Gayk HRE 1000 User manual

Hydraulic Ram Unit

HRE 1000 / HRE 3000 / HRE 4000

Translation of the original operating instructions

Hydraulic Ram Unit HRE

Issue 06.2016

Gayk Baumaschinen GmbH

Dieselstraße 3

D-63762 Großostheim

Telephone: +49-6026 97885-0

Telefax: +49-6026 9788529

E-mail: info@gayk-baumaschinen.de

Internet: www.gayk-baumaschinen

Publisher's copyright:

These operating instructions are intended for installation, operations and maintenance personnel. They may

be duplicated, translated or made available to others only with the expressed approval of the publisher. Also,

the operating instructions contain regulations and drawings of a technical nature which may not be

duplicated, in their entirety or partially, modified or utilised for the purposes of unauthorised competition, or

given to others.

Table of contents

Hydraulic Ram Unit HRE

Issue 06.2016

1

Table of contents

1Basic information.................................................................................................................5

1.1 Notes on the operating instructions........................................................................5

1.2 Explanations in the operating instructions..............................................................5

1.3 Proper use..............................................................................................................5

1.4 Usage conditions....................................................................................................6

1.5 Guarantee and liability............................................................................................6

2Safety instructions...............................................................................................................7

2.1 Standards and guidelines.......................................................................................7

2.2 Explanation of labels in the operating instructions .................................................8

2.3 Safety labels on the machine .................................................................................8

2.4 Safety labels at the setup location..........................................................................9

2.5 Basic safety measures .........................................................................................10

2.6 Safety instructions for transport............................................................................10

2.7 Safety instructions for installation.........................................................................11

2.8 Safety instructions for operation...........................................................................11

2.9 Safety instructions for maintenance and repair....................................................12

2.10 Operator responsibility..........................................................................................12

2.11 Requirements of personnel ..................................................................................14

2.12 Personal protective work clothing.........................................................................14

2.13 Behaviour in an emergency..................................................................................15

2.14 Disposal................................................................................................................16

3Technical data ....................................................................................................................19

4Technical description ........................................................................................................21

4.1 Chassis.................................................................................................................22

4.2 Drive motor...........................................................................................................23

4.3 Hydraulic aggregate .............................................................................................28

4.4 Mast (carriage) .....................................................................................................31

4.5 Hydraulic hammer ................................................................................................32

4.6 Control console.....................................................................................................33

4.7 Electrical system...................................................................................................35

4.7.1 Battery..................................................................................................................36

4.7.2 Automatic self-regulation......................................................................................37

4.7.3 Electrical switch box.............................................................................................38

Table of contents

2

Issue 06.2016

Hydraulic Ram Unit HRE

5Transport.............................................................................................................................41

5.1 General transport instructions...............................................................................41

5.2 Incoming inspections by the operator...................................................................41

6Assembly and start-up.......................................................................................................43

6.1 General assembly instructions..............................................................................43

6.2 Aligning the machine ............................................................................................43

7Operating the machine.......................................................................................................45

7.1.1General instructions..............................................................................................45

7.1.2 Operating procedure.............................................................................................45

7.1.3 Ramming the profiles............................................................................................46

8Maintenance and repair .....................................................................................................49

8.1 General instructions..............................................................................................49

8.2 Maintenance and repair measures .......................................................................50

9Disruptions..........................................................................................................................57

Table of figures

Hydraulic Ram Unit HRE

Issue 06.2016

3

Table of figures

Fig. 1: Nameplate ...................................................................................................................19

Fig. 2: Main assemblies with optional accessories.................................................................21

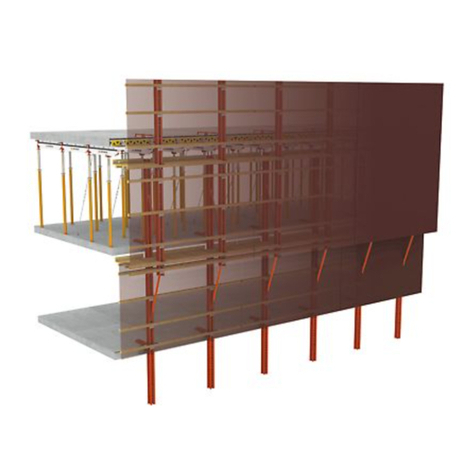

Fig. 3: Chassis........................................................................................................................22

