Gastrodomus TR 70 Operating instructions

MOD. TR 70 - TR 75/E

Cop Man TR70 75_E:00678 Cop Man TR70-75/E 2-08-2012 12:49 Pagina 1

OPERATING AND MAINTENANCE MANUAL

16

Thank you for choosing this machine. We are sure that its performance will meet your requi-

rements.

It is in your interest to keep the machine in perfect running order. In this handbook you will

find the necessary instructions on how to use and service it.

SAFETY STANDARDS

Throughout the manual this symbol indica-

tes important information warning you of

any hazardous operation. Always read the

message that follows it.

GENERAL WARNINGS

This machine has been manufactured to make your work as safe as possible.

Caution is, nevertheless, the golden rule to follow to prevent accidents.

KNOWING YOUR MACHINE

Caution: Store this manual in a safe

place, near the machine, and disclo-

se its storage location to all involved

personnel.

Do not put this manual away without having

first read it, regardless of any previous perso-

nal experience. A little time spent in reading

will save time and extra work.

Read this handbook thoroughly before pro-

ceeding with start-up, use, maintenance

and other operations. Read and rigorously

follow the herein contained instructions and

recommendations:

• read all warning labels applied to any part of the machine, and promptly replace them

when they become worn or illegible;

• only trained and authorised personnel should operate the machine;

• if any part jams or locks up, before clearing make sure you first switch off the motor. DO

NOT clean, oil or grease by hand any moving parts of the machine. In addition, all repair

and setting operations of any moving parts with the motor running, are prohibited, unless

the necessary precautions to prevent any accidents have been taken beforehand;

• all moving parts are fitted with adequate guards and protections. Always remount

them after removal for servicing.

Man TR ING:Man TR ING 2-08-2012 13:44 Pagina 16

17

ENGLISH

WEAR ADEQUATE CLOTHING

Be sure to wear tight-fitting clothing without

any loose parts. Never wear open or unfaste-

ned jackets, shirts or overalls.

IMPORTANT

To prevent accidents and ensure best performance the machine must not be

modified or altered unless authorised by the manufacturer. Nor must it be used in

conditions or for purposes other than those for which it has been expressly desi-

gned. Any arbitrary modification implemented in this machine will automatically

exempt the manufacturer from any liabilities for ensuing damage or injury.

This machine has been designed and engineered in conformity to European directives:

2006/42/CE, 2014/30/CE and the regulation 1935/2004/CE..

BE SURE TO READ “IMPORTANT” MESSAGES

Information highlighted as “Important” in the Operator’s Manual and/or machine indicate

specific instructions about settings, maintenance and so on. Failure to comply with these

instructions may lead to damage to the machine.

ELECTRICAL SHOCK

For your own personal safety, before connecting the machine to mains:

•check that power mains leading to distribution socket is fitted with an appropriate multi-

polar switch protected against overloads and shortcircuits.

•carry out all phase connections, as well as any neutral and ground connections (compul-

sory) with a standard plug compatible with the above mentioned socket. The protection

lead (ground) is the one with the yellow/green insulating sheath; make sure that the power

supply cable is appropriate to its use, according to length, mains voltage and machine

consumption.

•unless adequate protections against electrical shock are fitted, do not operate the machi-

ne in damp or wet environments.

Strictly do not start up the machine without the protective panelling. This may jeopar-

dise personnel safety and machine serviceability.

18

- SAFETY STANDARDS AND GENERAL WARNINGS page 16-17

- TECHNICAL SPECIFICATIONS OF MODELS page 19

- INSTRUCTIONS page 20

- 1. PREPARING THE MACHINE page 21

- 2. OPERATING PRINCIPLE page 21

- 3. USE OF THE MACHINE page 21-22

3.1 USEFUL ADVICE IN ORDER TO OBTAIN GOOD DOUGH page 22

3.2 QUANTITIES IN ORDER TO OBTAIN GOOD DOUGH page 22-23

3.3 INSTALLATION OF THE DRAWPLATE AND START-UP OF PRODUCTION page 23-24

- 4. TRANSPORTATION AND HANDLING page 24

- 5. INSTALLATION, CONNECTION AND SET-UP page 24-25

5.1 CONTROL OF THE INSTALLATION page 25

- 6. CLEANING page 25-26

6.1 COVER AND POOL CLEANING page 26-27

6.2 CLEANING OF THE ARCHIMEDEAN SCREW, MIXER, RING NUT AND DRAWPLATE page 27

- 7. MAINTENANCE AND ADJUSTMENT page 27

7.1 BELT STRETCHING page 27

- 8. MACHINE WHIRR page 28

- 9. DISMANTLING AND DEMOLISHING THE MACHINE page 28

- 10. INCONVENIENCES AND THEIR REMEDIES page 28

ANNEX A: STATEMENT OF CONFORMITY.

