GASTRON GPD-100 User manual

Design, Develop, Manufacture, Install and Maintenance Service for Gas Leak Alarm

DOC NO.G -046IM00E

GPD-100

Instruction Manual

Revision: 1.1

Copyright ⒞GAS RON, Co., L D. All rights reserved.

For proper use, please read this manual carefully prior to

GPD-100 Instruction Manual

PAGE

2 of 27

Rev 1.1(2019.05.23)

Thank you for purchasing our GASTRON’s product.

Gastron is a specialized company in producing gas detector and gas monitoring system.

We have been recognized by customers for our best quality products and excellence in easy-to-

use design. We are striving to provide the suitable product that fits customer’s needs, and

continuously put every effort to develop better gas detector to satisfy customer’s requirements.

From now on, we will be your reliable partner to shed a bright light on your concern about gas

detector. Please contact us if you have any question. You can obtain best solution from us with

great satisfaction.

his instruction manual describes how to operate the gas detector. It also briefly explains how

to repair and maintain the device. Please keep this manual in safe place after reading carefully.

his instruction manual will be of great help when you encounter any trouble or question while

you are using the device.

If you have any problem when using our product, contact us to following address:

Address: 18-8, Dogeumdanji 1-gil(Palgok 2-dong), Sangrok-gu, Ansan-si, Gyeonggi-do

el : 031-490-0800

Fax : 031-490-0801

URL : www.gastron.com

E-mail : gastron@gastron.com

Note

• We recommend that the gas detector should be inspected and

calibrated with calibration gas prior to use for accurate operation.

• Without getting calibrated, the device might be malfunctioned due to

sensor aging problem.

• When it is necessary to disassemble the device, technician with special

skills for a gas detector must perform it.

• For more details about maintenance and calibration of gas detector,

contact our technical department via email or visiting our web site.

GASTRON reserves the right to change published specifications and designs without prior notice.

GPD-100 Instruction Manual

PAGE

3 of 27

Rev 1.1(2019.05.23)

TABLE OF CONTENTS

1.

Introduction ......................................................................................................................4

2.

Structure ..........................................................................................................................4

3.

Specification .....................................................................................................................5

3.1.

General Specifications .................................................................................................5

3.2.

Mechanical Specifications ............................................................................................5

3.3.

Electrical Specifications (Standard ype) .......................................................................5

3.4.

Environmental Specifications .......................................................................................6

4.

Name and Functional Description of Components ..............................................................6

4.1.

Composing Elements ...................................................................................................6

4.2.

Front Panel Display part ...............................................................................................7

5.

Operation .........................................................................................................................9

5.1.

Connecting Sampling Probe ........................................................................................9

5.2.

Power On ...................................................................................................................9

5.3.

Gas Measurement Mode .............................................................................................9

5.4.

Mode Configuration .................................................................................................. 10

5.5.

Power Status ............................................................................................................. 10

5.6.

How to use a log mode ............................................................................................. 11

5.6.1.

Gas log file ....................................................................................................... 13

5.6.2.

Report log file ................................................................................................... 13

6.

System Mode .................................................................................................................. 15

6.1.

Mode configuration .................................................................................................. 15

6.2.

Detailed Mode description ......................................................................................... 15

6.3.

Configuration Mode .................................................................................................. 16

6.4.

Program setting mode ............................................................................................... 18

6.5.

Zero Calibration ........................................................................................................ 19

6.5.1.

Auto Zero Calibration ....................................................................................... 19

6.5.2.

Manual Zero Calibration ................................................................................... 19

6.6.

Span Calibration ........................................................................................................ 20

6.7.

Alarm mode .............................................................................................................. 21

6.8.

Log Save Mode ......................................................................................................... 22

7.

roubleshooting .............................................................................................................. 24

7.1.

Fault Code ................................................................................................................ 24

7.2.

Warning Code ........................................................................................................... 24

7.3.

Recovery List ............................................................................................................. 25

8.

Appearance and Dimensions ........................................................................................... 26

9.

Revision History ............................................................................................................... 27

GPD-100 Instruction Manual

PAGE

4 of 27

Rev 1.1(2019.05.23)

1. Introduction

he GPD-100 is a portable gas detector that has been developed to detect a variety of gases so

as to prevent serious accidents caused by unexpected gas leaks in hazardous areas such as

industrial plants, gas storage facilities and factories in the process of producing or consuming

combustible gases and toxic gases.

he portable gas detector GPD-100 continuously monitors the air for detecting dangerous gas

leaks and displays the measured value of gas concentration. It makes a visual signal and an

audible alarm when it detects gas leaks.

2. Structure

he body of GPD-100 is made of polycarbonate-ABS housing. A sampling pump is equipped

inside the GPD-100. he sampling pump pulls the air containing leaked gas in the device.

he GPD-100 mainly consists of three parts as follows: (1) LED that presents the measured

value of gas concentration and shows alerts to the user at front panel, (2) Port that takes in and

releases gas, and (3) terminal that enables to connect USB, Micro SD card and DC jack. A sensor

is a removable cartridge type, so that it can be easily detached and replaced.

[Figure 1. GPD-100 Overview]

GPD-100 Instruction Manual

PAGE

5 of 27

Rev 1.1(2019.05.23)

3. Specification

3.1. General Specifications

I T E M S S P E C I F I C A T I O N

Measuring ype Auto Sampling type

Display ype Flexible Numeric Display LED

Measuring Method

Electrochemical / Cartridge

Catalytic/ Cartridge

semiconductor / Cartridge

Photoionization detector(PID) / Cartridge

Detectible Gas Flammable gas, oxic gas, Oxygen (Note1)

Measuring Range 000.0 ~ 9999(Note1)

Accuracy ≤ ±3% / Full Range

Zero Drift ≤ 2% / Full Range

Response ime

arget gas response time may vary. Refer to the

sensor module datasheet or contact GAS RON for

specific sensor data.

