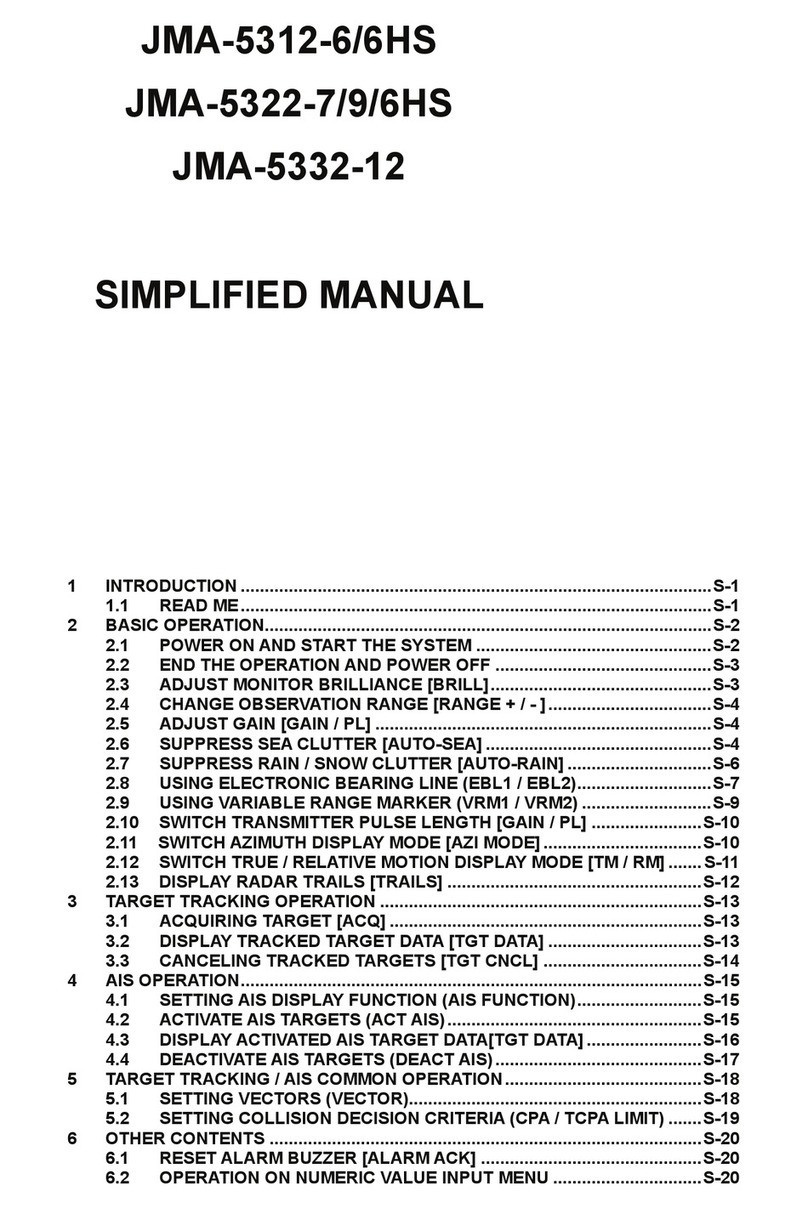

CONTENTS

1. OVERVIEW

2. INSTALLATION OF THE SCANNER

2.1 SELECTING THE INSTALLATION POSITION ........................................ 2-1

2.2 INSTALLATION PROCEDURE ................................................................ 2-5

2.3 CONNECTING THE INSTALLATION CABLE (NKE-2103) ..................... 2-9

2.4 CONNECTING THE INSTALLATION CABLE (NKE-2254) ....................2-11

3. INSTALLATION OF THE DISPLAY UNIT

3.1 SELECTING THE INSTALLATION POSITION ........................................ 3-1

3.2 INSTALLATION OF THE LCD MONITOR................................................ 3-2

3.3 INSTALLATION OF THE OPERATION UNIT .......................................... 3-4

3.4 INSTALLATION OF THE POWER CABLE (CFQ-5436).......................... 3-5

3.5 INSTALLATION OF THE CABLE (CFQ-6912)

BETWEEN THE RADAR PROCESS UNIT AND THE SCANNER .......... 3-8

3.6 CONNECTING TO THE GPS RECEIVER.............................................. 3-10

3.7 CONNECTING TO THE GPS COMPASS .............................................. 3-15

3.8 CONNECTING TO NMEA HEADING OUTPUT DEVICE....................... 3-23

3.9 CONNECTING TO THE GYRO AND ELECTROMAGNETIC LOG

(NSK UNIT SETTING) (OPTION)........................................................... 3-25

3.10 CONNECTING TO THE PC PLOTTER.................................................. 3-31

3.11 CONNECTING TO OTHER NMEA DEVICES ........................................ 3-32

3.12 CONNECTION WITH OTHER DEVICES

(SUB INDICATOR OUTPUT AND SLAVE INPUT) ................................ 3-34

3.13 POWER SUPPLY (NBA-5111) (OPTION) .............................................. 3-38

3.14 TARGET TRACKING (NCA-877A) (OPTION) ....................................... 3-39

3.15 PLOTTER CIRCUIT (NDB-44) (OPTION) .............................................. 3-41

3.16 CONNECTING TO AIS (NQA-2155) (OPTION) ..................................... 3-43

3.17 COASTLINE ROM CARD/MEMORY CARD .......................................... 3-47

3.18 CONNECT SLAVE MONITOR / VDR..................................................... 3-50

3.19 SIMPLIFIED INTER-SWITCH INSTALLATION...................................... 3-52

3.20 SUB KEY-BOARD INSTALLATION....................................................... 3-54

3.21 CONNECTING TO EXTERNAL BUZZERS............................................ 3-56

3.22 CONNECTING CONTACT SIGNALS TO EXTERNAL DEVICES.......... 3-58