INDEX

Man TR ING:Man TR ING 2-08-2012 13:44 Pagina 18

19

ENGLISH

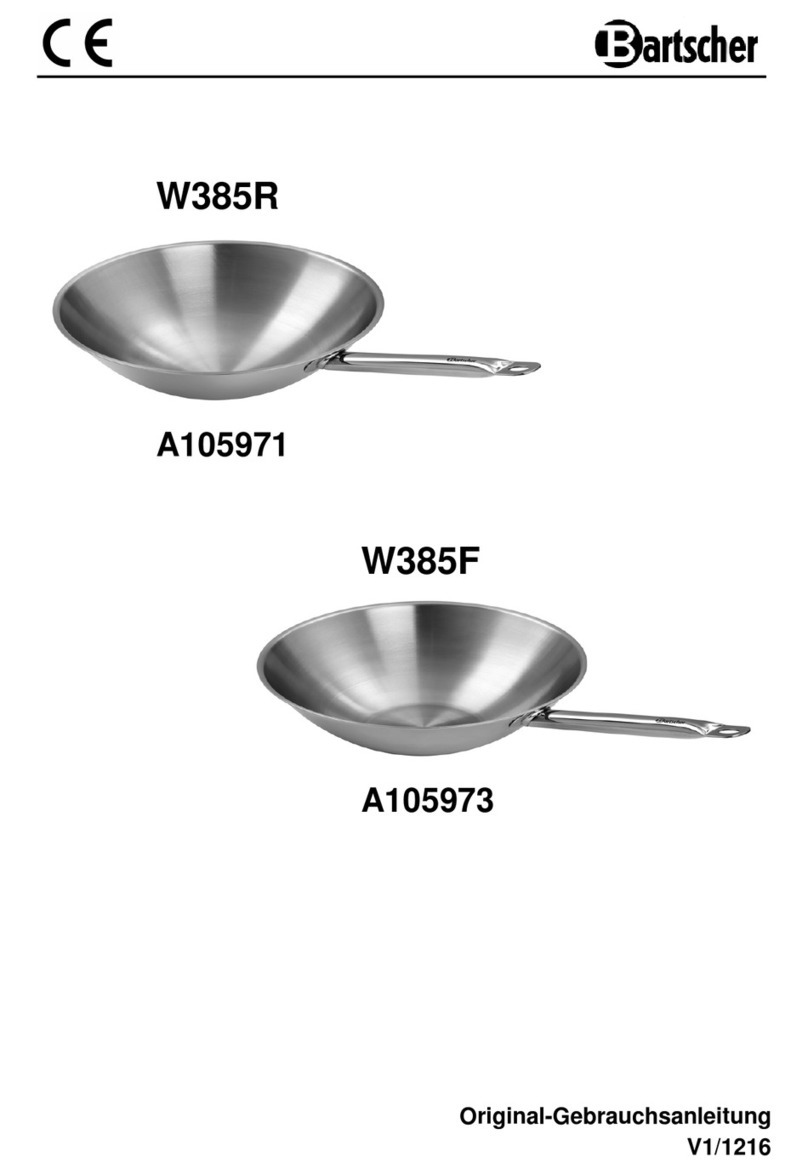

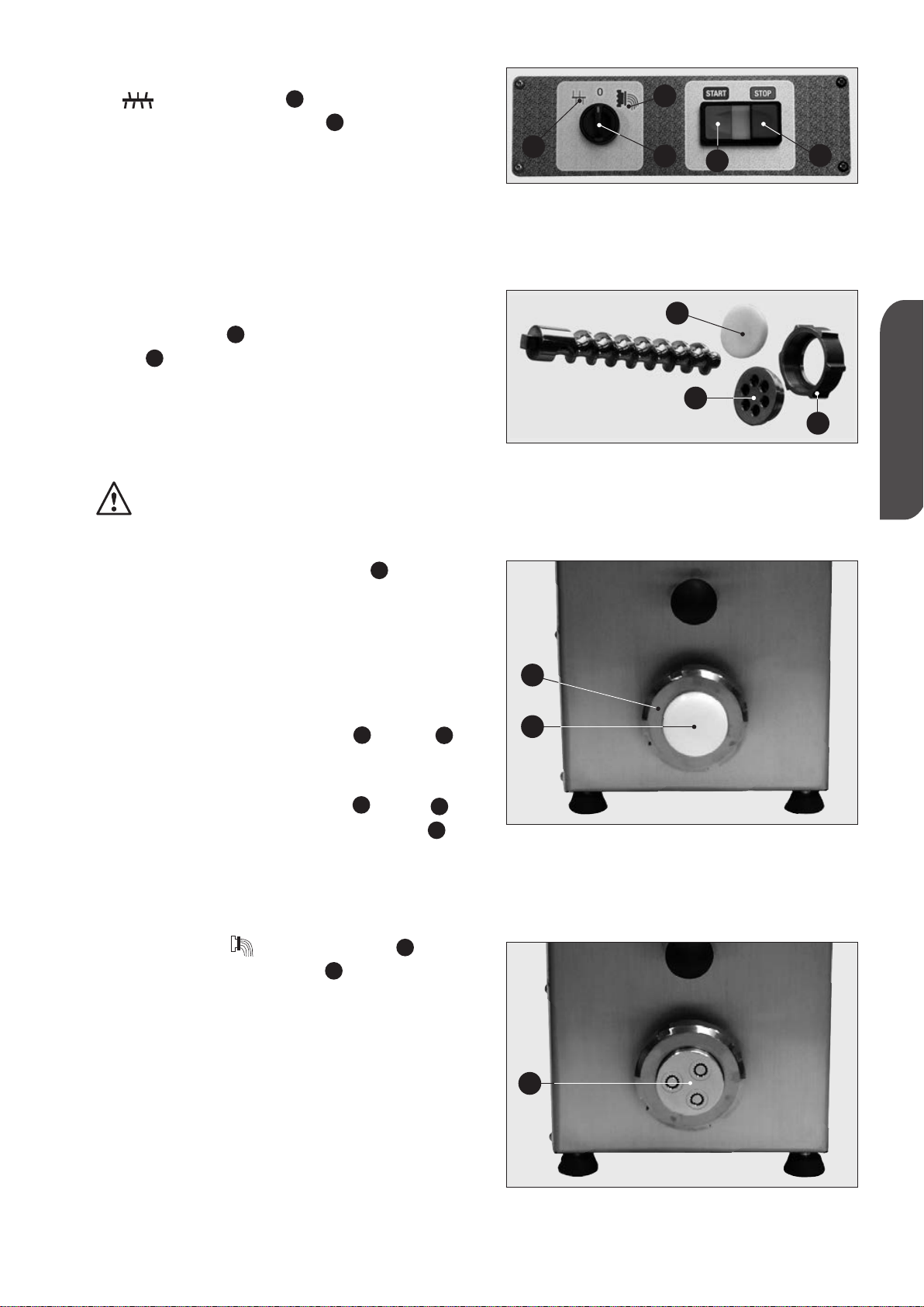

TECHNICAL SPECIFICATIONS OF MODEL TR 70 - TR 75/E

Model A B C Kneading Mass Motor Maximum production

Length Width Height capacity daN power per hour daN/h

daN (based on the kind

mm mm mm ≅kg ≅kg kW of drawplate used)

TR 70 440 250 425 1.5 28 0.38 4

TR 75/E 510 310 570 3 48 0.55 8

SPECIFICATIONS TABLE

B

C

A

Man TR ING:Man TR ING 2-08-2012 13:44 Pagina 19

20

• The elements in contact with the noodles

are made of stainless steel or bronze for

foodstuffs.

• Moving parts mounted on ball bearings

with long-life sealing gaskets or with sup-

ports with greaser.

• Driven by one motor; belt transmissions

with a reducer without maintenance requi-

rements.

• The machine has special footers which

can be adjusted and equipped with plastic

material.

• Connection by flameproof power cable

according to necessary supply voltage,

standard length L = 2 m, without terminal

plug (only 75/E).

• Supplied accessories:

- liquid measure decanter;

- noodle-collecting frame (only 75/E);

- wrench for locking ring nut.

• Working elements with the ability of tur-

ning in two directions: this enables the

kneading of the initial dough, not yet ready,

without any damage to the drawing group.

• Protection of iron parts by furnace coating

with epoxy powders.

• Easy disassembling of the working parts;

the machine is freely accessible in order

to carry out thorough cleaning.

• The possibility of obtaining different pro-

ducts thanks to the change of the relevant

drawplate.