Pump ype

Diaphragm Pump

Flow Rate 100 ~ 1,000 ml (Normal 300~500ml / min)

Gas Sample Line 5m ( 1/4" ube )

Approvals Classification CE ( No. K5004/E12 )

Storage SD Card

Warranty Main Unit 2Year

Sensor 1Year

Note1. Refer to the “List of detectable gases & vapours” or contact GASTORN for specific gas

3.2. Mechanical Specifications

I T E M S S P E C I F I C A T I O N

Dimension / mm 218(W) × 95(H) × 100(D) mm

Weight including Sensor App. 1.2kg

Sample gas vent / inlet 1/4" eflon ube

Body material PC-ABS(polycarbonate-ABS)

3.3. Electrical Specifications (Standard Type

I T E M S S P E C I F I C A T I O N

Battery ype Lithium-Ion DC 7.4 V / 4.3A

Charge ime 4 Hours

Operating ime Normal Sensor ype 10 Hours

CEC Sensor ype 5 Hours

Charge Voltage

DC 12V /2A

AC Adapter Input Voltage AC100~230V 50/60Hz

GPD-100 Instruction Manual

PAGE

6 of 27

Rev 1.1(2019.05.23)

3.4. Environmental Specifications

I T E M S S P E C I F I C A T I O N

peration Temperature

Main Unit

-10 to 60 ℃

Sensor

Sensor dependant, Refer to the

sensor module datasheet or contact

GASTR N for specific sensor data.

Storage Temperature

Main Unit

-10 to 60 ℃

Sensor

Sensor dependant, Refer to the

sensor module datasheet or contact

GASTR N for specific sensor data.

peration Humidity

Main Unit

5 to 99% RH (Non-condensing)

Sensor

Sensor dependant, Refer to the

sensor module datasheet or

contact GASTR N for specific

sensor data.

Pressure Range 90 to 110KPa

Max. air velocity 6m/s

4. Name and Functional Description of Components

4.1. Composing Elements

[Figure 2. GPD-100 구성요소]

GPD-100 Instruction Manual

PAGE

7 of 27

Rev 1.1(2019.05.23)

4.2. Front Panel Display part

[Figure 3. 전면 Display 구성도]

No Name Descriptions

1 Calibration icon Indicating that calibration procedure is being processed.

2 Setting icon Indicating that value setting operation is being processed.

3 Pump Icon Pump Operation Status display

4 est Icon

Indicating that gas detector operates in test mode.

5 ime setting Icon

It turns on when internal time is being set.

6 Setup Status Icon

It turns on when internal time is being set.

7 AC Adaptor Icon Indicating that AC adapter connection status

8 Battery Icon Indicating that Battery charging status

9 Measurement Unit

Indicating that current measuring unit presented on

screen.(PPM, PPM, %VOL, %LEL, mA)

10 Flow Rate When this icon appears, measured value of flow is indicated as

10 different levels, while in normal measuring state.

11 Communication

Icon his icon is turned on, when USB communication is being used.

12 Lock Icon Indicating device is in lock mode. Configuration mode is not

allowed.

13 CEC Icon Indicating that CEC operation status

14 rouble icon It turns on when fault is detected

15 Alarm2 icon Indicating that 2

nd

alarm is set or detected.

16 Alarm1 icon Indicating that 1

st

alarm is set or detected.

17 Zero, Span icon Indicating that zero or span mode is entered during calibration

18 Gas concentration

display It is used for displaying measured value or message to the user

GPD-100 Instruction Manual

PAGE

8 of 27

Rev 1.1(2019.05.23)

19 Power LED his Power LED is turned on when power is successfully

supplied.

20 rouble LED his rouble LED is turned on when a device is recognized as

malfunctioned

21 Alarm LED his Alarm1 LED is turned on, when the measured value of gas

concentration exceeds the preset value of Alarm1 level

22 Power Key Power on /off control key

23 RUN / MODE Key his key is used for changing setting mode or measuring mode.

24 AU O ZERO Key Auto Zero calibration key

25 Down Key It is a key to decrease a setting value in function setting mode.

26 Up Key It is a key to increase a setting value in function setting mode.

27 RESE key In function setting mode, Reset Key is used for recovering the

device’s state back to menu state or standby state.

[Ta le 1. Front Display part description]

GPD-100 Instruction Manual

PAGE

9 of 27

Rev 1.1(2019.05.23)

5. Operation

5.1. Connecting Sampling Probe

Connect a sampling Probe(1/4”Teflon tube) to a gas inlet port

Figure 4. Sampling Port Conne tion

5.2. Power On

Press power switch( ) and hold it more than 2 seconds. Then it starts up.

Power LED turns on and ‘L Ad’ is displayed (during about 15 seconds) indicating sensor

data is being loaded. After ‘WaIt’ is displayed, make sure that ‘Stby’(stand by) shows up

blinking.

When you turn on the power switch, version information will show up

in LCD like “U-XX”. hen “L0Ad”(Load) message flashes on and off

during about 15 seconds. Once warming-up is finished, “Stby”(Stand by)

message will come up, which indicates that the device is now ready to

measure. If the device detects a fault in device or sensor cartridge, a

faulty alarm occurs.

5.3. Gas Measurement Mode

When you press a switch “RUN/MODE”, the device will count down from

20 to 1, which is the time duration necessary to allow the sensor to

stabilize. When it reaches to 0, the measured value of gas concentration

is displayed on LCD.

Note 1)

In the occurrence of fault in sensor cartridge, error message

ranging from “E-10” to “E-33” flashes in LCD and also trouble LED turns

on. (Please refer to error and warning messages)

Note 2)

In case where gas concentration value is greater than 10% of

specified high scale value, “OuEr” message flashes every half a second.

Note 3)

Sensor stabilization time varies depending on the sensor type.

In case of combustible sensor : 10 seconds

In case of toxic sensor : 20 seconds

GPD-100 Instruction Manual

PAGE

10 of 27

Rev 1.1(2019.05.23)

5.4. Mode Configuration

5.5. Power Status

Item Power Icon disp ay Description

Full charge

Full charge status. utline of the battery icon

keeps blinking. Battery is not charged in this

state.

80%

charge

more than 80% of Battery level indicator

60%

charge

more than 60% of Battery level indicator

40%

charge

more than 40% of Battery level indicator

20%

charge

more than 20% of Battery level indicator

5% charge

Battery low message shows up in LCD and

battery icon keeps blinking.

charging

status

This icon keeps blinking when battery is

being charged. When AC adaptor is

recognized after it is inserted, this icon turns

on.

