Part # 4521056 Rev 2 (02/21/12) Page 9

SERVICING

Introduction

Although this appliance has only an on-off switch and

two indicating lamps there is a computerized control to

provide accurate temperature control, fault diagnostics and

low water detection. In most cases of component failure

the control is designed to allow the appliance to continue

operating in a service mode. It is important to understand

the operation of the control and how it reacts to faults in

order to properly diagnose and correct faults.

In order to maintain the safety and accuracy of the appliance

it is also important to closely follow the parts replacement

procedures and inspection guidelines. For safety and

optimum performance use only parts obtained through

Garland or an authorized service agency.

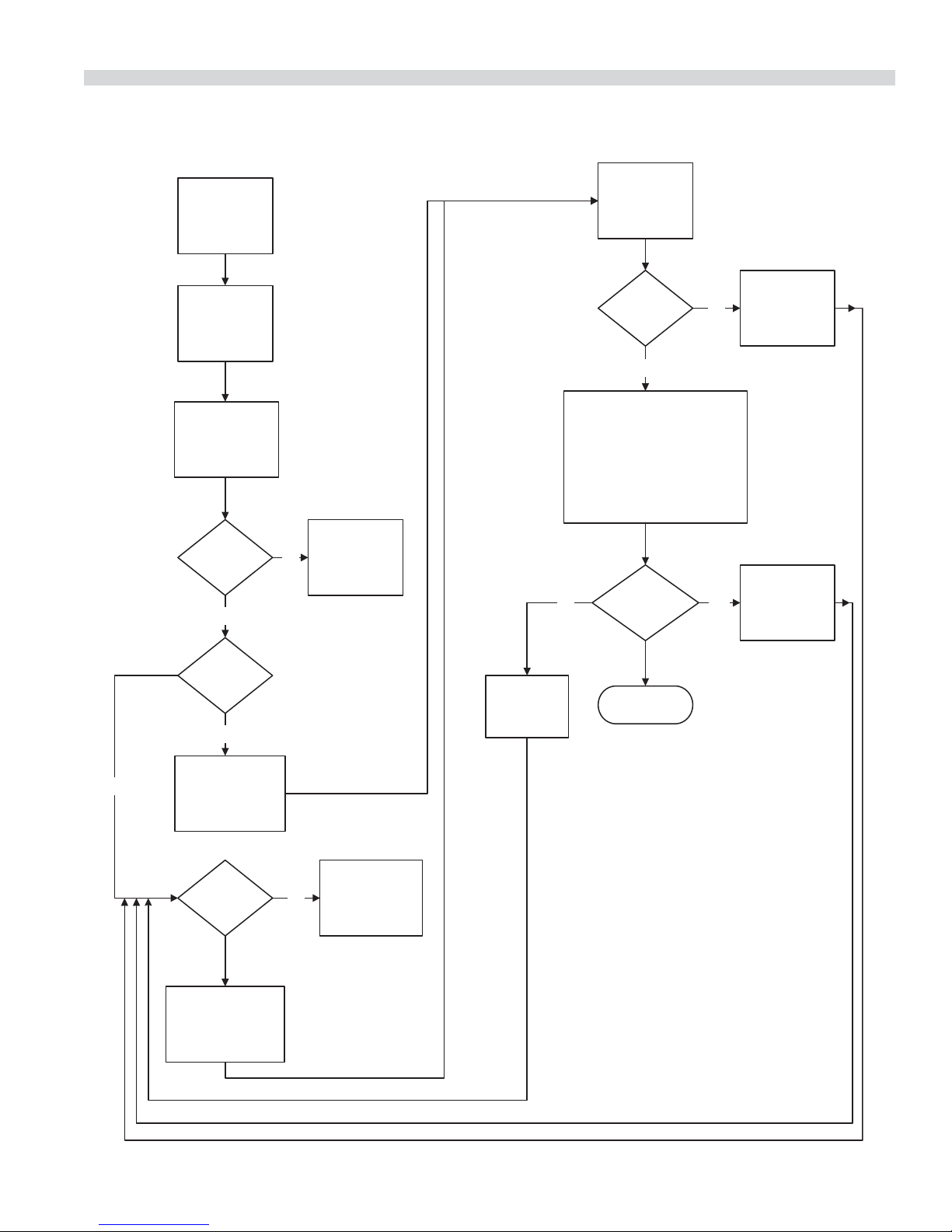

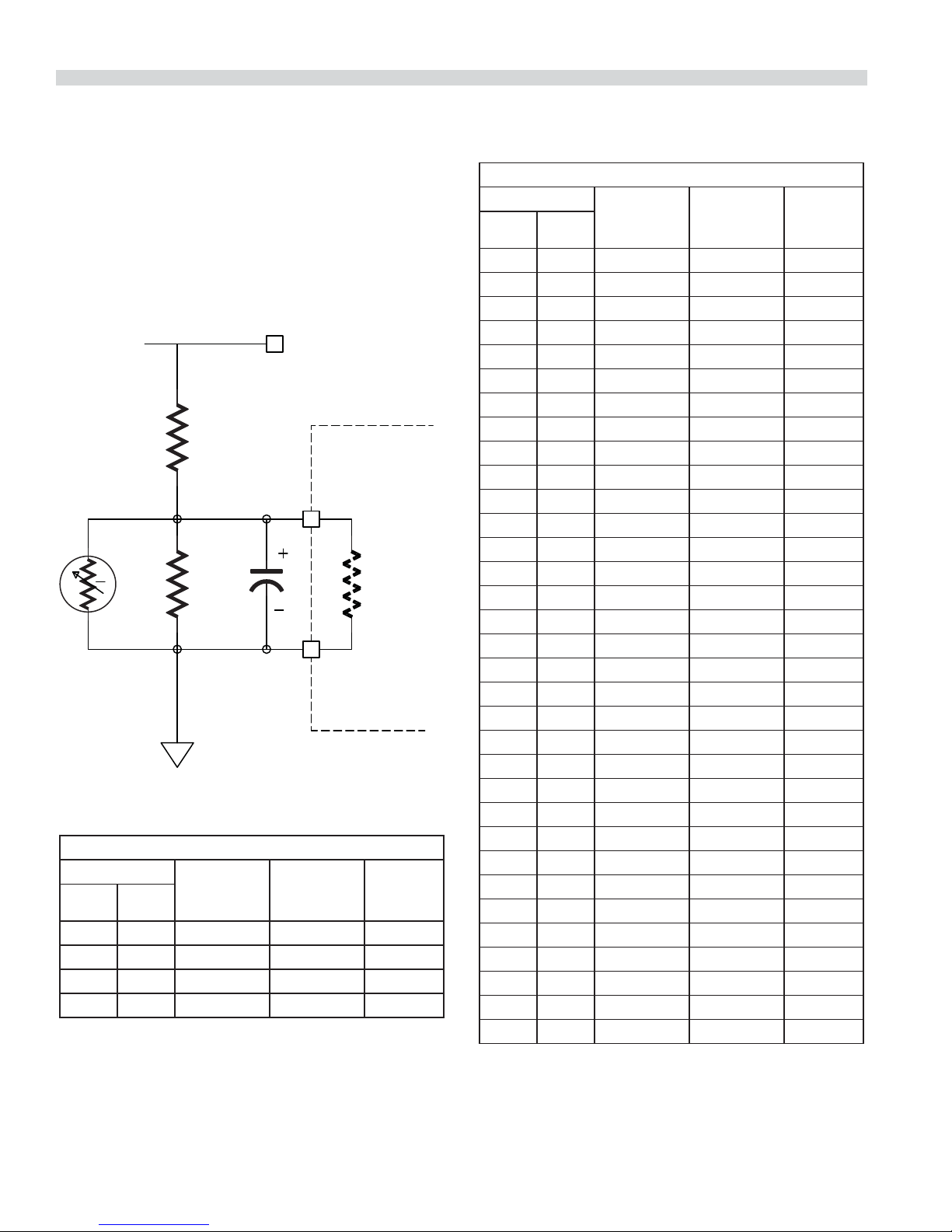

System Block Diagram

Power Supply

Computer

Control

Sensor Input

Indicators

Heater Heater

Tank

Sensor

Service Procedure

When performing any service operations on this equipment

it is important to perform the following inspections to

maintain the performance and safety of the appliance.

Visual Inspection

1. Unplug the unit.

2. Drain the liquid from the tank.

3. Turn the unit over and remove the bottom.

4. Examine the insulation. It should not be moist or wet. Wet

insulation could indicate the unit has been immersed in

water. Assess any potential damage.

5. Remove the bottom insulation. Examine the silicon

heaters. There should be no staining or delamination

from the tank.

6. Examine the high limit thermostats and the position of

the high limit bracket. The bracket is positioned so both

limit thermostats are over the heaters. There should be

