www.furuno.com

ll brand and product names are trademarks, registered trademarks or service marks of their respective holders.

Installation Manual

Stabilized FISH SIZE INDICATOR

Model FCV-38

(Product Name: FISH FINDER)

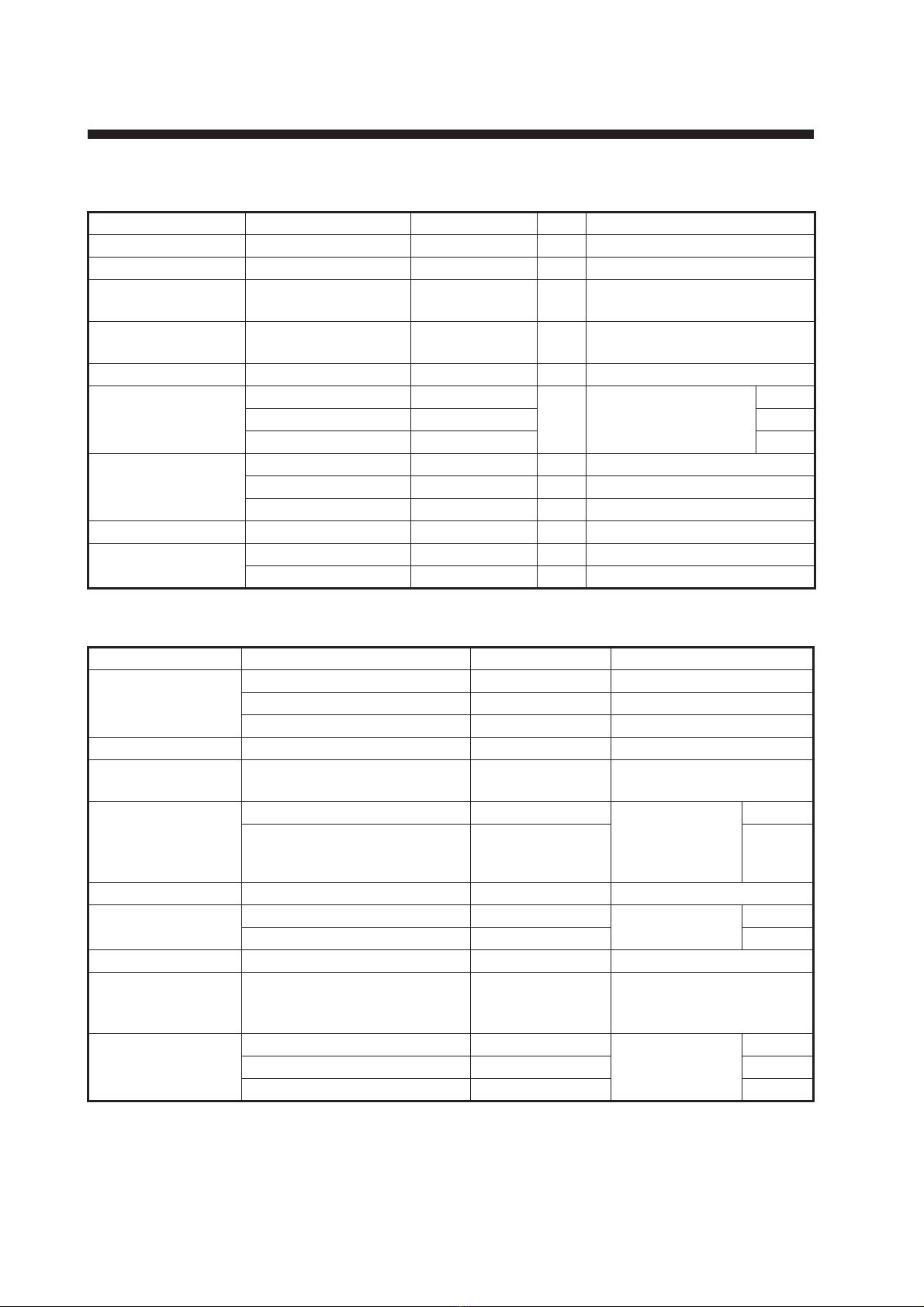

