ii

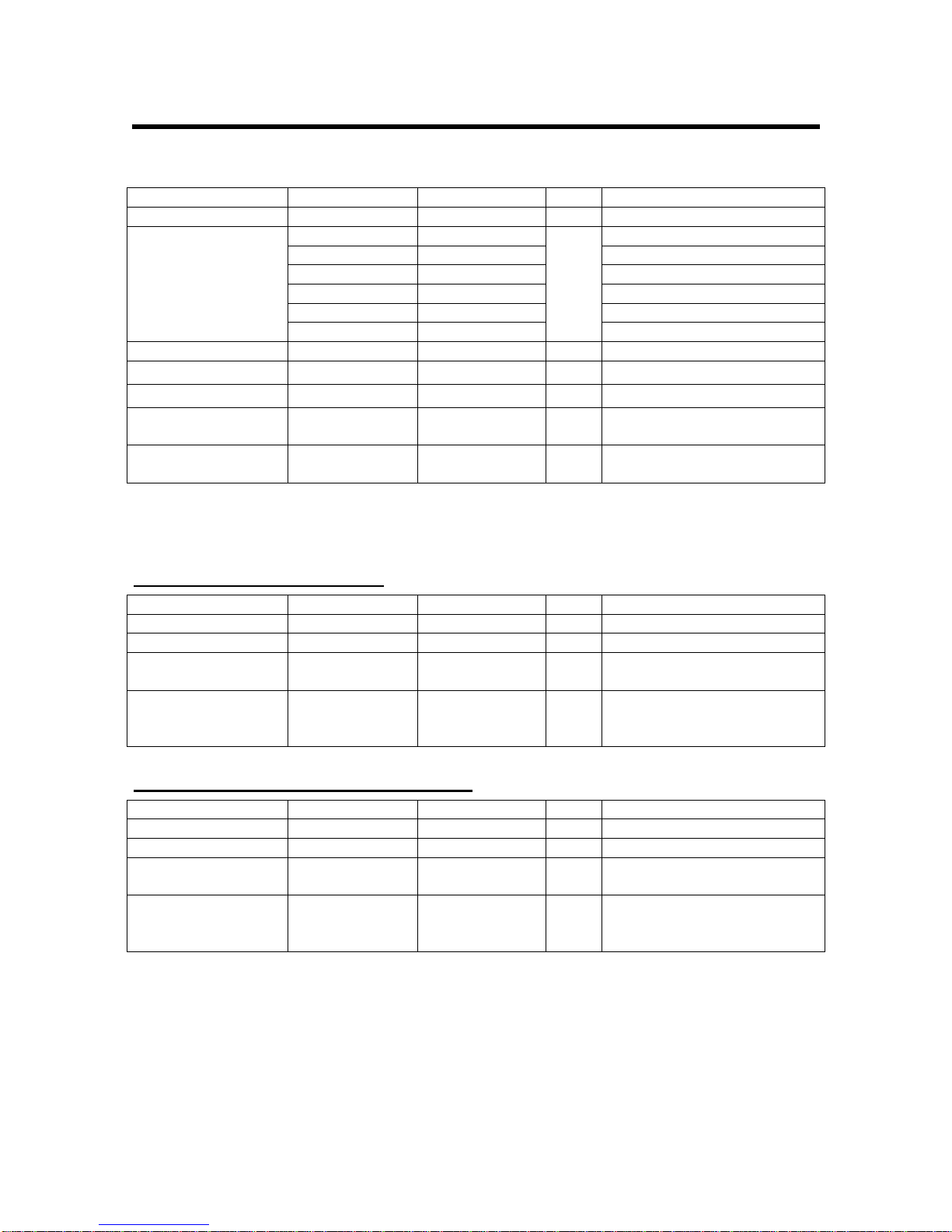

TABLE OF CONTENTS

SYSTEM CONFIGURATION ................. iii

EQUIPMENT LISTS .............................. iv

1. MOUNTING ........................................ 1

1.1 Category of Equipment ...........................1

1.2 Display Unit ............................................2

1.3 Transceiver Unit......................................3

1.4 Transducer Unit ......................................4

1.5 Distribution Box ....................................12

1.6 Terminal Box (option)............................13

1.7 Digital Indicator, Distance Indicator

(option)................................................13

1.8 Junction Box (option)............................14

1.9 Dimmer (option)....................................15

1.10 Range Switch Box, Analog Display Unit

(option)................................................15

2. WIRING ............................................ 16

2.1 Precautions for cable Installation...........16

2.2 Wiring of Distribution Box......................17