[Table 2. Power Status des ription]

While the device displays ”Stby”(Stand by), press and hold “RUN/MODE” key

more than 2 seconds. hen you will enter menu selection mode.

Password entering screen shows up. Input password using “ ”Key or

“ ”Key. If you press “RUN/MODE” key after entering password, then you

enter a configuration menu (“ConF”) (Initial password: [--]).

Select “COnF”(configuration) using “ ” key or “ ” key and then press

“RUN/MODE” key. You will enter environment configuration mode.

GPD-100 Instruction Manual

PAGE

11 of 27

Rev 1.1(2019.05.23)

5.6. How to use a log mode

When you want to read data stored in an external memory after operating the log mode,

connect the external memory to PC.

You can see the folders named by date when the data has been stored. he date is

determined by the date you set in “tImE” mode. (04-17 folder of the figure below, displays

the April 17)

[Figure 5. Date folders stored in SD card]

Inside the folder named by date, there are folders named by time(hour_min_sec) stored.

Each of these folders contains log data regarding measurement record and equipment

information. (04-17 folder of the figure below, displays the April 17)

[Figure 6. Time folders generated in date folder]

hree types of files are generated as log data in the hour_min_sec folder.

GPD-100 Instruction Manual

PAGE

12 of 27

Rev 1.1(2019.05.23)

[Figure 7. Log data files saved in time folder]

File Name Descrip ion

Gas Log File GAS00. X Log about gas measurement records

Report File REPOR . X Log about System Status and

Measurement Status

System File INFO.DA System File

[Ta le 3. Log File description]

GPD-100 Instruction Manual

PAGE

13 of 27

Rev 1.1(2019.05.23)

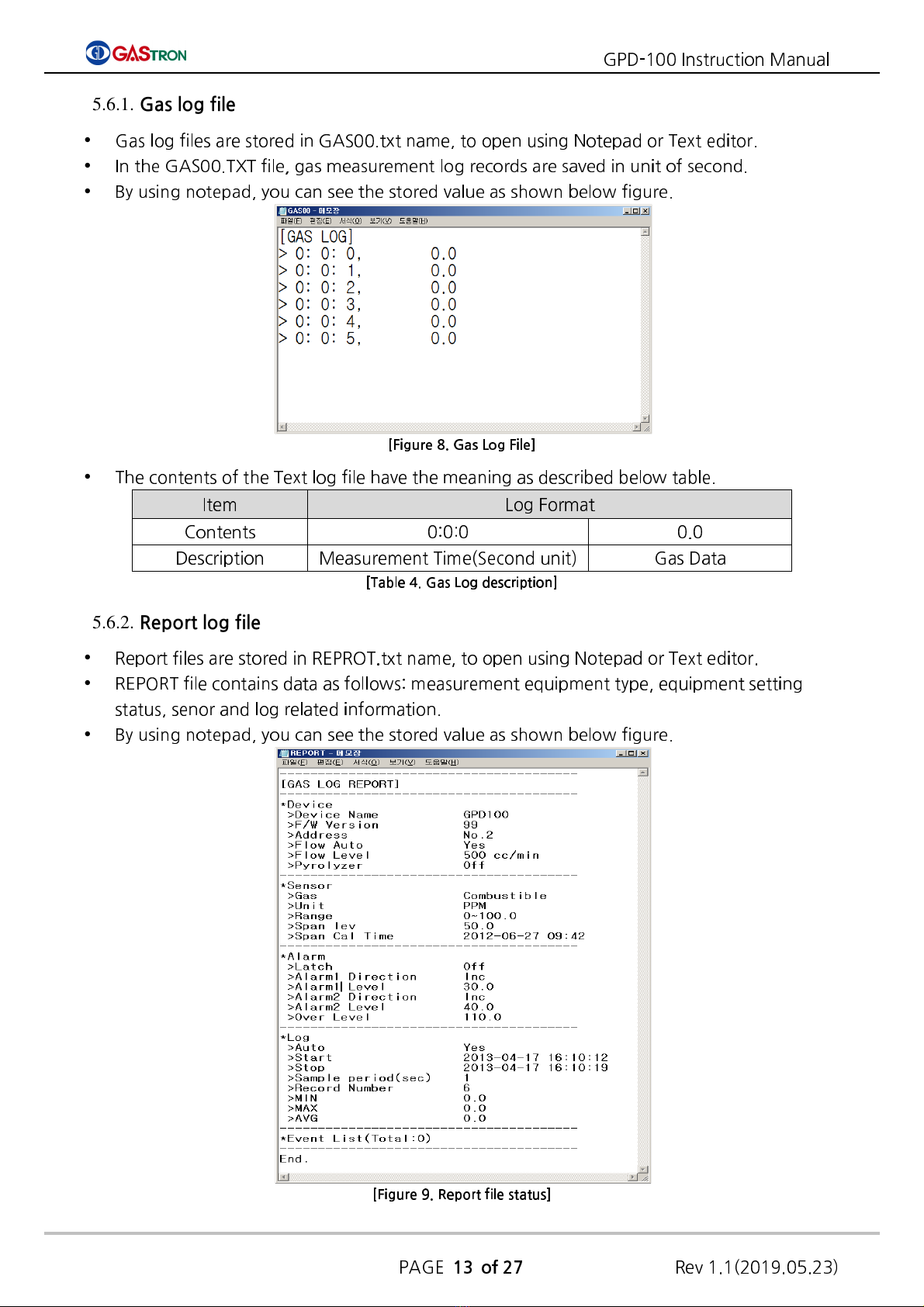

5.6.1. Gas log file

Gas log files are stored in GAS00.txt name, to open using Notepad or ext editor.

In the GAS00. X file, gas measurement log records are saved in unit of second.

By using notepad, you can see the stored value as shown below figure.

[Figure 8. Gas Log File]

he contents of the ext log file have the meaning as described below table.

