3Rev. 3/18

GAGE BILT ●615A-61 Pulling Heads

MAINTENANCE, REPAIR AND ADJUSTMENTS

Universal Head Countersunk Head

ASSEMBLY INSTRUCTIONS

1. Replace any broken or worn parts. When reassembling drawbolt,

press in special washer (16) while inserting retaining ring (17).

When retaining ring is in place turn special washer until its lug is

positioned between the ends of the retaining ring.

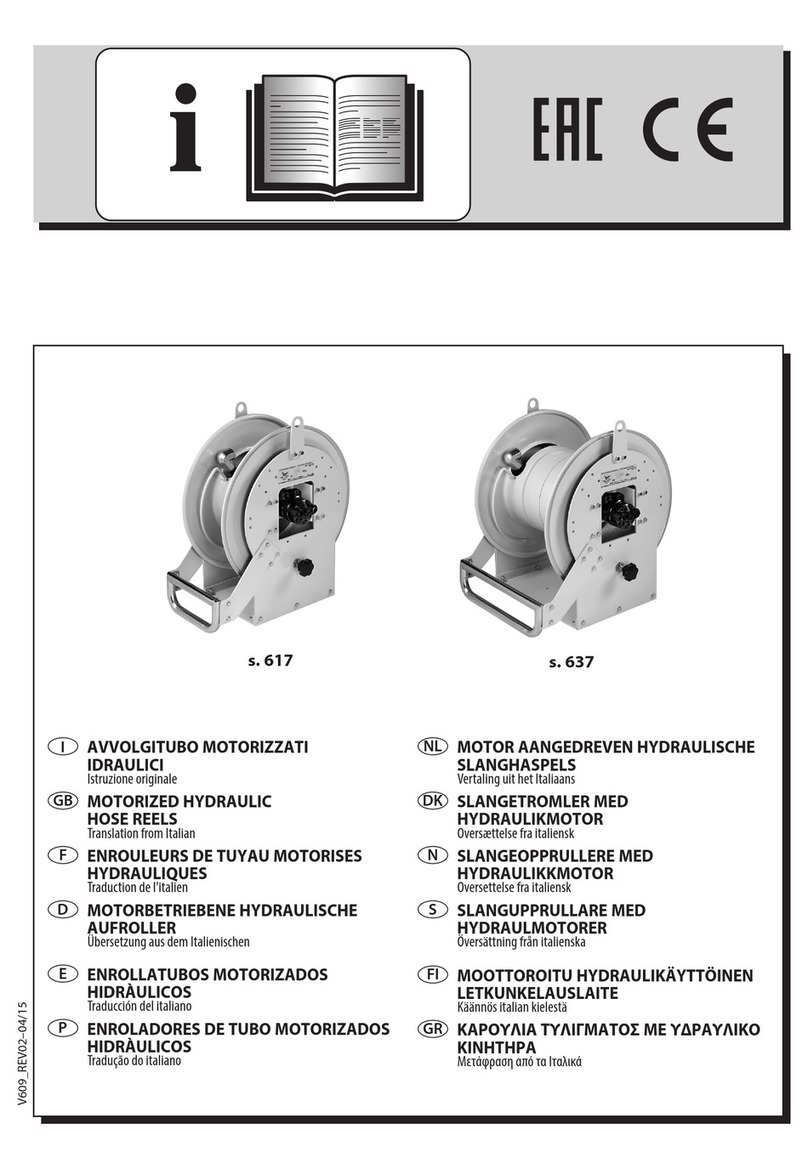

2. If shift slide (4) has been removed from nose assembly for repair or

replacement it should be repositioned by turning screw (3) until it

protrudes from the back of the slide 3/16" to 7/32". With the shift

slide pressed snugly against rear of drawbolt (5), run cap screw (2)

in until tight. Shift slide will then be in approximately the correct

operating position, but may require minor adjustments as shown in

the shift point adjustment instructions.

3. Apply a coating of high pressure grease, such as Lubriplate®

130AA, to the top and bottom of drawbolt (5) and to the bottom of

rocker arm (20). Reassemble nose.

DISASSEMBLY INSTRUCTIONS

1. Loosen jam nut (28) and remove adapter sleeve (31). Remove

spring (30) and drawbolt adapter (29).

2. Remove four button head screws (25) and lift off cover (1).

3. Remove retaining ring (22), button screw (25), guard (24) and pivot

pin (23). This will allow rocker arm (20), anvil (21) and drawbolt (5)

to be removed from sleeve assembly (27).

4. To disassemble drawbolt, remove retaining ring (17) and washer

(16). The stem stop (8), jaws (9), ejector (10), spring (11), follower

(12), seat (13), spacer (14) and spring (15) will then come out of

rear of drawbolt.

5. It is not usually necessary to remove the shift slide (4), stop block

(6) or outer anvil (18), but if any of them have been damaged they

may be removed by loosening screws (2), (7) and (19).

CLEANING NOSE ASSEMBLY

It is important that the nose assembly be kept clean, especially

around the riveting end, as adhesives, chips, sealants, etc. Will

clog the serrations of the jaws and cause slipping. The outer

anvil and the inner anvil must be kept especially clean since

foreign matter can build up and keep the anvil from going all the

way forward to set the locking collar in the rivet.

An occasional application of good grade high pressure grease, such

as Lubriplate 130AA, to the bottoms of the drawbolt and rocker arm

will prolong the life of these parts.

