Garlock Life Point Duo User manual

P/N 161594 Rev 3/15/16

Garlock provides this Operators’ Manual as

a tool to help instruct the owner/worker in

the proper use of this equipment. Garlock

expects the reseller and equipment owner to

comply with OSHA 1926.503 and make every

effort to educate the worker in the proper

use and limitations of this equipment before

putting it into service.

Keep this Manual with the Life Point Duo Tie-Off System at all times. This will allow new users

to read it before operating this equipment.

It is the Life Point Duo Tie-Off System owner’s responsibility to ensure that all workers using

this anchor are thoroughly trained. Provide workers with this Operators’ Manual. Make sure

they understand its’ contents. Read it to them if necessary. Letting poorly trained workers use

this anchor can result in serious injury or death to personnel.

LIFE POINT DUO TIE-OFF SYSTEM

Operators’ Instruction Manual

Per OSHA 1926.503 it is the equipment owner’s responsibility to ensure that all workers

using this Anchor are thoroughly trained in its’ use and limitations.

Consulte la página 17 para Español

2

NOTICE TO WORKERS USING THE LIFE POINT DUO:

3

Specifications:

Length-Minus Handle 70”

Height 20”

Width 28

Weight 930 Lbs.

Tire Contact Pressure Front: 27 PSI each Rear: 35 PSI each

Contact Pressure (actuated): 1.45 PSI

Counterweights Quantity 8 Concrete or Quantity 12 Steel as supplied by Garlock.

Limitations:

The Life Point Duo has been tested and approved for 1-Person Fall Arrest plus 1-Person Fall Restraint for

the following roof substrates (coverings):

Built-up roofing systems (BUR)

TPO / EPDM Adhered Membranes

Metal Decks 22 gauge minimum.

Plywood/Hardboard Decking

ISO insulation

Concrete

FALL RESCUE PLAN:

Federal law requires the Employer to have a Fall Rescue Plan for their employees in the event a fall should

occur.

ANSI Z359.2-2007 mandates that “Employers shall develop and maintain written fall protection and rescue

procedures for every location where an active fall protection system is used to control a fall”.

ANSI Z359.2-2007 Section 6.1:

“The employer shall provide prompt rescue to all fallen authorized persons”

ANSI Z359.2-2007 Section 6.2:

“Written rescue procedures shall be prepared and maintained by the competent person for all instances

where authorized persons work at heights. Such procedures shall contain provisions for the prompt rescue

and self-rescue of any authorized person who falls”.

ANSI Z359.2-2007 Section 6.3 provides specific guidelines regarding the circumstances during which emer-

gency services can be called to carry out a rescue.

ANSI Z359.2-2007 is very specific about the roles of all individuals involved in the rescue process.

OSHA 1910.66 subpart F Section 1(e)(8) states “The employer shall provide for prompt rescue of employees

in the event of a fall or shall assure the self-rescue capability of employees.”

OSHA 1926.502(d)(20) reads “The employer shall provide for prompt rescue of employees in the event of a

fall or shall assure that employees are able to rescue themselves.”

Refer to these standards in their entirety for specific requirements regarding the creation and use of a Fall

Rescue Plan.

Garlock Equipment Company strongly advises the employer to read, understand and adhere to these Federal

Standards.

