GE DPI 610 IS User manual

Other GE Controllers manuals

GE

GE ARITECH FP400 Series User manual

GE

GE PACSystems* RX3i User manual

GE

GE Multilin F650 User manual

GE

GE M5 Assembly instructions

GE

GE PACSystems* RX3i User manual

GE

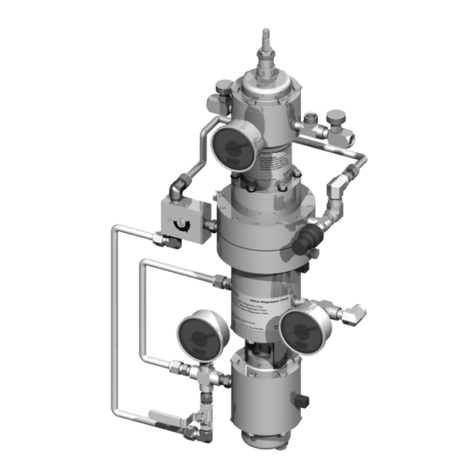

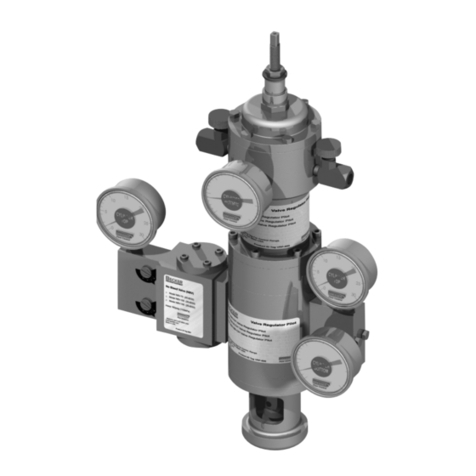

GE Becker VRP-SB-PID Series User manual