NOODLES PRODUCING MACHINE

Produces different kinds of noodles and is basically made up of

a kneading part and of an extrusion unit in order to cut

the finished product

INSTRUCTIONS

The machine has only been realized to prepare cereal-based flour noodles for noodle

shops and catering requirements.

WARNING

For reasons of hygiene, health and warranty, it is strictly prohibited to use the

machine for the processing of substances other than foods. Any other uses are

contrary to the applications as originally intended by the manufacturer, who shall con-

sequently not be held liable for any damage to the machine itself or to other objects,

or for any injuries to persons that may arise thereof. In taking the risk of misuse, the

user will be held responsible for any consequences.

Always keep children away from the machinery.

• Power:

Model

TR 70 1-phase standard power 1-phase optional power

230/50 Hz. 110/60 Hz. 220/60 Hz.

TR 75/E

Standard power supp. - three phase

1-phase optional power

400/50 Hz. 230/50 Hz. 220/60 Hz.

Man TR ING:Man TR ING 2-08-2012 13:44 Pagina 20

21

ENGLISH

1. PREPARING THE MACHINE

Prepare the machine before every pro-

cess cycle. BE SURE that the machine,

especially parts which come in contact

with food products (extrusion sleeve,

Archimedean screw, pool, mixer and draw-

plate) are perfectly clean (see chapter 6

CLEANING on page 25).

Always clean with machine off.

2. OPERATING PRINCIPLE

This machine kneads the different products

desired and enables you to obtain different

kinds of noodles with a different group of

lengths because it draws the dough, thanks

to different discs.

This action is carried out thanks to a mixer

linked to an Archimedean screw which obli-

ges the product to assume the desired

shape going through a drawplate.

3. USE OF THE MACHINE

Only after making sure that the

machine is completely clean, espe-

cially all the parts which are directly

in contact with the product (extru-

sion sleeve, Archimedean screw, pool,

mixer, drawplate, cover, control

system; if it is necessary, use some

warm water; see chapter 6 CLEANING

page 25) you can carry out the reque-

sted operations in order to have the

desired dough.

Caution: the machine will run only if

the safety microswitch is serviceable

and perfectly positioned.