4

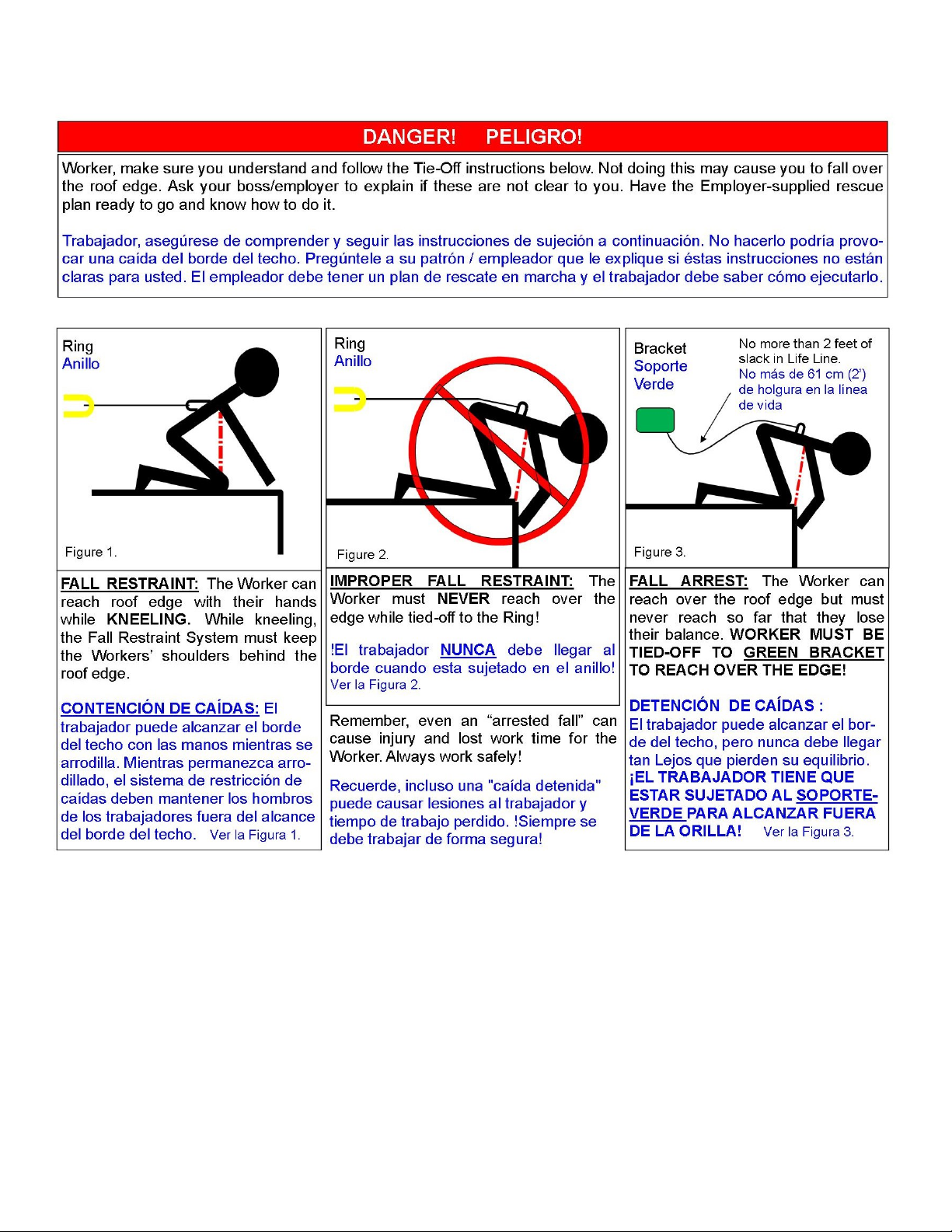

WARNING! Working at or near the roof edge is dangerous and can subject the Worker to serious injury or

death from falls. The Roofing Contractor and the Worker must make every effort to ensure the area where

he/she will be working is as safe as possible. This means taking only the tools you need to the roof edge,

removing all trip hazards and loose material, the wearing and proper use of OSHA approved Harnesses and

Life-Lines, making no sudden or unplanned moves and being constantly aware of your surroundings and

your position/location relative to the roof edge.

It is also imperative that the Worker read the Operators’ Manual for this equipment and thoroughly under-

stand how to set up and use this equipment. This includes knowledge of what the equipment can do and

also how to avoid situations this equipment was not designed to handle. Garlock provides this Operators’

Manual at the time of sale as a tool to help instruct the owner/worker in the proper use of the equipment and

expects the reseller and owner/worker to make every effort to educate themselves before putting this Life

Point Duo Tie-Off System into service.

Garlock recommends that no worker be on the roof or sent to any job or repair site by themselves.

This leaves the worker unaided should an accident occur regardless of its’ nature.

1. OPERATOR PREPARATION:

Read Operators’ Instruction Manual!

Reading and understanding the instructions completely is the first step to safe operation. An uninformed

operator can subject themselves and others to serious injury or death.

NOTICE TO OPERATOR! Make sure you have a thorough knowledge of how to set up and use the Life Point

System, as well as a complete understanding of the systems’ limitations and conditions for use before you

attach yourself to the system. READ THE OPERATORS’ INSTRUCTION MANUAL!

Wear Proper Attire When Roofing

When doing roofing or roofing repair work, wear safety glasses and protective clothing if any cutting, scraping,

or sweeping is being done in your work area. Wear safety shoes. Hard hat must be worn by Worker when

work is being done overhead. When working with hot stuff, long sleeved cotton shirt buttoned at sleeves and

collar must be worn (or other suitable protective clothing). Long pants without cuffs and a face shield are also

required when working with hot bitumen.

2. BEFORE HOISTING OR CARRYING LIFE POINT SYSTEM TO THE ROOF:

Make sure roof is in good condition. It must be able to support the combined weight of the Life Point System

(930 lbs.) plus all material, equipment and personnel which will be near or working near the system.

Be sure to include the Building Owner and/or a certified Architect when making this evaluation.

5

3. HOISTING ANCHOR TO THE ROOF:

BEFORE HOISTING OR CARRYING LIFE POINT SYSTEM TO THE ROOF:

Make sure roof is in good condition. It must be able to support the combined weight of

the Life Point System (930 lbs.) plus all material, equipment and personnel which will

be near or working near the system.