Item Log Format

Contents 0:0:0 0.0

Description Measurement ime(Second unit)

Gas Data

[Ta le 4. Gas Log description]

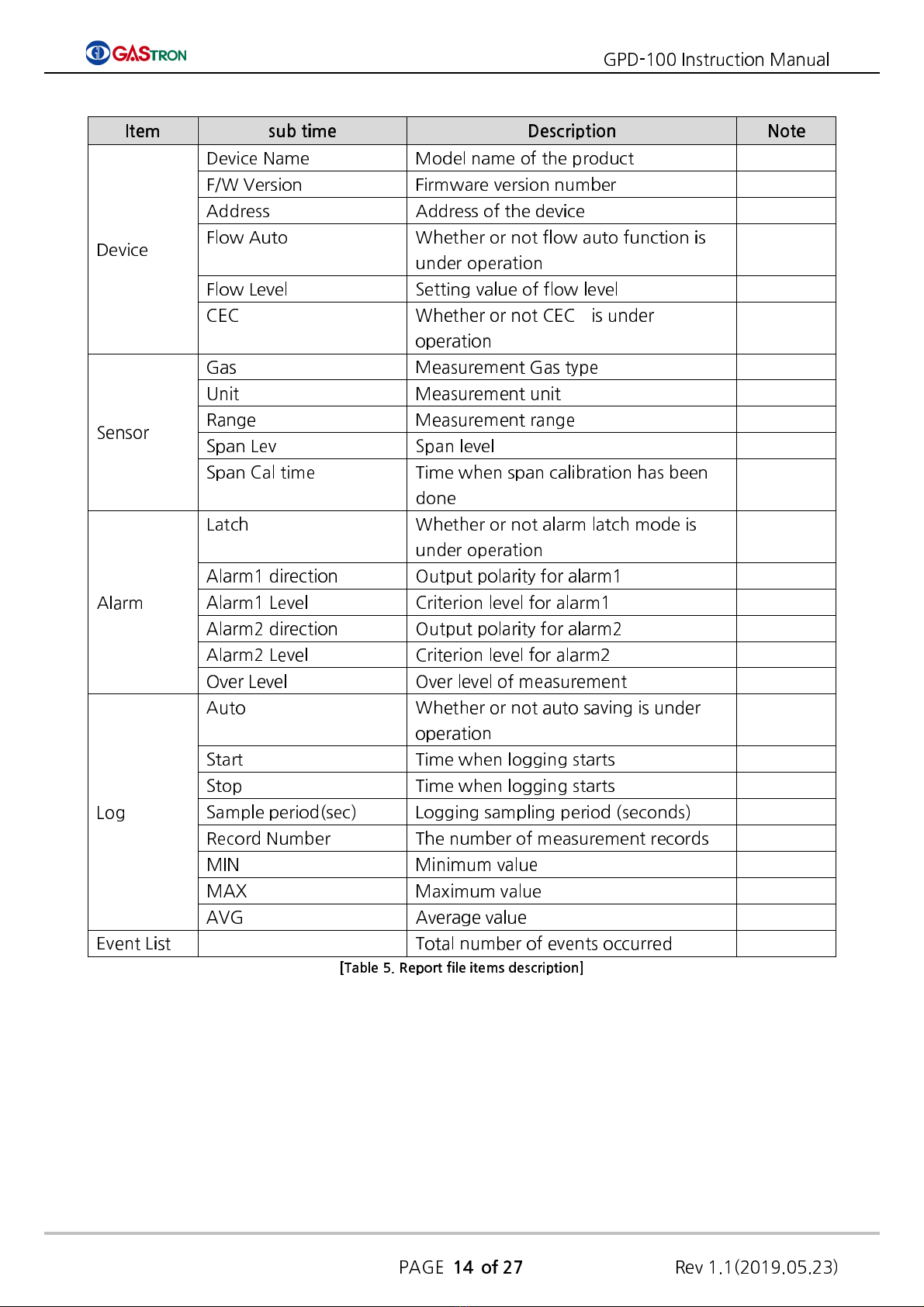

5.6.2. Report log file

Report files are stored in REPRO .txt name, to open using Notepad or ext editor.

REPOR file contains data as follows: measurement equipment type, equipment setting

status, senor and log related information.

By using notepad, you can see the stored value as shown below figure.

[Figure 9. Report file status]

GPD-100 Instruction Manual

PAGE

14 of 27

Rev 1.1(2019.05.23)

I em sub ime Descrip ion No e

Device

Device Name Model name of the product

F/W Version Firmware version number

Address Address of the device

Flow Auto Whether or not flow auto function is

under operation

Flow Level Setting value of flow level

CEC Whether or not CEC is under

operation

Sensor

Gas Measurement Gas type

Unit Measurement unit

Range Measurement range

Span Lev Span level

Span Cal time ime when span calibration has been

done

Alarm

Latch Whether or not alarm latch mode is

under operation

Alarm1 direction Output polarity for alarm1

Alarm1 Level Criterion level for alarm1

Alarm2 direction Output polarity for alarm2

Alarm2 Level Criterion level for alarm2

Over Level Over level of measurement

Log

Auto Whether or not auto saving is under

operation

Start ime when logging starts

Stop ime when logging starts

Sample period(sec) Logging sampling period (seconds)

Record Number he number of measurement records

MIN Minimum value

MAX Maximum value

AVG Average value

Event List otal number of events occurred

[Ta le 5. Report file items description]

GPD-100 Instruction Manual

PAGE

15 of 27

Rev 1.1(2019.05.23)

6. System Mode

6.1. Mode configuration

Menu structure of the device is as following table.

