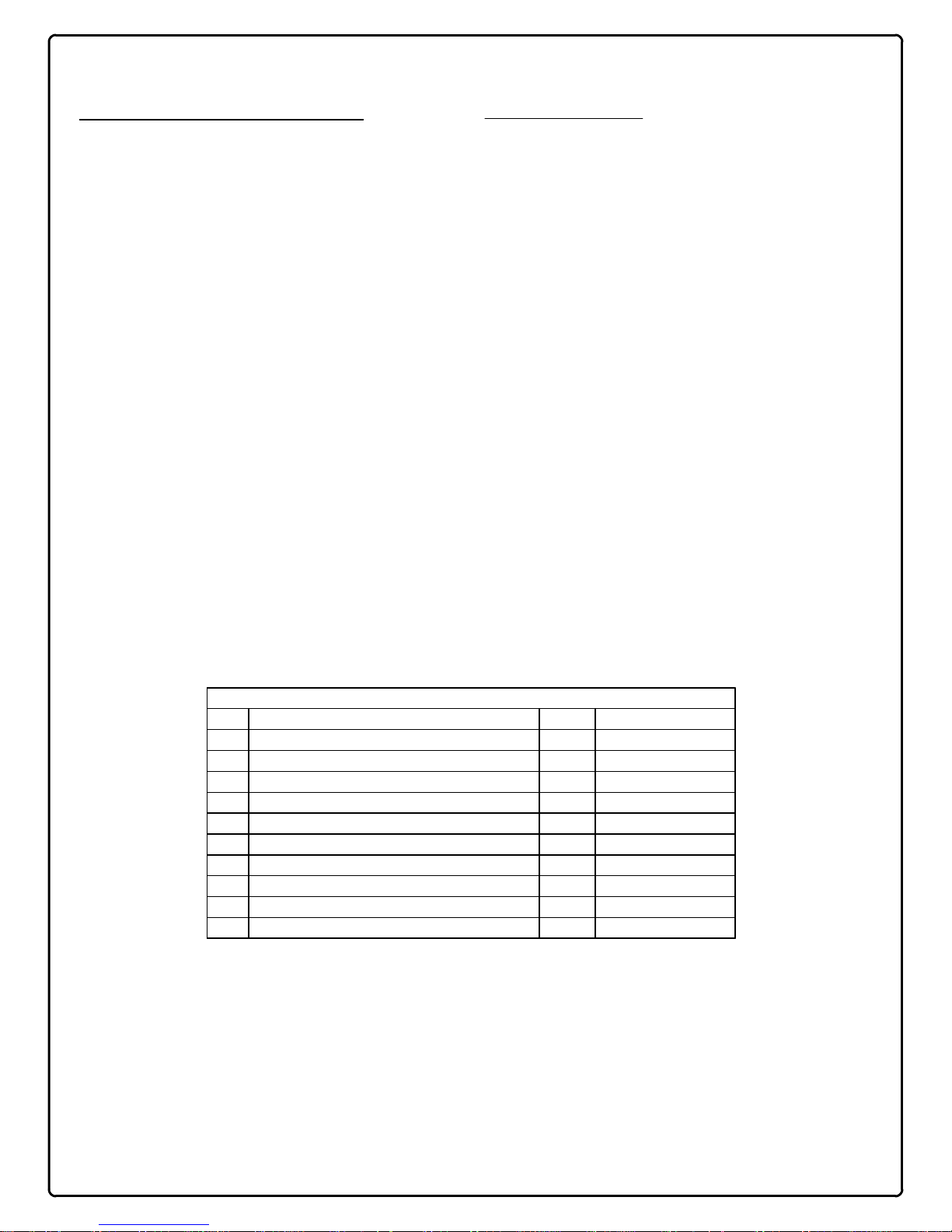

2 PAGE

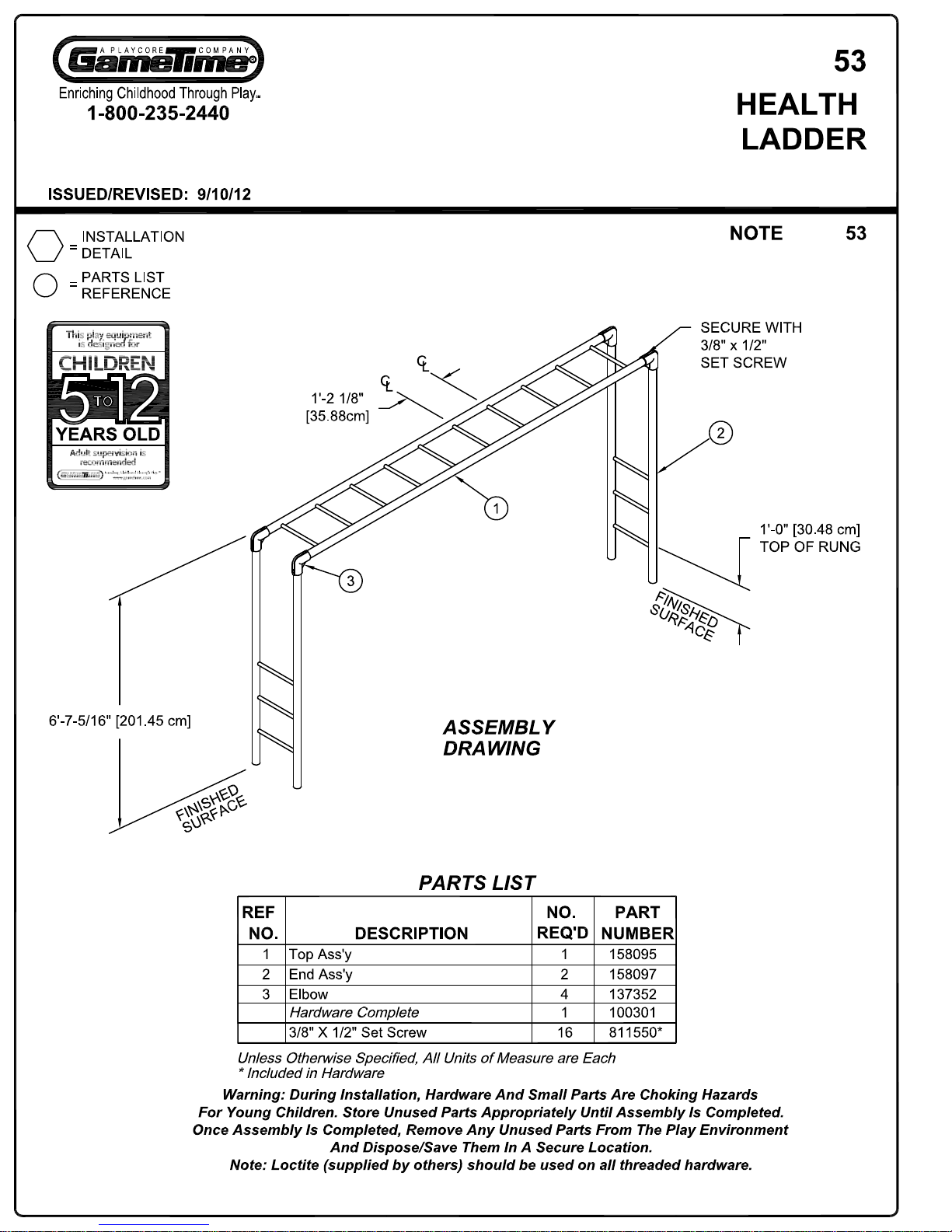

PARTS LIST

PART NUMBER

QTYDESCRIPTION

ITEM

147862

4

BENCH LEG (3'-11 1/2" [120.65cm])1

1601881

PUNCHED STEEL BENCH ASS'Y

2

1760891FOOTRAIL ASS'Y3

202095**

1

SIT-UP STATION SIGN

4

2120941

HARDWARE COMPLETE

135038*

4

1/2" ANCHOR ROD (1'-0" [30.48cm])

811051*

6

3/8" x 1 1/4" B.H.C.S.

817424*

8

3/8" FLAT WASHER (1 1/4" O.D.)

