6

2.INTRODUCTION

Features

RS301CR/RS302CD servo is especially designed for robotic applications, having the

following features.

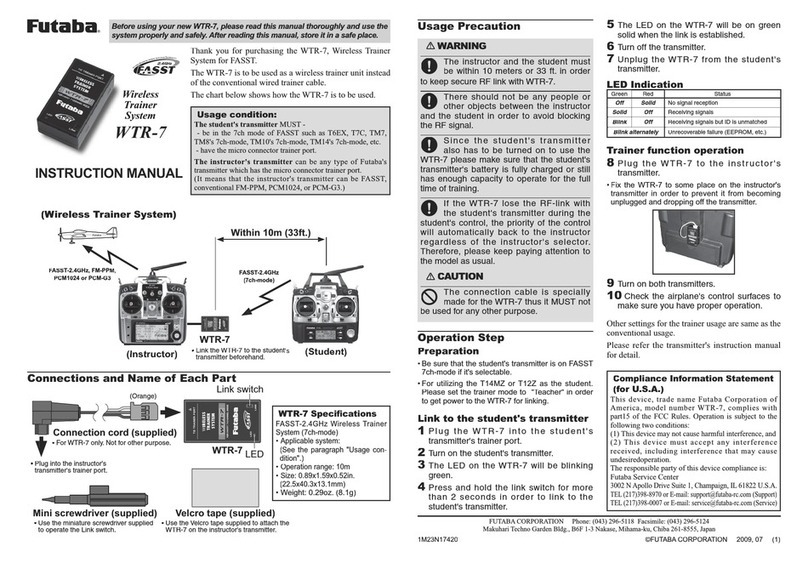

● Small and Lightweight

RS301CR and RS302CD are small and

lightweight servos specially designed for

robots, which are 28g and 21g

respectively.

