DESCRIPTION

The Furman PowerLink is a compact, low-cost

rackmount Remote Sequencer that provides

timing for up to six power control devices, turning

them on and off in a preset seq uence. The delay

interval between the turn-on or turn-off of each

device and the next in sequence is user-

adjustable via an internal trimpot.

PowerLink can work with a group of relay-con-

trolled circuits such as Furman MiniPorts, to

create a very exible power control system that

can expand to handle as many circuits carrying

as much current as needed.

An on or off sequence can be initiated from the

PowerLink itself, using the built-in high-security lock-

ing key switch, or, if the key switch is set to enable

Remote operation, by one or more momentary or

maintained-action switches in distant locations.

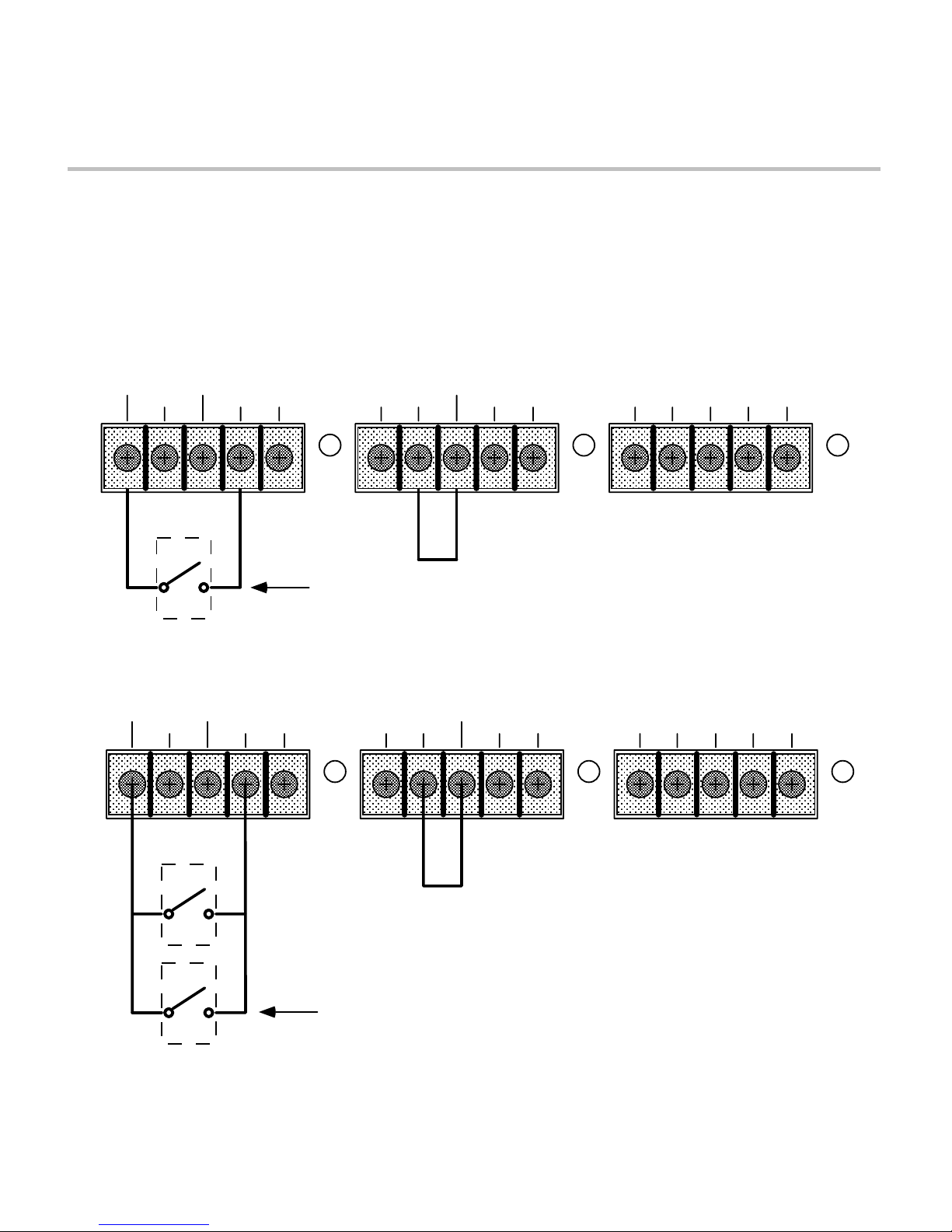

The outputs of the PowerLink are low power relay

contacts, accessible through rear-panel screw

terminal strips. Outputs may be congured to

be normally-closed or normally-open by internal

jumpers. All input and output commons are

electrically isolated to avoid the creation of ground

loops.

Power sequencing is needed whenever various

kinds of equipment must be powered up or down

in groups, rather than all simultaneously. In audio

systems, sequenced powering is often necessary

to allow turn-on transients from low level pream-

pliers and processors to settle down before any

power amps are turned on. This is because

simultaneous powering can result in a loud, an-

noying, and potentially destructive “pop” reaching

the speakers. In any large system whose com-

ponents present an inductive load to the AC line

(including electric motors, power supplies, and

power ampliers of all kinds), sequenced power-

ing can avoid excessive inrush currents that can

cause circuit breakers to trip even though the

steady-state currents are not excessive.

The PowerLink’s front panel provides a three-

position switch for each control output that al-

lows each control output to be part of the power

up/down sequence, or to remain on or off apart

from the sequence. It also provides an LED that

indicates when the circuit in on.

The outputs of the PowerLink are low power relay

contacts, which can control Furman PowerPorts,

MiniPorts, PS-PRO and PS-8R Power Sequenc-

ers, or any other circuits that need to know when

a particular time delay has elapsed. In larger

systems, one or more additional PowerLinks can

be installed in remote locations and operated via

low-voltage control wiring, providing the capability

of controlling power sequencing for a system of

any size.

CONTROLLING ON/OFF

SEQUENCE

A normal, time-delayed on or off sequence may

be initiated in either of two ways: locally, via the

front panel key switch, or remotely, via a remotely

located maintained or momentary switch connect-

ed to the PowerLink’s rear panel terminal strip. In

addition, the behavior of any individual circuit may

be overridden by its corresponding front panel

ON/SEQ/OFF toggle switch.

The PowerLink’s control circuits turn on the circuits

in order from A to F when sequencing on, and

turn the circuits off in the reverse order from F to

A when sequencing off. The time for each step is

internally adjustable with a trim pot, with a range

of 0.2 to > 12 seconds per step. (Total time for the

entire sequence is from 1 second to > 1 minute).

Local control: Turning the key to the ON (or possi-

bly REM) position initiates an on sequence. Please

3