ADJUSTING NOSE ASSEMBLY

These nose assemblies are factory adjusted to properly install rivets

in the A-Group (shorter lengths). If nose assembly has been disas-

sembled for repair it will be necessary to readjust it. Gages can be

purchased and are identified by their color: 1/8" No. 628-4 is green;

5/32" No. 628-5 is red; 3/16" No. 628-6 is blue; and 1/4" No. 628-8 is

plain

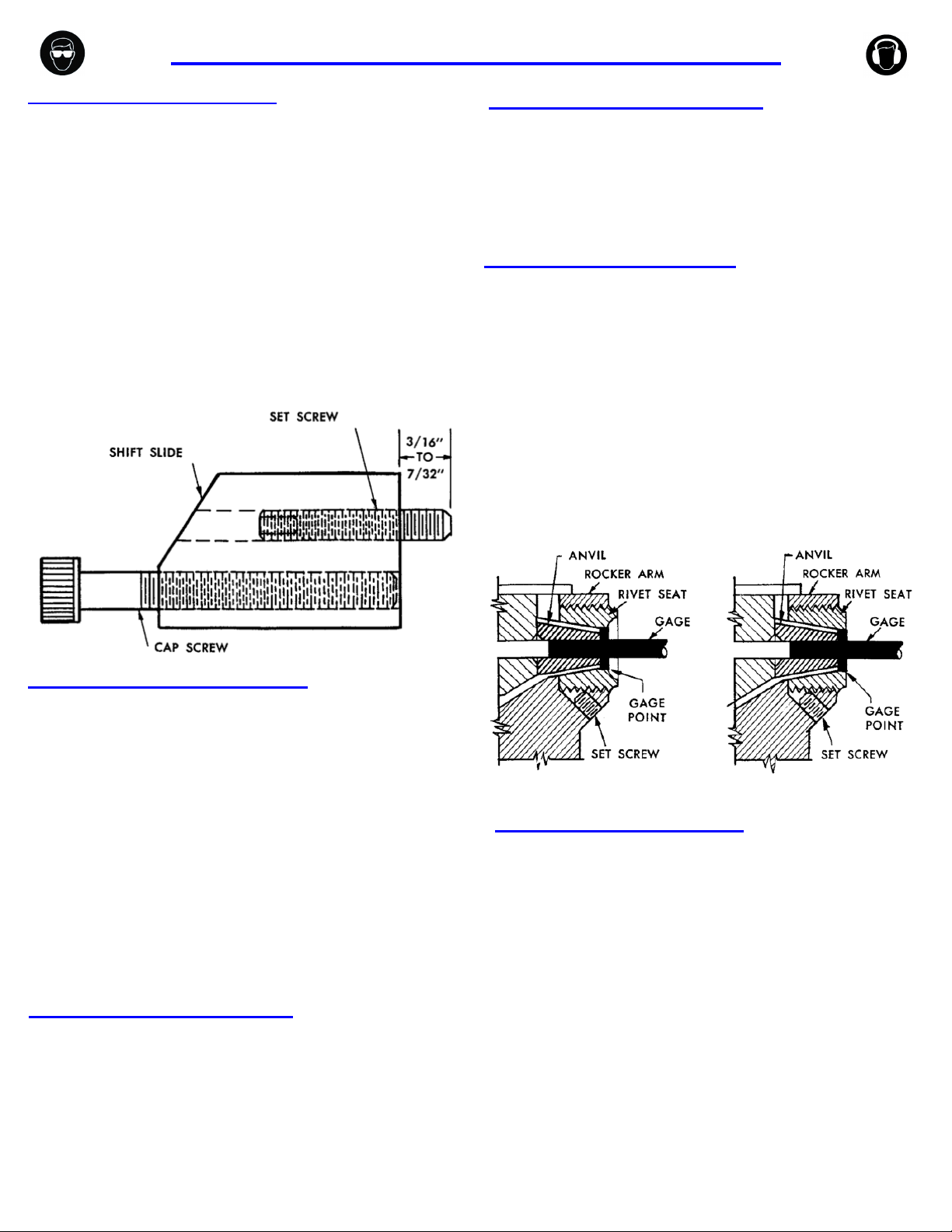

INNER ANVIL ADJUSTMENT

1. When adjusting nose assembly, either on or off tool, make sure the

drawbolt (5) is in the full forward position.

2. Push rocker arm (20) back toward drawbolt so it will rest on shift

slide (4).

3. Insert short end of setting gage into outer anvil (18) until inner face

of gage collar rests against end of inner anvil (21) and anvil rests on

crossbar in sleeve. Outer face of gage collar should be approxi-

mately .010 above face of countersunk head outer anvil or approxi-

mately .010 above bottom recess on universal head outer anvil.

4. If adjustment is required, loosen set screw (19) and turn outer anvil

(18) for proper positioning.

5. Tighten set screw (19) snugly to prevent anvil from getting out of

adjustment.

SHIFT POINT ADJUSTMENT

This adjustment determines the flushness of the broke pintail. After

the lock ring is set, the pintail should fracture substantially flush with

the rivet head.

1. If the stem breaks below flush, loosen cap screw (2) and turn set

screw (3) clockwise 1/4 turn (maximum). Tighten cap screw (2).

2. Test setting by installing rivet and repeat if necessary.

3. If stem breaks above flush, loosen cap screw (2) and turn set

screw (3) counterclockwise 1/4 turn (maximum). Tighten cap screw

(2).

4. Test setting by installing rivet and repeat if necessary.

5. If nose assembly is so far out of adjustment that it does not re-

spond to these 1/4 turn adjustments, it may be quicker to remove

the rocker arm (20) and shift slide (4) and reposition the adjusting

screw (3) to its approximate starting position outlined under assem-

bly Instructions line 2.