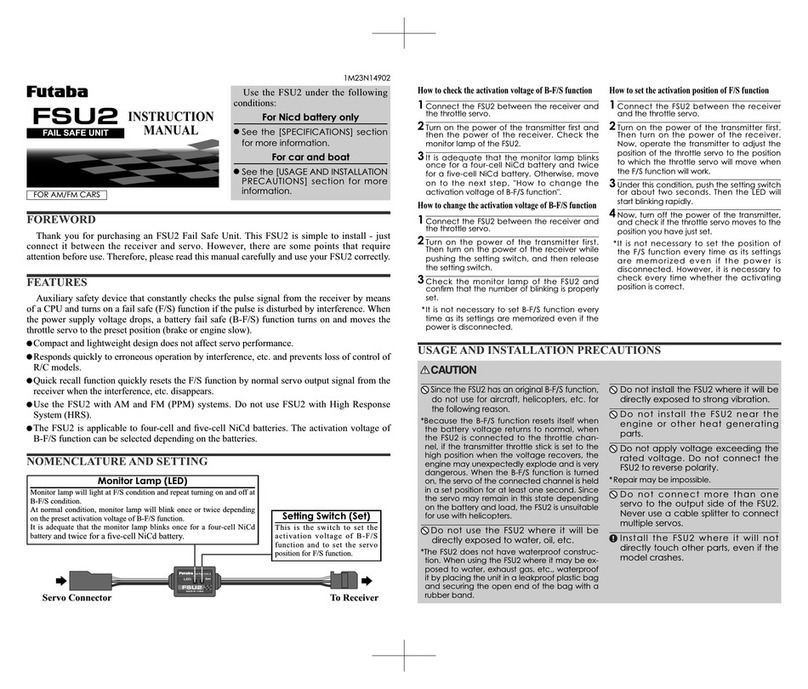

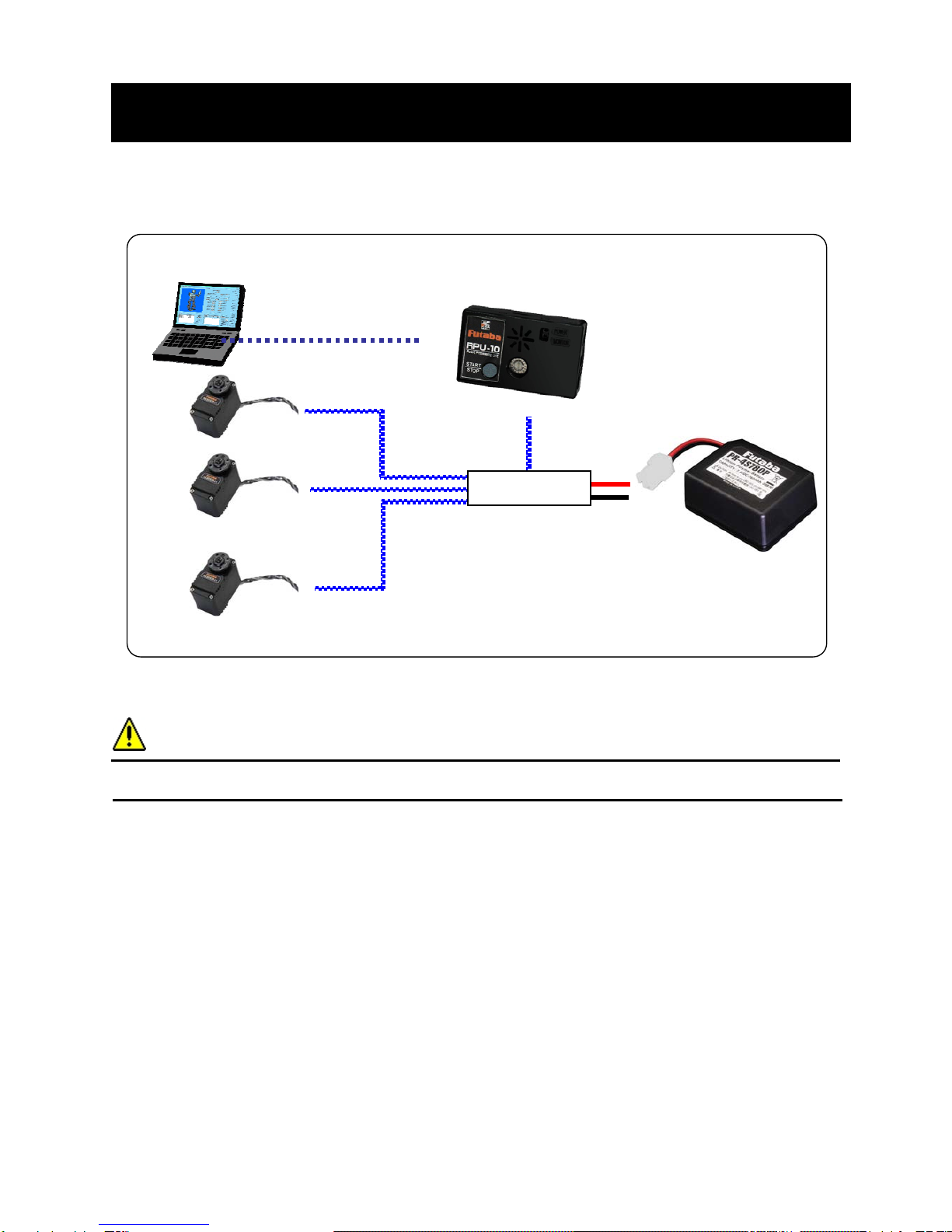

● Interactive high speed

RS485 communication

RS485 half duplex communication

carries out bidirectional high-speed

communication up to 460kbps. RS485 is

used for the communication between the

robot’s processor unit and servos at very

high speed.

●Command type control

The servo can be controlled by commands

sent from the robot’s processor unit

through RS485. And a single command can

convey multiple data, including a period of

time to move and a target position. This

relieves the robot’s processor unit from load

significantly.