GE

GE Becker VRP-B-CH Series User manual

GE

GE C30 User manual

GE

GE GFK-2741C User manual

GE

GE b30 User manual

GE

GE GEK-113045B User manual

GE

GE Multilin F650 User manual

GE

GE Masoneilan 12400 Series User manual

GE

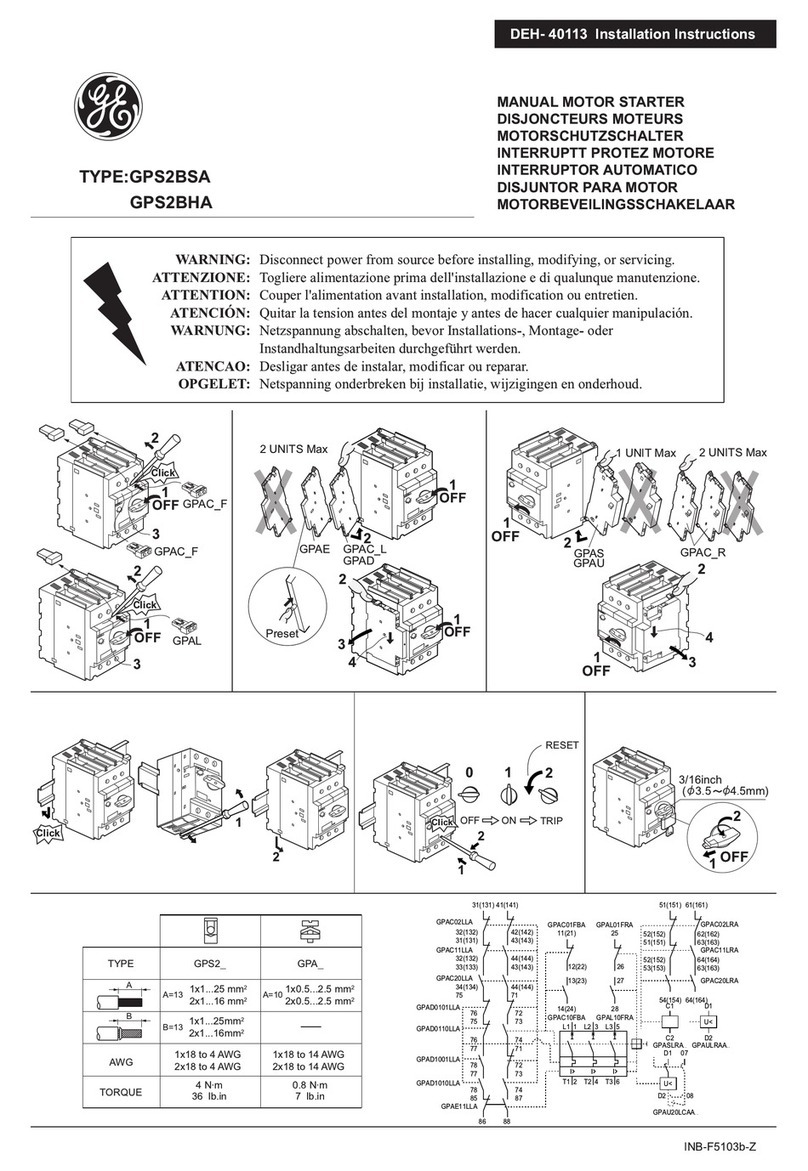

GE GPS2BHA User manual

GE

GE IC695PNC001 User manual

GE