817334*

6

3/8" LOCKWASHER

804053*63/8" HEX NUT

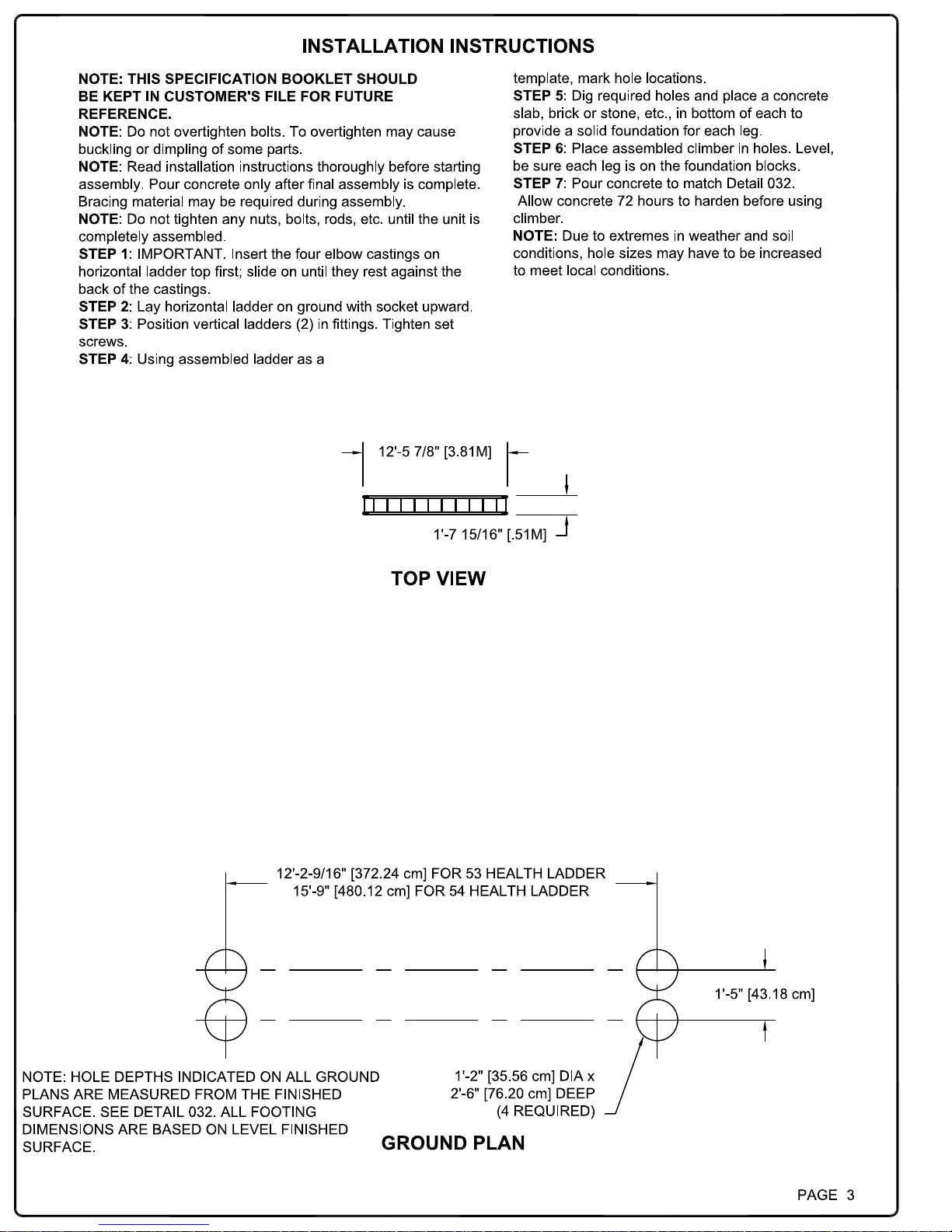

INSTALLATION INSTRUCTIONS

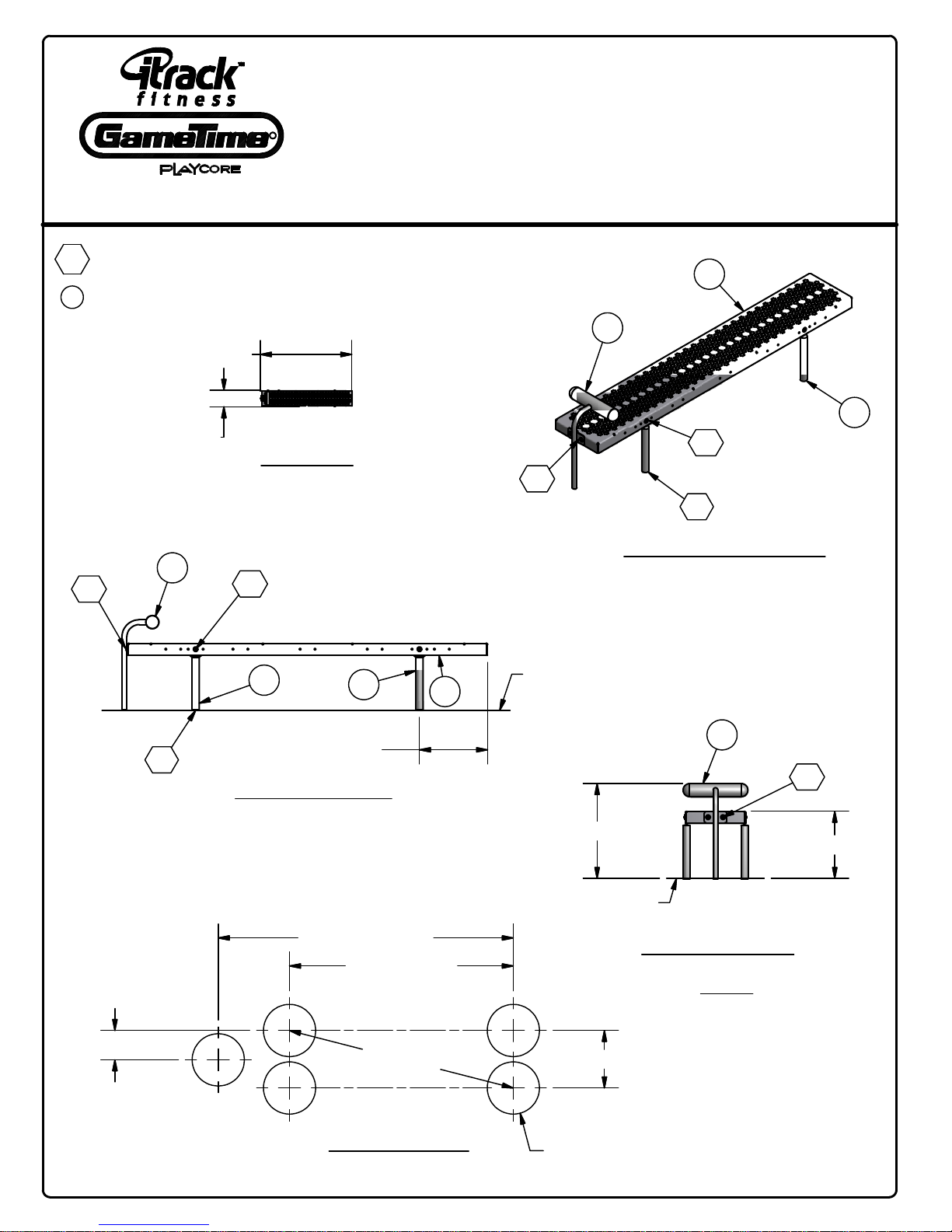

1.) Before starting assembly, review the General

Installation Instructions at the beginning of this Installation

Guide and the Typical Assembly Details in the back.