Fig. 4: Machine in the transport position.................................................................................22

Fig. 5: Locking and positioning lever ......................................................................................23

Fig. 6: Drive motor ..................................................................................................................24

Fig. 7: Motor oil fill opening with oil dipstick............................................................................24

Fig. 8: Electric starter and speed adjustment lever.................................................................25

Fig. 9: Ignition switch with message lights..............................................................................25

Fig. 10: Fuel tank......................................................................................................................26

Fig. 11: Fuel tank shut-off valve................................................................................................26

Fig. 12: Hydraulic tank..............................................................................................................28

Fig. 13: Vent filter with contamination display...........................................................................29

Fig. 14: Visual fill level display..................................................................................................29

Fig. 15: Cooling package..........................................................................................................30

Fig. 16: Functioning principle of the cooling package...............................................................30

Fig. 17: Mast (carriage) with hydraulic hammer........................................................................31

Fig. 18: Hydraulic hammer........................................................................................................32

Fig. 19: Control console (optional)............................................................................................33

Fig. 20: Gear lever....................................................................................................................34

Fig. 21: Control console (standard)...........................................................................................35

Fig. 22: Tool box for battery and tool kit....................................................................................36

Fig. 23: Electrical switch box with automatic self-regulation (option)........................................37

Fig. 24: Exterior of the electrical cabinet (optional)...................................................................38

Fig. 25: Interior of the electrical cabinet (optional)....................................................................38

Fig. 26: Electrical cabinet (standard) ........................................................................................39

Fig. 27: Circular level................................................................................................................44

Fig. 28: Limit switch for shutting off the automatic ramming function .......................................46

Table of figures

4

Issue 06.2016

Hydraulic Ram Unit HRE

Basic information

Hydraulic Ram Unit HRE

Issue 06.2016

5

1 Basic information

1.1 Notes on the operating instructions

These operating instructions are provided to educate the user concerning the design,

function, operation, setup, maintenance and upkeep of hydraulic ram unit HRE 1000/

HRE 3000/ HRE 4000. The hydraulic ram unit HRE 1000/ HRE 3000/ HRE 4000 was

developed and built by Gayk Baumaschinen GmbH. Before using hydraulic ram unit

HRE 1000/ HRE 3000/ HRE 4000, please carefully read through the operating

instructions. They must be available at the machine at all times for operating personnel.

The operating instructions will allow you to quickly understand the technical details, and

contains necessary information on important technical data and on the expert use of

the machine. Hydraulic ram unit HRE 1000/ HRE 3000/ HRE 4000 is only intended to

be used for the purposes listed in the operating instructions. The manufacturer cannot

be responsible for claims arising from improper use and insufficient maintenance of the

equipment. The component documentation located in the appendix, as well as all other

documentation provided with the equipment, must be adhered to.

1.2 Explanations in the operating instructions

NOTE

Hydraulic ram unit HRE 1000/ HRE 3000/ HRE 4000 is only called a machine in the

following chapters of these operating instructions.

1.3 Proper use

The machine may only be operated in its technically proper state and only for its

intended purpose, in accordance with these operating instructions. The machine is

operated fully-hydraulically and its exclusive purpose is to precisely ram steel or

wooden profiles into earthen soil. The profiles are rammed into the ground through

repeated impacts depending on the ramming depth and the soil characteristics.

No other use of the machine beyond this qualifies as proper use. Any other use can be

dangerous and is not allowed. The manufacturer is not liable for any consequences

arising from improper use of the machine or for any use not in accordance with the

instructions in these operating instructions. If the machine is altered without the

approval of the manufacturer, the manufacturer is not liable for any damages that may

result. Adherence to inspection and maintenance specifications is also part of the

proper use of this equipment. Connection data must be adhered to. If changes are

made to the system by the operator, the CE certificate of compliance will become

invalid.

Basic information

6

Issue 06.2016

Hydraulic Ram Unit HRE

1.4 Usage conditions

Before beginning work, check the area to make sure it meets the following criteria:

Make sure there are no cables, lines, sewer lines, etc., in the area that could

present a hazard.

Prepare the work area according to how it is found. If necessary, re-route,

disconnect, or secure existing lines.

The ground must be free of any contaminants and explosive ordinance.

The ground must be evenly supportive of construction machines being driven on it.

Establish traffic routes and storage areas and identify them.