I em Display Descrip ion No e

CONFIGURA ION MODE CONF Configuration of internal

function

PROGRAM MODE PRGM Configuration of related gas

measurement

CALIBRA ION MODE CALB Calibration gas

ALARM MODE ALAM Configuration of Alarm setting

IME MODE IME Setting of Internal ime Factory Mode

SENSOR DA A MODE S-D Check of sensor data Factory Mode

ES ES MODE est Mode Factory Mode

FLOW MODE FLOW Configuration of flow setting Factory Mode

Log Mode Log Configuration of log function

MAIN ENANCE MODE M- Configuration of Maintenance

setting Factory Mode

[Ta le 6. Mode Configuration]

6.2. Detailed Mode description

Detailed menu and sub-menu of the device is as following table

Level 1 Level 2 Level 3

COnF

Configurat

ion

Add Specify a detector

number [01] ranges between 01 and 64

PSWd

Set password [00] ranges between 00 and 99

SUPr

Set the measured gas

suppression rate OFF 1~50%

PyrO

Set if CEC is used or not ON / OFF

Py-U

Indicate CEC voltage 1.50U

U-00

Program version number

Prgm

Measurem

ent data

UnIt Measurement unit %LEL, %VOL, PPM, PPB

dP-S Specify location of the

decimal point Set 0000, 0.000, 00.00 or 000.0

H-SL Set Full Scale Set value between 0 and 9999

CALb

Calibration

mode

ZERO ZERO Calibration Mode

YES/no

Set ZERO Calibration

0.0

Measured value display

mode

WA t

Under zero calibration

0.0 Measured value after

completing calibration

GPD-100 Instruction Manual

PAGE

16 of 27

Rev 1.1(2019.05.23)

SPAN SPAN Calibration Mode

YES/no

Span calibration setting

50.0

Span calibration value

50.3

Measured value of

standard gas

WAIt

Under span calibration

50.0

Measured value after

completing calibration

ALAm

Alarm

setting

LACH

Alarm occurrence setting

on/ FF

AL-1

Alarm1 value setting 90% setting of 0~Full Scale

1H/1L

Alarm1 operational

direction

H:Upward Alarm

L: Downward Alarm

AL-

Alarm2 value setting 90% setting of 0~Full Scale

H/ L

Alarm2 operational

direction

H:Upward Alarm

L: Downward Alarm

L g Saving log

CtrL Log saving mode n/ FF

AUto Set log auto saving mode

n/ FF

mSdC

Set type of external

memory

[Table 7. Menu Table]

6.3. Configuration Mode

While the device displays ”Stby”(Stand by), press and hold “RUN/MODE” key

more than 2 seconds. hen you will enter menu selection mode.

Password entering screen shows up. Input password using “ ”Key or

“ ”Key. If you press “RUN/MODE” key after entering password, then you

enter a configuration menu (“ConF”) (Initial password: [--]).

Select “COnF”(configuration) using “ ” key or “ ” key and then press

“RUN/MODE” key. You will enter environment configuration mode.

“Add” message will show up. In this state, you can set an address that is

used to identify the device when communicating data.

If you press ”RUN/MODE” key, then you enter an address setting function.

Address is a mode in which you can set the device’s address so as to

identify each detector by PC uniquely. Address number(initially [01]) will

increase or decrease by pressing “ ” or “ ” key.

When desired address is displayed, press “RUN/MODE” key. hen the

address is set to be the number displayed in the screen. After that, the

GPD-100 Instruction Manual

PAGE

17 of 27

Rev 1.1(2019.05.23)

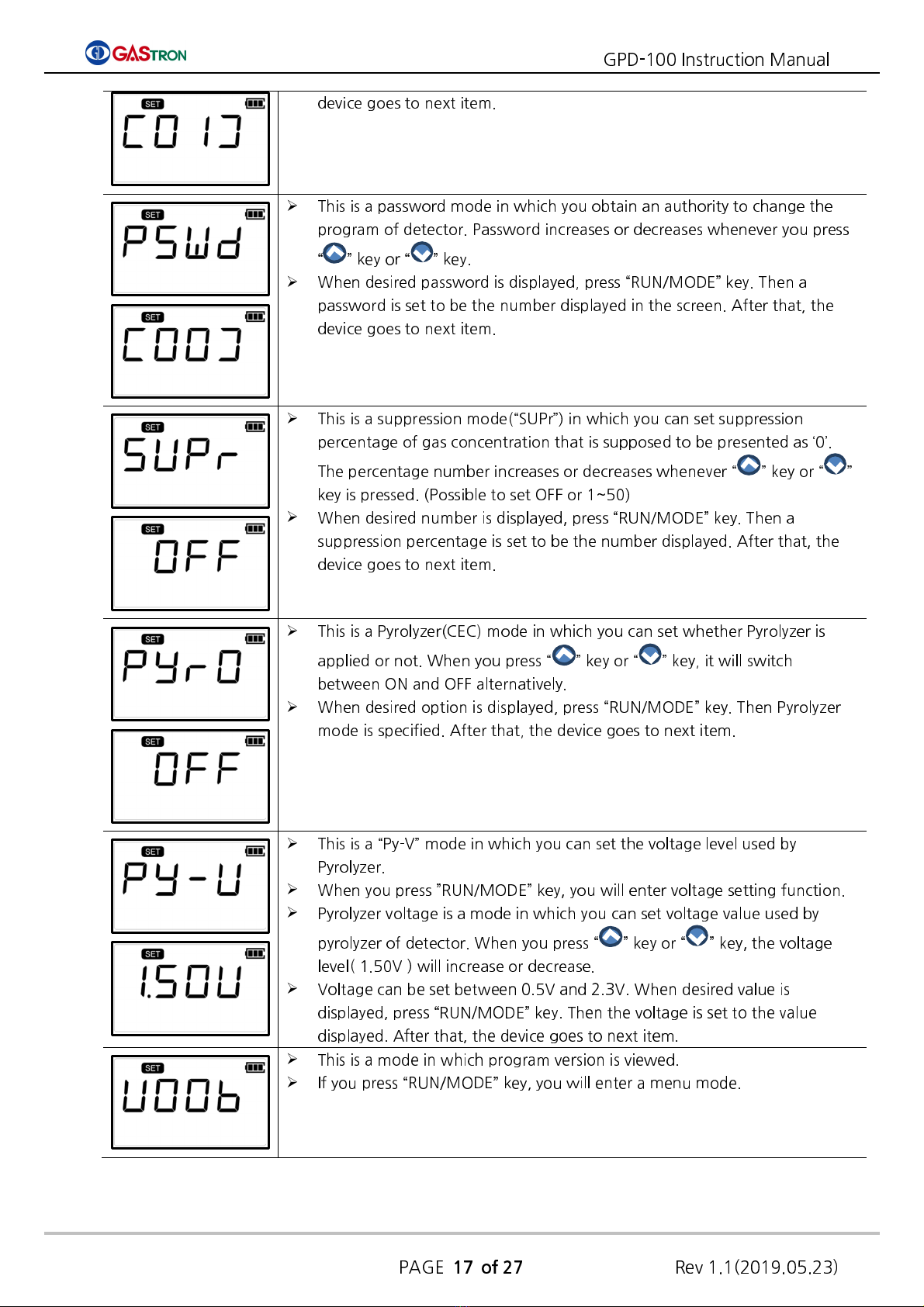

device goes to next item.

his is a password mode in which you obtain an authority to change the

program of detector. Password increases or decreases whenever you press

“ ” key or “ ” key.

