www.gassense.eu

Gas Sensor

GS-220.P

GS-220.P CONTENTS

1. Introduction .................................................................................................. 4

1.1. Safety instructions .................................................................................. 4

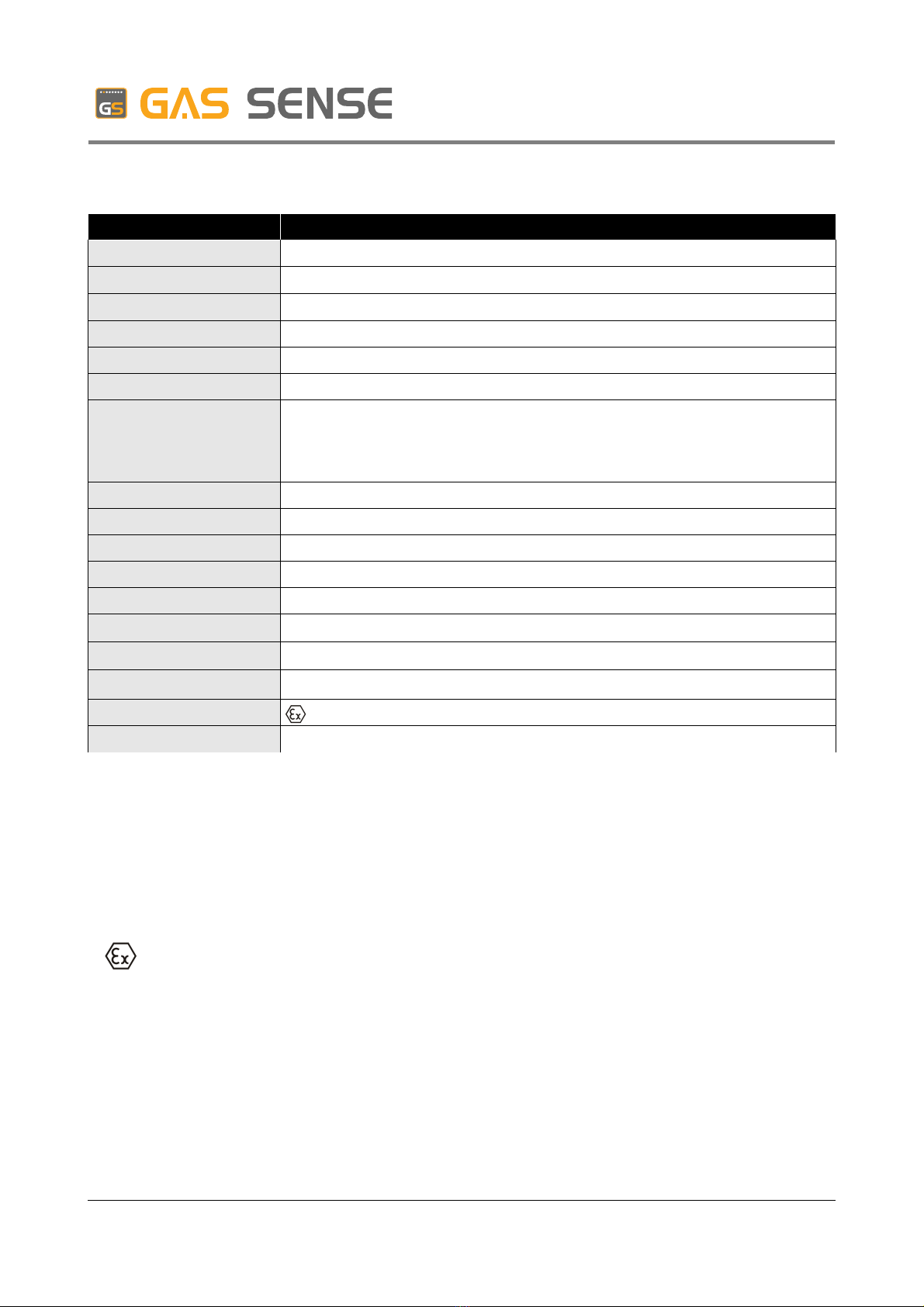

1.2. Specifications ......................................................................................... 5

1.3. Certificates and standards ..................................................................... 5

2. Product review ............................................................................................. 6

2.1. General review ....................................................................................... 6

2.2. Typical application .................................................................................. 7

2.3. Semiconductor gas sensing element .......................................................... 7

3. ount ............................................................................................................. 8

