GEK-45375

Vlhen

setting

these relays

to

coordinate

1;1th

downstream

relays,

a coordination time

of

from

0.25

()

to 0.40 seconds

is

generally allowed,

depend·inq

on

the

clearing

time

of

the breaker invo·lved. These

coordination

t·imes

include, in addition to breaker clear·ing time, 0.10 seconds for relay overtravel

and

0.17 seconds

for

safety

factor.

For

examp"le,

if

the breaker c'learing time

is

0.13 seconds

(8

cycles),

the coordination time

1<ould

be

0.40 seconds (0.13+0.l0+0.17).

If

the relay time

is

set

by

test

at

the

current

level in

question,

the

safety

factor

may

be

reduced to 0.07 seconds.

Then

H the

downstream

breaker time

is

5 cycles (0.08 seconds) a

minimum

of

0.25 seconds (0.08+0.10+0.07) could

be

allowed for coordination.

If

relay coordination times are maroinal

or

impossible to

obtain,

use the

relay overtravel curves

of

Figures 10,

ll

or

12

to

refine

the

relay

settings.

First

determine the relay

operating time necessary to

just

match

the operating time

of

the downstream

relay

with

which

coordination

is

desired. Determine the mu'ltiple

of

pickup

and

the necessary time dial

setting

to provide

this

relay

operating time.

Use

the appropriate curve

of

Figure 10,

11

or

12

to determine the overtravel time in

percent

of

operating

t·ime

and

convert

this

itlto real time.

Add

this

time to the breaker time

and

the

safety

factor

time

and

the

original

relay

operating time to determine the

final

relay

operating time

re-

quired. Set the relay to

this

value.

Once

the

current

in the relay operating coil

is

cut

off

the

relay

contacts

wi"ll

open

in approximately

six cycles (O. l second) with

normal

adjustment

of

contact wipe. This permits the

use

of the

relay

in

conjunct·ion with instantaneous reclosing

schemes

without

risk

of

a

false

retrip

when

the

circuit

breaker

is

reclosed

on

a

circuit

from

v1hich

a

fault

has

just

been

cleared.

The

instantaneous overcurrent

unit

present in the I

FC51

B,

I

FC53B

and

I

FC77B

re1

ays

has a trans

·i

ent

overreach

characteristic

as

illustrated

in Figure

13.

This

is

the

result

of

the

DC

offset

that

is

usuall~

present in the

line

current

at

the inception

of

a

fault.

When

determining the pickup

setting

for

this

unit

the

transient

overreach

must

be

taken

into

consideration.

The

percent

transient

overreach

should

be

app"lied to proportionately reduce the

calculated

pickup

setting

so

that

the instantaneous

unit

will not overreach a

downstream

device

and

thereby cause a loss

of

coordination in the system

protection

scheme.

The

operating time

characteristics

of

this

unit

are

sho'-m

in Fioure 14.