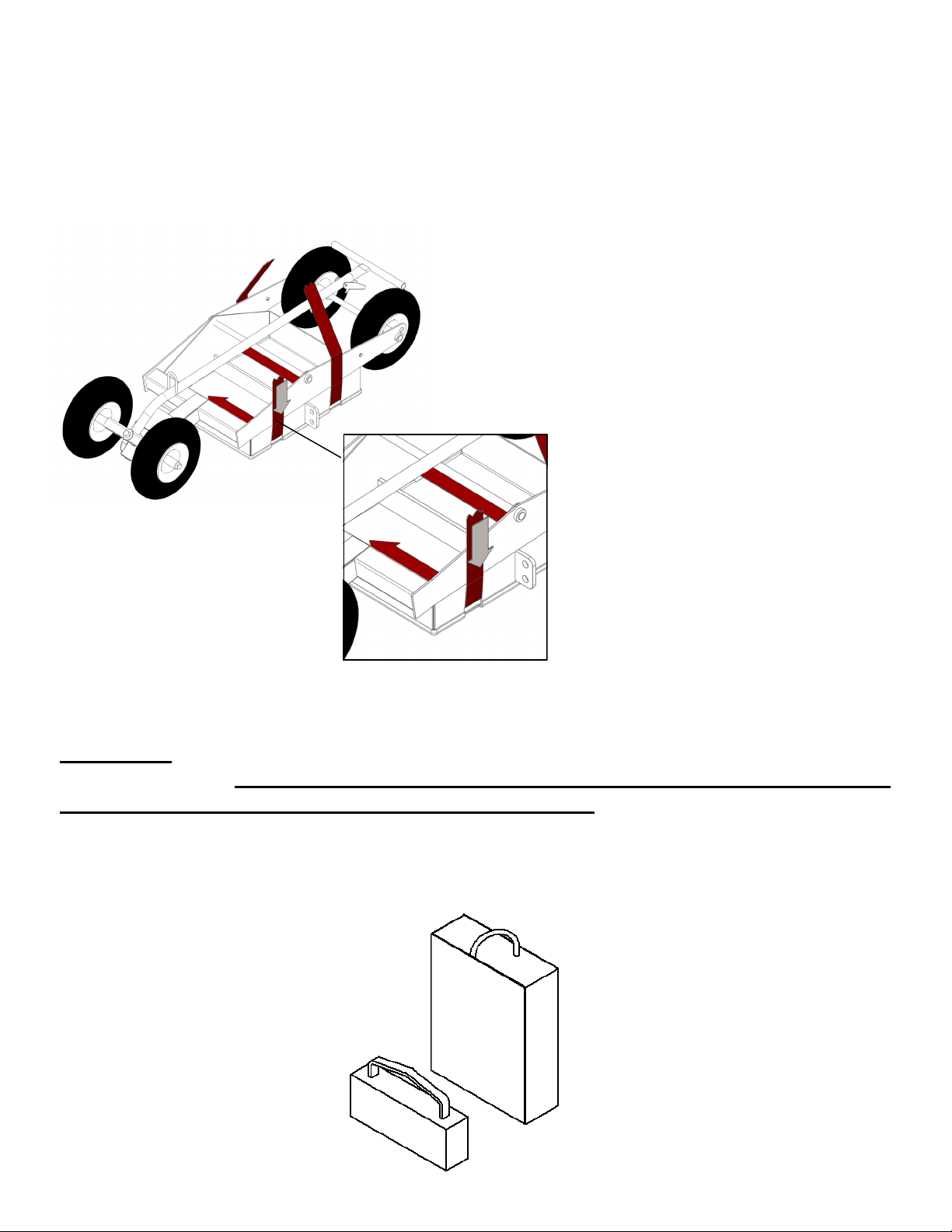

LOADING COUNTERWEIGHTS:

Remove all Counterweights.

Insert lifting straps through the slots along

bottom of Box and out the other side.

Connect all 4 ends of straps to hoist hook.

Hoist Counterweights separate from Anchor.

WARNING! Use counterweights supplied by Garlock Safety Systems as ballast

for this anchor. Use of any other ballast may result in an anchor not able to

arrest a fall, causing serious injury or death to user.

Use 12 steel weights (408996S) or 8 weight cans (408999) filled to top with concrete.

Table of contents

Languages:

Other Garlock Safety Equipment manuals

Popular Safety Equipment manuals by other brands

Lanex

Lanex PB-20 instruction manual

SKYLOTEC

SKYLOTEC ANCHOR ROPES Instructions for use

Besto

Besto Buoyancy Aid 50N Instructions for use

TEUFELBERGER

TEUFELBERGER NODUS Manufacturer's information and instructions for use

Troy Lee Designs

Troy Lee Designs Tbone Product owners manual

Innova

Innova Xtirpa Instruction and safety manual

bolle SAFETY

bolle SAFETY B810 quick start guide

SHENZHEN FANHAI SANJIANG ELECTRONICS

SHENZHEN FANHAI SANJIANG ELECTRONICS A9060T instruction manual

Hiltron security

Hiltron security POWER8E Installation and use manual

Salewa

Salewa MTN SPIKE user manual

Hatco

Hatco B-950P installation guide

Sitec

Sitec TX MATIC operating manual