Required tools and installations equipment

Depending on type of installation, the following tools are required:

-set of screw drivers

-drill and set of bits

-wrench

-crimping shears for the12/24V wire connection

For connection of inverter to the battery, the following cable connecting

hardware is needed:

-2 different flexible cable connections.

-Various terminals, multi-core cable ends

Caution:

Before drilling any mounting holes, make sure that there are no wires,

fuel lines or tanks directly below the surface being drilled.

Installation

The inverter has to be installed in a dry and clean place not being

exposed to humidity.

Make sure there is proper ventilation.

Keep at least a free space of 10 cm surrounding the inverter.

If installed into housing, make sure there’s good ventilation.

The air intake on the bottom of the inverter and the air outlet on the back

side may not be blocked.

The installation surface must be balanced and sufficiently strong.

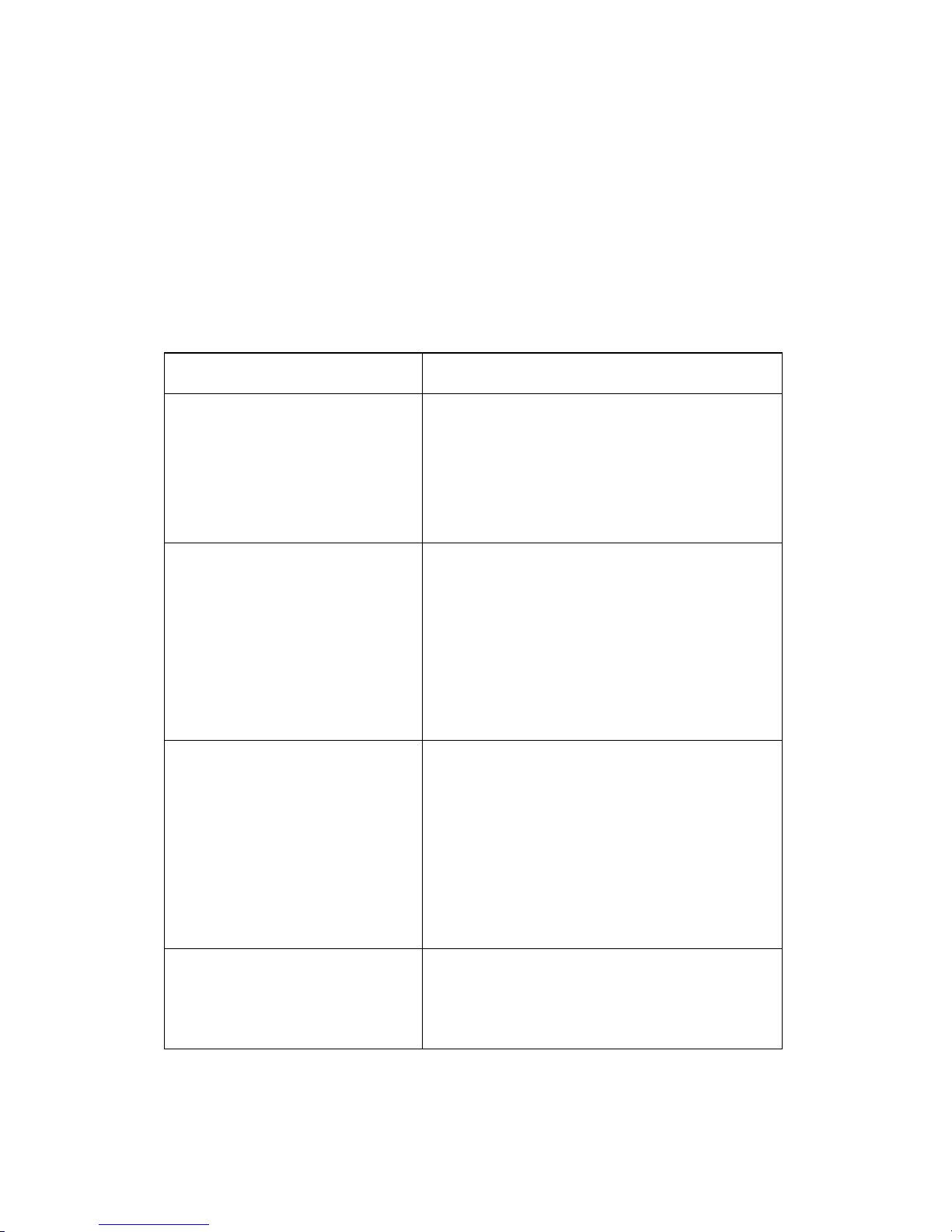

Installation of the inverter

-Adjust the inverter to the chosen installation place and mark the fixing

points.

