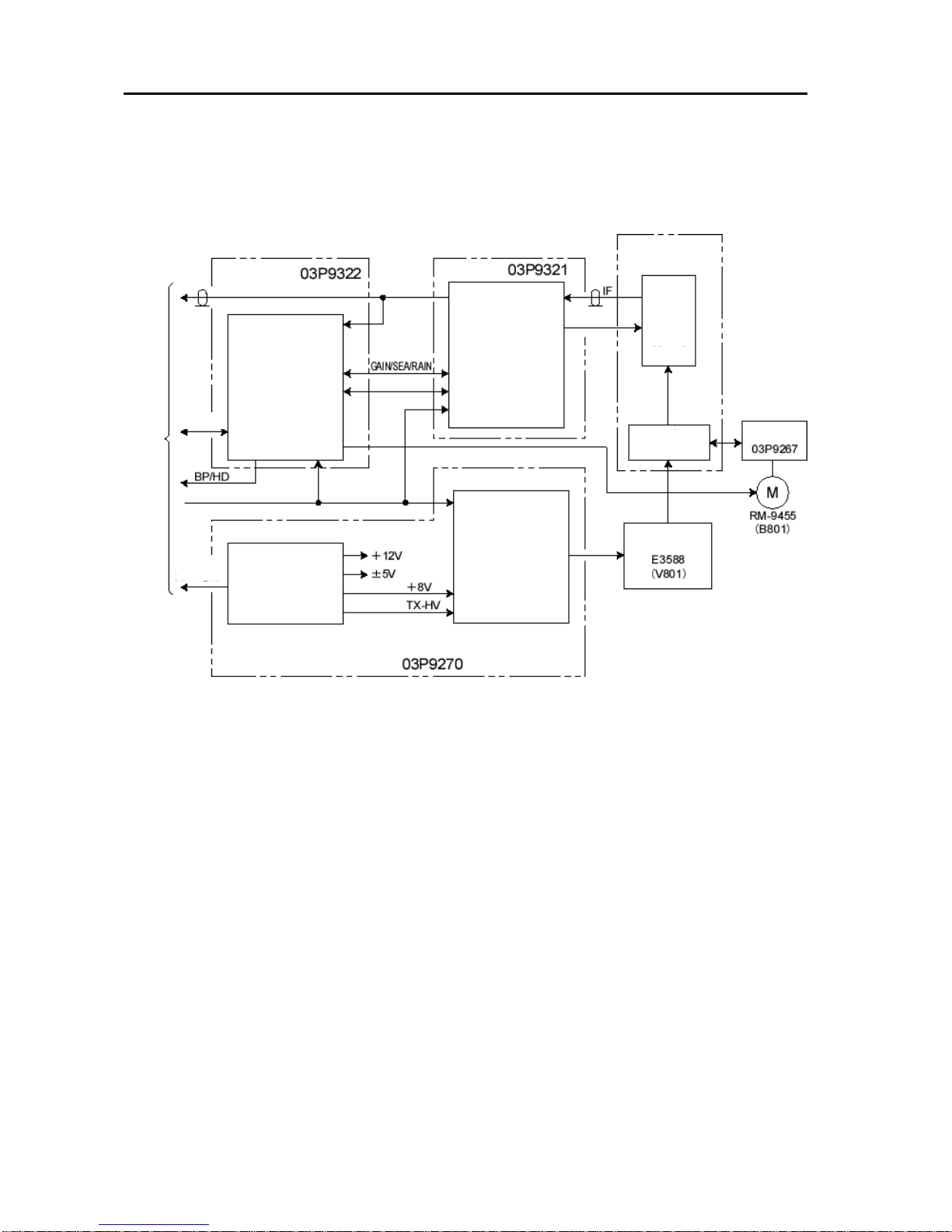

1.2 Display unit

3

The display unit consists of PNL board (03P9356), DU board (03P9320) and LCD unit

(EW50300FDWR). Each board functions as below.

PNL Board (03P9356)

This board functions as a man-machine interface, equipped with keys, LEDs for

panel-illumination, and a buzzer.

DU Board (03P9320)

According to the range setting, gate array U79 generates TX trigger pulses in specified pulse

repetition rate. Reference oscillator output is divided by the data from the CPU to decide the

PRR.

The pulse repetition rates differs slightly from set to set to prevent the radar interference.

The video signal from the scanner unit inputs to the video circuit on the DU board.

The video circuit includes FTC circuit that rejects the reflecting signals from the rain and snow.

CPU switches on or off the FTC according to control panel setting.

The video signal is converted by the A/D converter into seven-level digital signal, and input to

the radar signal processing circuit in the gate array U78. The digital video signal is sampled in

U78 with the sampling clock corresponding to the range setting. Further, when the interference

rejecter is turned on, each video signal is correlated with the corresponding transmission to

eliminate or reduce the radar interference signals. The processed video signal by U78 is written

into VRAMs via U79 for indication.

The bearing signal and heading signal are input to serial-to-parallel converter and then applied to

G/A U79 individually. Heading error obtained at heading alignment in installation menu is stored

in EEPROM U28, and used by CPU to calculate the correct antenna direction. TX time delay

data is also stored in EEPROM U28.

Unlike R/θcoordinate sweep, LCD display employs X-Y coordinate method similar to so called

TV- sweep method. U79 converts the R/θvideo signal to X-Y coordinates using formulas, RSIN

θand RCOS θ. The coordinate-converted video signal is written and maintained onto VRAM for

trail indication.

The data writing/reading onto/from the VRAM is carried out by U79 in time sharing. U79

retrieves data from VRAM to display it on the LCD display.

Scanner unit control data is converted to serial data by RS-422 interface, U27 and sent to the

scanner unit through a balanced RS-422 line. The control data includes transmission on/off, TX

pulsewidth selection, Gain and STC signals.

The data from the navigational aid is received through photo-couplers U10 and U11.