2.3 Wiring of Transceiver Unit.....................21

2.4 Wiring of Terminal Box ..........................23

2.5 Display Unit (Digital Indicator, Distance

Indicator) ............................................ 24

2.6 Dimmer, Analog Display Unit, Range

Switch Box.......................................... 24

2.7 Grounding............................................ 25

2.8 Wiring Check ....................................... 25

3. SYSTEM SETTINGS ........................ 26

3.1 Transducer Adjustment ........................ 26

3.2 Setting of System Menu 2 .................... 27

3.3 Checking the Interconnection............... 28

3.4 Setting of the Maximum Speed Range . 29

3.5 Ship's Speed Adjustment...................... 29

3.6 Setting for Analog Display .................... 30

3.7 DIP Switch S4 Settings ........................ 31

4. CHANGING AC POWER TAP .......... 33

APPENDIX CALIBRATION ..............AP-1

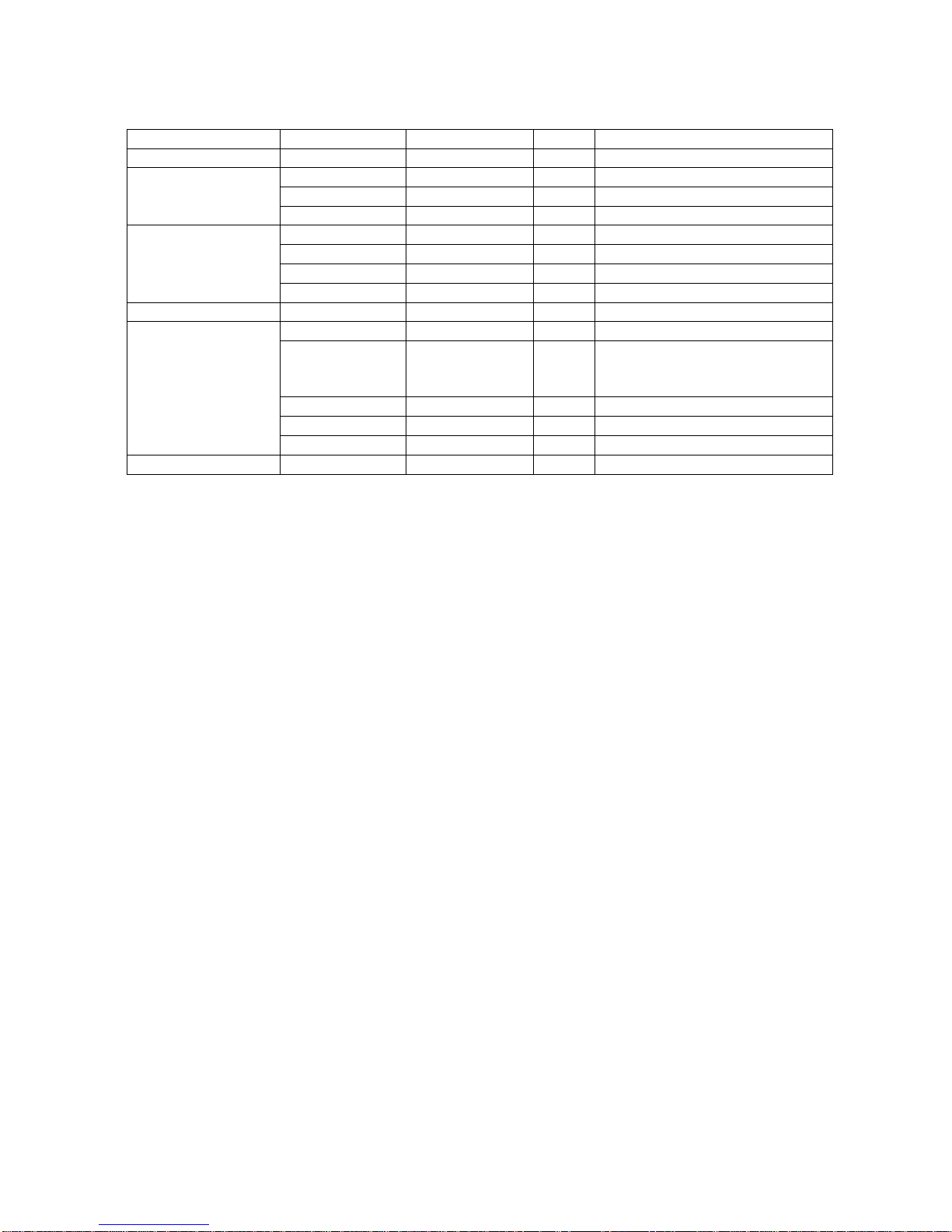

PACKING LISTS................................. A-1

OUTLINE DRAWINGS........................ D-1

INTERCONNECTION DIAGRAMS..... S-1