-Fix the inverter by using the self chosen fixing method.

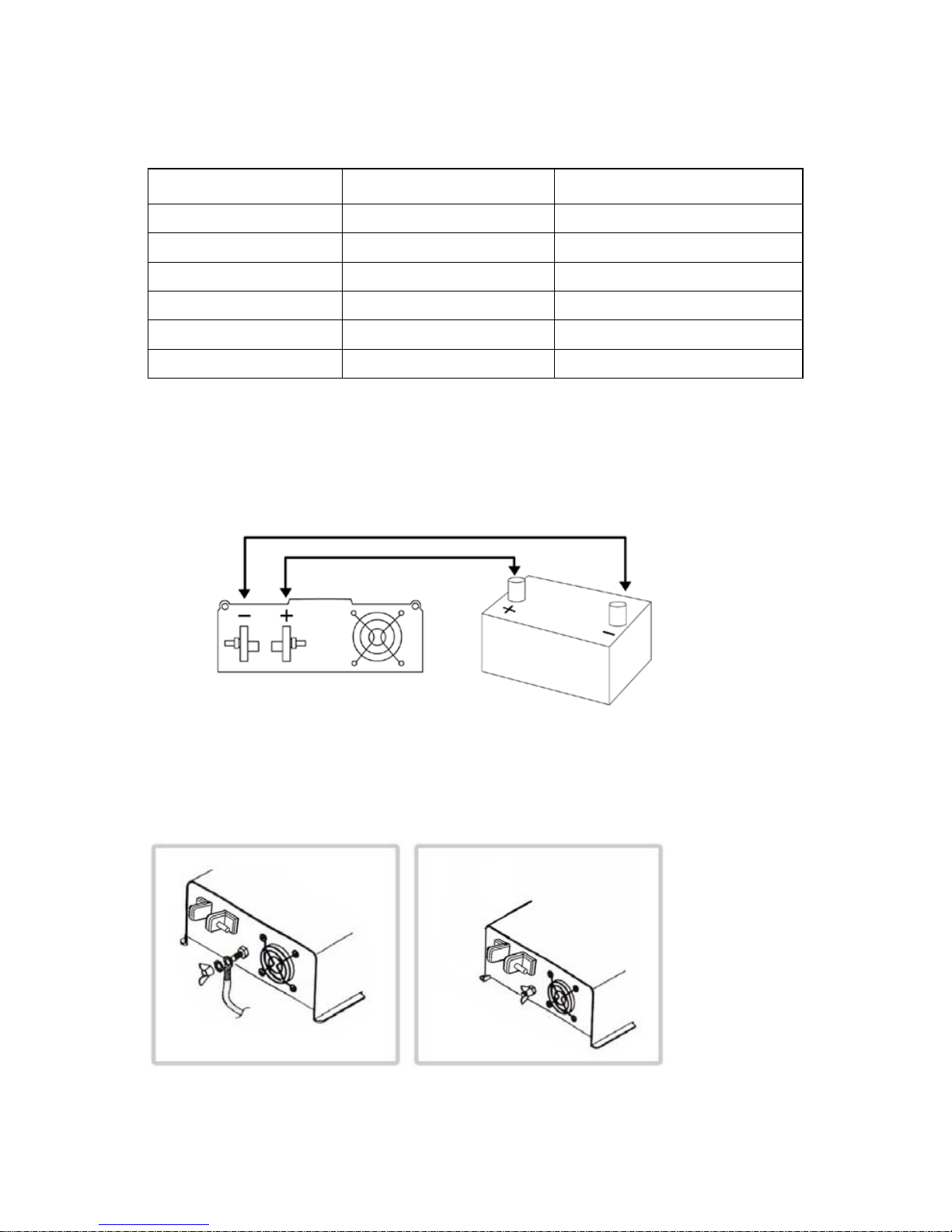

Electrical connection

General instructions for electrical connection.

In case of the inverter is installed into vehicles or boats it has to be

connected to the chassis (ground).

If cables have to be inserted to metal walls or other sharp-edged means,

use a cable duct or cable bushes.

Do not pull the cables.

Do not lay cables loose or in sharp bends on electrical conducting

materials (metal).

Do not lay 110V mains cable and 12/24 VDC cable together into the

same cable duct.

The specified minimum cable cross section must be complied with.

Secure cables properly.

Lay cables in such a way that no tripping is possible.

Lay cables in such a way that no exposure to or risk of damage is

possible.