When desired password is displayed, press “RUN/MODE” key. hen a

password is set to be the number displayed in the screen. After that, the

device goes to next item.

his is a suppression mode(“SUPr”) in which you can set suppression

percentage of gas concentration that is supposed to be presented as ‘0’.

he percentage number increases or decreases whenever “ ” key or “ ”

key is pressed. (Possible to set OFF or 1~50)

When desired number is displayed, press “RUN/MODE” key. hen a

suppression percentage is set to be the number displayed. After that, the

device goes to next item.

his is a Pyrolyzer(CEC) mode in which you can set whether Pyrolyzer is

applied or not. When you press “ ” key or “ ” key, it will switch

between ON and OFF alternatively.

When desired option is displayed, press “RUN/MODE” key. hen Pyrolyzer

mode is specified. After that, the device goes to next item.

his is a “Py-V” mode in which you can set the voltage level used by

Pyrolyzer.

When you press ”RUN/MODE” key, you will enter voltage setting function.

Pyrolyzer voltage is a mode in which you can set voltage value used by

pyrolyzer of detector. When you press “ ” key or “ ” key, the voltage

level( 1.50V ) will increase or decrease.

Voltage can be set between 0.5V and 2.3V. When desired value is

displayed, press “RUN/MODE” key. hen the voltage is set to the value

displayed. After that, the device goes to next item.

his is a mode in which program version is viewed.

If you press “RUN/MODE” key, you will enter a menu mode.

GPD-100 Instruction Manual

PAGE

18 of 27

Rev 1.1(2019.05.23)

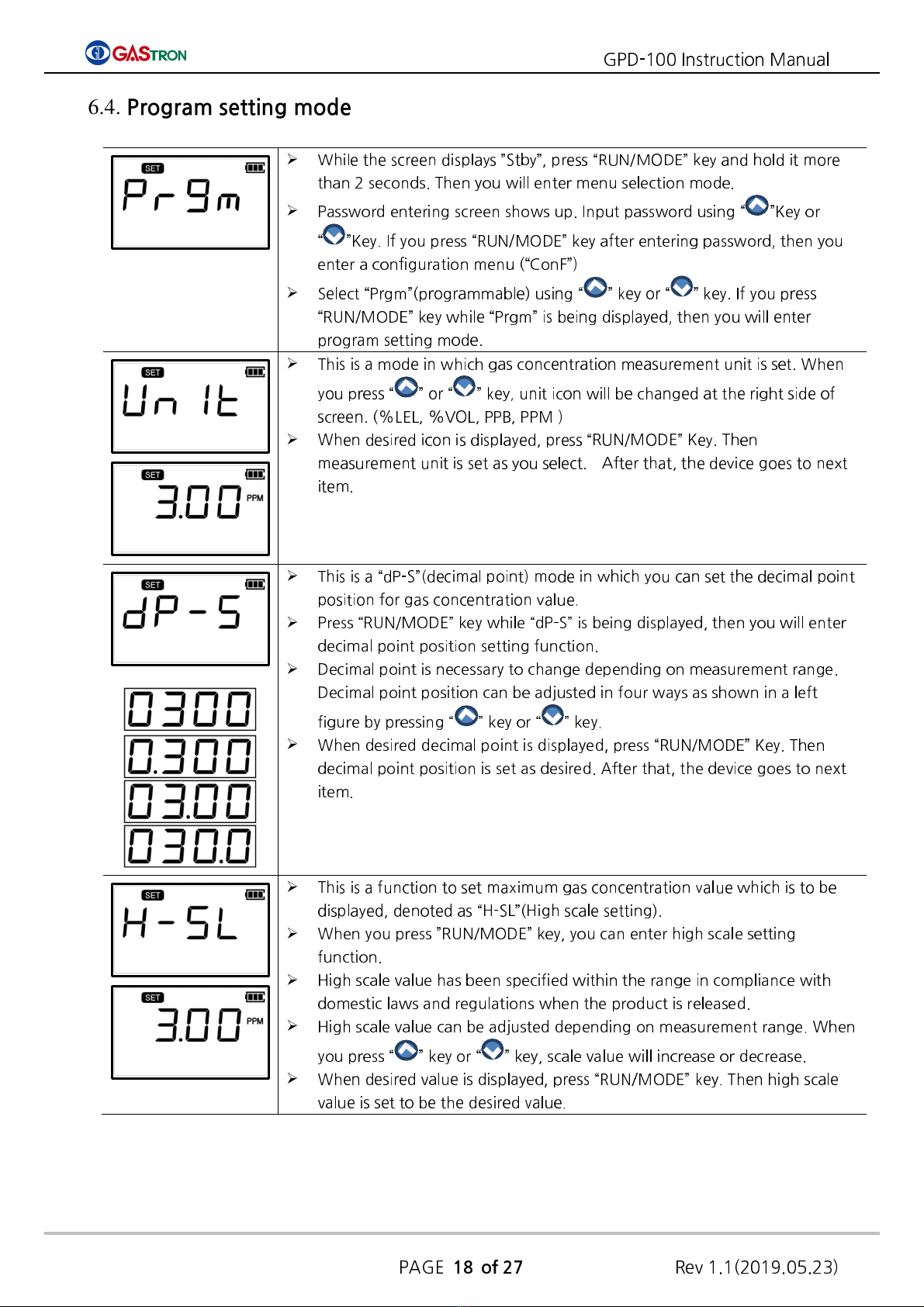

6.4. Program setting mode

While the screen displays ”Stby”, press “RUN/MODE” key and hold it more

than 2 seconds. hen you will enter menu selection mode.