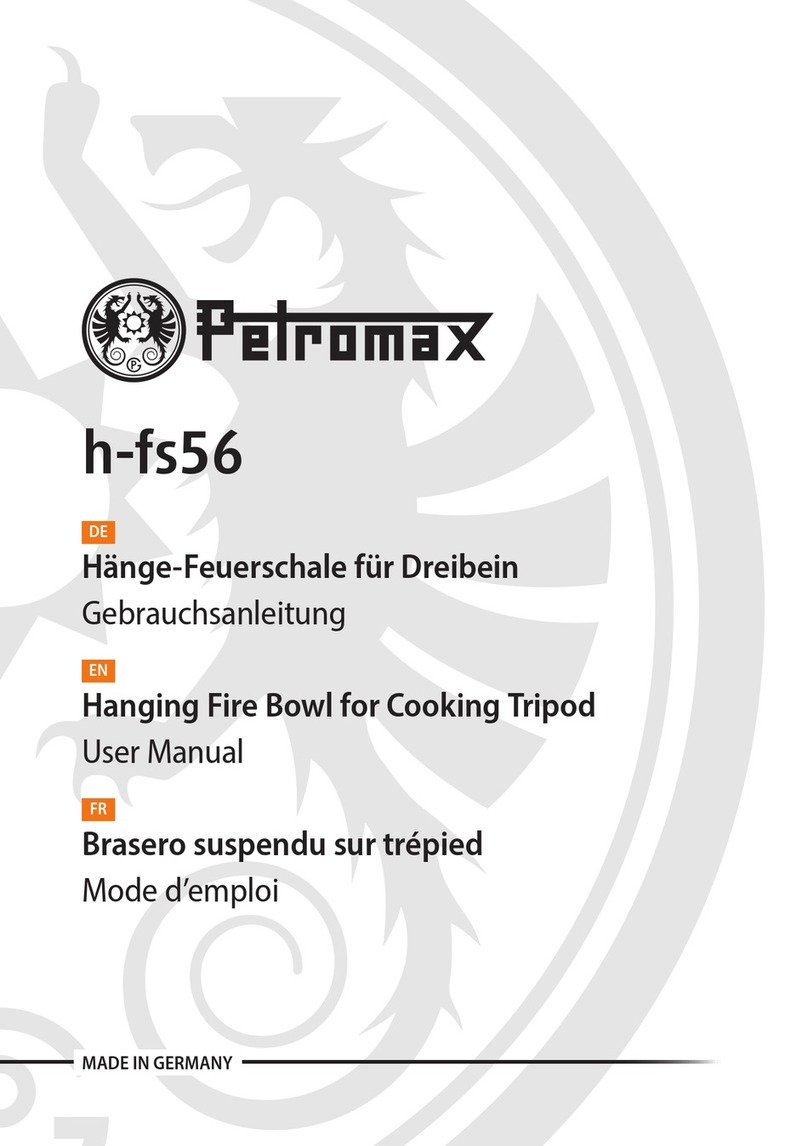

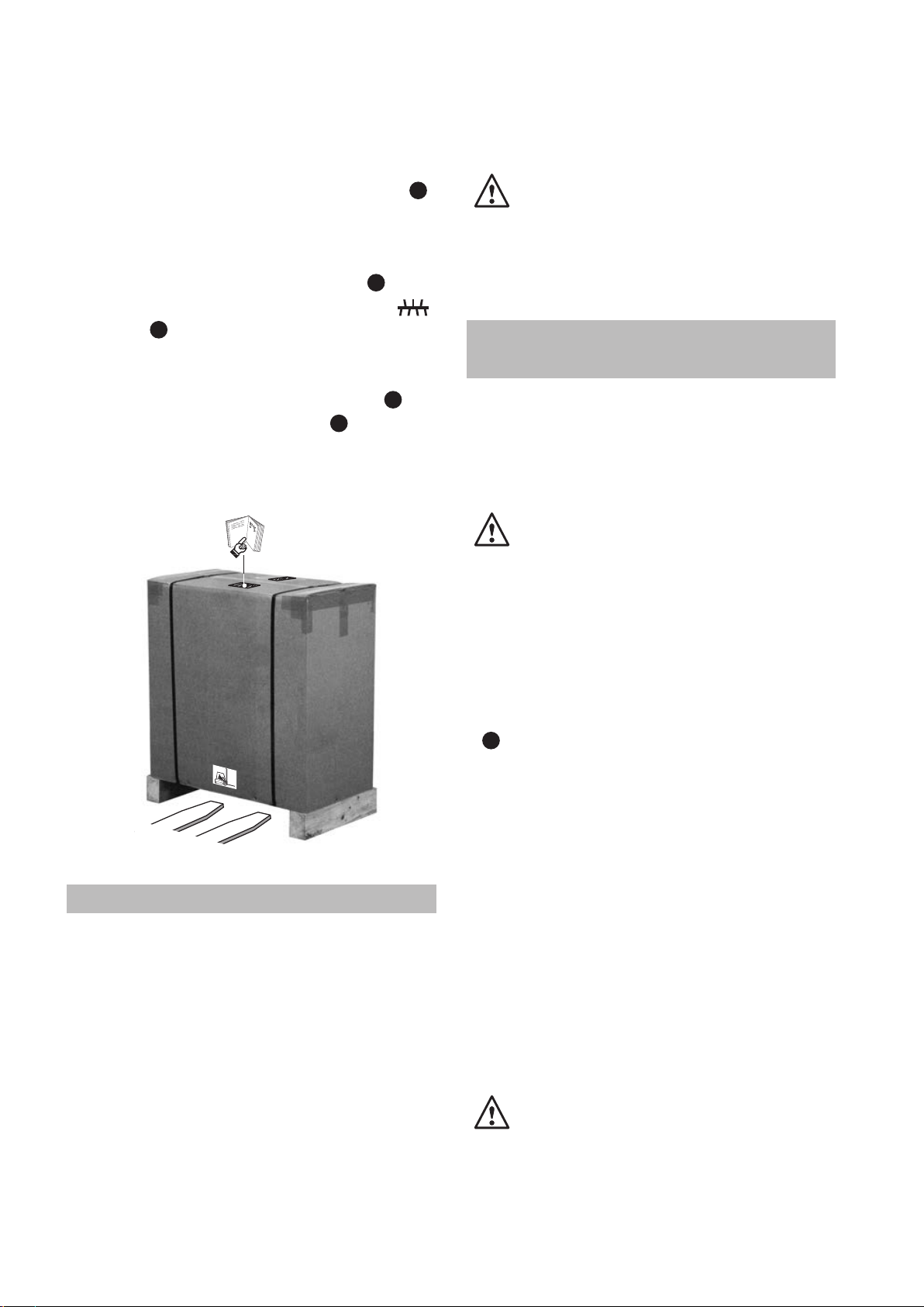

After having turned the machine off:

• position the selector on “0” (Fig. 2 ) and

verify the correct set-up of the Archi-

medean screw (Fig. 1 ) making sure that

the cylinder part is sustained by the drag-

ging shaft;

A

C

Fig. 1

Fig. 3

C

B

A

A

D

E

Fig. 1 bis

Mobile

support

for TR 75/E

Fig. 2

C

Man TR ING:Man TR ING 6-08-2012 13:03 Pagina 21

Any kind of flour can be used (bran or bran-

flour). The dough can be kneaded only with

eggs or with a mix of water and eggs. Water

can be partially replaced by spinach or well-

cut vegetables in order to obtain green

noodles.

Because the flour’s humidity changes

according to the kind, the environment and

the place where it is stocked, the indicated

quantities have to be adapted to the kind of

flour which is used, lowering or increasing

the quantity of water.

The dough is the right one when, at the end

of kneading, it is as big as coffee beans.

If the flour forms lumps you have poured in

too much liquid.

In this case, before turning the switch from

KNEAD to DRAWPLATE you have to add

some more flour and knead a little longer. If

flour does not form a ball and is too floury,

add some more water.

For the dough for the sheet of pasta which is

to be re-kneaded please use “00” flour and

add two eggs per kilo of flour (maximum).

With these quantities you will obtain a very

stretchy dough which is easy to knead.

22

• then make sure that the plastic cap

(Fig. 1 ) which replaces the drawplate is

correctly positioned and the ring nut

(Fig. 1 ) is tightly well-screwed on;

• lastly lock the mixer (Fig. 1 ) tightly in its

seat by means of the head-knob (Fig. 1 )

or tighten the mobile support in the TR

75/E (Fig. 1 bis see page 21).