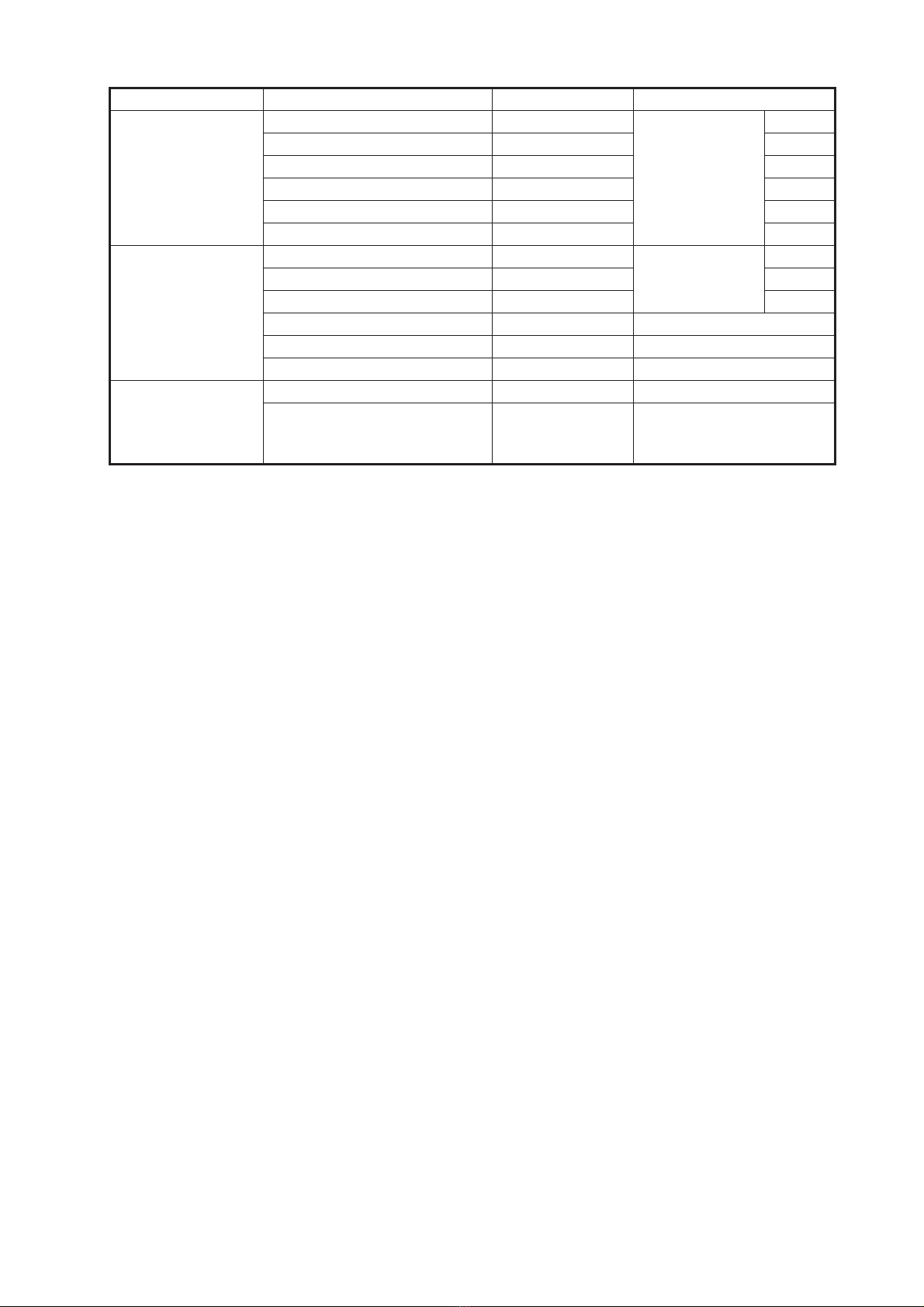

SAFETY INSTRUCTIONS ................................................................................................ i

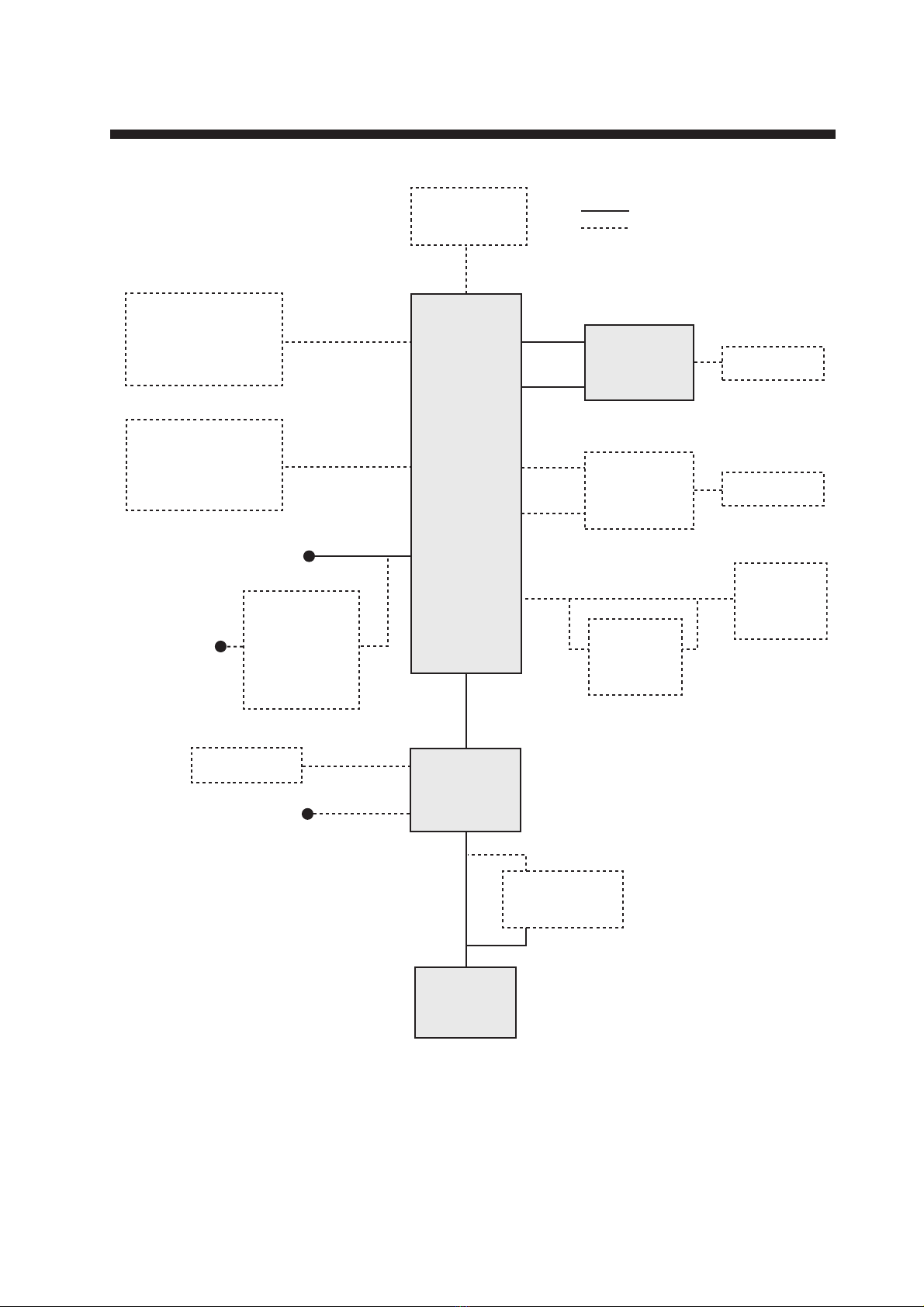

SYSTEM CONFIGURATIONS........................................................................................ iii

EQUIPMENT LISTS........................................................................................................ iv

1. MOUNTING..............................................................................................................1-1