GE Masoneilan 173 Series User manual

GE

GE Masoneilan 37 User manual

GE

GE PACSystems IC695CPU3104 User manual

GE

GE ACT17CWA User manual

GE

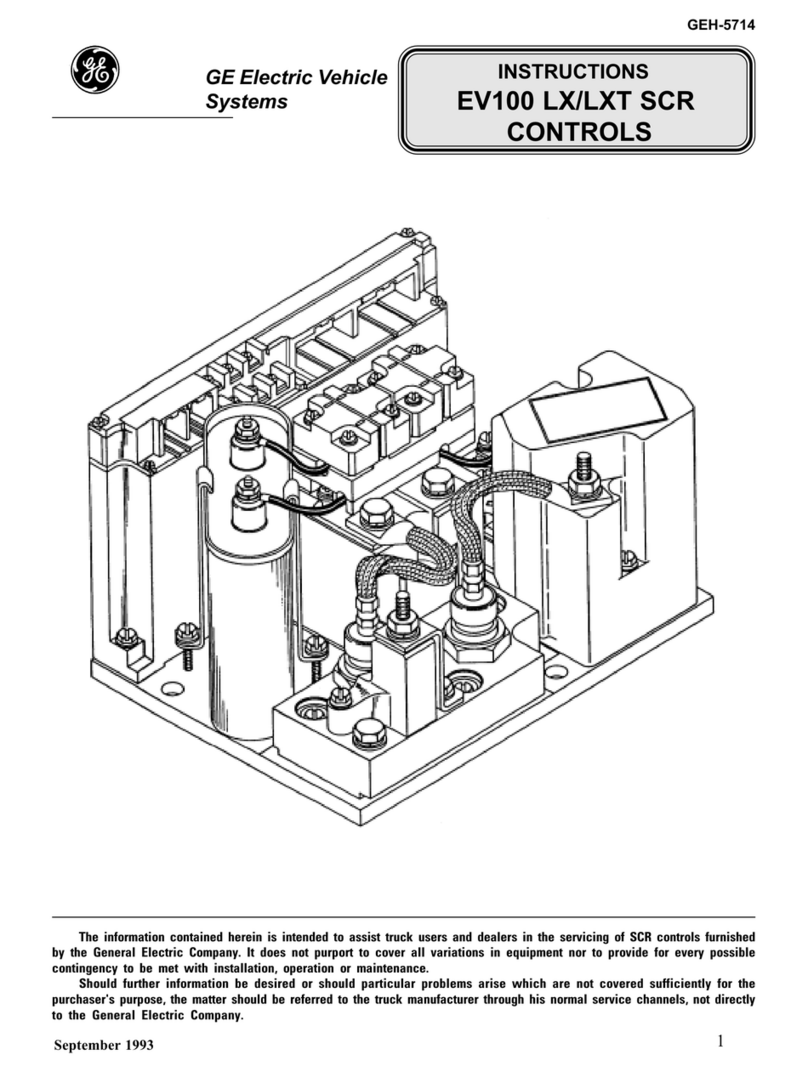

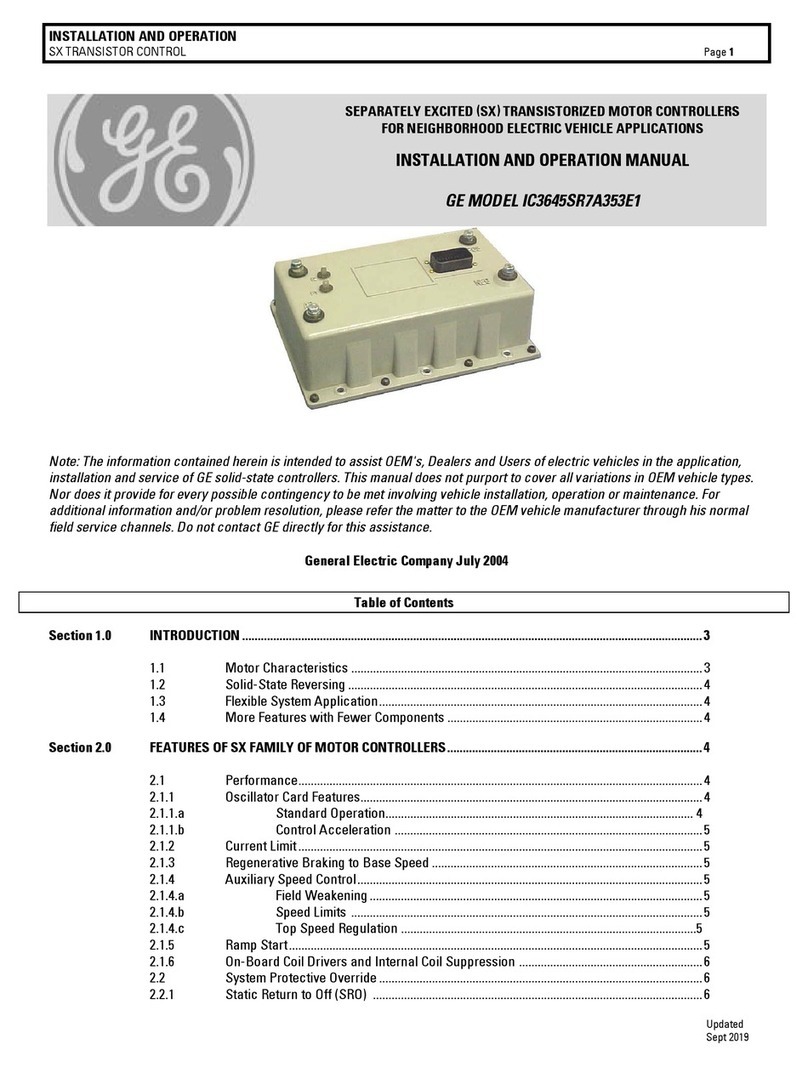

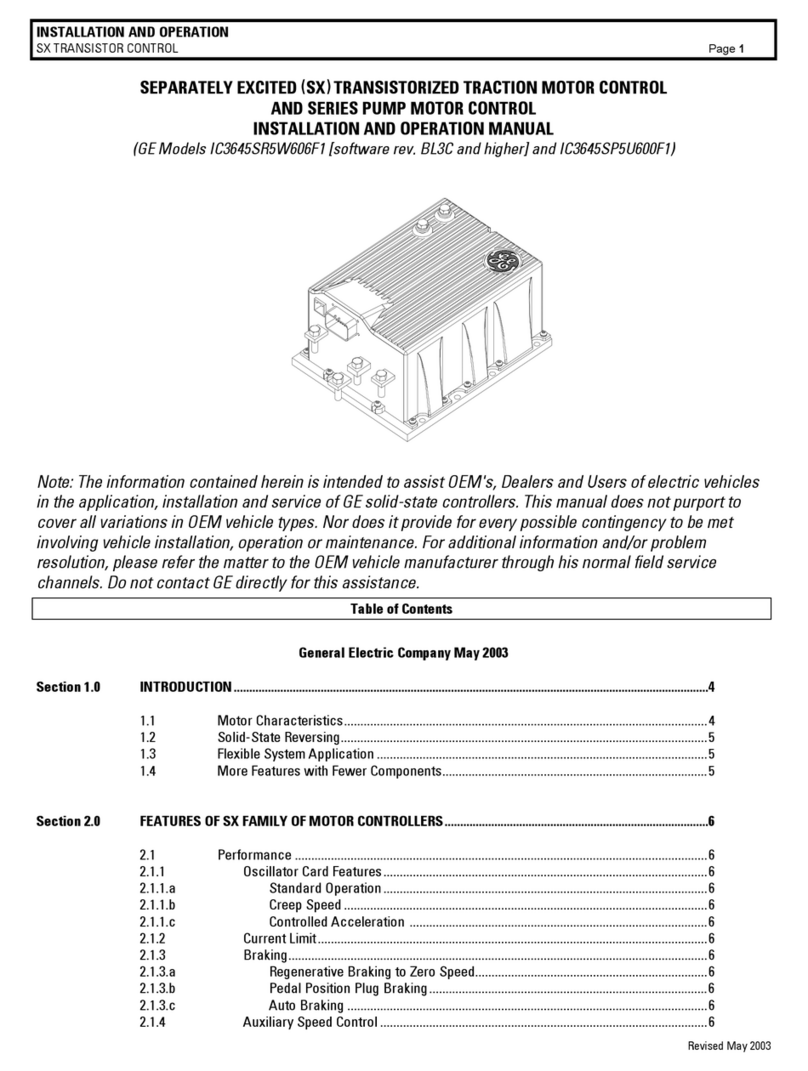

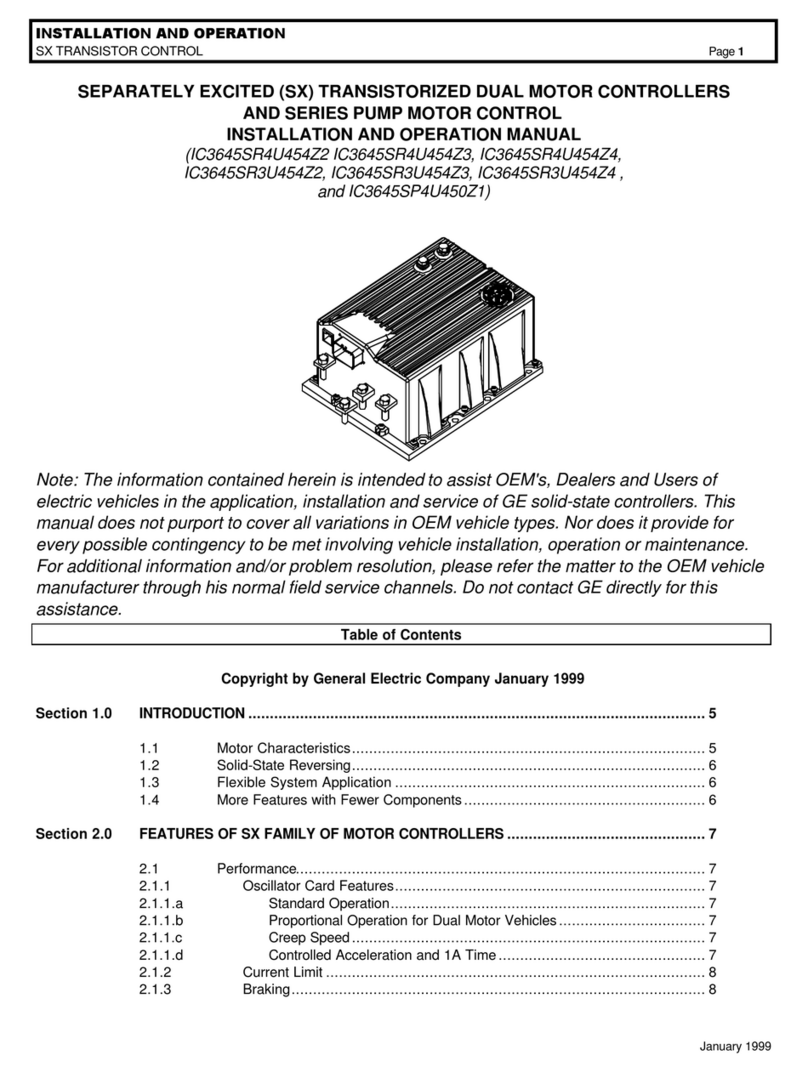

GE IC3645SR4U454Z2 User manual

Popular Controllers manuals by other brands

Digiplex

Digiplex DGP-848 Programming guide

YASKAWA

YASKAWA SGM series user manual

Sinope

Sinope Calypso RM3500ZB installation guide

Isimet

Isimet DLA Series Style 2 Installation, Operations, Start-up and Maintenance Instructions

LSIS

LSIS sv-ip5a user manual

Airflow

Airflow Uno hab Installation and operating instructions