Password entering screen shows up. Input password using “ ”Key or

“ ”Key. If you press “RUN/MODE” key after entering password, then you

enter a configuration menu (“ConF”)

Select “Prgm”(programmable) using “ ” key or “ ” key. If you press

“RUN/MODE” key while “Prgm” is being displayed, then you will enter

program setting mode.

his is a mode in which gas concentration measurement unit is set. When

you press “ ” or “ ” key, unit icon will be changed at the right side of

screen. (%LEL, %VOL, PPB, PPM )

When desired icon is displayed, press “RUN/MODE” Key. hen

measurement unit is set as you select. After that, the device goes to next

item.

his is a “dP-S”(decimal point) mode in which you can set the decimal point

position for gas concentration value.

Press “RUN/MODE” key while “dP-S” is being displayed, then you will enter

decimal point position setting function.

Decimal point is necessary to change depending on measurement range.

Decimal point position can be adjusted in four ways as shown in a left

figure by pressing “ ” key or “ ” key.

When desired decimal point is displayed, press “RUN/MODE” Key. hen

decimal point position is set as desired. After that, the device goes to next

item.

his is a function to set maximum gas concentration value which is to be

displayed, denoted as “H-SL”(High scale setting).

When you press ”RUN/MODE” key, you can enter high scale setting

function.

High scale value has been specified within the range in compliance with

domestic laws and regulations when the product is released.

High scale value can be adjusted depending on measurement range. When

you press “ ” key or “ ” key, scale value will increase or decrease.

When desired value is displayed, press “RUN/MODE” key. hen high scale

value is set to be the desired value.

GPD-100 Instruction Manual

PAGE

19 of 27

Rev 1.1(2019.05.23)

6.5. Zero Calibration

6.5.1. Auto Zero Calibration

6.5.2. Manual Zero Calibration

Alternative way to conduct zero calibration is to start calibration in

measurement state.

Insert clean air or 100% nitrogen through gas in port using calibration tool.

When you press and hold “A UO ZERO” key in measurement mode, AU O

ZERO calibration will start up.

While zero calibration is being performed automatically, “WAIt” message

will display on LCD. If it completes successfully, “gOOd” (Good) will appear

on LCD.

If Zero Calibration fails, “FAIL” will show up during 2 seconds. hen the

device will transit to the calibration mode.

While the screen displays ”Stby”, press “RUN/MODE” key and hold it more

than 2 seconds. hen you will enter menu selection mode.

Password entering screen shows up. Input password using “ ” or “ ”

key. If you press “RUN/MODE” key after entering password, then you will

go to a configuration menu (“ConF”)

Select “CALb”(Calibration) using “ ” key or “ ” key. If you press

“RUN/MODE” key while “CALb” is being displayed, then you will enter

calibration mode.

While “ZERO” icon at the left corner of the bottom is blinking, press

“RUN/MODE” key. hen you will enter Zero Calibration mode.

You can set No/YES using “ ” key or “ ” key.

If you select YES, you will enter zero(0) calibration mode.

Insert clean air or 100% nitrogen through gas in port using calibration tool.

GPD-100 Instruction Manual

PAGE

20 of 27

Rev 1.1(2019.05.23)