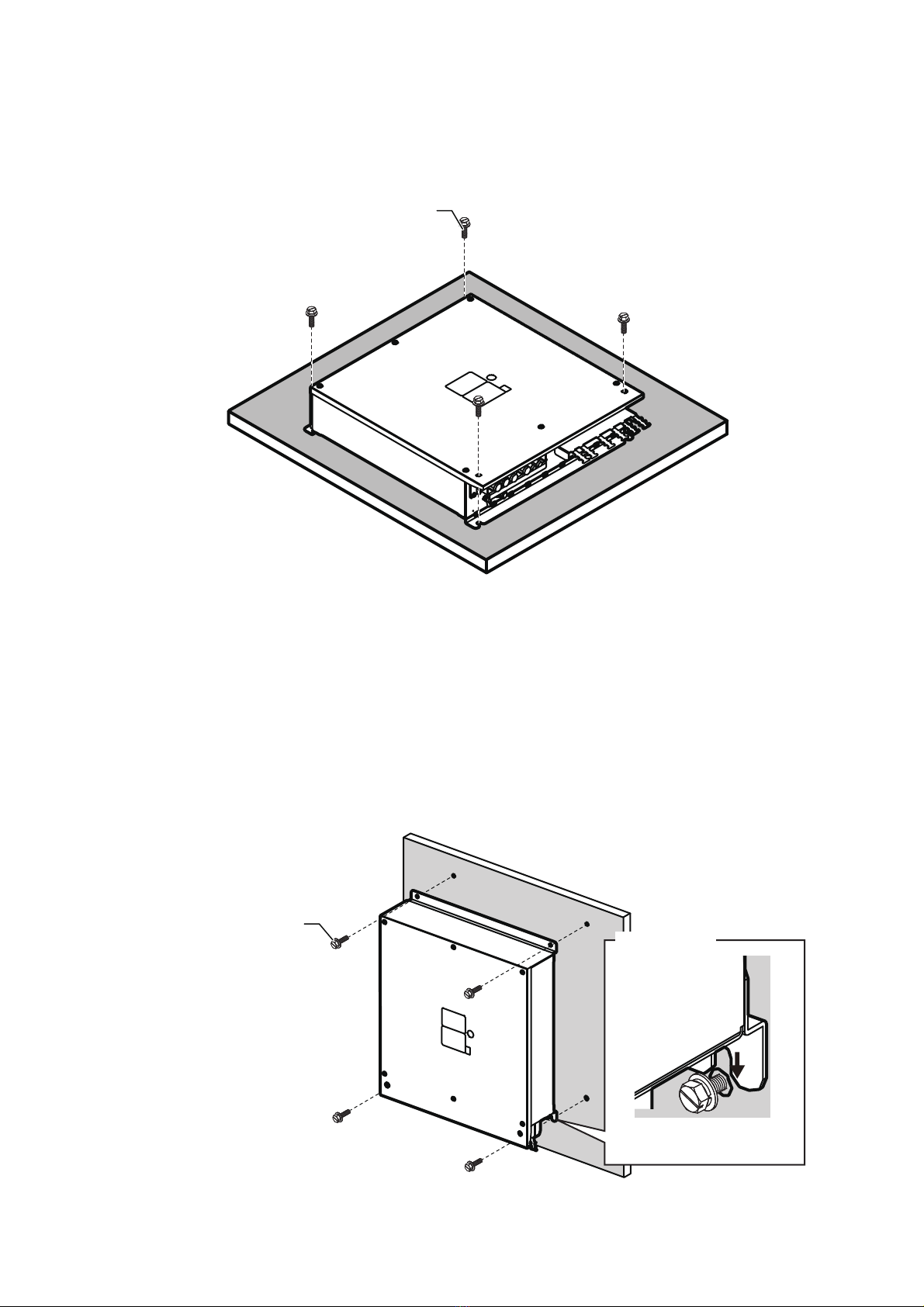

1.1 Processor Unit ...................................................................................................................1-1

1.2 Transceiver Unit.................................................................................................................1-3

1.3 Trackball Control Unit ........................................................................................................1-4

1.4 Transducer.........................................................................................................................1-7

1.5 Junction Box (Option) ......................................................................................................1-10

1.6 DVI/USB Repeater (Option).............................................................................................1-10

2. WIRING....................................................................................................................2-1

2.1 Processor unit ....................................................................................................................2-2

2.2 Transceiver Unit.................................................................................................................2-6

2.3 Trackball Control Unit ........................................................................................................2-8

2.4 Transducer.......................................................................................................................2-10

2.5 Junction Box (option) .......................................................................................................2-11

2.6 DVI/USB Repeater (Option).............................................................................................2-13

2.7 Input/Output Sentences (NMEA0183) .............................................................................2-14

3. INITIAL SETTINGS..................................................................................................3-1

3.1 How to Set the Language and Measurement Unit .............................................................3-1

3.2 How to Set the [Service] Menu ..........................................................................................3-2

3.3 Communication Port Setting ..............................................................................................3-7

3.4 External Echo Sounder Setting........................................................................................3-10

3.5 Calibration Setting............................................................................................................3-12

3.6 Stabilization Setting .........................................................................................................3-16

3.7 How to Take a Still Image of the RX Monitor...................................................................3-19

3.8 Reset to Default Setting...................................................................................................3-19

3.9 Retrofit from FCV-30........................................................................................................3-20

APPENDIX 1 JIS CABLE GUIDE .............................................................................AP-1

PACKING LISTS ......................................................................................................... A-1

OUTLINE DRAWINGS ................................................................................................ D-1

INTERCONNECTION DIAGRAMS.............................................................................. S-1