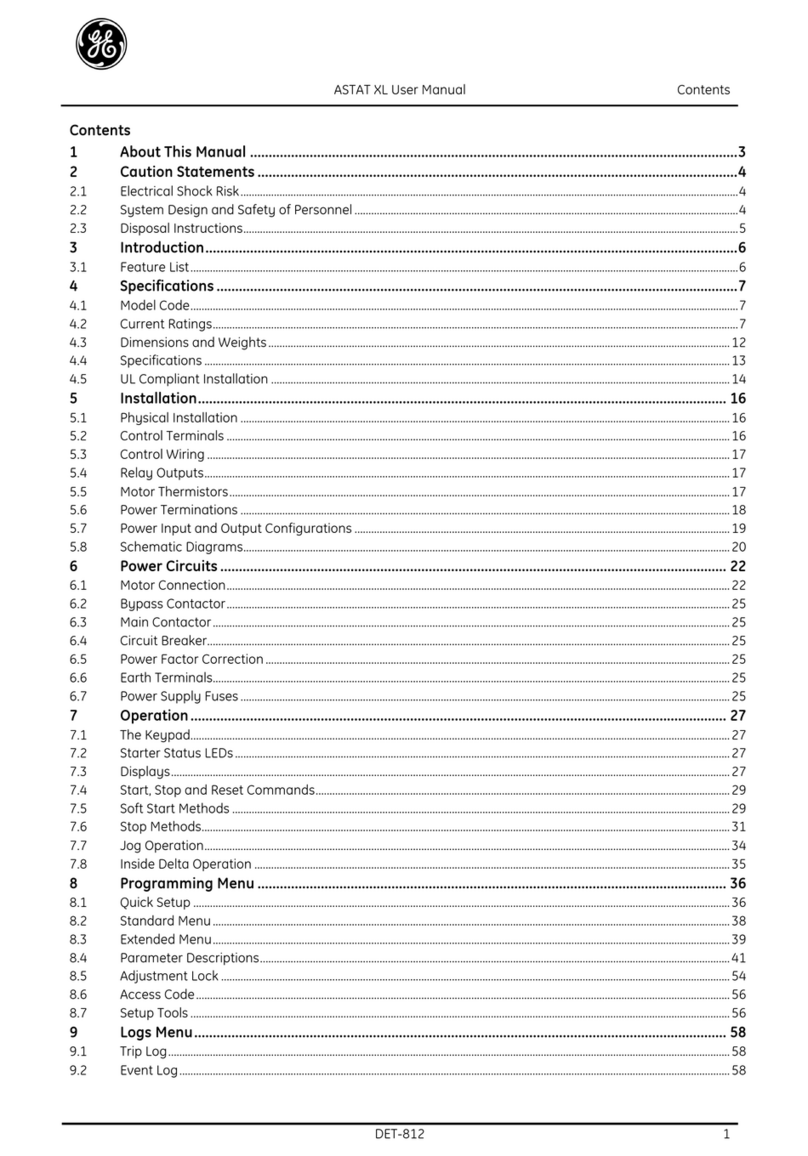

4 • Table of Contents

5. Installation ....................................................................................................................................................47

5.1 Prior to Installation.......................................................................................................................................................................47

5.2 Mounting...........................................................................................................................................................................................47

5.3 Temperature Range & Heat Dissipation............................................................................................................................47

5.3.1 Forced Ventilation........................................................................................................................................................48

5.4 Main PCB and Optional PCBs..................................................................................................................................................48

5.5 Dip Switch Settings on the Main PCB..................................................................................................................................49

5.5.1 Switch # 1 – Display Modes ....................................................................................................................................49

5.5.2 Switch # 2 – Not used ................................................................................................................................................50

5.5.3 Switch # 3 – Main/ D.Set: Generator Parameters.........................................................................................50

5.5.4 Switches # 5, 6 – Language Selection................................................................................................................50

5.5.5 Switch # 7 – Expanded Settings............................................................................................................................50

5.5.6 Switch # 8 – Software Lock .....................................................................................................................................50

5.6 Internal Fan Control ....................................................................................................................................................................51

5.7 Analog I/O (Terminals T1, T2, Gnd, Out (-), Out (+)) ........................................................................................................51

5.8 Remote Key-Pad Installation..................................................................................................................................................52

6. Starting Procedure ......................................................................................................................................53

6.1 Standard Starting Procedure..................................................................................................................................................54

6.2 Examples of Starting Curves...................................................................................................................................................55

6.2.1 Light Loads - Pumps, Etc. .........................................................................................................................................55

6.2.2 High Inertia Loads: Crushers, Centrifuges, Mixers, Etc...............................................................................55

6.2.3 Special Starting Using DUAL Settings ................................................................................................................56

6.2.3.1 Special Starting – Using DUAL Settings – Wiring Diagram ............................................................57

6.2.4 Choosing a Suitable Pump Curve (Centrifugal Pumps)..............................................................................57

6.2.4.1 Starting Curve ......................................................................................................................................................57

6.2.4.2 Stopping Curve....................................................................................................................................................58

6.2.4.3 End Torque During Soft-Stopping a Pump Motor...............................................................................58

7. Trouble Shooting..........................................................................................................................................59

8. Application diagrams..................................................................................................................................62

8.1 Terminal 21 Connections With Various Mains................................................................................................................62

8.2 Control Supply, Control Input and Mains are From the Same Source, Neutral Connected to Terminal 21

63

8.3 Control Supply and Control Input From the Same Source, Neutral not Connected to Terminal 21....63

8.4 Control Supply and Control Input from Separate Sources ......................................................................................64

8.5 Soft Start, Soft Stop and Stop, Control Supply and Control Input from the Same Source........................64

8.6 Soft Start, Soft Stop and Stop, Control Supply and Control Input from Separate Sources ......................64

8.7 Soft Start and Immediate Stop (no Soft Stop).................................................................................................................65

8.8 Soft Start and Soft Stop.............................................................................................................................................................65

8.9 Soft Start, Soft Stop and Immediate Stop.........................................................................................................................65

8.10 Energy Save, Slow Speed or Reset.................................................................................................................................66

8.11 Slow Speed and Slow Speed Reverse ...........................................................................................................................66

8.12 External Fault............................................................................................................................................................................67

8.13 Line Contactor..........................................................................................................................................................................67

8.14 Bypass Contactor...................................................................................................................................................................68

8.15 Reversing with Two Line Contactors.............................................................................................................................69

8.16 Operating via Communication Links.............................................................................................................................70

8.17 D.Set: Generator Parameters Wiring.............................................................................................................................71

8.18 Short Circuit Protection........................................................................................................................................................72

8.18.1 Type 1 Coordination ...................................................................................................................................................72

8.18.1.1 Type 1 Coordination with GE Circuit Breakers: ....................................................................................72

8.18.1.2 Type 1 Coordination with Type aM Siba Fuses:...................................................................................72

8.18.2 Type 2 Coordination ...................................................................................................................................................72

8.19 Transient Protection ..............................................................................................................................................................73

8.20 Inside Delta Configuration..................................................................................................................................................74

8.20.1 General Information ...................................................................................................................................................74

8.20.2 Notes on Inside Delta Connection .......................................................................................................................74

8.20.3 Motor Connection and Terminals.........................................................................................................................75