All necessary operating materials such as oils, greases and the like must be made

available in sufficient amounts and qualities prior to start-up corresponding to the

specifications contained in the operating instructions.

The manufacturer must be timely notified of any environmental and operating

conditions that are out of specification at the set-up location of the machine. The

deviating environmental and operating conditions must be listed.

1.5 Guarantee and liability

The “General Conditions of Sale and Delivery” submitted by the manufacturer to the

operator apply fundamentally. Guarantee and liability claims for personal injury and

property damages are not valid if they can be attributed to one or more of the following

causes:

Use of the machine in a manner that is not intended.

Improper start-up, operating and maintenance of the machine.

Alterations to the machine without prior consultation with the manufacturer.

Operation of the machine with defective safety equipment or improperly attached

safety and protective equipment.

Non-adherence to the instructions in these operating instructions with regard to

operation and maintenance.

Insufficient monitoring of machine assemblies that are subject to wear.

Safety instructions

Hydraulic Ram Unit HRE

Issue 06.2016

7

2 Safety instructions

2.1 Standards and guidelines

The machine is designed according to the current state of the art according to

recognised safety rules. The machine was designed according to basic safety

requirements, standards and guidelines. All safety information refers to currently

applicable ordinances of the European Union (EU). In countries outside of the EU, the

applicable laws and ordinances of those countries must be adhered to. In addition to

the safety instructions contained in these operating instructions, the generally

applicable regulations concerning accident prevention and environmental protection

must be followed and adhered to. All information in the operating instructions must be

followed fully. The machine was designed according to the following basic safety

requirements, standards and guidelines.

Machine Guidelines 2006/42/EC dated 17.05.2006

Applied harmonised norms, in particular

DIN EN-ISO 12100

“Machine Safety - General Structural Guidelines - Risk Assessment and Risk

Minimization” (ISO 12100:2010), German Version EN ISO 12100:2010

DIN EN 60204-1

“Machine Safety – Electrical Equipment in Machines”

DIN EN 13849

“Machine Safety – Safety-related Parts in Control Systems”

DIN EN 13850

“Machine Safety – EMERGENCY STOP Structural Guidelines”

DIN EN 13857

“Machine Safety – Safe distances to prevent reaching into dangerous areas with

upper and lower extremities”

DIN EN 1037

“Machine Safety – Preventing unexpected starting of moving elements”

DIN EN 13478

“Machine Safety – Fire protection”

DIN EN 414

“Rules for the drafting and presentation of safety standards”

DIN EN 4844-1

“Graphical Symbols - Safety colours and safety signs Part 1: Structural

fundamentals for safety signs for use in workshops and in public areas”

DGUV [German Social Accident Insurance] Regulation 3 “Portable and fixed

operating resources

Accident prevention regulation “Electrical systems and resources”

BGV A8 / DGUV Regulation 9

“Safety and health protection signage at the workplace”

Safety instructions

8

Issue 06.2016

Hydraulic Ram Unit HRE

2.2 Explanation of labels in the operating instructions

DANGER

Type and source of danger!

Immediate danger with high risk of death or serious bodily injuries. Measures to avoid

danger.

WARNING

Type and source of danger!

Possible danger with medium risk of death or serious bodily injuries. Measures to

avoid danger.

CAUTION

Type and source of danger!

Dangers with low risk of medium bodily injuries or property damage. Measures to

avoid danger.

NOTE

User tips and useful information.

NOTE

User tips and useful information on environmental protection.

DANGER

Type and source of danger!

Dangers with risk of environmental damages. Measures to avoid danger.

2.3 Safety labels on the machine

The instructions attached to the machine identify the sources of danger and must be

adhered to absolutely. They must be attached in an easily recognizable area and

maintained in fully legible condition. If these labels are destroyed, new ones must be

attached. The following symbols are attached to the equipment and must be adhered

to:

DANGER

Warning of dangerous electrical voltage.

Safety instructions

Hydraulic Ram Unit HRE

Issue 06.2016

9

DANGER

Warning of crush injuries.

DANGER

Warning of rotating parts.

DANGER

Warning of crushing at chain drives.

DANGER

Warning of hot surfaces.

DANGER

Warning of flammable materials.

DANGER

Warning of explosive materials.

DANGER

Warning of corrosive materials.