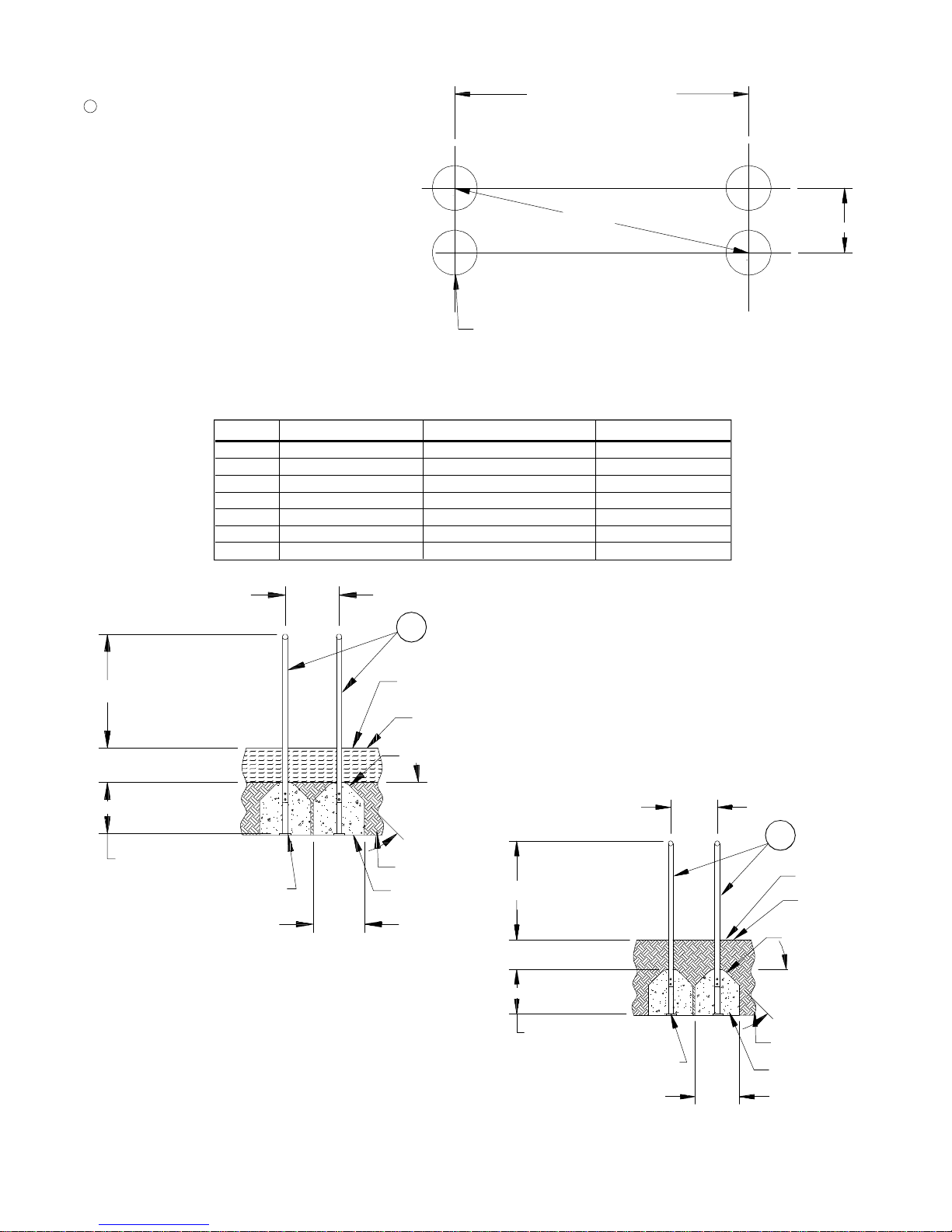

2.) Determine proper location for Sit-Up Station.

Refer to Equipment Layout Plan provided and any

applicable project site drawings.