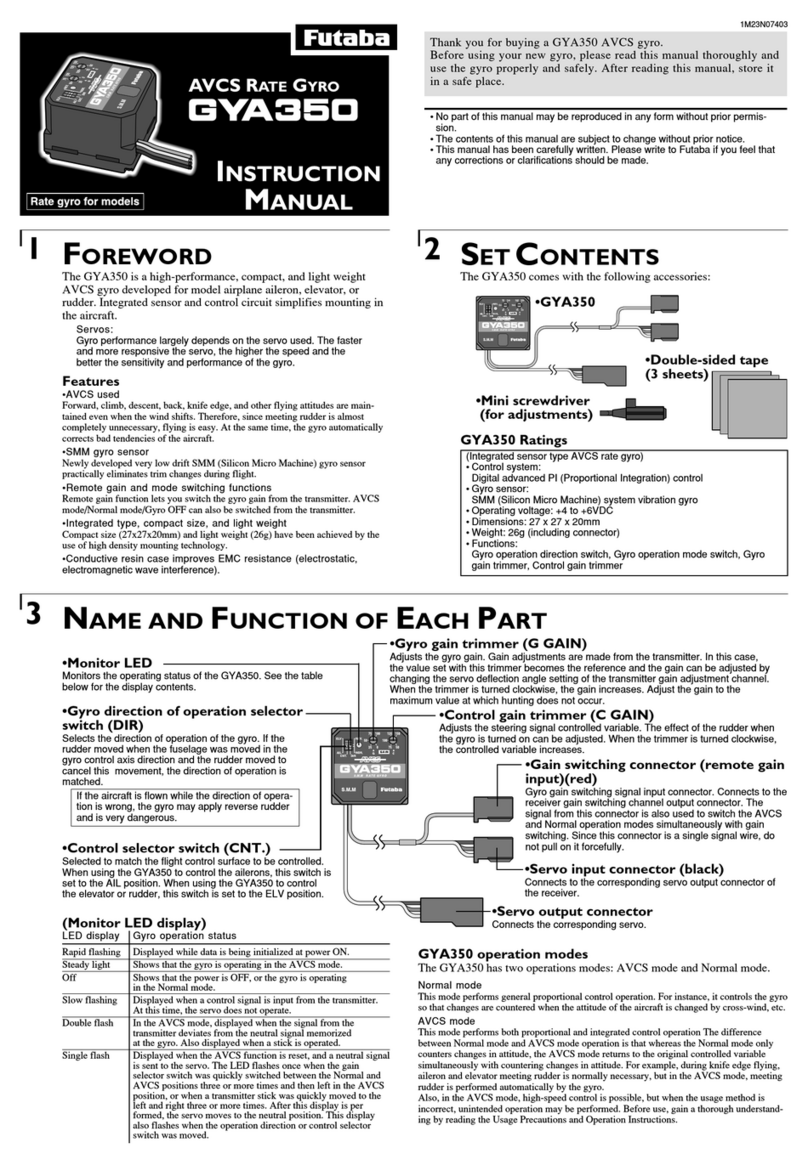

●Data Feedback

Various kinds of information about the

servo such as angular position, load,

temperature, current and alarm can be

obtained via RS485.

●Compliance control

With this feature, the movement of the

RS301CR/RS302CD is controlled in

accordance with the distance between the

present and target positions. This enables

the robot to move very smoothly without

trembling its arms and legs and to absorb

turbulence from external force.

●Calibration

Angular position of every

RS301CR/RS302CD servo is calibrated by

our standard gauge before their shipment.

Even if another RS301CR/RS302CD servo

is employed, it does not require any

bothersome work for adjusting its angular

position.

● 12bit-A/D converter

for precise positioning

Angular feedback using the 12bit-A/D

converters makes it possible to position the servo

angle precisely.

● Wiring from the output shaft

Wires pass through the backside of the

output shaft to avoid getting wires

entwined in operation.

● Horn with a mark for reference position

凹marks are placed on the

circumference of the servo horn in order

to make sure the reference position even

after being built in. (one 凹for 0°

position, two for 90°, three for 180°

and four for 270°).