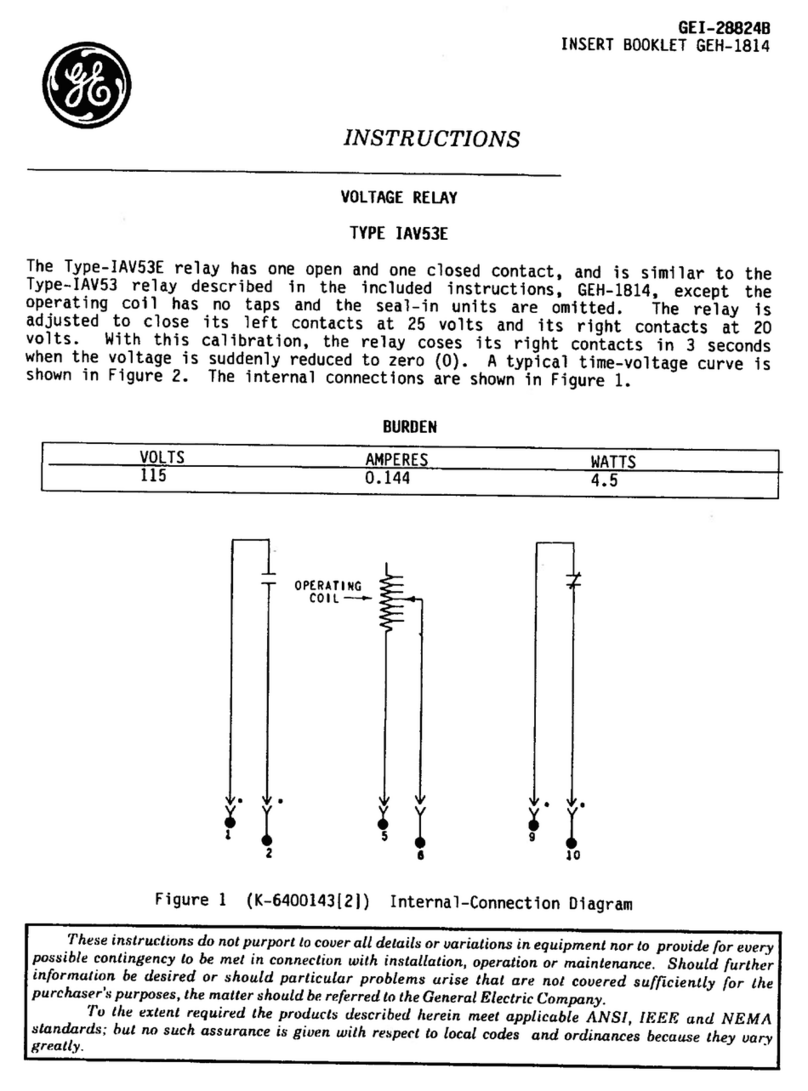

CONSTRUCTION

The

IFC

induction disk relays

consist

of

a

molded

case, cover, support

structure

assembly,

and

a

connection plug to

make

up

the

electrical

connection.

See

Cover

Figure

and

Figures 1

,2,3

and

19.

Figures 2

and

3

show

the induction

unit

mounted

to the

molded

support

structure.

This disk

is

activated

by

a

current

operating

coil

mounted

on

either

a laminated

EE

or

U-Magnet.

The

disk

and

shaft

assembly

carries

a

moving

contact

wh·ich"

completes the alarm

or

trip

circuit

·1vhen

it

touches a

stationary

contact.

The

disk assembly

is

restrained

by

a

spiral

spring to give the proper contact closing

current.

Its

rota-

tion

is

retarded

by

a permanent

magnet

mounted

in a

molded

housing

on

the support

structure.

The

drav1out

connect·ion/test system for the

Cl

case,

shown

in Figure 19,

has

provisions for

14

connec-

tion

points,

and

a

visible

CT

shorting

bar located

up

front.

As

th~

connection plug

i~

wi~hdr~vm?

it

clears

the

shorter

contact fingers in the output contact

circuits

f·1rst. Thus, the

trip

c1rcu1t

1s

opened

before

any

other

circuits

are disconnected. Next,

current

circuit

fingers

on

the case connection block

engage the shorting bar (located

at

the lower

front

of

the case) to

short··circuit

external

current

transformer secondary connections.

The

window

provides visual confirmation

of

CT

shorting.

The

connection plug then

clears

the

current

circuit

contact

fingers

on

the case

and

finally

those

on

the

relay

support

structure

to

completely de-energize the drawout element.

There

is

a Hi-Seismic

target

and

seal-in

unit

mounted

on

the

front

to the

left

of

the

shaft

of

the time overcurrent

unit,

see Figure 1.

The

sea·l··in

unit

has

its

coil in

series

and

its

contacts in

parallel

with the contacts of the time overcurrent unit

such

that

when

the induction

unit

contacts

close

the

seal-in

unit

picks

up

and

seals

in.

When

the

seal-in

unit

picks up,

it

raises

a

target

into

view

which

latches

up

and

remains exposed

until

released

by

pressing a

reset

button located

on

the upper

left

side

of

the cover.

The

!FC

"B"

model

re.lays in addition

to

the

above

contain a Hi-Seismic instantaneous un'it, see

Figure 1.

The

instantaneous

unit

is

a small hinged type

unit

which

is

mounted

on

the

front

to

the

right

of

the

shaft

of

the time overcurrent

unit.

Its

contacts are normally connected in

parallel

with the

contacts

of

the time overcurrent

unit

and

its

coil

is

connected in

series

with the time overcurrent

unit.

When

the instantaneous

unit

picks

up

it

raises

a

target

which

latche~

up

~nd

remains exposed

until

it

is

released.

The

same

reset

button

that

releases

the

target

seal-in

urnt

also

releases

the

target

of

the instantaneous un'it.

Amaqnetic shie.ld, depicted in Figure

1,

is

mounted

t?

~he

support

structure

of inverse

and

very

inverse time overcurrent

IFC

relays,

to eliminate the proximity

affect

of

external magnetic

materials.

Courtesy of NationalSwitchgear.com