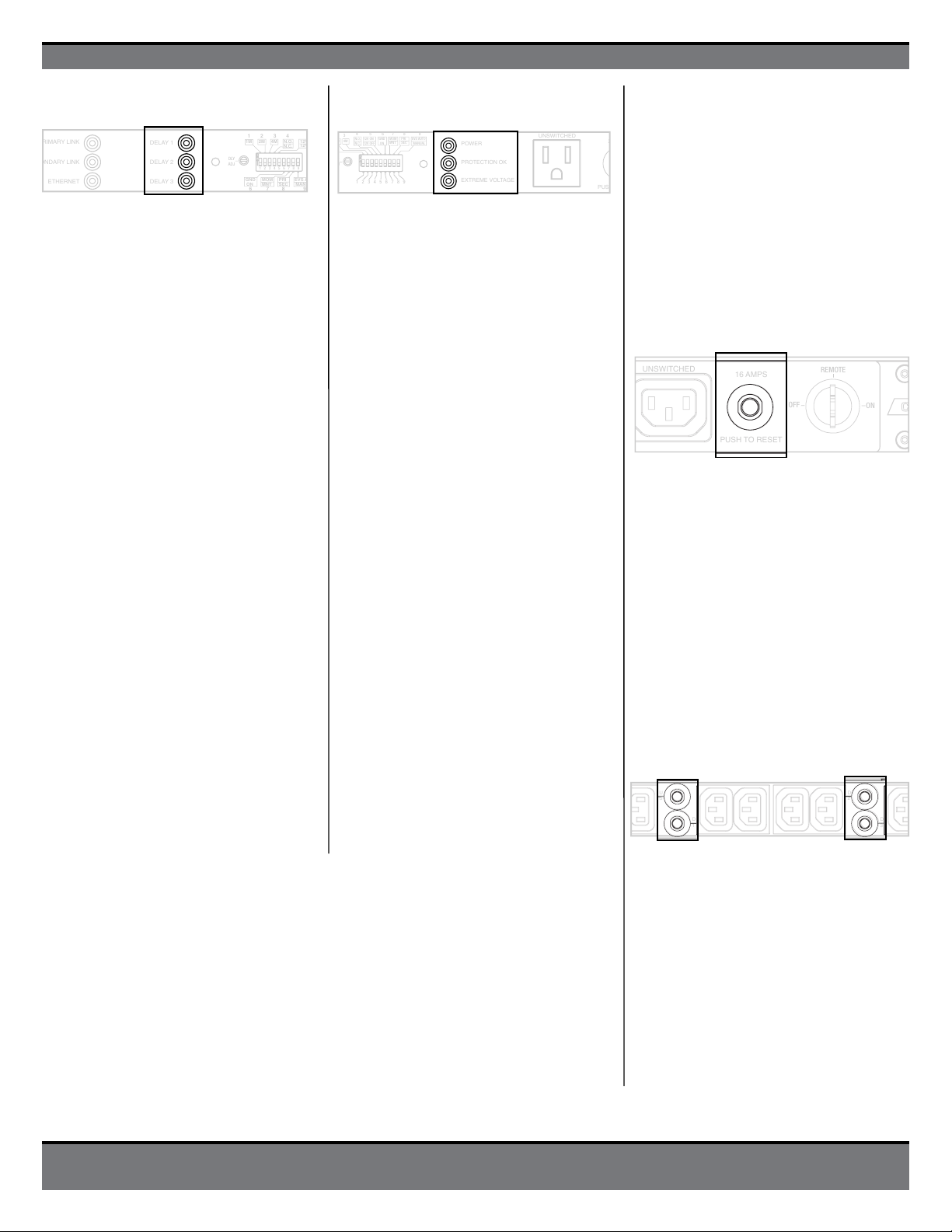

Forming a chain of sequencers:

Create a SmartSequencing chain by linking the

Primary (P) OUT terminals of the Primary to the

Secondary (S) IN terminals of the first Second-

ary sequencer. To add more sequencers, simply

connect

connect this first upstream Secondary Primary

OUT (P) terminals to the Secondary (S) IN ter-

minals of the next Secondary sequencer down-

stream. This pattern continues until all sequenc-

ers have been linked together as is shown in the

figure below.

Example of SmartLink connections

SmartSequencing is polarity independent, so it

does not matter which OUT (P) terminal is con-

nected to the IN (S) terminals on the next se-

quencer. All that matters is that the connections

proceed in the order in which you would like your

chain of sequencers to activate.

COMM/

POWER

+12V

STAT

REM

GND

P

P

S

S

OUT

IN

SmartSequencing

REMOTE PORT

PRIMARY

P

P

S

S

OUT

IN

PRIMARY UNIT

P

P

S

S

OUT

IN

SECONDARY

SECONDARY

P

P

S

S

SmartSequencing

PRIMARY (OUT)

SECONDARY

SECONDARY UNIT

P

P

S

S

PRIMARY (OUT)

SECONDARY (IN)

SECONDARY UNIT

P

P

S

S

PRIMARY

SECONDARY (IN)