3.1. Introduction ............................................................................................ 8

3.2. Transportation and storage .................................................................... 8

3.3. Prior to mount ......................................................................................... 8

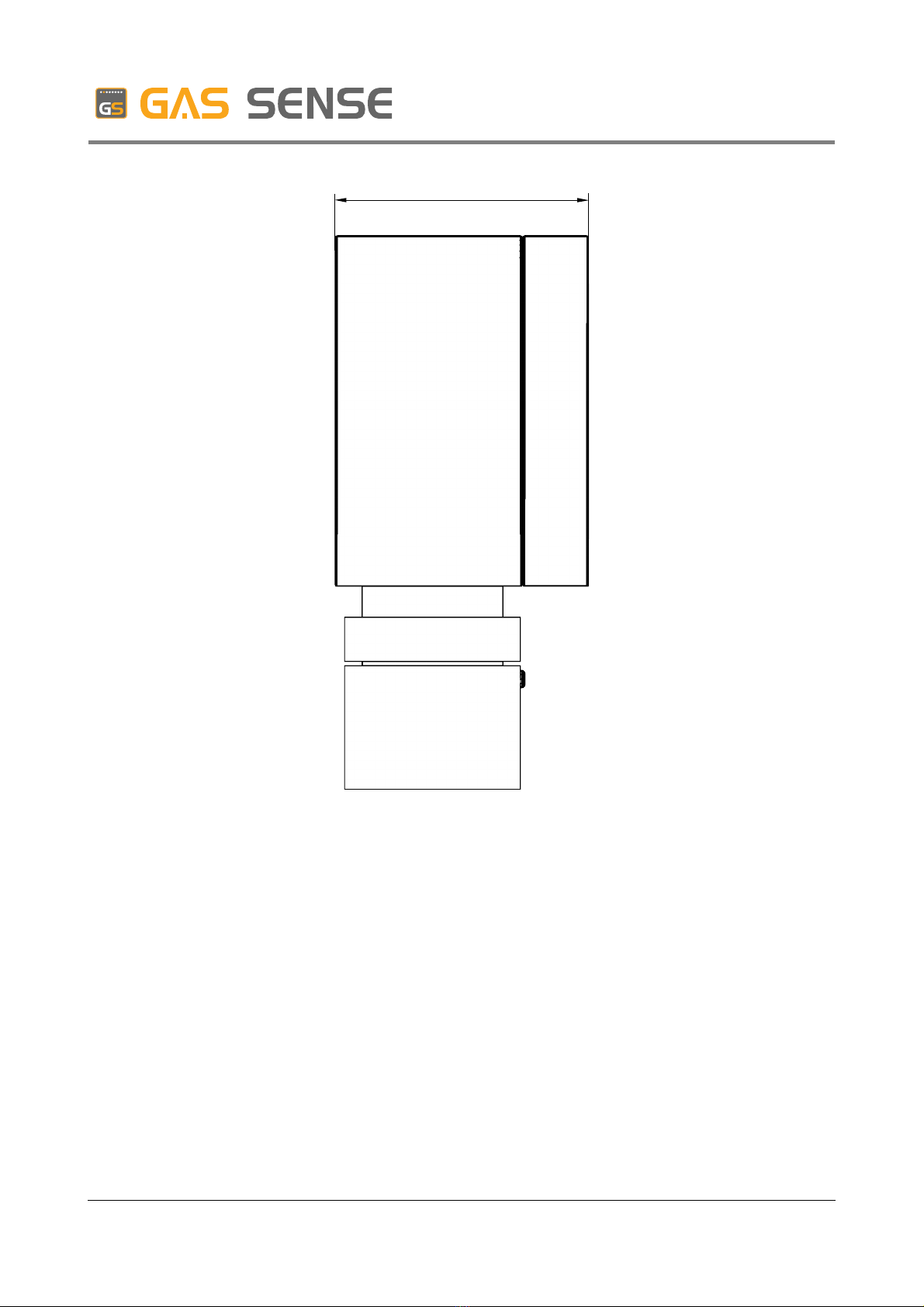

3.4. Dimensions ............................................................................................ 9

3.5. Mechanical installation ......................................................................... 10

3.6. Electrical installation ............................................................................. 12

4. Settings ....................................................................................................... 14

4.1. Introduction .......................................................................................... 14

4.2. Sensor cali ration ................................................................................ 14

5. Operation .................................................................................................... 16

5.1. Operation modes .................................................................................. 16

5.1.1. Warm up mode ............................................................................. 16

5.1.2. Normal operation mode ................................................................ 16

5.1.3. Danger mode ............................................................................... 17

5.1.4. Alarm mode .................................................................................. 17

5.1.5. Fault mode ................................................................................... 17

6. aintenance ............................................................................................... 19

6.1. Check and re-adjustment ..................................................................... 19

6.2. Diagnostics of frequent pro lems ........................................................ 19

ver.1.0 page 2 / 23