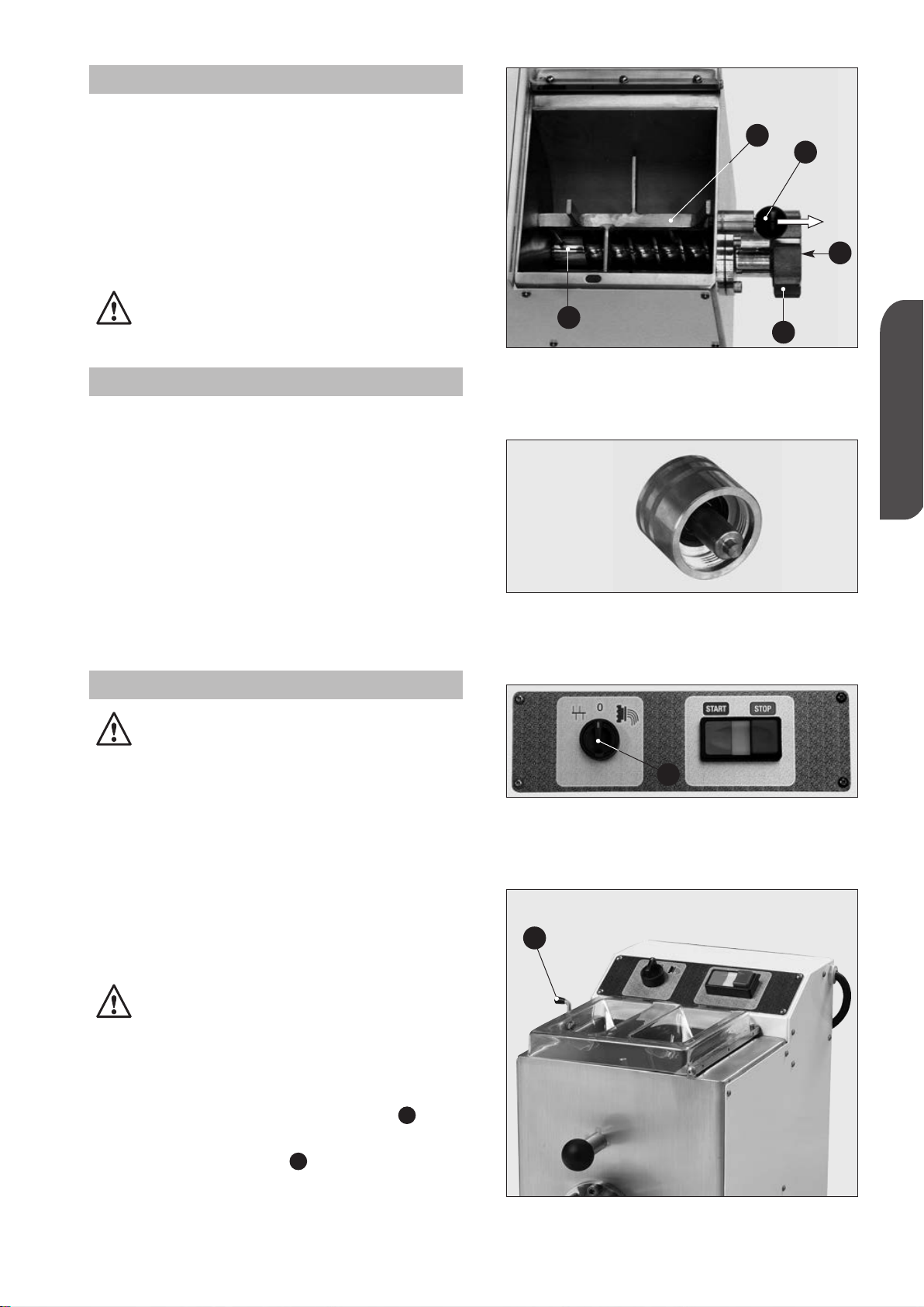

Pull up the pool cover (Fig. 3 ) and

always put in the pre-established ingre-

dients in the following sequence: flour and

then, after closing the cap, all the other

liquid elements.

In order to obtain the right dough, you need

to create the right ratio between the weight

of the flour and the weight of the liquid part;

in order to obtain a very good product, the

flour has to contain a humidity percentage

of no more than 15%; this allows the addi-

tion of water equal to 35% or up to 38% of

the flour’s weight. If you are using flours

with different humidity contents, please

change the quantity of the liquid in the

opposite ratio. Moreover, in order to better

use the machine, the product inside the

pool has to be higher than at a minimum

level which coincides more or less with the

position of the mixer axle.

B

C

A

E

D

3.1 USEFUL ADVICE IN ORDER TO OBTAIN GOOD DOUGH

3.2 QUANTITIES IN ORDER TO OBTAIN GOOD DOUGH

Pour the desired quantity of flour into the pool; it needs 7 eggs per kilo of flour:

• Supposed weight of an egg: 50 grams.

• If you take 1 egg away you need to add 50 grams of water.

Model Flour kg. Number of eggs

Grams of pasta product

0,5 3 650

TR 70 1 7 1.350

1,2* 9 1.650

1 7 1.350

TR 75/E 2 14 2.700

3 21 4.150

* This is the maximum capacity of the pool.