no gap between the bracket and the heater. If there

is, remove the bracket and bend it slightly so it makes

contact with the heaters.

7. Look for any loose or damaged wiring.

8. Check fuse FS1.

System Checks

Check the Following in Powered State.

Warning: before applying power make sure the components

are located in a safe manner. Always perform the visual

inspection described above before applying power. Do not

apply power if there is any damage to heaters, wiring or any

components that might compromise safety.

The front control section can be removed from the body by

removing the 4 screws on the sides and loosening the 2 nuts

that attach the front section to the tank.

• Check for a green indicator on the power supply. If there

is no indicator on, check input voltage to the power

supply. If there is 120V AC present at the input terminals

and no output the power supply must be replaced. There

are no serviceable components in the power supply.

• Check the output of the power supply. It should be

12.0V DC ± 0.1V DC. There is a voltage adjustment

potentiometer next to the green indicator. If the power

supply cannot be adjusted to 12.0V DC

± 0.1V DC, it could indicate there is a problem either with

the power supply or the load attached to it (the controller

or sensing circuit). Typically if a voltage regulator is

defective the voltage error will be greater than 2 volts.

• Check the voltage between 12 volt – terminal and the

load side of fuse FS1. 12 volts should be present.

• Check the indicator lamp on the electronic control. In

normal conditions it will be green. If it appears red the

control has malfunctioned. If the indicator is red the

control must be replaced.