2.4 Safety labels at the setup location

The operator of the machine must make sure that the entire work area in which the

machine is set up is identified appropriately according to operational conditions,

respectively, by means of the following instructions.

DANGER

Risk of accidents!

Unauthorised personnel access to the machine is forbidden.

DANGER

Fire and explosion danger!

The starting of fires and handling of open flames is strictly forbidden. Areas must be

labelled accordingly.

Safety instructions

10

Issue 06.2016

Hydraulic Ram Unit HRE

During installation, maintenance and repair work, the entire danger area surrounding

the machine must be blocked off with the following identifying tape:

2.5 Basic safety measures

The following must be adhered to:

The machine may only be used as intended.

All safety instructions in these operating instructions and in other documents must

be followed and adhered to.

The machine may only be set up, installed, operated and maintained by trained

expert personnel. The personnel must have read and understood these operating

instructions. This includes in particular the understanding of how risk of injury can

be averted for the operator and others.

Unauthorised personnel may not have any direct access to the machine.

Downtime and environmental impairments due to incorrect handling must be

avoided.

During transport, installation/removal, operation and care and maintenance, the

pertinent work safety regulations and environmental protection regulations must be

adhered to.

All work on the machine must be carried out with care and with a perspective on

safety.

2.6 Safety instructions for transport

The following must be adhered to:

The machine is transported, set up and installed as a complete machine. The

danger area must be blocked off with a wide berth and identified as such.

Safety regulations as to the transport materials used must be adhered to.

Unauthorised transport work is not permitted. Significant dangers and property

damages can result.

Transport activities may only be carried out by trained personnel.

Only approved lifting equipment and attachment means with sufficient support

capacity may be used.

Ropes and belts must meet safety requirements. No torn ropes or ropes with

abraded areas may be used. Do not let ropes and belts sit against sharp edges and

corners, do not knot or twist them. When fastening, be aware of the centre of

gravity of the machine.

Safety instructions

Hydraulic Ram Unit HRE

Issue 06.2016

11

2.7 Safety instructions for installation

The following must be adhered to:

The machine may only be installed by trained, instructed expert personnel.

Unauthorised assembly is not permitted.

To avoid dangerous situations, and to ensure optimum performance, no

modifications or alterations may be made to the machine.

The set-up area for the machine must be of such dimensions that sufficient support

is guaranteed.

Before beginning work, sufficient freedom of installation must be ensured. Maintain

order and cleanliness at the work place. Any components and tools lying around

must be removed.

Be aware of the dimensions and weight data for the machine. An operational

environment suitable for use of the machine must be guaranteed.

The machine must be checked each time prior to being turned on for damages and

proper condition. Any modifications to the machine that affect operational safety

must be reported. The causes must be remedied immediately.

The machine may only be connected to supply lines that are provided and designed

specifically for it.

2.8 Safety instructions for operation

The following must be adhered to:

The operational safety of the machine must be guaranteed at all times.

The machine must be immediately shut down if changes are detected during

operation. Listen for any unusual noise.

Proper attachment and connection of the control console, safety equipment

(EMERGENCY OFF switch, safety switches sensors).

The machine must be checked each time prior to being turned on for damages and

proper condition. Any modifications to the machine must be reported. The causes

must be remedied immediately.

Proper connection of all supply media (electrical energy bonding for safe contact,

hydraulics).

Safety instructions

12

Issue 06.2016

Hydraulic Ram Unit HRE

2.9 Safety instructions for maintenance and repair

The following must be adhered to:

All maintenance and repair work on the machine may only be carried out with the

machine turned off.

The machine may only be maintained and repaired by service personnel from the

manufacturer or personnel specially trained and instructed in the same.

Unintentional turning of the machine back on must be prevented (shut of the main

switch, attach a warning sign to the main switch, block off the area).

During maintenance and repair work, sometimes safety equipment needs to be

turned off. This equipment must be properly re-installed immediately after the

maintenance and repair work and checked for proper functioning.

After the maintenance work, the following checks must be carried out prior to

turning the machine back on, during which time safety regulations are adhered to:

–Check that all bolted connections are tight.

–Ensure that all tools, materials and other equipment used have been removed

from the work area.

–Clean the work area and remove any materials, such as liquids, processing

materials, etc.

CAUTION

Damage to the machine!