Man TR ING:Man TR ING 6-08-2012 13:03 Pagina 22

23

ENGLISH

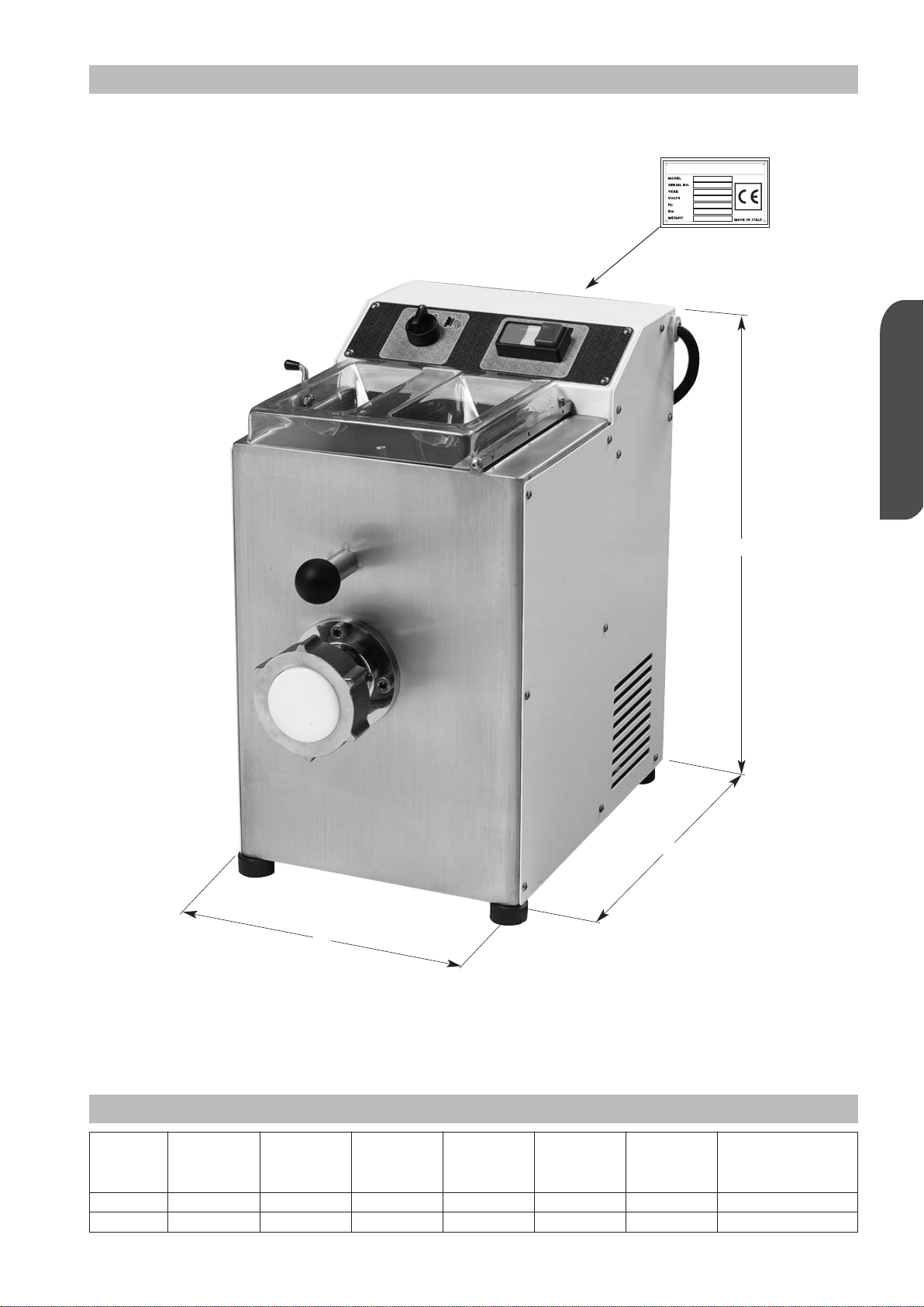

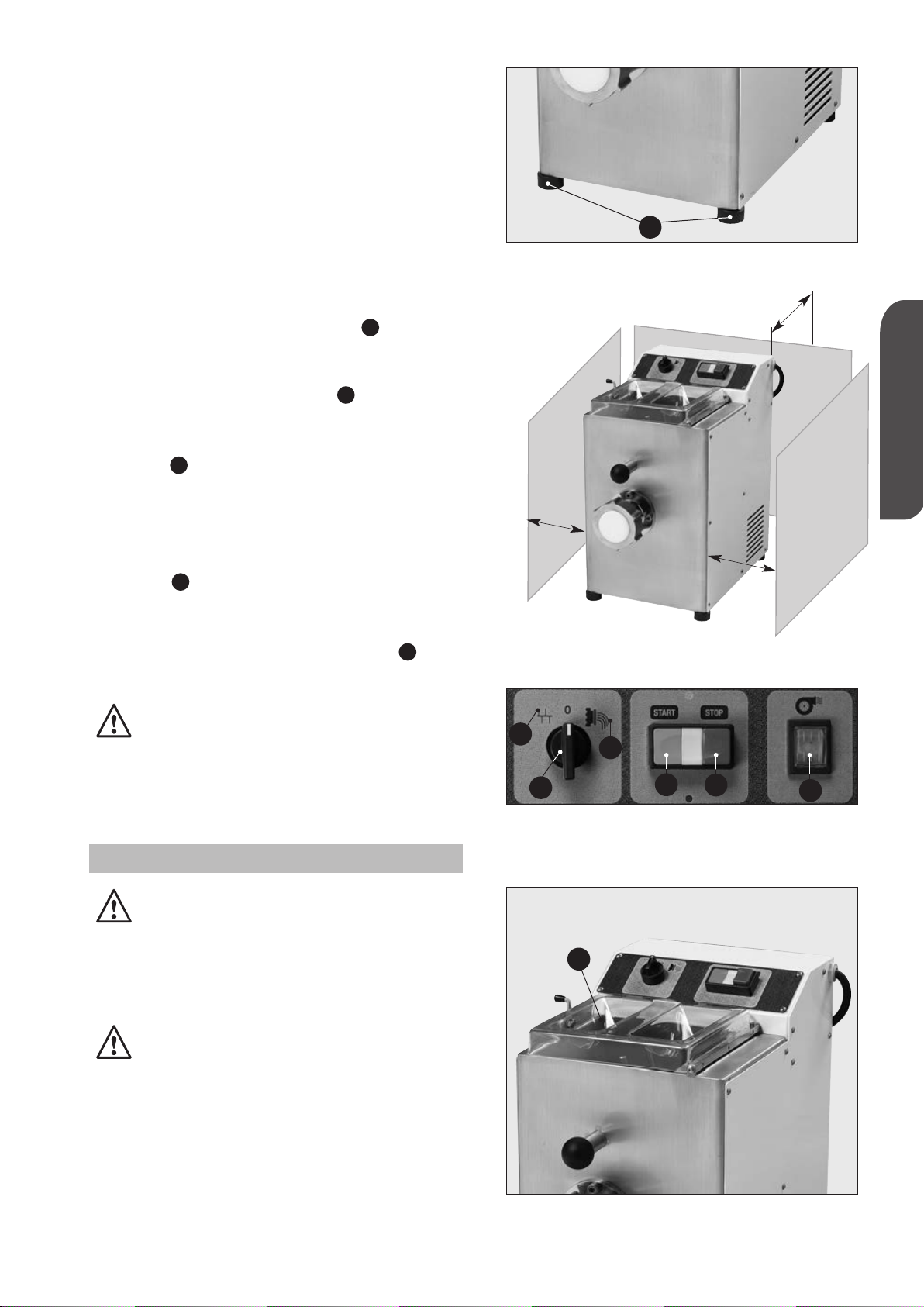

Now shut the cover and put the selector in

the position (Fig. 4 ).

Push the start button (Fig. 4 ).

Add the liquid part pouring it slowly but

quickly through the small hole in the cover.

At the end of the kneading operation, which

should take around 10 minutes, make sure

the product has the right thickness and

should look like coffee beans (check throu-

gh the small holes of the cover).

Turn the machine off by switching the selec-

tor to “0” (Fig. 4 ), or push the Stop button

(Fig. 4 ).

3.3 INSTALLATION OF THE DRAWPLATE

AND START-UP OF PRODUCTION

Make sure the machine is switched

off.

Withdraw the drawplate (Fig. 5 ) reque-

sted by the container filled with water where

it was put after its last use.

Thoroughly rinse with plenty of running

warm water in order to have the piece at the

right temperature (see chapter 6 CLEANING

page 25). Dry it with a soft cloth. Unscrew

the blocking ring nuts (Fig. 5 and 6)

and carefully clean the internal part inclu-

ding the edging.

Take the plastic cap off (Fig. 5 and 6).

Disassemble the drawplate (Fig. 7 ).

Screw in the ring nuts by hand and verify

that all the pieces are in their places and

that they are aligned along the axle.

In order to start production, position the

selector on the position (Fig. 4 ) and

push the start button (Fig. 4 ).

The initial product coming out of the machi-

ne has an unacceptable look; this is the rea-

son why it has to be eliminated.

After a short time (a couple of minutes) the

product coming out is acceptable, the

colour goes from whitish to yellow and it has

a greater thickness.

The cut of the pasta at the desired length

can be made by hand or by knife.

In the first case it is usually long length

B

D

A

C

B

B

A

A

E

C

B

A

Fig. 5

C

B

A

Fig. 6

Fig. 7

B

A

A

Fig. 4 - TR 70 Panel

C

D

A

B

E

Man TR ING:Man TR ING 6-08-2012 13:13 Pagina 23

24

noodles (spaghetti or tagliatelle) and in the

second case is especially short noodles

(macaroni, etc.).

If the product is quite wet and tends to be

sticky, it is best to dry the surface in any

case, by switching on the fan (Fig. 11 ,

only 75/E).

At the end of the operation:

• stop the machine by switching the selec-

tor to the “0” position (Fig. 11 ) and

then turn it on the kneading position

(Fig. 11 ) for 10-15 seconds so that the

pressure on the drawplate, caused by the

product itself, is eliminated;

• switch the selector to “0” (Fig. 11 ) or

push the Stop button (Fig. 11 );

• disassemble and wash the moving pieces

and clean the machine (see chapter 6

CLEANING page 25).

4. TRANSPORTATION AND HANDLING

The machine is forwarded contained in spe-

cial packaging which is securely closed

with bands (Fig 8).

Apart from the machine, you can find the

operating instructions and the conformity

declaration to the EC directive.

The machine has to be unloaded from the

means of transport, pulling it up and tran-

sporting it with a wheel-trolley.

Unless you need to check its contents, you

are recommended not to open the packing

until the moment of installation.

E

C

A

C

G

Remove straps, packing and polystyrene

strips. Dispose of this material according to

the regulations in force. Lift the machine

and place on the installation site.