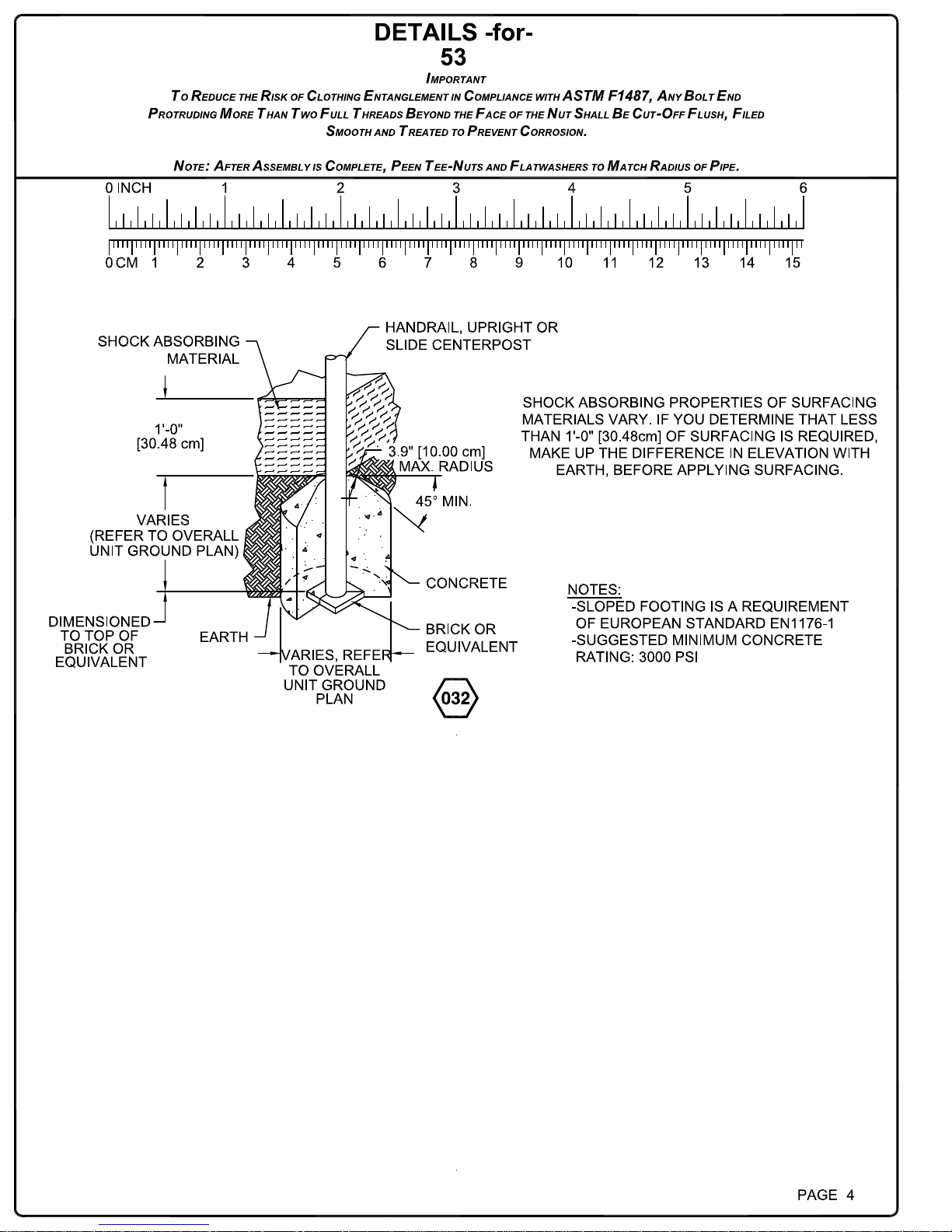

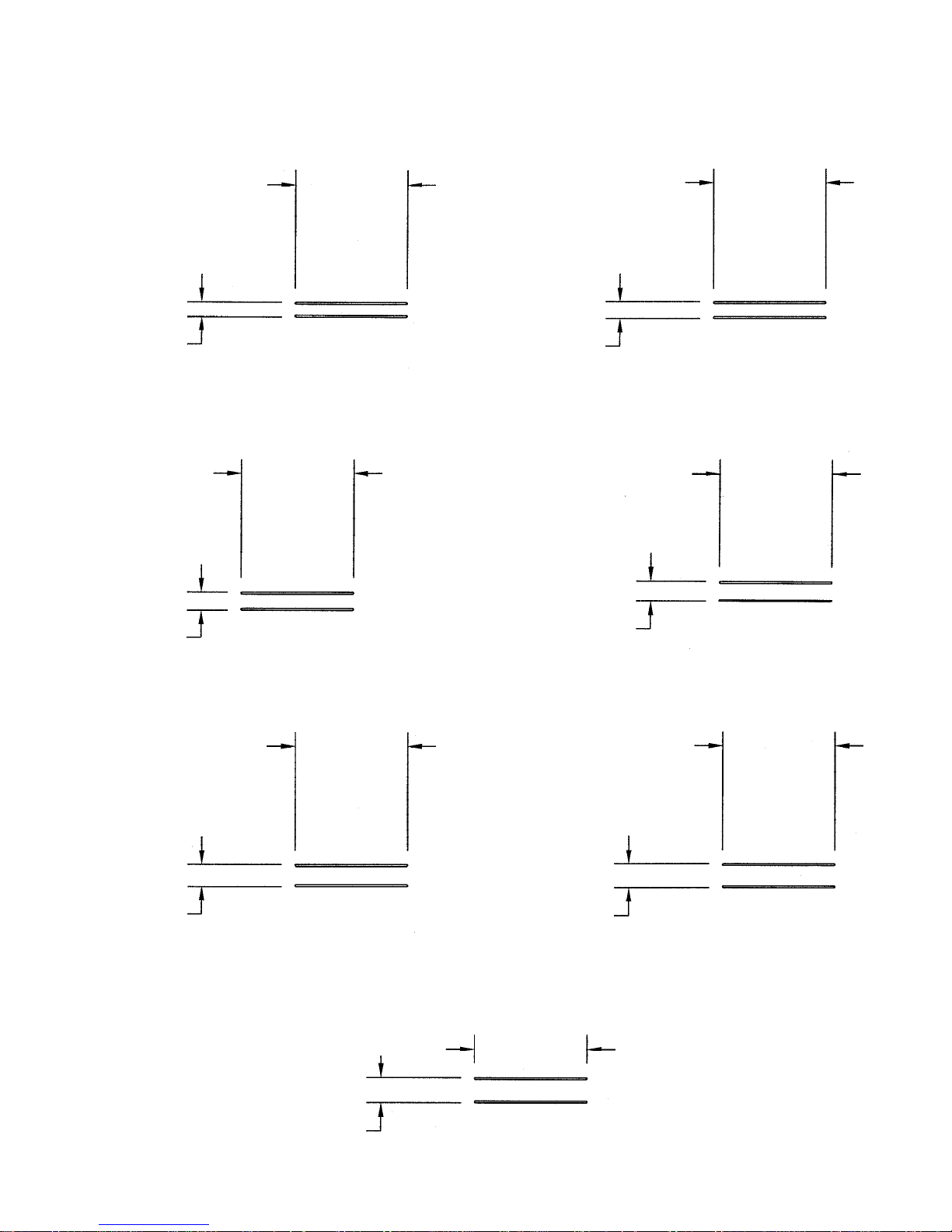

3.) Dig footings for bench supports. Maintain footing

spacing, size and depth as indicated on the ground plan.

Refer to Detail 321. Allow for depth of desired Finished

Surface.