Operational disruptions caused by insufficient or improper maintenance can cause

very high repair costs and long downtimes of the machine. The manufacturer assumes

no liability for damages caused by improper maintenance and care. Maintenance

intervals must be recorded and maintained in a maintenance plan.

2.10 Operator responsibility

The operator of the machine is subject to legal obligations with regard to work safety. In

addition to the safety instructions in these instructions, the applicable safety, accident

prevention and environmental protection regulations must be adhered to.

The operator must be aware of the applicable work safety specifications. Any

additional dangers that arise from special working conditions at the point of use

must be recorded in an overview. The additional dangers determined to exist must

be recorded by the operator in its operating instructions and incorporated in the

daily handling instructions for the machine.

During the entire time of use of the machine, the operator must check whether its

operating instructions correspond to the current version of the regulatory policies,

and if not, modify them as needed.

The operator must use the machine in good, operationally safe condition. The

technical condition must correspond to the legal requirements and regulations.

The operator must clearly regulate and establish responsibilities for installation

operation, maintenance and cleaning.

Safety instructions

Hydraulic Ram Unit HRE

Issue 06.2016

13

The operator must make sure that all employees handling the machine have read

and understood these instructions. Also, the operator must train its personnel at

regular intervals and make the aware of the risks. Training by the operator must be

recorded.

CAUTION

Risk of injury if personnel is insufficiently qualified!

Improper handing can result in serious personal injury and property damage. All

activities must be carried out by qualified personnel only.

The operator must provide its personnel with the required work safety clothing.

The operator must make sure that the listed maintenance intervals are being

adhered to.

The operator must check all safety equipment regularly for functionality and

completeness.

As to requirements to be placed on personnel, the operator must adhere to the

following criteria:

Operating personnel

The instruction as to the tasks to be assumed and

possible risks from improper behaviour is done by the

operator.

Maintenance and repair

personnel

Maintenance and repair personnel must be capable, as a

result of expert training, experience and knowledge of the

pertinent specifications, of autonomously carrying out

maintenance and repair work, and of recognising possible

risks and avoiding them. Maintenance personnel are to be

specially trained for this.

Electrician

The electrician must be capable, as a result of expert

training, experience and knowledge of the pertinent

specifications, of autonomously working on electrical

machines and of recognising possible risks and avoiding

them. The electrician is specially trained for this.

Safety instructions

14

Issue 06.2016

Hydraulic Ram Unit HRE

2.11 Requirements of personnel

The following must be adhered to:

Smoking, eating and drinking in the area of the machine are not allowed.

Working on the machine while tired, under the influence of alcohol and medications

is not allowed.

Personnel may not have any physical limitations that would temporarily or

permanently impair their attentiveness and ability to evaluate a situation.

Operating personnel must have mastered the national language of the operator

verbally and in written form enough to allow all tasks pertaining to the machine and

the contents of the operating instructions to be understood and internalised.

Personnel must wear appropriate clothing for the work at hand.

All safety instructions in these operating instructions and in all other documents

must be followed and adhered to in unlimited extent.

If danger is recognised which could result in personal injury, the machine must be

shut off immediately.

Personnel must have thorough understanding of operational procedures,

regulations and processes.

–Operational processes of the machine

–Setting up of perimeters, securing and identifying the area of danger

–Behaviours and actions in case of emergency

The machine may only be operated and maintained by authorised personnel. If

additional qualifications of personnel are necessary to perform certain work, the

operator must meet all prerequisites for it.

DANGER

Risk of accidents!

Unauthorised persons who do not meed the requirements described must be kept

away from the work area.

2.12 Personal protective work clothing

The operator will determine which protective work clothing must be worn by personnel.

PROTECTIVE WORK CLOTHING

Wear snugly-fitting protective work clothing to protect against getting caught by

moving parts. However, the clothing must not restrict the freedom of movement of

personnel.

SAFETY SHOES

To protect from falling parts and slipping on floors that are not non-slip surfaces and

when current-carrying components could possibly be touched.

Safety instructions

Hydraulic Ram Unit HRE

Issue 06.2016

15

SAFETY GLOVES

To protect the skin from friction, scrapes, punctures or deeper injuries of the hands

and to protect against the touching of hot surfaces and substances that are hazardous

to a person's health.

HEARING PROTECTION

Hearing protection offers protection against injury to the auditory system due to excess

and sustained noise.