Make sure that the bearing surface

of the machine is horizontal and

steady.

5. INSTALLATION, CONNECTION

AND SET-UP

Install and use the machine in a room that

can be efficiently ventilated, and where the

floor is smooth and compact and easy to

clean.

WARNING: During the machine’s

operation, in order to obtain a pro-

duct with the right thickness and

humidity, avoid air currents which will

cause precocious drying of the pro-

duct together with its deterioration.

In order to give the necessary stability to

the machine, check that the footers (Fig.

9) are securely attached to the floor;

otherwise, turn them to avoid instability.

Position the machine in the desired place

with a free back space of around 50 centi-

meters and a side space of 70-80 centime-

ters in order to guarantee easy use of the

machine and its cleaning (Fig. 10).

Please check that the voltage of the machi-

ne which is written on the identification

label, (see page 19) matches the one fore-

seen by the system on your premises.

Attach the right plug to the machine power

cable in order to make the electrical con-

nection to the system.

WARNING: (75/E) Have the plug fit-

ted to the power supply by quali-

fied personnel. Take the necessary

precautions to prevent the cable from

being crimped or damaged.

A

Fig. 8

Man TR ING:Man TR ING 6-08-2012 13:13 Pagina 24

50

cm

25

ENGLISH

After mating the plug to the mains socket,

the machine is ready for use.

First, however, check out proper operation

of all moving parts and components of the

machine.

5.1 CONTROL OF THE INSTALLATION

NOTE: Every drive is voluntarily run by

the start button, when the bowl

cover is closed (Fig. 12 ).

Verify that:

• In the “0” position (Fig. 11 ) all the ele-

ments of the machine have to stop; for

model TR 75/E, in the “drawplate position”

(Fig. 11 ) the mixer rotates in a clockwise

direction and the Archimedean screw must

rotate in the same direction (check through

the slots in the lid); for model TR 70, on the

other hand, in the “drawplate position”

(Fig. 11 ) the mixer rotates in a counter-

clockwise direction and the Archimedean

screw must rotate in the opposite direction;

in the “knead” position (Fig. 11 ) the

parts must rotate in the opposite direction.

If the machine or some of its parts fail,

call your local authorised dealer or

concessionaire for repairs.

6. CLEANING

Warning: For healthy and

hygienic processing of nutritio-

nal products, be sure to keep

your machine and the surroun-

ding environment clean.

DANGER: Always cut off power sup-

ply before cleaning.

You have to properly clean all the elements

which are in contact with the product; pro-

tection cover, pool, mixer, Archimedean

screw, drawplate, ring nut, when the pro-

duct is still soft.

A

D

D

C

F

Fig. 9

Fig. 10

A

Fig. 12

F

Fig. 11 - TR 75/E Panel

A

C

D

B

E

G

70÷80

cm

70÷80

cm

Man TR ING:Man TR ING 6-08-2012 13:14 Pagina 25

Fig. 14

26

The moving parts have to be disassembled

as follows:

• Mixer: make sure the external shovel is in

the upper vertical position (Fig. 13 )

(only this position allows the disassem-

bling of the piece).

For model TR 70: remove the mixer, pull

out the knob (Fig. 13 ) until the mixer

disengages;

for model TR 75/E: remove the mixer by

unscrewing the external mobile support

until the mixer disengages (Fig. 13 bis ).

Take the square shaft away from its place

(Fig. 13 ) and at the same time turn the

external end upwards. If you want to

assemble the piece follow these instruc-

tions vice versa. Line the central point of

the shaft with the peg of the moving sup-

port; then, leave the handle.

•Ring nut: (Fig. 13 ) and drawplate

(Fig. 13 ): unscrew the ring nut by hand,

avoiding pieces falling when the ring nut

comes out of its place, in order to avoid

causing damage both to people or to the

pieces themselves.

• Archimedean screw: (Fig. 13 ): after

disassembling the ring nut and the draw-

plate, the Archimedean screw can easily

be taken off from the machine by pushing

its spiral from the internal end.

6.1 COVER AND POOL CLEANING

Eliminate the dough residue and make sure

to thoroughly clean the most remote-access

pieces: connections of the Archimedean

screw and mixer movements (Fig 14), extru-

sion sleeve, cover and pool internal parts.

Use some warm water in order to eliminate

the residual product and then rinse; dry the

surfaces with the help of blotting paper.

WARNING: Never use non-nutritional,

abrasive or corrosive chemicals to

clean. Also never use coarse or abrasi-

ve objects such as steel wool, abrasive

sponges and so on.

To clean machine internal and external

parts:

F

E

D

C

A

B

A

Fig. 15

A

Fig. 13

D

F

A

E

B

C

Fig. 13 bis

A

Man TR ING:Man TR ING 6-08-2012 13:14 Pagina 26

27

ENGLISH

•remove power supply plug from power

mains socket;

•clean coated surfaces with soft cloth and

disinfect with alcohol;

•to clean internal parts of machine:

- turn the machine and lay it down on a

side;

-

clean the internal parts with the help of a

soft cloth and blow with a compressed air

jet.

CAUTION: Do not clean the tank lid

with alcohol or other solvents.

6.2 CLEANING OF THE ARCHIMEDEAN SCREW,

MIXER, RING NUT AND DRAWPLATE (Fig. 15)

Eliminate the dough residue and wash the

pieces with water; you may use a soft brush

or a plastic egg-slice.

These elements can be thoroughly washed

in a dishwasher. Rinse and dry the mixer, the

Archimedean screw and the ring nut and

reassemble them on the machine.

The drawplate (Fig. 15 ) is to stay in a

container with water when it is not in use.

For reasons of hygiene, please change

the water every day.

7. MAINTENANCE AND ADJUSTMENT

WARNING: Remember that all main-

tenance operations are hazardous if

you do not first disconnect the power

supply plug from power mains.

The points of the machine which need a

certain maintenance are the following: the

transmission gears, the dragging belt and

the mixer external support. Please carry out

the first maintenance after the first 100

hours and thereafter every 500 hours.

Mixer support: Use registered fats for foods

(USDA-H1) (in case of requirement contact

your local dealer).

Drive gears and chain: please use mineral

grease SAE MR3.