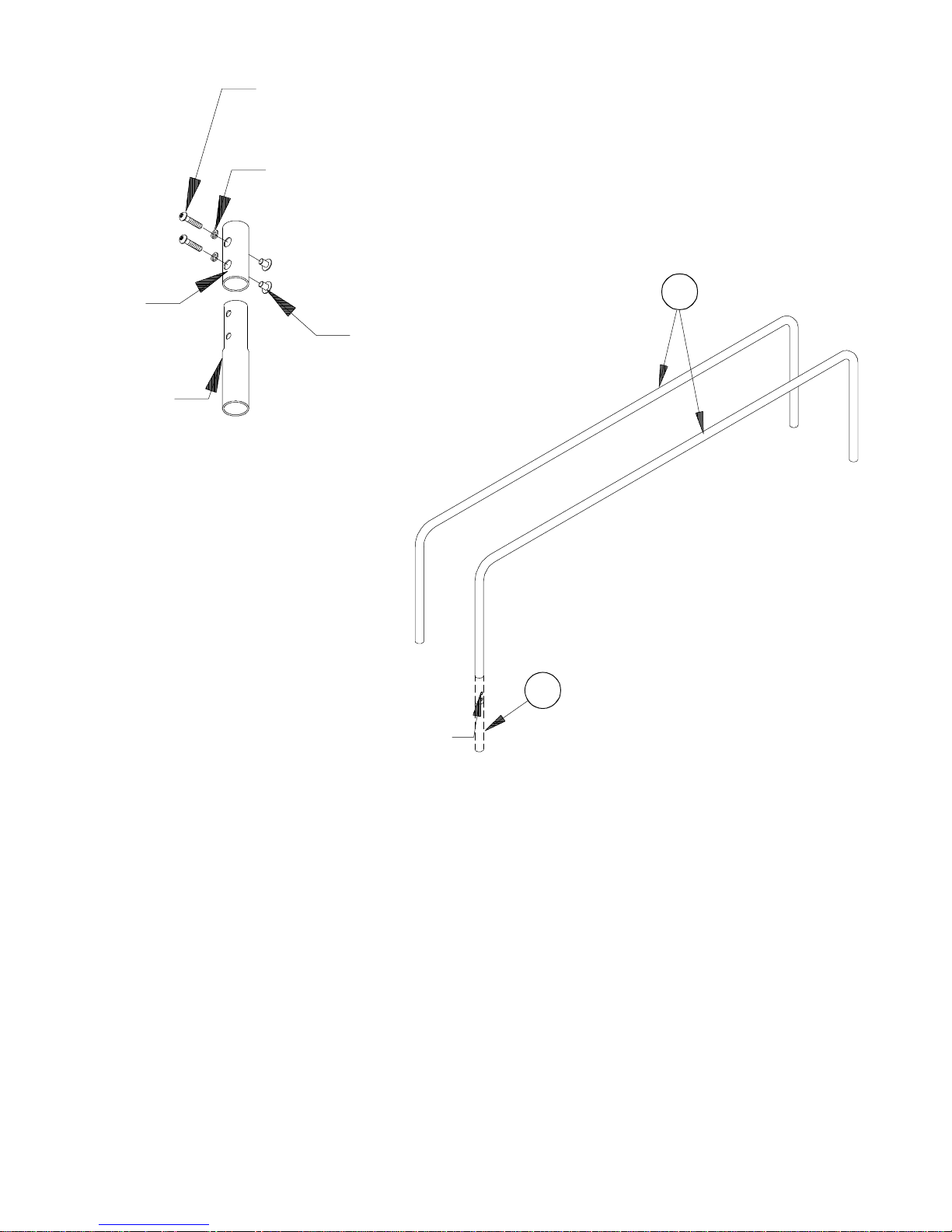

4.) Attach four legs to the bench. Refer to Detail E04.

5.) Attach footrail assembly to bench. See Detail E05.

6.) Position assembled bench in footings; align, plumb,

and brace bench in place. Pour concrete as shown on

Detail 321. Be sure to hold top of concrete footing 0'-6"

[15.24cm] down from the Finished Surface. Slope top of

concrete for proper drainage.

7.) Refer to Sign Frame Installation Sheet for instructions

on Sign mounting.

8.) Allow concrete a minimum of 48 hours to cure and

harden before using bench.

SPECIFICATIONS

BENCH LEG: Shall be made of 1-7/8" O.D. galvanized

pipe.

BENCH ASSEMBLY: Shall be fabricated of punched

steel metal with a plastisol coating.

FOOTRAIL ASSEMBLY: Shall be an all-welded

construction fabricated of 3-1/2" O.D. (13 gauge)

galvanized pipe, 1-5/16" O.D. galvanized pipe, 3/16" x 3"

H.R. flat steel, and galvanized pipe cap. Final assembly

shall also include cast aluminum caps and self-sealing

pop rivets.

FINISH: The Bench Legs, Footrail Assembly and

Handrail Assembly shall all have a powder coat finish.

HARDWARE: All nuts, bolts, screws, inserts, and

lockwashers used in the assembly of all play equipment,

shall be stainless steel, yellow dichromate plated steel,

blue-coat plated steel, mechanically galvanized or powder

coated/yellow dichromate plated steel. All primary

fasteners shall be 300 series stainless steel. Fasteners

with yellow dichromate treatment have an electro

deposited, 99.9% pure zinc substrate applied from a

specially formulated solution sealed with a yellow

dichromate top coat designed to work in conjunction with

the zinc plating. Yellow dichromate has a 320% longer

life to white corrosion and 275% longer to red corrosion

than does hot-dip galvanizing.

SPECIFICATIONS: GAMETIME® has a policy of

continuous improvement and reserves the right to

discontinue or change specifications without notice.

* Included in Hardware

Warning: During Installation, Hardware And Small Parts Are Choking Hazards

For Young Children. Store Unused Parts Appropriately Until Assembly Is Completed.

Once Assembly Is Completed, Remove Any Unused Parts From The Play Environment

And Dispose/Save Them In A Secure Location.

Unless Otherwise Specified, All Units of Measure are Each

Note: Peen Tee-Nuts and Flatwashers to match radius of pipe after assembly is complete.

**Sign Frame with Hardware Sold Separately