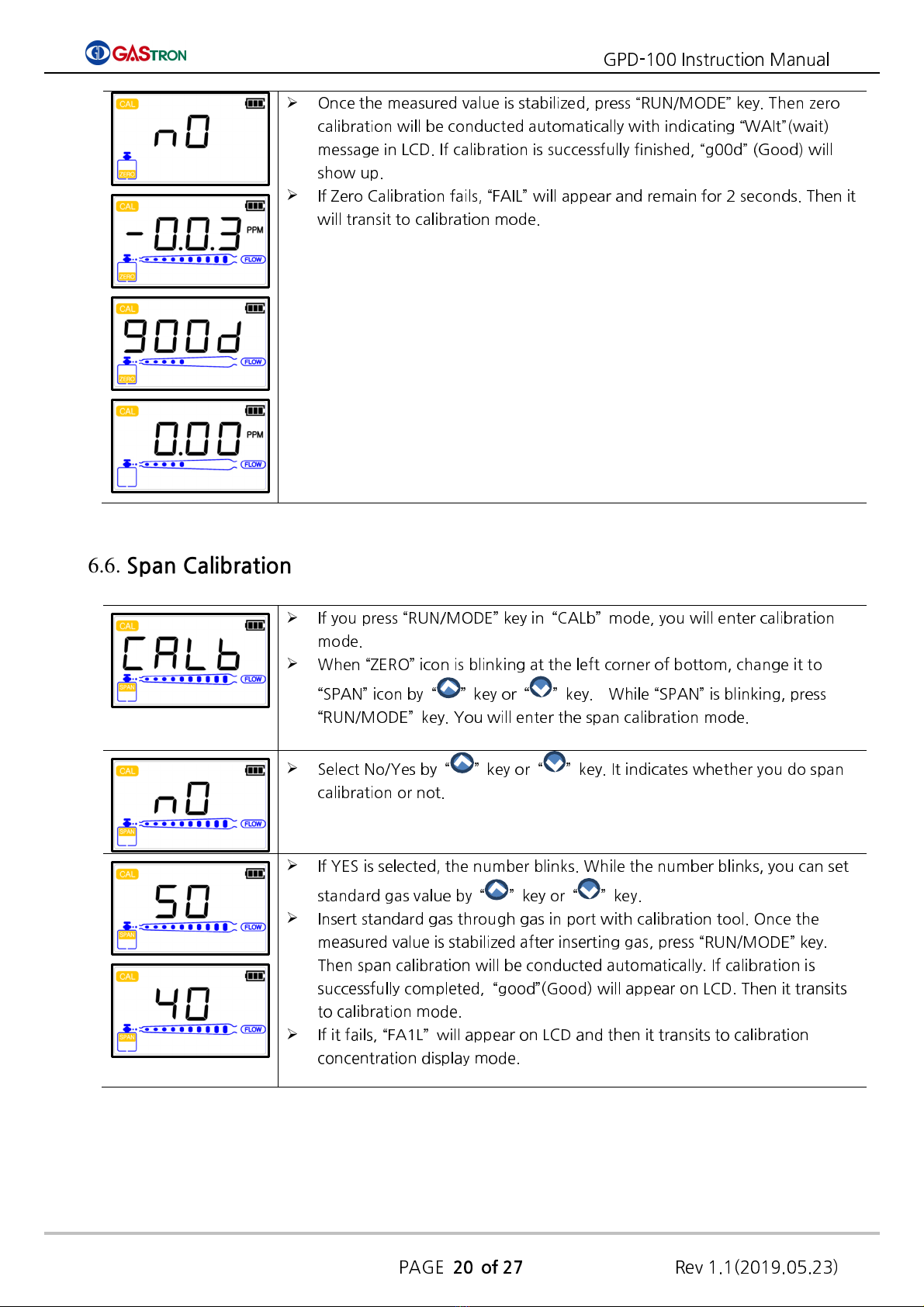

6.6. Span Calibration

Once the measured value is stabilized, press “RUN/MODE” key. hen zero

calibration will be conducted automatically with indicating “WAIt”(wait)

message in LCD. If calibration is successfully finished, “g00d” (Good) will

show up.

If Zero Calibration fails, “FAIL” will appear and remain for 2 seconds. hen it

will transit to calibration mode.

If you press “RUN/MODE” key in “CALb” mode, you will enter calibration

mode.

When “ZERO” icon is blinking at the left corner of bottom, change it to

“SPAN” icon by “ ” key or “ ” key. While “SPAN” is blinking, press

“RUN/MODE” key. You will enter the span calibration mode.

Select No/Yes by “ ” key or “ ” key. It indicates whether you do span

calibration or not.

If YES is selected, the number blinks. While the number blinks, you can set

standard gas value by “ ” key or “ ” key.

Insert standard gas through gas in port with calibration tool. Once the

measured value is stabilized after inserting gas, press “RUN/MODE” key.

hen span calibration will be conducted automatically. If calibration is

successfully completed, “good”(Good) will appear on LCD. hen it transits

to calibration mode.

If it fails, “FA1L” will appear on LCD and then it transits to calibration

concentration display mode.

Other manuals for GPD-100

3

Table of contents

Other GASTRON Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

PCB Piezotronics

PCB Piezotronics IMI SENSORS 602D02 Installation and operating manual

Circutor

Circutor CEM-C31-T1 instruction manual

LaMotte

LaMotte SMART3 Operator's manual

Tektronix

Tektronix RFM150 instruction manual

Aeroflex

Aeroflex 9102 user guide

Standard Imaging

Standard Imaging MAX 4000 PLUS user manual

Endress+Hauser

Endress+Hauser Proline Prosonic Flow B 200 Brief operating instructions

Prismatibro

Prismatibro Prisma DI-5C manual

Anritsu

Anritsu Spectrum Master MS2723B Maintenance manual

LOVATO ELECTRIC

LOVATO ELECTRIC DME D305T2 instruction manual

BURK Technology

BURK Technology BTU-4 Installation and operation

Hobo

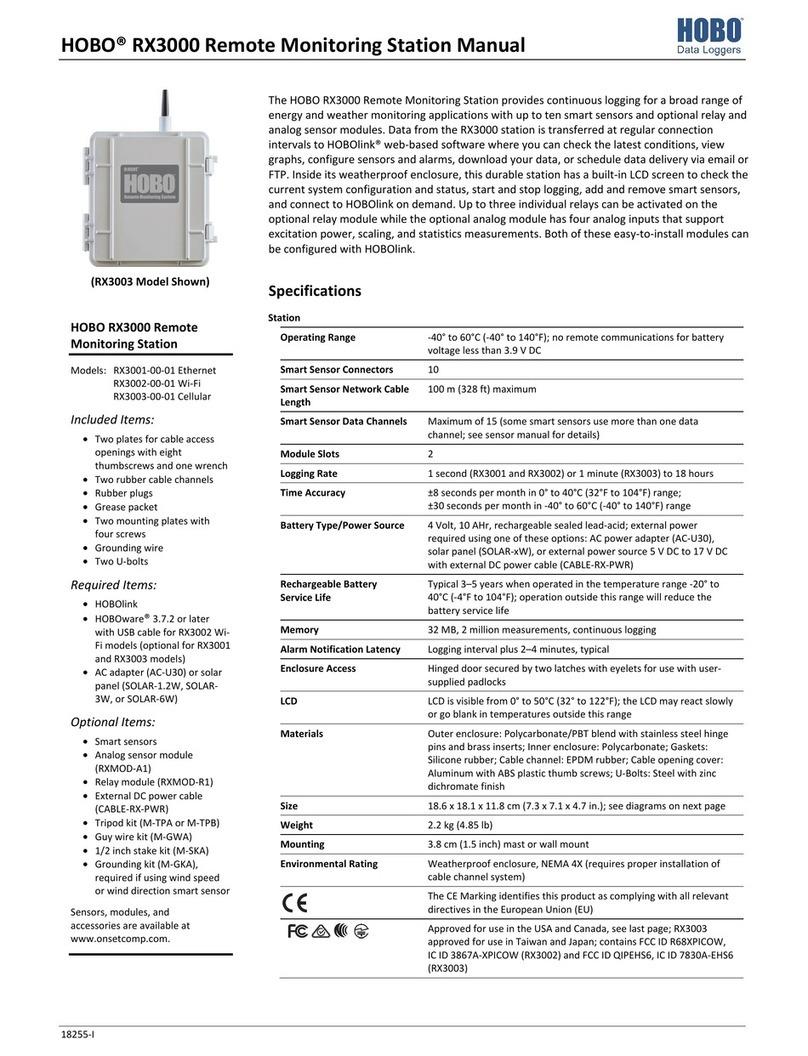

Hobo RX3000 Series manual