A

Fig. 16

A

B

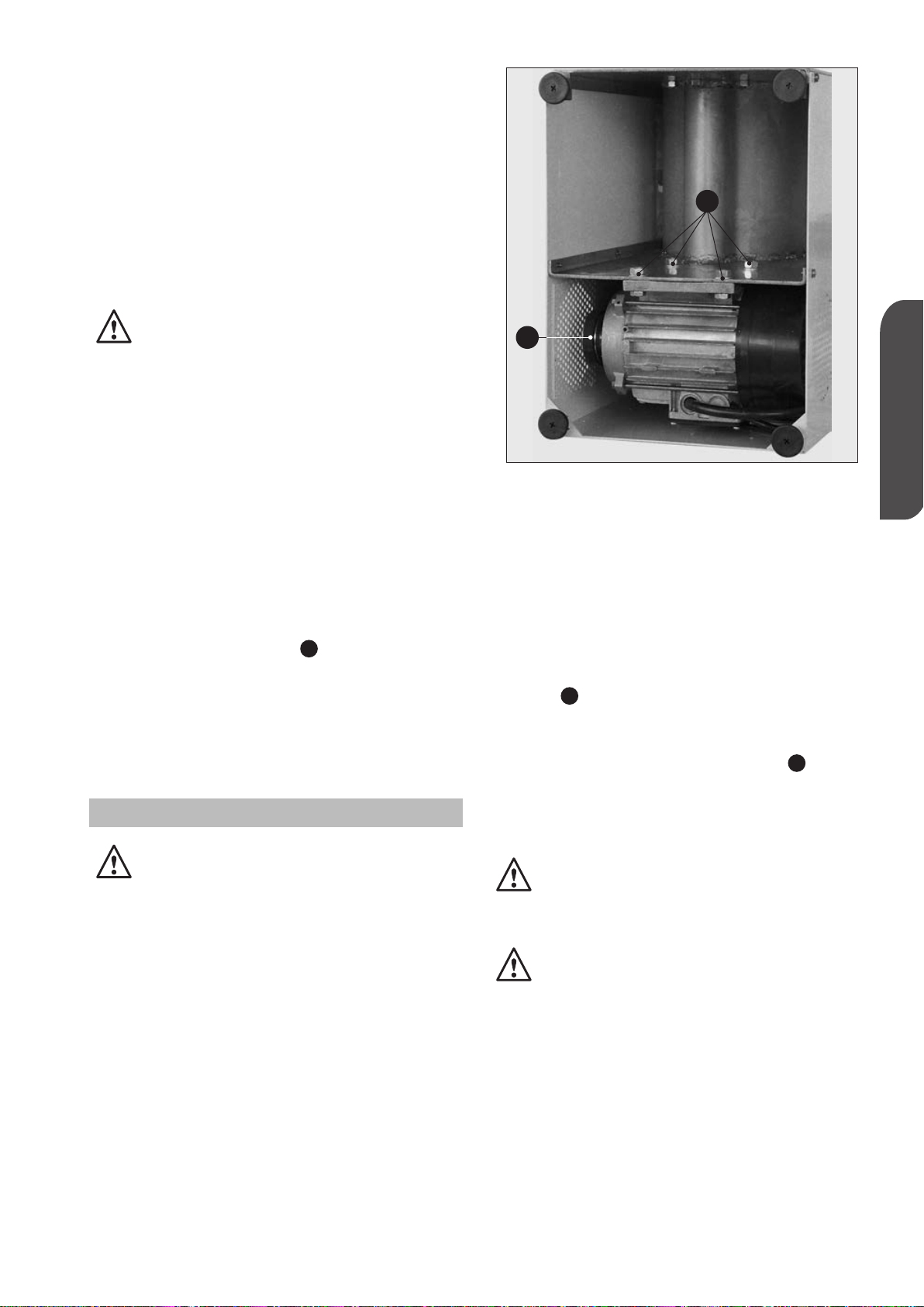

7.1 BELT STRETCHING

When performing the abovementioned

maintenance or when the machine is not

working properly, (loss of rounds) verify the

correct stretching of the transmission belt

(Fig. 16 ). Put the machine on one side

and make sure that the belt is sufficiently

stretched. If necessary, unscrew the

blocking motor screws (Fig. 16 ) and

push it downwards and stretch the belt

without exaggerating; then re-block the

screws.

Never use the machine with any mis-

sing, disassembled or open guards

and shields.

If servicing operations require repairs

to electrical system and/or replace-

ment of bearings or mechanical com-

ponents, call an expert technician or

your local dealer.

B

A

Man TR ING:Man TR ING 6-08-2012 13:15 Pagina 27

28

8. MACHINE WHIRR

The whirring noise emitted by the machine has been measured on an identical sample

machine in compliance with standard DIN 45635. A constant value not exceeding 70_dB(A)

was measured as stated in the manufacturer’s test report.

9. DISMANTLING AND DEMOLISHING THE MACHINE

If machine needs to be dismantled and/or demolished, its components do not entail a

degree of danger that requires any particular precaution.

Remember, however, that to facilitate material recycling operations, it is a good rule to

remove electrical system components from the machine.

10. INCONVENIENCES AND THEIR REMEDIES

INCONVENIENCES CAUSES REMEDIES

1) Machine operation • disconnected plug • connect plug

failure • plug leads not • check lead connections

correctly connected

• trip switch adjusted • adjust trip switch

for insufficient values accordingly

• unsuitable trip switch • replace trip switch

• the security hook • position the hook

on the pool cover is not at the end of the run

inserted properly

2) Problems on the product:

The product gets stuck • dough too humid is used • reduce the quantity of

when being poured out water used for the dough

respecting the abovemen-

tioned percentage

The product looks • too short kneading time • increase the kneading time

unacceptable even after • too reduced water • increase the quantity of

the initial minutes: it percentage water in order to respect

breaks and looses flour the aforementioned

percentage

The product does not come • the blocking of the drawplate • disassemble and clean

out from the drawplate because of dried dough the drawplate

INFORMATIVE REPORT TO THE CUSTOMERS

according to the art.13 of Decree Legislative 25 July 2005, n.151 “Performance

Directives 2002/95/CE, 2002/96/CE and 2003/108/CE, relative to the reduction of the use

of dangerous substances in the electronic and electrical equipment, let alone to dispos-

al of the refusals”.

The symbol of the crossed bin brought back on the equipment or its packing indicates that the product at

the end of its own life cycle must be collected separately from the other refusals. The differentiated collec-

tion of the present equipment at the end of its life cycle is organized and is managed from the distributor.

The customer who want to unravel itself the present equipment will have therefore to contact the distribu-

tor and follow the system that he has adopted in order to concur the separate collection of the equipment

at the end of its life cycle. The adapted differentiated collection for the successive start of the cast-off

equipment to the recycling, to the treatment and to the compatible with environment disposal contributes

to avoid possible negative effects on the atmosphere and the health and favours the re-employment

and/or the recycling of the materials of which the equipment is made. Illicit disposal of the product by the

holder involves the application of the previewed administrative endorsements from the enforced norm.

EN 50419

Man TR ING:Man TR ING 3-08-2012 9:18 Pagina 28

This manual suits for next models

1

Table of contents

Other Gastrodomus Cooking Equipment manuals