SAFETY GLASSES

Safety glasses protects the eyes against flying parts (dust particles, liquid and acid

sprays).

2.13 Behaviour in an emergency

In emergencies or accidents, the machine must be shut off immediately!

Since in the event of an accident quick reaction can save lives, the following actions

must be introduced:

Immediately initiate the EMERGENCY SHUT-DOWN system.

Initiate first aid measures. Operating personnel must know where safety equipment,

accident and danger alarms, and first aid and life-saving equipment are located and

must be familiar with how to handle them.

Remove injured persons from the danger zone.

Notify responsible parties at the location of use.

Notify first responders.

Open access routes to allow access to ambulance vehicles.

The operator is responsible for appropriate training of its operations personnel. All first

aid equipment (first aid kits, stretchers, etc.) and fire-fighting agents (fire extinguishers)

must be maintained in accessible locations and must always be available. All

equipment must be in proper condition and regularly checked.

FIRST AID AND FIRE-FIGHTING EFFORTS

The locations for first aid equipment and fire-fighting agents must be identified with

information signs. The user must be familiar with these resources. The user must be

able to correctly use and operate them in the event of accidents.

Safety instructions

16

Issue 06.2016

Hydraulic Ram Unit HRE

2.14 Disposal

Legal fundamentals on disposal:

Recycling and Waste Management Act (KrW/AbfG)

State Waste Act for each of the federal states (LAbfG)

Ordinance for determining wastes that require monitoring (BestbüAbfV)

Waste Oil Ordinance (AltölV)

Packaging Ordinance (VerpackV)

Battery Ordinance (BattV)

Commercial Waste Ordinance (GewAbfV)

Chemicals Act (ChemG)

Hazardous Materials Ordinance (GefStoffV)

Industrial Safety Ordinance (BetrSichV)

Water Management Act (WHG)

Technical Rules for Hazardous Materials, TRGS 201 Classification and

identification of wastes for disposal while handling

GUV-SR-2005 Handling hazardous materials in industry

DANGER

Environmental hazard!

If environmentally hazardous materials are handled incorrectly, in particular if they are

disposed of incorrectly, serious damages to the environment can occur.

The following must be adhered to:

The information contained in the operating instructions concerning environmental

protection must be followed at all times.

If environmentally-hazardous materials accidentally come in contact with the

environment, suitable measures must be taken immediately. The appropriate

authorities must be notified of the damages.

CAUTION

For all auxiliary materials and cleaning agents used, the regulations and EC safety

data sheets of the respective manufacturer with regard to storage, handling, use and

disposal must be adhered to.

CAUTION

Electrical scrap and electronic assemblies require hazardous waste treatment and

may only be disposed of by approved expert operators.

Safety instructions

Hydraulic Ram Unit HRE

Issue 06.2016

17

The following must be adhered to:

No materials may be used if their physical properties are unknown. A consultation

with the manufacture is required.

If there is no take-back or disposal agreement in place, the disassembled

components must be sent to a recycling facility after proper disassembly.

–Metallic material residue is scrapped.

–Plastic components are sent to a recycling facility.

–Sort other components according to material properties and dispose of

accordingly.

Cleaning agents and their containers may not be disposed of as domestic waste or

allowed to flow to sewer systems and to the soil. Applicable disposal regulations

must be adhered to.

Safety instructions

18

Issue 06.2016

Hydraulic Ram Unit HRE

This manual suits for next models

2

Table of contents

Popular Construction Equipment manuals by other brands

IMER USA

IMER USA WHEELMAN 1105422 instruction manual

SafeWaze

SafeWaze FS-EX330-LERF instructions

Ranger Products

Ranger Products RSC-2TF Installation and operation manual

Kubota

Kubota KC120HC Operator's manual

allen

allen TRTP275 Operations & parts manual

A.T.I.B.

A.T.I.B. INTEGRAL SIDESHIFT 122 Instruction manual for use

Grove Crane

Grove Crane GMK6350 Product guide

Bomag

Bomag BW 211 D-4 Service manual

S.D.P.

S.D.P. EZ Hauler 3000 Training & Procedure Manual

Conquip

Conquip Concrete Coneflow Kibble 500 user guide

ALFIX

ALFIX MOBILE SCAFFOLD TOWER ALUFIX 200 Instructions for assembly and use

Epiroc

Epiroc EC Series Safety and operating instructions